Contents

Manufacturing Insight: Horizontal Milling Machines

Precision Horizontal Milling for Complex Production Challenges

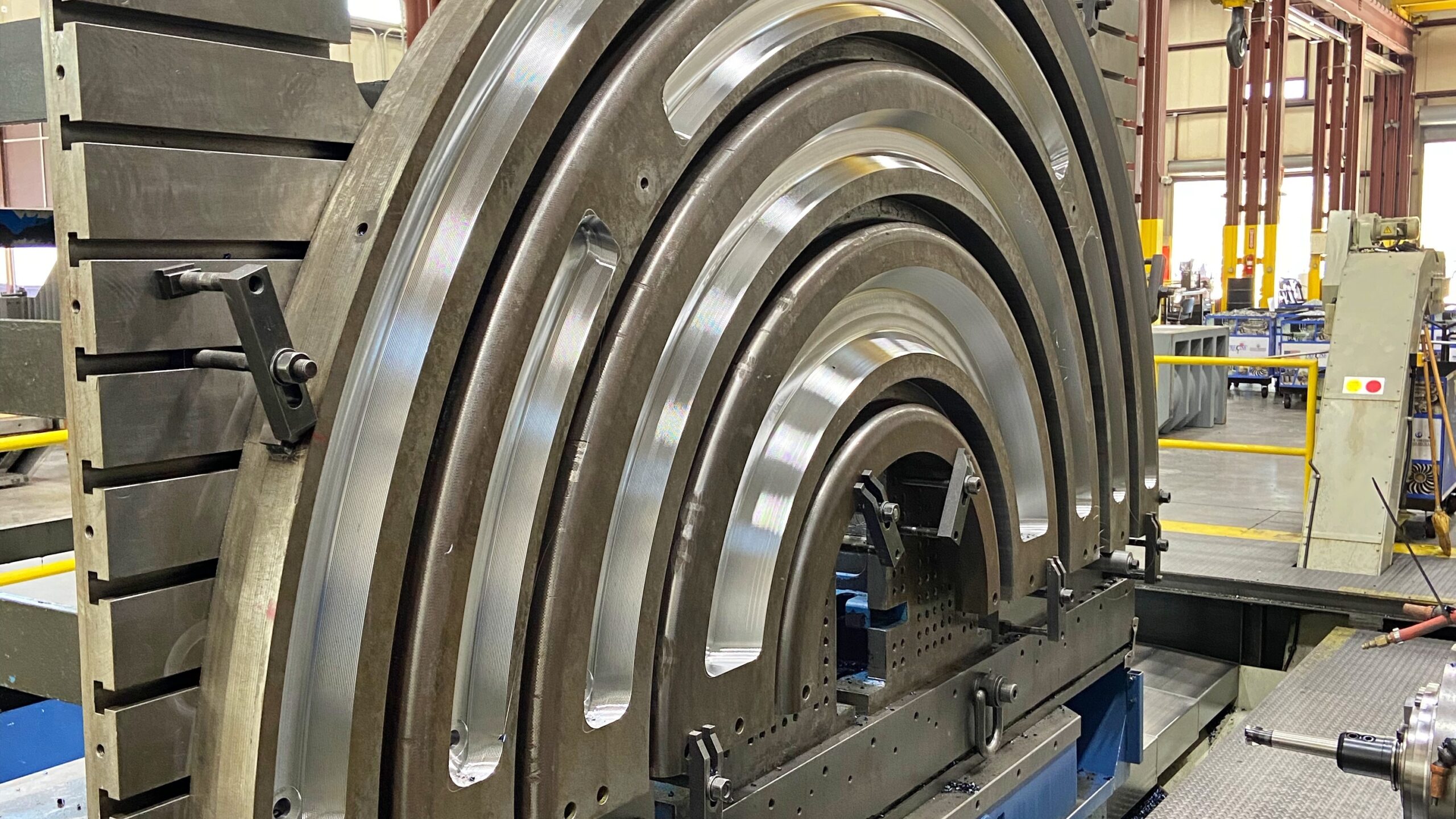

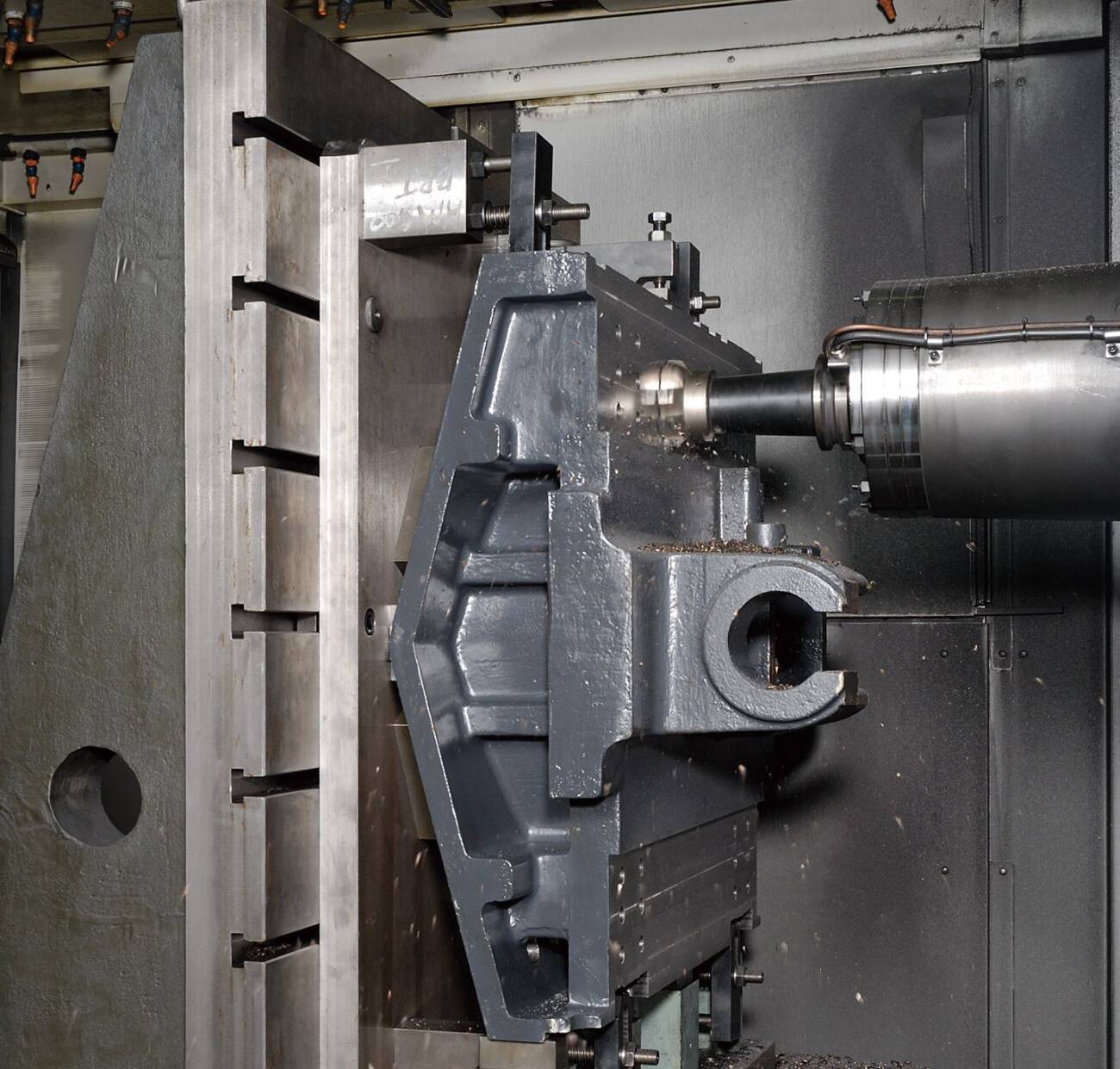

Horizontal milling machines represent a critical capability for manufacturers requiring high-efficiency machining of complex, multi-faced components. Unlike vertical configurations, horizontal mills utilize a horizontally oriented spindle that enables simultaneous machining of multiple surfaces, heavier material removal rates, and superior chip evacuation—particularly vital for large-scale housings, transmission cases, and structural aerospace components. At Honyo Prototype, our fleet of advanced CNC horizontal milling centers integrates high-torque spindles, 4th/5th axis rotary tables, and automated pallet systems to deliver exceptional geometric accuracy and throughput for low-to-mid volume production runs.

Our engineering team leverages these platforms to tackle demanding geometries that challenge conventional vertical machining, including deep pocketing, intricate slotting, and precision boring operations. Each machine is maintained to stringent calibration standards, featuring thermal compensation systems and 20+ tool changers to minimize non-cut time while ensuring ±0.005mm tolerances across extended production cycles. This capability directly translates to reduced lead times and lower per-part costs for clients in automotive, energy, and industrial equipment sectors where component integrity is non-negotiable.

For rapid project initiation, Honyo Prototype streamlines procurement with our Online Instant Quote platform. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—no manual RFQ delays. This digital workflow, combined with our horizontal milling expertise, ensures your complex components move from design to certified production faster, with full traceability and first-pass yield optimization. Partner with us to transform challenging machining requirements into scalable production success.

