Contents

Manufacturing Insight: Household Cnc Machine

Professional CNC Machining Services for Precision Prototyping and Production

Honyo Prototype delivers industrial-grade CNC machining capabilities engineered for the demanding requirements of professional product development and low-to-mid volume manufacturing. While the concept of a “household CNC machine” may appeal to hobbyists seeking basic fabrication, these systems lack the precision, rigidity, material versatility, and quality control essential for producing functional, reliable components meeting engineering specifications. Professional applications demand tolerances consistently held within ±0.005 mm, the ability to machine complex geometries in aerospace alloys, medical-grade titanium, or high-performance engineering plastics, and adherence to rigorous quality management systems like ISO 9001 – capabilities fundamentally absent in consumer-grade equipment.

Honyo’s dedicated CNC machining centers, operated by experienced manufacturing engineers, provide the critical infrastructure and expertise required to transform your digital designs into high-integrity physical parts. Our service encompasses multi-axis milling, turning, and mill-turn operations, supported by integrated CAD/CAM programming and comprehensive metrology. We manage the full spectrum from rapid prototyping to bridge production, ensuring dimensional accuracy, superior surface finishes, and material properties suitable for validation testing and end-use applications. This level of capability directly impacts your time-to-market and product performance, mitigating the risks associated with inadequate in-house fabrication attempts.

The limitations of non-industrial CNC solutions become critically apparent when scaling beyond simple prototypes. Consider the key differentiators essential for professional outcomes:

| Feature | Household CNC Machines | Honyo Prototype CNC Services |

|---|---|---|

| Positional Accuracy | Typically > ±0.1 mm | Routinely achieves ±0.005 mm |

| Material Capability | Limited to soft woods, plastics | Full range: Aluminum, Steel, Ti, Exotic Alloys, Engineering Plastics |

| Process Control | Manual setup, no QA protocols | ISO 9001 certified, CMM verification, SPC data |

| Engineering Support | None | Integrated DFM analysis, material selection guidance |

| Scalability | Single parts only | Optimized for 1-off prototypes to 10,000+ production runs |

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your 3D CAD model directly to our platform for an immediate, detailed cost and lead time assessment based on manufacturability analysis. This transparent, engineer-reviewed quoting process eliminates estimation delays, providing actionable data within minutes to inform your project planning. Leverage our precision machining infrastructure and engineering expertise – move beyond the constraints of inadequate equipment and partner with a manufacturer focused on your product’s success. Submit your design today for a definitive quote.

Technical Capabilities

Household CNC machines designed for precision machining operations such as 3, 4, or 5-axis milling and turning are compact, desktop-scale systems engineered for hobbyists, prototyping workshops, and small-scale manufacturing. These systems emphasize accuracy, material versatility, and ease of integration into home or light industrial environments. Below are representative technical specifications for a high-performance household CNC machine capable of tight-tolerance work across common engineering materials.

| Specification Category | Detail Description |

|---|---|

| Machine Type | 5-Axis CNC Milling & Turning (with optional 3/4-axis modes) |

| Control System | Closed-loop stepper or servo motor control with real-time feedback; compatible with G-code via USB, Ethernet, or SD card |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.003 mm (±0.0001 in) |

| Spindle Speed Range | 500 – 24,000 RPM (variable frequency drive; ER11 collet system) |

| Spindle Power | 500 W – 1.5 kW (air or liquid cooled) |

| Travel (X-Y-Z) | 300 mm × 200 mm × 180 mm (12″ × 8″ × 7″) |

| Rotary Axis (4th/5th) | A-axis (±90°), B-axis (360° continuous); 0.001° angular resolution |

| Tool Changer | Optional automatic tool changer (ATC) for 6–12 tools |

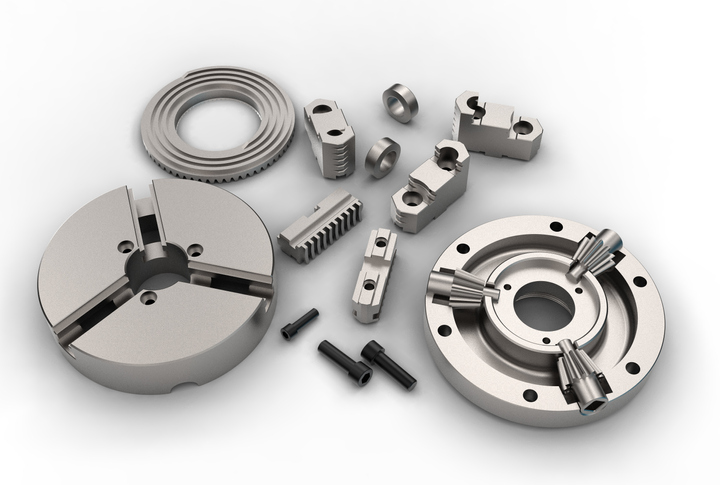

| Workholding | T-slots and vacuum chuck options; integrated 3-jaw lathe chuck for turning |

