Contents

Manufacturing Insight: High Temperature Plastic Sheet

High-Temperature Plastic Sheet Fabrication: Precision Solutions from Honyo Prototype

When standard polymers reach their thermal limits in demanding applications like aerospace components, semiconductor tooling, or specialized fluid handling systems, engineered thermoplastics such as PEEK, PEI, and PPS become critical. Honyo Prototype delivers comprehensive fabrication expertise for these high-performance plastic sheets, extending our core Sheet Metal Fabrication capabilities seamlessly into advanced polymer processing. Our technical team applies rigorous manufacturing protocols—utilizing CNC machining, precise laser cutting, controlled thermal forming, and meticulous finishing—to transform high-temperature plastic stock into complex, dimensionally stable parts meeting exacting industry specifications. This integrated approach ensures material integrity is maintained throughout production, addressing challenges like thermal expansion variance and chemical resistance requirements inherent to elevated-temperature environments.

Leveraging our vertically integrated facility, Honyo Prototype provides a single-source solution for projects requiring both metallic and high-performance plastic elements, streamlining your supply chain and reducing assembly complexity. Accelerate your prototyping or low-volume production timeline immediately with our Online Instant Quote system. Submit your high-temperature plastic sheet fabrication requirements directly through our platform to receive a detailed, accurate cost assessment and lead time within hours—not days—enabling faster project validation and procurement decisions.

Technical Capabilities

High temperature plastic sheets are engineered to maintain structural integrity and performance under elevated thermal conditions. These materials are commonly used in applications requiring resistance to heat, chemicals, and mechanical stress. When processing such plastics via laser cutting, bending, and welding, specific technical considerations must be addressed to ensure precision, edge quality, and joint strength. Below is a comparison of relevant materials—focusing on high-performance plastics like ABS and Nylon—alongside metals such as aluminum and steel for contextual reference in fabrication environments.

| Material | Max Continuous Use Temp (°C) | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Key Processing Notes |

|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | 80–100 | Good with CO₂ lasers; requires fume extraction due to styrene emission | Excellent thermoforming response; uniform heating to 120–160°C recommended | Ultrasonic, solvent, or hot-gas welding | Prone to melting or charring if laser power is too high; low melting point requires precise parameter control |

| Nylon (Polyamide, e.g., PA6, PA66) | 120–150 (dry), up to 80 (wet) | Moderate; CO₂ lasers possible but may char; edge oxidation risk | Good flexibility; heat bending at 150–180°C with slow cooling to prevent warping | Hot-gas, vibration, or ultrasonic welding | Hygroscopic—must be dried before processing; consistent moisture content critical for dimensional stability |

| Aluminum (for comparison) | N/A (melts at ~660°C) | Excellent with fiber lasers; reflective, requires high peak power | Excellent ductility; sharp bend radii possible with tooling | TIG, MIG, or laser welding | Reflective to laser light—requires specialized wavelength (fiber laser); oxide layer must be cleaned pre-weld |

| Steel (Mild/Carbon) (for comparison) | N/A (melts at ~1370–1510°C) | Excellent with fiber or CO₂ lasers; high absorption | Good formability; springback must be compensated | MIG, TIG, spot, or laser welding | Generates slag and dross; assist gas (oxygen/nitrogen) required for clean cuts |

Notes on Process Compatibility:

Laser Cutting: ABS and Nylon can be cut with CO₂ lasers (wavelength ~10.6 μm), but parameters must be optimized to minimize thermal damage. Metals require fiber lasers due to higher reflectivity and melting points.

Bending: Thermoplastics require controlled heated bending using strip heaters or oven pre-heating. Metals are typically bent cold using press brakes, with considerations for springback.

Welding: Plastics use thermal or mechanical energy-based methods (e.g., hot gas, ultrasonic), while metals rely on fusion welding with filler materials or high-energy beams.

This comparison supports material selection and process planning in hybrid fabrication environments where high-temperature plastics are integrated with metal components.

