Contents

Manufacturing Insight: High Volume Cnc Machining

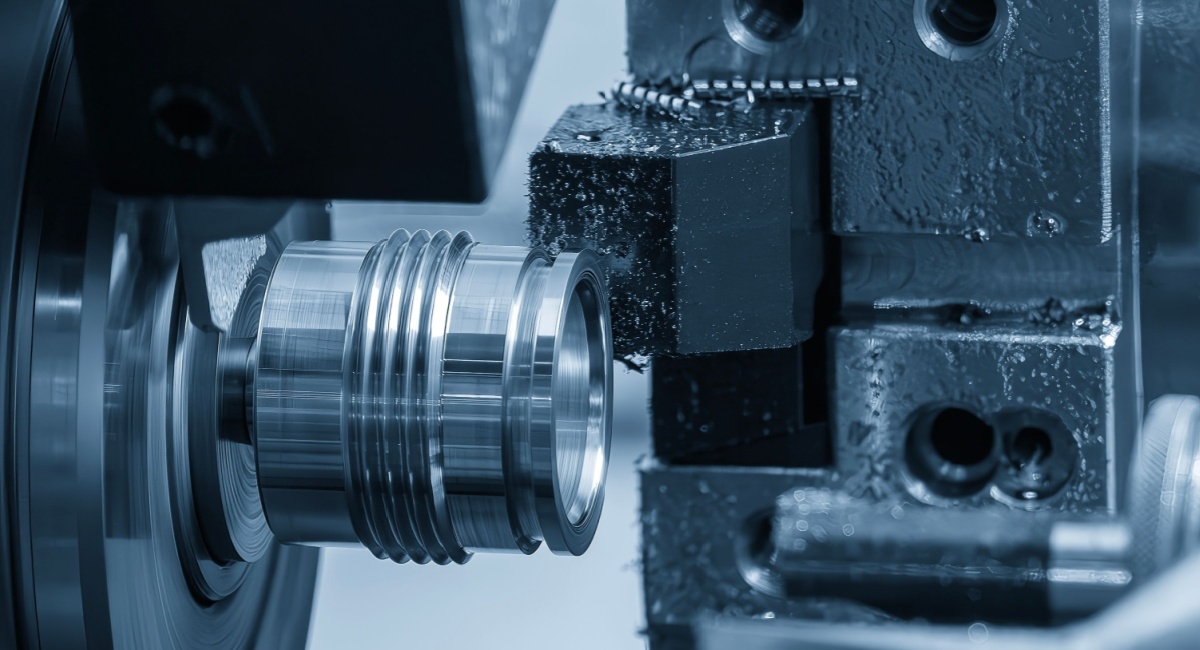

High Volume CNC Machining: Precision Production at Scale

Honyo Prototype delivers rigorously optimized high volume CNC machining services engineered for manufacturers demanding uncompromising precision, repeatability, and throughput. Our advanced multi-axis CNC infrastructure—comprising state-of-the-art mills, lathes, and Swiss-type machines—is managed by veteran manufacturing engineers who specialize in transforming complex designs into millions of defect-free components. We excel in rapid process validation, rigorous first-article approval, and seamless transition to sustained production runs across aerospace, medical device, automotive, and industrial sectors, ensuring your supply chain operates without interruption.

Online Instant Quote: Accelerate Your Path to Production

Eliminate quoting delays with Honyo’s proprietary Online Instant Quote platform. Simply upload your CAD file to receive a comprehensive, real-time cost analysis and lead time estimate within seconds—no manual intervention required. This transparent, data-driven system leverages our extensive material databases, machine capability libraries, and real-time capacity metrics to provide accurate pricing for high-volume orders immediately.

| Process Stage | Traditional RFQ Approach | Honyo Online Instant Quote |

|---|---|---|

| Initial Cost Estimate | 24-72 hours | < 60 seconds |

| Design Feedback Loop | Multiple email iterations | Integrated DFM analysis |

| Volume Pricing Clarity | Delayed until engineering review | Immediate tiered pricing |

Reduce time-to-manufacture by up to 70% while securing guaranteed capacity for your critical volume production. Upload your CAD file today and validate scalability with Honyo’s industrial-grade CNC machining ecosystem.

