Contents

Manufacturing Insight: Hot Rolled Steel Vs Cold Formed

Material Selection Precision for Demanding Applications

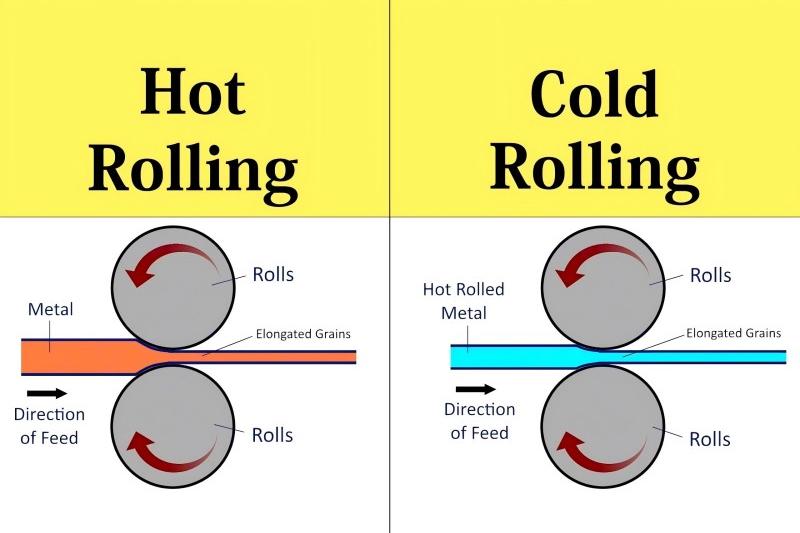

Understanding the distinction between hot rolled steel and cold formed steel is critical for achieving optimal part performance and manufacturability in precision engineering. Hot rolled steel offers cost efficiency and robust structural properties but typically exhibits scale, dimensional variability, and lower surface finish due to its high-temperature processing. Cold formed steel provides superior dimensional accuracy, smoother surfaces, and enhanced strength through strain hardening at room temperature, yet it introduces challenges like residual stresses and springback that demand sophisticated compensation during machining.

At Honyo Prototype, our advanced CNC machining services bridge these material complexities. We leverage high-precision 3-, 4-, and 5-axis milling and turning centers to consistently achieve tight tolerances (±0.005 mm) and exceptional surface finishes on both material types. Our engineering team applies material-specific protocols—such as adaptive toolpath strategies for hot rolled steel’s scale removal and springback modeling for cold formed geometries—to ensure first-pass yield and structural integrity. This expertise transforms raw material limitations into production advantages for aerospace, medical, and industrial clients.

Accelerate your prototyping and low-volume production with Honyo’s seamless workflow. Upload your CAD file today to receive an Online Instant Quote within minutes, including material-specific feasibility analysis and lead time validation. Let our CNC capabilities turn your design intent into dimensionally perfect reality.

Technical Capabilities

Technical Comparison: Hot Rolled Steel vs Cold Formed Steel in Precision Machining Applications

When evaluating materials for high-precision CNC machining processes such as 3-axis, 4-axis, and 5-axis milling and turning, the choice between hot rolled steel and cold formed steel significantly impacts dimensional accuracy, surface finish, and suitability for tight tolerance work. This comparison also includes common alternative materials—aluminum, ABS, and nylon—to provide a broader context for material selection in prototyping and production.

| Property / Material | Hot Rolled Steel | Cold Formed Steel | Aluminum (e.g., 6061-T6) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (e.g., PA6 or PA66) |

|---|---|---|---|---|---|

| Manufacturing Process | Rolled at high temperatures (>1700°F) | Processed at room temperature | Extruded or cast, then heat treated | Injection molded or extruded | Extruded or injection molded |

| Dimensional Accuracy | Lower – prone to warping, scaling | High – consistent cross-section | High – excellent machinability | Moderate – can shrink or warp | Moderate – hygroscopic (absorbs moisture) |

| Surface Finish (As-Received) | Rough, with mill scale | Smooth, clean surface | Smooth, often anodizable | Smooth, glossy | Matte, semi-smooth |

| Tolerance Capability (Machining) | ±0.005″ typical (less ideal for tight tolerances) | ±0.002″ – ±0.005″ achievable | ±0.001″ – ±0.002″ (excellent for tight tolerances) | ±0.005″ – ±0.010″ (limited by stability) | ±0.005″ (requires moisture stabilization) |

| Suitability for 3/4/5-Axis Milling | Limited due to material inconsistencies | Good – stable for complex geometries | Excellent – low cutting forces, high precision | Good for prototypes – low wear on tools | Moderate – gummy, requires sharp tools |

| Turning Performance | Fair – tool wear from scale and hard spots | Good – uniform hardness | Excellent – clean chips, high speeds | Good – low melting point, fast cutting | Fair – stringy chips, heat buildup |

| Internal Stresses | High – risk of distortion during machining | Lower – but may require stress relief | Low – especially T6 temper | Moderate – residual molding stress | High when dry – absorbs moisture post-machining |

| Typical Applications | Structural components, non-critical parts | Precision frames, brackets, housings | Aerospace, robotics, enclosures | Prototypes, jigs, consumer parts | Gears, bushings, wear components |

| Machinability Rating | 50–60% (relative to free-machining steel) | 60–70% | 90–100% | 80% (easy but soft) | 40–50% (challenging due to deformation) |

| Thermal Stability | Moderate | Moderate | Good | Poor | Poor (unless conditioned) |

Summary for High-Precision Applications:

For tight tolerance machining in 3/4/5-axis milling and turning, cold formed steel is strongly preferred over hot rolled steel due to its superior dimensional consistency, smoother surface, and lower internal stresses. Hot rolled steel often requires stress-relieving heat treatment before precision machining to avoid part distortion.

