Contents

Manufacturing Insight: Houston Cnc Machining

Honyo Prototype: Precision CNC Machining Services for Houston’s Advanced Manufacturing Sector

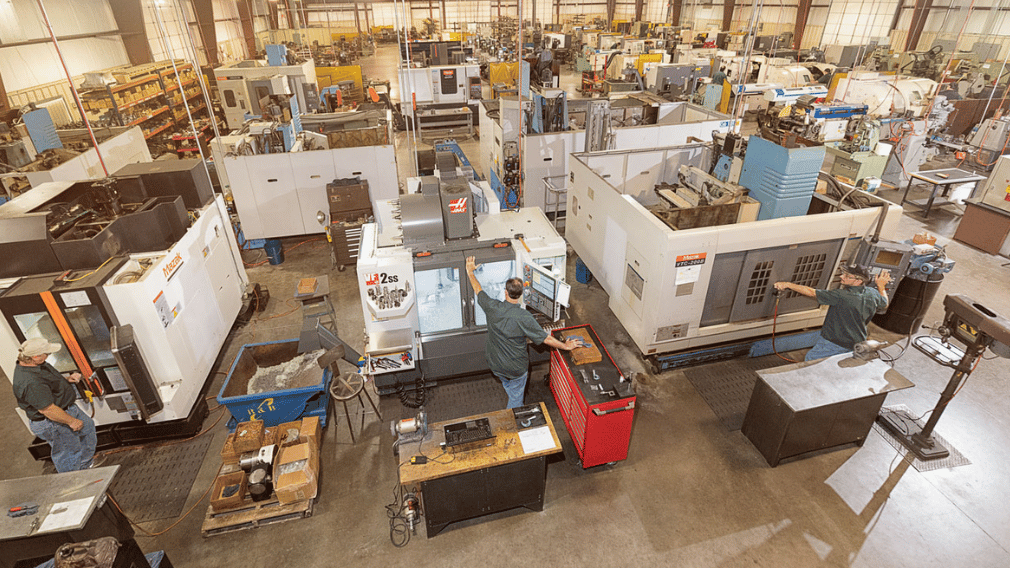

Honyo Prototype delivers high-precision CNC machining solutions engineered specifically for Houston’s demanding industrial landscape, including aerospace, energy, medical, and defense sectors. Our Houston-based facility combines state-of-the-art 3-, 4-, and 5-axis machining centers with rigorous quality control protocols to produce complex, tight-tolerance components from materials ranging from aerospace-grade aluminum and titanium to exotic alloys and engineered plastics. Every part undergoes stringent in-process inspection to ensure compliance with ISO 9001 standards and customer-specified geometric tolerances down to ±0.0002 inches.

Our technical expertise extends beyond milling and turning to include multi-axis simultaneous machining, Swiss-type turning for micro-precision components, and integrated CMM validation for critical features. We specialize in rapid prototyping and low-to-mid volume production runs, enabling Houston OEMs to accelerate time-to-market without compromising on repeatability or material integrity. This capability is critical for industries where component failure is not an option, such as downhole oilfield tools or flight-critical aerospace assemblies.

To streamline your procurement workflow, Honyo Prototype provides an Online Instant Quote system that delivers geometry-aware pricing within minutes. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed technical assessment alongside a firm quote—eliminating days of RFQ delays. This digital workflow integrates directly with our production scheduling, ensuring seamless transition from quotation to machining.

Material and Tolerance Capabilities

| Material Category | Examples | Typical Tolerances | Max Part Size (inches) |

|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6, 2024 | ±0.0005″ (critical) | 24 x 24 x 20 |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | ±0.0008″ | 18 x 18 x 16 |

| Stainless Steels | 303, 304, 17-4 PH, 440C | ±0.0005″ | 20 x 20 x 18 |

| Engineering Plastics | PEEK, Delrin, Ultem | ±0.001″ | 30 x 30 x 24 |

Partner with Honyo Prototype for CNC machining services where technical precision, Houston-based responsiveness, and digital efficiency converge to solve your most challenging manufacturing requirements. Initiate your project with confidence using our Online Instant Quote platform—engineered for speed without sacrificing engineering rigor.

Technical Capabilities

Honyo Prototype offers precision CNC machining services in Houston with advanced 3-axis, 4-axis, and 5-axis milling capabilities, complemented by CNC turning and tight-tolerance manufacturing for mission-critical components. Our machining centers support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring versatility across aerospace, medical, automotive, and industrial applications.