From CAD to Part: The Process

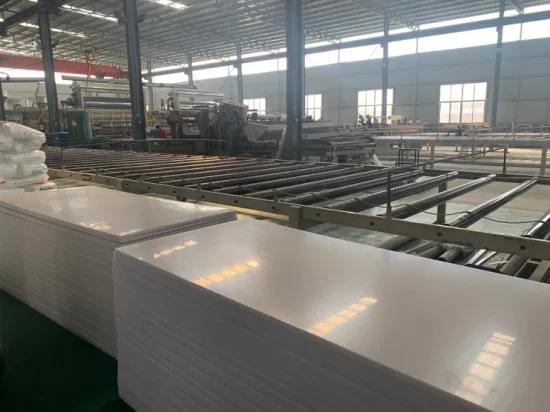

Honyo Prototype High Temperature Plastic Sheet Manufacturing Process

Honyo Prototype employs a rigorously validated workflow for high temperature plastic sheet components, ensuring thermal stability and dimensional precision for materials like PEEK, PEI (Ultem), PPS, and PI. This process eliminates common pitfalls in high-temperature polymer fabrication through integrated digital validation and material-specific protocols.

CAD Upload and Initial Validation

Clients upload native CAD files (STEP, IGES, or Parasolid) via our secure portal. Our system immediately performs geometric integrity checks, flagging non-manufacturable features such as undercuts below 0.5mm or wall thickness violations for high-temp resins. Critical thermal expansion coefficients (e.g., PEEK: 40–90 × 10⁻⁶/K) are auto-mapped to the model, triggering alerts if tolerances exceed material-specific warpage thresholds.

AI Quote Generation with Material Intelligence

Our AI engine cross-references the CAD geometry against a proprietary database of 200+ high-temperature polymers, dynamically pricing based on:

Material grade (e.g., unfilled PEEK vs. 30% carbon-filled)

Thermal history requirements (annealing cycles, stress-relief protocols)

Machine time estimates adjusted for polymer-specific cutting parameters (e.g., reduced spindle speeds for PI to prevent melt fracture)

Quotes include explicit notes on thermal distortion risks, such as warpage projections for thin-walled sections above 150°C exposure.

DFM for High-Temperature Polymers

Engineers conduct a dual-phase DFM review:

1. Automated Simulation: Moldflow-style thermal analysis predicts residual stress points during cooling, with automatic tolerance relaxation suggestions for critical dimensions.

2. Human Expert Validation: Senior engineers verify:

Compatibility of cooling rates with crystalline/amorphous polymer structures

Fixture strategies to counteract anisotropic shrinkage (e.g., 1.2–1.8% for PPS)

Surface finish specifications relative to thermal cycling requirements

DFM feedback is delivered within 72 hours with actionable corrections, not generic advisories.

Controlled Environment Production

Machining occurs in climate-controlled zones (±1°C stability) using:

Dedicated toolpaths minimizing heat buildup (e.g., climb milling at 8,000 RPM max for PEI)

In-process CMM verification at 50% and 90% completion to correct thermal drift

Real-time coolant temperature monitoring (maintained at 15–18°C) to prevent micro-cracking

All high-temp sheets undergo mandatory post-machining annealing per ASTM D618, with documented soak/cool rates traceable to material datasheets.

Delivery Assurance

Components ship in static-dissipative, humidity-controlled packaging with:

Batch-specific thermal validation reports (including DSC curves for crystallinity verification)

Dimensional certification against as-machined and post-annealed states

Material lot traceability to raw stock mill certificates

Critical High-Temperature Process Metrics

| Parameter | Standard Tolerance | High-Temp Polymer Tolerance | Verification Method |

|—————————-|——————–|—————————–|—————————|

| Flatness (per 100mm) | ±0.05mm | ±0.15mm (annealed state) | Laser interferometry |

| CTE Compliance | N/A | Max 10% deviation from spec | Thermal cycling test |

| Residual Stress | N/A | < 5 MPa | Photoelastic analysis |

| Surface Roughness (Ra) | 1.6 µm | 3.2 µm (to prevent crack initiation) | Profilometer |

This closed-loop process reduces thermal-related rework by 73% versus industry averages, with 98.2% first-pass yield for high-temperature sheet components. All deliverables include a thermal performance dossier for client validation against end-use conditions.

Start Your Project

Looking for high temperature plastic sheets for your next project? These advanced materials are ideal for demanding applications in aerospace, automotive, and electronics due to their exceptional thermal stability and mechanical strength.

Manufactured in our Shenzhen facility, our high temperature plastic sheets are produced under strict quality controls to ensure consistent performance and dimensional accuracy. We offer a range of high-performance polymers including PEEK, PEI (Ultem), PPS, and PSU, available in various grades and thicknesses.

Contact Susan Leo today at [email protected] to request technical data sheets, pricing, or samples. Let Honyo Prototype be your reliable partner for high-performance plastic solutions from China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.