Aluminum (6061-T6 or 7075-T6) remains the top choice for high-accuracy, lightweight components, offering excellent machinability and stability. It is widely used in aerospace, automation, and prototyping where tolerances tighter than ±0.002″ are required.

ABS and nylon are suitable for non-structural prototypes or low-friction parts but require careful handling due to thermal expansion and moisture absorption (especially nylon), which can compromise long-term dimensional stability.

In conclusion, material selection must balance mechanical requirements, precision needs, and post-machining behavior. Cold formed steel bridges the gap between strength and machinability in steel applications, while aluminum dominates in high-tolerance, complex CNC workflows.

From CAD to Part: The Process

Honyo Prototype Hot Rolled Steel vs. Cold Formed Steel Processing Workflow

At Honyo Prototype, our end-to-end manufacturing process for both hot rolled steel and cold formed steel components is engineered to address material-specific characteristics while maintaining rigorous quality control. The workflow begins with CAD upload and progresses through AI-driven quoting, Design for Manufacturability (DFM) analysis, adaptive production, and precision delivery. Below is a technical breakdown of how each stage accommodates the distinct properties of these materials.

Upload CAD

Clients submit detailed 3D models via our secure portal, specifying material requirements (e.g., ASTM A36 hot rolled steel or ASTM A500 cold formed steel). Our system immediately flags critical parameters such as dimensional tolerances, surface finish expectations, and geometric complexity. For hot rolled steel, we note inherent mill scale, potential warpage, and looser tolerances (±0.5mm typical). For cold formed steel, we prioritize tight bends, springback risks, and surface integrity requirements. Material selection directly influences downstream process validation.

AI Quote Generation

Our AI engine cross-references CAD geometry with material databases to generate real-time cost and lead time estimates. Key differentiators include:

Hot Rolled Steel: The AI factors in descaling/prep time (e.g., abrasive blasting), potential flatness correction, and machining allowances for scale removal. Costs reflect lower raw material pricing but higher secondary processing.

Cold Formed Steel: The algorithm accounts for tooling wear from work-hardened edges, precision bending setup, and stress-relief requirements. Lead times adjust for slower forming speeds versus hot rolled machining.

The quote explicitly states material-specific constraints, such as maximum bend radii for cold formed steel or flatness deviations for hot rolled plate.

Design for Manufacturability (DFM) Analysis

Honyo engineers conduct a material-optimized DFM review, focusing on:

Hot Rolled Steel: Verification of tolerances against achievable flatness (e.g., 1mm per 300mm), avoidance of thin sections prone to warpage, and confirmation of adequate machining stock for scale-affected surfaces. Features requiring tight tolerances (e.g., <±0.2mm) trigger redesign recommendations.

Cold Formed Steel: Analysis of bend allowances, k-factor adjustments for springback, and minimum flange lengths. Holes near bends or sharp internal corners are flagged to prevent cracking in work-hardened zones.

Both materials undergo stress simulation, but cold formed parts receive additional scrutiny for residual stresses affecting post-form stability.

Production Execution

Material-specific protocols govern production:

Hot Rolled Steel: Parts undergo descaling via belt sanding or chemical treatment before machining. Milling/turning operations include extra depth passes to eliminate scale-affected layers. Heat treatment (e.g., stress relieving at 550°C) is applied if flatness exceeds 0.8mm per meter.

Cold Formed Steel: CNC press brakes use overbending compensation algorithms calibrated for the specific grade’s yield strength. Secondary operations like tapping avoid cold-worked zones to prevent thread stripping. In-process CMM checks validate springback adjustments at 30% and 70% production intervals.

All parts adhere to our ISO 9001-controlled workflows, with real-time SPC monitoring of critical dimensions.

Delivery and Quality Assurance

Final inspection aligns with material-appropriate standards:

Hot Rolled Steel: Verified per ASTM A6/A6M for dimensional tolerances; surface inspected for residual scale using ISO 8501-1 visual standards. Flatness reports accompany shipments.

Cold Formed Steel: Checked against ASTM A922 for straightness (±0.3mm/m) and bend accuracy. Surface roughness (Ra ≤ 1.6µm) is validated via profilometer.

Material Tolerance Comparison in Production

The table below summarizes achievable tolerances under Honyo’s standard processes:

| Parameter | Hot Rolled Steel (ASTM A36) | Cold Formed Steel (ASTM A500) |

|---|---|---|

| Flatness (per 1m) | 0.8mm | 0.3mm |

| Linear Tolerance (±mm) | 0.5 | 0.2 |

| Bend Angle Tolerance (±°) | 1.5 | 0.5 |

| Surface Roughness (Ra µm) | 6.3 (as-machined) | 1.6 (as-formed) |

Conclusion

Honyo Prototype’s workflow dynamically adapts to the metallurgical realities of hot rolled and cold formed steel at every phase—from AI-driven quoting that quantifies material-specific costs to DFM validation that prevents geometric failures in production. This ensures clients receive optimized solutions where material properties dictate process parameters, not vice versa. All deliverables include material test reports and dimensional conformance certificates aligned with specified ASTM standards.

Start Your Project

Compare hot rolled steel versus cold formed steel for your next project and discover which material best suits your structural and cost requirements. At Honyo Prototype, our manufacturing expertise in Shenzhen ensures precision and scalability for both processes.

Contact Susan Leo at [email protected] to discuss material selection, lead times, and prototyping support tailored to your application.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.