Contents

Manufacturing Insight: High Tolerance Machining

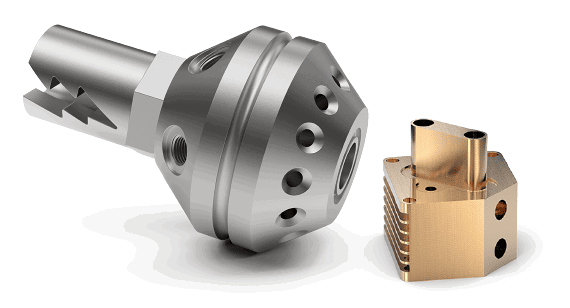

Precision Engineered for Demanding Applications

High tolerance machining represents the pinnacle of dimensional accuracy in component manufacturing, where deviations measured in microns directly impact performance, safety, and regulatory compliance. At Honyo Prototype, our advanced CNC machining services specialize in delivering parts consistently within tight tolerances of ±0.0002 inches (±0.005 mm) across complex geometries and challenging materials including titanium, Inconel, and high-performance polymers. This capability is non-negotiable for mission-critical sectors such as aerospace hydraulics, medical implants, and semiconductor equipment, where functional integrity depends on absolute precision.

Our integrated approach combines state-of-the-art 5-axis machining centers, rigorous in-process metrology using calibrated CMMs and vision systems, and AS9100-certified quality protocols to eliminate variability. Unlike standard machining providers, we engineer solutions for features like micro-bore alignments, critical surface finishes under Ra 0.8 μin, and multi-feature concentricity—all validated through full first-article inspection reports. The table below illustrates key differentiators in our high tolerance process:

| Parameter | Standard Machining | Honyo High Tolerance Machining |

|---|---|---|

| Typical Tolerance | ±0.001 in (±0.025 mm) | ±0.0002 in (±0.005 mm) |

| Material Complexity | Limited alloys | Aerospace-grade superalloys, ceramics |

| Process Validation | Post-process only | Real-time thermal compensation + SPC |

| Lead Time Reduction | N/A | 30% faster via digital workflow |

Accelerate your precision component development with Honyo’s Online Instant Quote platform. Upload CAD files to receive detailed manufacturability feedback and a validated price within hours—not days—enabling faster iteration cycles without compromising on the exacting standards your application demands. Partner with engineering expertise where micron-level accuracy meets operational agility.

Technical Capabilities

High tolerance machining refers to precision manufacturing processes capable of achieving tight dimensional accuracy and tight geometric tolerances, typically within ±0.0002″ (±0.005 mm) or tighter depending on part geometry, material, and equipment capability. At Honyo Prototype, high tolerance machining is performed using advanced 3, 4, and 5-axis CNC milling centers and precision turning centers, enabling complex geometries, superior surface finishes, and consistent repeatability. These capabilities are critical for industries such as aerospace, medical, and robotics, where fit, function, and performance are paramount.

The following table outlines the technical specifications for high tolerance machining across key parameters, including process type, tolerance capability, surface finish, supported materials, and typical applications.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Typical Tolerance | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) | ±0.0001″ (±0.0025 mm) | ±0.0002″ (±0.005 mm) |

| Positional Accuracy | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.00008″ (±0.002 mm) | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.00008″ (±0.002 mm) | ±0.0001″ (±0.0025 mm) |

| Surface Finish (Ra) | 32–64 μin (0.8–1.6 μm) | 32–64 μin (0.8–1.6 μm) | 16–32 μin (0.4–0.8 μm) | 16–32 μin (0.4–0.8 μm) |

| Spindle Speed (max) | 24,000 RPM | 24,000 RPM | 30,000 RPM | 12,000 RPM |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Key Features | High-speed precision milling for prismatic parts | Indexing rotary axis for multi-sided machining | Continuous 5-axis motion for complex contours | High-precision external/internal turning, threading |

| Typical Applications | Enclosures, brackets, jigs | Aerospace components, fixtures | Impellers, molds, medical implants | Shafts, bushings, connectors |

Material Notes:

Aluminum (e.g., 6061-T6, 7075-T6): Lightweight, excellent machinability, high strength-to-weight ratio. Ideal for tight tolerance parts in aerospace and automotive.

Steel (e.g., 4140, 1018, Stainless 303/316): High strength and wear resistance. Requires rigid setups and specialized tooling for tight tolerance work.

ABS (Acrylonitrile Butadiene Styrene): Thermoplastic with good dimensional stability. Used in prototypes and low-stress functional parts.