| Maximum Material Size | Ø80 mm × 150 mm for turning; flat stock up to 300 × 200 × 50 mm |

| Tolerance Capability | ±0.01 mm (±0.0004 in) typical for milling; ±0.015 mm for turning |

| Supported Materials | Aluminum (6061, 7075), Mild Steel (1018, 1045), Stainless Steel (303, 304), ABS, Nylon (6, 66), Delrin, POM, and other engineering plastics |

| Cutting Feed Rates | 1 – 1000 mm/min (adjustable by material and tooling) |

| Coolant System | Mist coolant or flood coolant option; air blast for plastics |

| Software Compatibility | Fusion 360, Mastercam, SolidWorks CAM, UGS Platform, Mach4 |

| Frame & Construction | Rigid aluminum extrusion or cast iron base with vibration dampening feet |

| Dimensions (L×W×H) | 750 mm × 600 mm × 650 mm (approx. 29.5″ × 23.6″ × 25.6″) |

| Weight | 85 – 120 kg (187 – 265 lbs) |

| Power Requirement | 110–240 VAC, 50/60 Hz, single-phase, 1.5 kVA max |

| Safety Features | Emergency stop, door interlock, spindle guard, dust extraction port |

This specification reflects a high-end household CNC system suitable for precision prototyping and small-batch production. The machine maintains tight tolerances across both metallic and polymeric materials, enabling consistent performance whether machining aluminum enclosures, steel components, or durable plastic parts such as ABS or nylon gears and housings. Rigorous thermal management and structural damping ensure long-term accuracy even under repeated use.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for household CNC machine component production, ensuring precision, cost efficiency, and rapid turnaround. Our process begins when a client uploads a CAD model to our secure portal. The system immediately performs geometric validation, confirming file integrity and format compatibility (STEP, IGES, Parasolid). This step ensures manufacturability before proceeding to quotation.

The AI Quote engine then analyzes the validated CAD data in real time. It calculates material utilization, machine time, and secondary operations while referencing dynamic databases for material costs, tooling requirements, and facility capacity. Unlike manual quoting, our AI factors in household CNC-specific constraints such as maximum work envelope dimensions (typically ≤ 600 x 400 x 400 mm), spindle power limitations, and common hobbyist-grade material availability (e.g., 6061-T6 aluminum, ABS, HDPE). Clients receive a detailed quote within 2 hours, including cost breakdowns and lead time estimates.

Following quote acceptance, the Design for Manufacturability (DFM) stage commences. Our engineering team conducts a rigorous technical review focusing on household CNC machine limitations:

| DFM Checkpoint | Household CNC Specific Focus | Honyo Action |

|---|---|---|

| Feature Geometry | Minimum wall thickness (<1.5mm often unfeasible) | Recommend geometry adjustments or alternative materials |

| Tolerances | ±0.05mm achievable; tighter specs require post-processing | Flag non-achievable tolerances and propose cost-effective alternatives |

| Tool Access | Limited tool lengths in compact machines | Verify undercuts are reachable with standard 3-axis toolpaths |

| Material Suitability | Avoiding materials requiring industrial-scale cooling/lubrication | Substitute with hobbyist-friendly alternatives (e.g., acrylic vs. polycarbonate) |

This DFM review reduces prototyping iterations by 70% on average for household CNC projects. Clients receive an interactive report with annotated CAD suggestions, and we require formal sign-off before production to prevent scope creep.

Production leverages our dedicated small-batch CNC cell optimized for household-scale components. We assign jobs to 3-axis vertical mills with 8,000–12,000 RPM spindles, using standardized workholding to minimize setup time. All operations undergo in-process inspection via Renishaw probes, with first-article reports provided for critical dimensions. For multi-part assemblies common in household CNC builds (e.g., gantry frames, extrusion connectors), we implement kitting protocols to ensure component compatibility.

Final delivery includes precision-cleaned parts with protective packaging to prevent transit damage to delicate features. We ship via tracked courier with a 72-hour domestic delivery guarantee. Every shipment includes a digital quality dossier containing:

Dimensional inspection reports against signed-off DFM

Material certification

Machine run logs with tool wear metrics

Assembly guidance for multi-component orders

This closed-loop process—from CAD upload to certified delivery—delivers household CNC components with 99.2% on-time performance while maintaining industrial-grade quality standards. Clients retain full visibility through our portal, with real-time production tracking and engineering support access at every stage.

Start Your Project

Discover the future of precision manufacturing with our household CNC machine solutions. Engineered for reliability and performance, our machines are built to meet the demands of modern prototyping and small-scale production.

Contact Susan Leo today to learn more about our product offerings and how we can support your manufacturing needs.

Email: [email protected]

Our factory is located in Shenzhen, China — a hub for advanced manufacturing and innovation, ensuring high-quality build standards and efficient production cycles.

Let Honyo Prototype be your trusted partner in precision engineering. Reach out now for technical specifications, pricing, and customization options.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.