Technical Capabilities

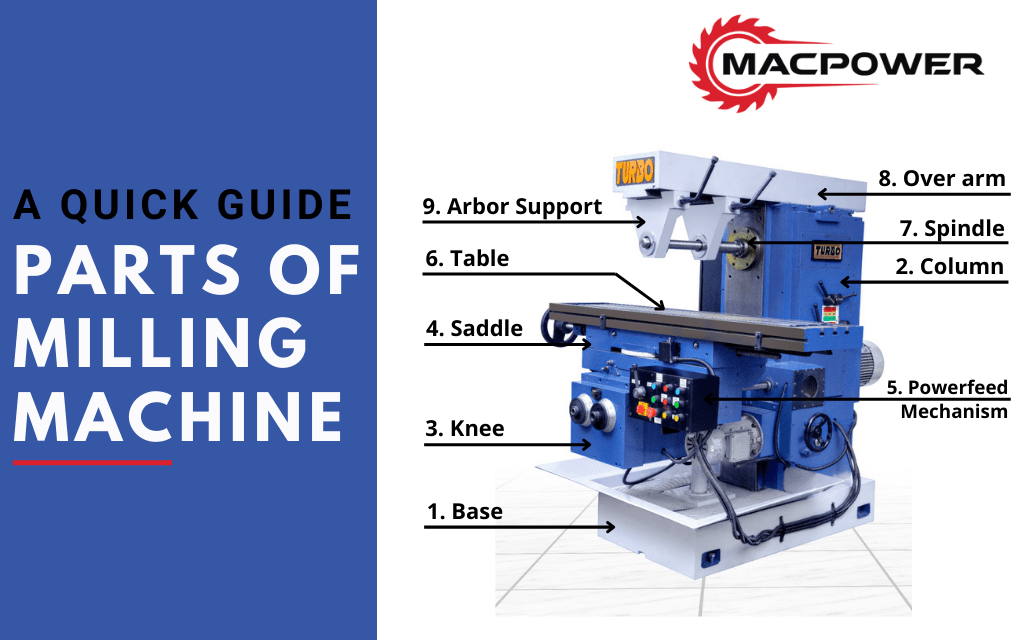

Horizontal milling machines are precision CNC machining platforms optimized for high accuracy, complex geometries, and efficient material removal, particularly in medium to high-volume production environments. These machines feature a horizontally oriented spindle, allowing for improved chip evacuation and the use of heavy-duty cutters such as face mills and side mills. They are commonly used in aerospace, automotive, and industrial manufacturing for components requiring tight tolerances and multi-axis machining capabilities.

Honyo Prototype employs advanced 3, 4, and 5-axis horizontal milling systems capable of integrating turning operations (mill-turn functionality) for complete part fabrication in a single setup. These machines support a wide range of engineering materials including aluminum alloys (e.g., 6061, 7075), carbon and stainless steels (e.g., 4140, 17-4 PH), and engineering thermoplastics such as ABS and nylon. Tight tolerance machining down to ±0.0002″ (±0.005 mm) is achievable with thermal compensation, high-resolution feedback systems, and rigid cast iron or polymer concrete machine bases.

The following table outlines the typical technical specifications for horizontal milling machines used in precision manufacturing environments:

| Parameter | Specification |

|---|---|

| Machine Type | CNC Horizontal Milling Center |

| Axis Configuration | 3-axis standard; 4-axis (rotary B or C); 5-axis (A-B or A-C rotary tables) |

| Spindle Orientation | Horizontal |

| Spindle Speed Range | 6,000 – 15,000 RPM (standard); up to 20,000 RPM with high-speed spindles |

| Spindle Power | 22 – 50 kW (30 – 67 HP) |

| Tool Capacity | 30 – 120 tools (automatic tool changer) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00005″ (±0.0013 mm) |

| Tolerance Capability | ±0.0002″ (±0.005 mm) typical; tighter with inspection and process control |

| Work Envelope (Max) | Up to 1200 x 800 x 800 mm (47 x 31.5 x 31.5 in) |

| Rapid Traverse Rate | 60 – 100 m/min (2,360 – 3,940 ipm) |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 3D simulation and probing |

| Coolant System | High-pressure through-spindle coolant (up to 1,000 psi) |

| Probe System | On-machine touch probe for in-process measurement and tool setting |

| Thermal Compensation | Standard (linear and volumetric) |

| Supported Materials | Aluminum (6061, 7075), Steel (4140, 17-4 PH), ABS, Nylon (6/66), PEEK, Delrin |

| Surface Finish | As low as 16 μin (0.4 μm) Ra with fine finishing tools |

| Mill-Turn Capability | Optional live tooling and C-axis for partial turning operations |

| Pallet System | Optional 2-6 pallet automation for unattended operation |

These machines are ideal for complex, high-precision components such as housings, impellers, transmission parts, and structural aerospace elements. The integration of 4 and 5-axis motion enables undercuts, angled features, and freeform surfaces to be machined without manual re-fixturing, reducing cycle time and improving geometric accuracy. Honyo Prototype leverages these capabilities to deliver tight-tolerance parts across diverse material families with consistent quality and traceability.