Nylon (e.g., PA6, PA66): Tough, abrasion-resistant engineering plastic. Requires controlled feed rates and cooling to maintain dimensional accuracy.

All high tolerance machining operations are supported by in-process metrology, environmental controls, and post-process CMM inspection to ensure compliance with GD&T requirements and customer specifications.

From CAD to Part: The Process

Honyo Prototype High Tolerance Machining Process Overview

Honyo Prototype executes high tolerance machining through a rigorously controlled workflow designed to ensure micron-level precision, repeatability, and compliance with stringent industry standards (ISO 2768-mK, ASME Y14.5). This process integrates advanced digital tools with precision manufacturing expertise to mitigate risks inherent in tight-tolerance production. Below is a technical breakdown of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, Parasolid, or native MCAD formats) via our secure portal. Our system performs automated geometry validation, checking for non-manufacturable features, unresolved tolerances, and unit inconsistencies. Critical dimensions and geometric tolerances (GD&T) are flagged for immediate review. Files failing validation trigger an automated notification requesting corrections, preventing downstream delays. This phase ensures the digital twin aligns with physical manufacturability constraints before quoting.

AI-Powered Quoting with Engineering Oversight

Honyo’s proprietary AI quoting engine analyzes validated CAD data against real-time machine capabilities, material databases, and historical process performance. It calculates achievable tolerances (±0.002mm to ±0.005mm typical), surface finishes (Ra 0.2–0.8 µm), and cycle times using physics-based simulations. Crucially, the AI cross-references tolerance callouts against our machine tool Cpk data (min. Cpk 1.67 for critical features) and material behavior models. Output includes feasibility warnings for statistically improbable tolerances. All AI outputs undergo mandatory review by a senior process engineer who validates toolpath strategies, fixturing requirements, and metrology plans.

Deep-Dive DFM Analysis

The Design for Manufacturability phase focuses exclusively on tolerance stack-up mitigation. Our engineers perform:

Statistical tolerance allocation using Monte Carlo simulation to identify risk zones

Material-specific thermal expansion compensation (e.g., Invar vs. 7075-T6 aluminum)

Fixture-induced distortion analysis via FEA

GD&T symbology verification against ASME Y14.5-2018 standards

Clients receive a formal DFM report detailing actionable modifications—such as relaxing non-critical tolerances or suggesting datum shifts—to avoid scrap rates exceeding 5%. This phase typically reduces production defects by 30–40% in high-tolerance builds.

Precision Production Execution

Machining occurs in climate-controlled cells (20°C ±0.5°C, 45% RH) on calibrated equipment (e.g., Makino A81X, DMG MORI CTX beta 1250). Key protocols include:

Pre-machining material certification with CTE validation

In-process probing for thermal drift compensation (using Renishaw RMP60)

Dedicated tooling with laser-set edge detection (±1µm accuracy)

Sequential machining to minimize residual stress

All critical features undergo first-article inspection via Zeiss CONTURA CMM (0.5µm + L/600) with NIST-traceable reports. Statistical process control (SPC) monitors Cp/Cpk in real time; any deviation beyond control limits halts production.

Certified Delivery and Traceability

Final inspection includes full-spectrum metrology: CMM for dimensional data, optical comparators for profile tolerances, and surface roughness testers. Each shipment includes:

Material test reports (MTRs) with heat lot traceability

Full FAI package per AS9102B (for aerospace)

Process capability data (Cp/Cpk for critical characteristics)

Cleanliness certification (per ISO 14644-1 Class 8 for medical parts)

Parts are packaged in anti-static, humidity-controlled containers with serialized tracking from machine to client dock.

Process Performance Parameters

| Parameter | Standard Machining | High Tolerance Machining |

|————————–|——————–|————————–|

| Typical Tolerance Range | ±0.025mm | ±0.002mm to ±0.005mm |

| Cpk Requirement | ≥1.33 | ≥1.67 (critical features)|

| Inspection Density | 10% critical dims | 100% critical dims + SPC |

| Thermal Stability | Ambient control | ±0.5°C active control |

This closed-loop process ensures Honyo consistently achieves tolerances demanding sub-5µm repeatability while maintaining 98.5% on-time delivery for complex precision components. All stages are audited under ISO 9001:2015 and IATF 16949 frameworks, with continuous improvement driven by metrology feedback into our AI models.

Start Your Project

For high tolerance machining solutions tailored to your precision engineering requirements, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen is equipped to deliver tight-tolerance components with consistent quality and on-time delivery. Partner with Honyo Prototype for precision, reliability, and technical excellence in every part produced.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.