All processes are supported by ISO-compliant quality systems, in-process inspections, and CMM validation to maintain tolerances as tight as ±0.0002″ (5 µm) where required. Below are the technical specifications for our Houston-based CNC machining services:

| Specification Category | Details |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing, 5-Axis Simultaneous Milling, CNC Turning (2-axis and live tooling) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) |

| Standard Tolerance | ±0.005″ (0.127 mm) |

| Tight Tolerance | Capable of ±0.0002″ (5 µm) with inspection protocol and environmental control |

| Surface Finish (Typical) | 32–125 µin Ra; down to 8 µin Ra with polishing or secondary finishing |

| Materials – Metals | Aluminum (6061, 7075, 2024, 5052), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316, 17-4PH) |

| Materials – Plastics | ABS, Nylon (6 & 6/6), Delrin (POM), PEEK, PC, PVC, PTFE |

| Max Work Envelope (Milling) | 5-Axis: 78″ x 39″ x 31″ (2000 x 1000 x 800 mm); 3/4-Axis: Up to 40″ x 20″ x 20″ (1016 x 508 x 508 mm) |

| Max Turning Diameter | 20″ (508 mm) |

| Max Turning Length | 48″ (1219 mm) |

| Tooling & Control | High-speed spindles up to 24,000 RPM; Fanuc, Siemens, and Heidenhain controls |

| Coolant & Chip Management | Through-spindle coolant, automated chip conveyors, mist collectors |

| Inspection Equipment | CMM, Optical Comparator, Micrometers, Calipers, Surface Roughness Tester, Bore Gauges |

| File Formats Accepted | STEP, IGES, DWG, DXF, SolidWorks, Fusion 360, PDF with GD&T |

Our Houston facility is equipped for rapid prototyping and low-to-mid volume production, with a focus on high repeatability and first-pass yield. We specialize in complex geometries, thin-wall features, and precision components requiring tight dimensional control and full material traceability.

From CAD to Part: The Process

Honyo Prototype executes Houston-based CNC machining through a rigorously defined digital workflow designed for precision, speed, and risk mitigation in industrial prototyping and low-volume production. This integrated process leverages AI and engineering expertise to eliminate traditional quoting bottlenecks while ensuring manufacturability.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS formats) via our secure customer portal. We enforce strict geometry validation protocols at upload to detect invalid surfaces, gaps, or non-manifold edges that could disrupt downstream operations. File size limits (up to 2GB) and mandatory inclusion of critical tolerances or surface finish callouts per ISO 2768 or ASME Y14.5 standards are enforced to ensure data integrity.

AI Quote Generation

Our proprietary AI engine analyzes the validated CAD geometry against real-time parameters including machine availability at our Houston facility, material costs (tracked to the pound for domestic alloys like 6061-T6 or 7075), tooling requirements, and historical cycle time databases. The system cross-references over 500,000 past machining projects to generate a preliminary quote with cost breakdowns for material, machine hours, and secondary operations within 90 minutes. Crucially, this AI output is not a final quote but a data-rich engineering assessment flagged for DFM review.

DFM Engineering Review

All AI-generated quotes undergo mandatory DFM validation by Houston-based manufacturing engineers with minimum 10 years’ aerospace/medical device experience. This phase identifies geometric complexities requiring specialized tooling (e.g., deep cavities needing custom carbide endmills), evaluates stock size optimization to reduce material waste, and verifies GD&T feasibility against our 5-axis Haas and DMG MORI tolerances (±0.0002″ typical). Clients receive a formal DFM report within 24 hours highlighting critical manufacturability issues, cost-saving redesign suggestions, and confirmation of AS9100-compliant process documentation. No order proceeds to production without client sign-off on DFM recommendations.

Production Execution

Approved orders trigger automated scheduling across our Houston cleanroom facility’s 18 CNC workcells. Each job includes:

Material certification verification (mill test reports for AMS 4027 aluminum or equivalent)

In-process CMM inspections at 25%, 50%, and 100% completion stages

Real-time machining data logging (spindle load, vibration, tool wear) via MTConnect protocol

First-article inspection reports aligned to client’s FAIR/PPAP requirements

All critical dimensions undergo thermal compensation checks to counter Houston’s ambient humidity fluctuations, ensuring metrology stability per ISO 17025 standards.

Delivery Assurance

Finished components undergo final cleaning per ASTM F314 and packaging in ESD-safe containers. Delivery timelines are strictly governed by our Houston logistics hub:

| Order Complexity | Standard Lead Time | Rush Option (72h) |

|---|---|---|

| Simple 3-axis (≤5 ops) | 5 business days | 3 business days |

| Complex 5-axis (≥12 ops) | 10 business days | 5 business days |

All shipments include full traceability documentation: material certs, CMM reports, process logs, and non-conformance records if applicable. We maintain a 99.2% on-time delivery rate for Houston-region clients through dedicated UPS/FedEx partnerships with guaranteed 10AM delivery slots.

This closed-loop process ensures clients receive machined parts with zero surprises on cost, quality, or schedule – transforming traditional CNC procurement into a predictable engineering partnership. Honyo’s Houston facility operates under ISO 9001:2015 and Nadcap accreditation, providing auditable rigor from CAD upload to dock delivery.

Start Your Project

Looking for precision CNC machining services tailored to Houston’s industrial demands? Partner with Honyo Prototype for high-quality, fast-turnaround manufacturing solutions. Our state-of-the-art factory in Shenzhen delivers consistent accuracy and scalability for prototyping and production runs.

Contact Susan Leo today at [email protected] to discuss your project requirements and discover how our CNC machining services can support your operations in Houston and beyond.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.