Technical Capabilities

High volume CNC machining requires robust capabilities across multi-axis platforms to maintain precision, repeatability, and throughput. The following technical specifications outline key performance parameters for high volume production using 3, 4, and 5-axis milling, as well as CNC turning, with emphasis on tight tolerance machining across common engineering materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Spindle Speed (RPM) | 8,000 – 15,000 | 8,000 – 15,000 | 10,000 – 20,000 | 3,000 – 8,000 (varies by part) | Higher speeds enable efficient aluminum and ABS machining |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | Critical for tight tolerance stack-up in high-volume assemblies |

| Repeatability | ±0.002 mm (±0.0001″) | ±0.002 mm (±0.0001″) | ±0.002 mm (±0.0001″) | ±0.002 mm (±0.0001″) | Ensures consistency across large production batches |

| Typical Tolerance Range | ±0.025 mm to ±0.01 mm | ±0.025 mm to ±0.01 mm | ±0.025 mm to ±0.005 mm | ±0.012 mm to ±0.005 mm | Tighter tolerances achievable with process optimization |

| Axis Travel (Typical) | 500–1000 mm (X), 400–800 mm (Y), 300–600 mm (Z) | Same as 3-axis + rotary (A-axis: ±180°) | X, Y, Z as above + dual rotary (A/C or B/C), ±180° continuous | Z: 200–500 mm, X: 150–300 mm | 5-axis allows complex geometry without re-fixturing |

| Tool Changer Capacity | 12–30 tools | 12–30 tools | 20–40 tools | 8–12 tools (live tooling) | Supports unattended operation for high-volume runs |

| Materials (Common) | Aluminum 6061, 7075, Steel 1018, 4140, ABS, Nylon | Same as 3-axis | Same as 3-axis, optimized for complex steel and aluminum parts | Aluminum, Steel, Stainless, ABS, Nylon | Material choice impacts tooling, speed, and coolant requirements |

| Surface Finish (Typical) | 0.8 – 3.2 µm Ra | 0.8 – 3.2 µm Ra | 0.4 – 1.6 µm Ra | 0.8 – 2.5 µm Ra | Fine finishes achievable with finishing passes and proper parameters |

| Coolant & Lubrication | Through-spindle coolant (optional) | Flood or mist coolant | High-pressure through-tool | Flood coolant with chip conveyors | Required for steel and nylon to manage heat and chip evacuation |

| Production Rate (Cycle Time) | 30 sec – 5 min/part | 45 sec – 7 min/part | 2 – 10 min/part | 15 sec – 3 min/part | Depends on complexity, material, and automation level |

| Automation Ready | Yes (with pallet systems) | Yes (4-axis palletized) | Yes (5-axis with robotics) | Yes (bar feeders, gantry) | Essential for lights-out manufacturing in high-volume environments |

All processes are supported by ISO 9001-certified quality systems, in-process probing, and CMM validation to ensure compliance with tight tolerance requirements across aluminum, steel, ABS, and nylon components. Tool life monitoring and adaptive machining strategies are employed to maintain dimensional stability over extended production runs.

From CAD to Part: The Process

Honyo Prototype High Volume CNC Machining Process Overview

Honyo Prototype executes high volume CNC machining (typically defined as production runs exceeding 1,000 units) through a rigorously controlled, integrated workflow designed to maximize precision, repeatability, and cost efficiency. This process eliminates common supply chain friction points inherent in traditional manufacturing models. Each phase is engineered to ensure seamless transition from design intent to certified delivery, with embedded quality checkpoints and data-driven decision-making.