From CAD to Part: The Process

Honyo Prototype Horizontal Milling Machine Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for horizontal milling machine projects, ensuring precision, efficiency, and seamless integration from design to delivery. Our process is engineered specifically for the complexities of horizontal machining, including multi-sided operations, tombstone fixturing, and high-volume production requirements.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. For horizontal milling, we prioritize models indicating features requiring simultaneous multi-face machining, deep cavity work, or complex part nesting on tombstones. Our system automatically checks file integrity, units, and geometric completeness, flagging potential issues like undercuts incompatible with horizontal spindle orientation before proceeding.

AI-Powered Quoting Engine

Uploaded CAD data is processed through Honyo’s proprietary AI quoting system, trained on 15,000+ historical horizontal milling projects. The AI analyzes: material type, feature complexity (e.g., pocket depths, slot tolerances), tombstone capacity utilization, and coolant accessibility constraints unique to horizontal setups. It generates a detailed quote within 2 business hours, including machine time estimates based on spindle power requirements (e.g., 40-taper vs. 50-taper mills), fixture costs, and secondary operation recommendations. Real-time material cost databases and regional supplier pricing ensure accuracy.

DFM Analysis with Horizontal Milling Expertise

All quotes trigger an automated Design for Manufacturability (DFM) review led by our CNC engineering team. For horizontal mills, we specifically evaluate:

Tombstone configuration feasibility and part nesting efficiency

Chip evacuation pathways to prevent re-cutting in horizontal orientation

Fixture interference with rotating pallet systems

Tolerance stack-up across multiple setups

Optimal coolant pressure/volume for deep cavity operations

Clients receive a formal DFM report within 24 hours highlighting manufacturability risks (e.g., thin walls prone to chatter during side milling) and actionable suggestions like adding draft angles or adjusting hole depths.

Production Execution

Approved projects move to production in our climate-controlled facility housing 12 horizontal machining centers (including Makino HMP series and DMG MORI NHX models). Key production phases:

Fixturing: Custom tombstone setups fabricated in-house using modular components; validated via 3D simulation

Machining: Programs run on Renishaw-probed machines with adaptive toolpathing for consistent surface finishes on all faces. In-process CMM checks verify critical features after each tombstone rotation.

Quality Control: Full FAI per AS9102B standards; 100% of critical dimensions measured using Zeiss CONTURA CMMs with horizontal-axis calibration.

Delivery and Traceability

Completed parts undergo final cleaning, deburring, and non-destructive testing (if specified). Each shipment includes:

Dimensional report with GD&T callouts

Material certification

Machining process log (including spindle load data)

Tombstone setup diagrams for future reference

Standard lead time for horizontal milling projects is 7–12 business days from CAD approval, with expedited options available. All components ship in custom anti-static packaging with real-time logistics tracking.

Process Timeline Comparison

| Phase | Standard Horizontal Milling | Typical Vertical Milling |

|---|---|---|

| AI Quote Generation | ≤ 2 business hours | ≤ 1 business hour |

| DFM Review | ≤ 24 hours | ≤ 12 hours |

| Production (avg. part) | 5–10 business days | 3–7 business days |

| Critical Factor | Tombstone optimization | Single-setup clearance |

This integrated workflow leverages horizontal milling’s advantages—reduced setup times, superior chip management, and multi-part efficiency—while mitigating its unique challenges through AI-driven planning and engineering oversight. For complex multi-operation projects, we recommend engaging our applications engineering team during CAD upload to optimize tombstone utilization upfront. Contact Honyo Prototype to discuss your horizontal milling requirements with a manufacturing specialist.

Start Your Project

Explore our range of high-precision horizontal milling machines engineered for demanding manufacturing applications. Built for efficiency, durability, and tight-tolerance performance, these machines are ideal for prototyping and low-to-mid volume production.

Manufactured in our Shenzhen facility, each machine undergoes rigorous quality control to ensure optimal performance and reliability.

For inquiries or technical specifications, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.