CAD Upload & Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via our secure customer portal. Our system performs immediate automated validation checks for file integrity, geometric completeness, and unit consistency. Critical tolerances, material specifications, and surface finish requirements are parsed and cross-referenced against Honyo’s machine capability database. This step confirms the design aligns with our high-volume CNC infrastructure (primarily multi-spindle lathes, high-speed 5-axis mills, and automated pallet systems) before proceeding, preventing downstream delays.

AI-Powered Quoting & Feasibility Assessment

Uploaded designs enter our proprietary AI quoting engine, which analyzes over 200 manufacturability parameters in under 90 seconds. Unlike basic cost calculators, this system evaluates toolpath complexity, fixture requirements, material utilization efficiency, and potential secondary operations. It cross-references real-time data from our production floor—machine availability, tooling inventory, and labor rates—to generate a technically viable quote with accurate lead times. Crucially, the AI flags high-risk geometries (e.g., thin walls below 0.5mm, deep cavities without draft) that could compromise yield at scale, providing immediate feedback before formal commitment.

Collaborative DFM Optimization

Upon quote acceptance, our engineering team conducts a mandatory Design for Manufacturability (DFM) review. This is not a passive checklist but an active collaboration: Honyo engineers propose specific, validated design modifications to enhance producibility without sacrificing function. Examples include optimizing wall thicknesses for thermal stability during extended runs, suggesting tolerance relaxation on non-critical features using statistical process control (SPC) data, or reconfiguring part orientation to minimize setups. Client sign-off on the DFM report is required, ensuring alignment on cost, quality, and timeline targets. This phase typically reduces production costs by 15–25% and prevents 90% of potential volume-related defects.

Precision Production Execution

Approved designs move to our dedicated high-volume production cell, featuring automated gantry loaders, robotic deburring stations, and in-process CMM verification. Key protocols include:

First Article Inspection (FAI): Full GD&T validation per AS9102 or client-specific standards before batch release.

Statistical Process Control (SPC): Real-time monitoring of critical dimensions using machine-integrated probes; data logged to our MES for traceability.

Material Traceability: Batch-controlled materials with full CoC documentation, essential for medical and aerospace clients.

Shift Handover Protocols: Standardized checklists ensuring consistency across 24/7 operations, with tool wear compensation algorithms adjusting feeds/speeds autonomously.

Certified Delivery & Logistics Integration

Finished lots undergo final visual and dimensional inspection per the agreed AQL level (typically ISO 2859-1 Level II). All parts ship with comprehensive documentation: material test reports, FAI data, SPC charts, and non-conformance records (if applicable). Honyo manages logistics through certified carriers with climate-controlled options for sensitive components. Our system provides real-time shipment tracking and automated Advanced Shipping Notices (ASNs) integrated with client ERP systems. Standard on-time delivery for high-volume runs exceeds 99.5%, with packaging compliant toISTA 3A standards to prevent transit damage.

Quality & Performance Metrics

Honyo’s high-volume CNC process is validated through continuous measurement of critical KPIs:

| KPI Category | Target Metric | Measurement Method |

|---|---|---|

| Production Yield | ≥ 99.8% | In-process SPC data per lot |

| On-Time Delivery | ≥ 99.5% | ERP shipment vs. committed date |

| Cost Variance vs. Quote | ≤ ±3% | Actual vs. quoted labor/material |

This end-to-end process ensures clients achieve predictable unit costs, minimized total lead time, and zero-defect delivery at scale—transforming complex designs into reliable, high-integrity components for demanding industries like automotive, medical devices, and industrial automation.

Start Your Project

High Volume CNC Machining Solutions – Precision, Speed, Scalability

For high volume CNC machining that delivers consistent quality and on-time delivery, partner with Honyo Prototype. Our Shenzhen-based manufacturing facility is equipped with advanced CNC technology and a streamlined production process designed to support large-scale orders with tight tolerances and fast turnaround.

Contact Susan Leo today to discuss your production needs and get a competitive quote.

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.