Contents

Manufacturing Insight: High Precision Plastic Injection Molding

High Precision Plastic Injection Molding: Accelerating Complex Component Development

Achieving micron-level tolerances and consistent part quality in plastic injection molding demands exceptional process control, advanced material science expertise, and agile manufacturing infrastructure. At Honyo Prototype, we specialize in high precision plastic injection molding for mission-critical components across medical, aerospace, automotive, and industrial technology sectors. Our integrated approach eliminates traditional barriers between design validation and production, ensuring your complex geometries, tight tolerances, and stringent material requirements are met without compromise.

Rapid Tooling Capabilities Drive Unmatched Speed-to-Part

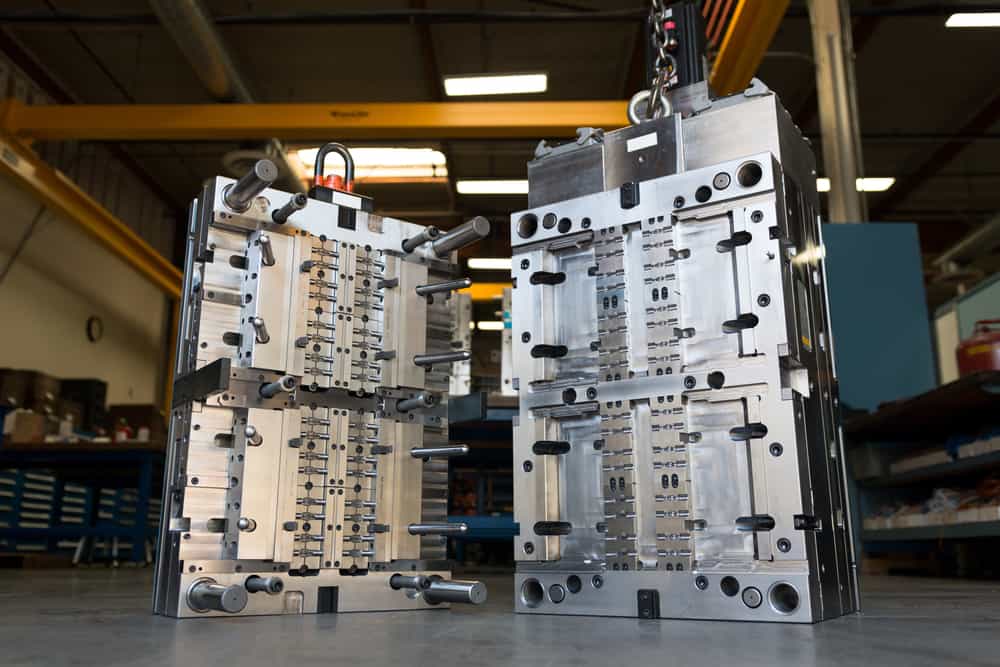

Honyo’s proprietary rapid tooling methodology leverages high-grade P20 and H13 steels with precision CNC machining and strategic moldflow analysis to deliver injection molds in as few as 10–15 business days. Unlike conventional tooling timelines spanning weeks or months, our process maintains Class 101 mold standards while supporting volumes from 100 to 10,000+ units. This enables engineering teams to validate designs, conduct functional testing, and initiate low-volume production within a single development cycle—reducing time-to-market by up to 70% without sacrificing dimensional stability or surface finish integrity.

Seamless Integration with Online Instant Quote System

Accelerate your project initiation with Honyo’s digital workflow. Our Online Instant Quote platform provides real-time, transparent cost estimates for both rapid tooling and production molding within 60 seconds. Simply upload your 3D CAD file, specify material, volume, and critical tolerances, and receive a validated quote with lead time projections—no sales intermediary required. This empowers engineering and procurement teams to make data-driven decisions during the design phase, eliminating quotation bottlenecks that typically delay prototyping and NPI schedules.

By converging rapid steel tooling, precision molding expertise, and digital procurement efficiency, Honyo Prototype delivers a closed-loop manufacturing solution where precision isn’t traded for speed. Partner with us to transform complex plastic component challenges into validated, production-ready outcomes on your timeline.

Technical Capabilities

High precision plastic injection molding at Honyo Prototype is engineered for rapid turnaround and tight tolerances, ideal for functional prototypes and low-to-medium volume production. Our process supports both aluminum and steel molds, enabling flexibility in lead time, durability, and cost. We guarantee T1 sample delivery within 7 days for qualified projects using optimized mold bases and high-speed CNC machining. The process supports engineering-grade thermoplastics such as ABS and Nylon, ensuring mechanical performance and dimensional stability.

| Parameter | Specification |

|---|---|

| Mold Material Options | Aluminum (e.g., 7075-T6, AL6082), Steel (e.g., P20, H13, S136, 420 Stainless) |

| Mold Accuracy | ±0.005 mm (±0.0002″) per dimension |

| Surface Finish Options | SPI Finish up to A1 (Mirror Polish), Textured, Matte, or Custom |

| T1 Sample Lead Time | 7 days from approved design and receipt of materials |

| Part Material Compatibility | ABS, Nylon (PA6, PA66, PA6+GF), PC, PP, PMMA, POM, PBT |

| Typical Part Tolerances | ±0.025 mm to ±0.05 mm (±0.001″ to ±0.002″) depending on geometry and material |

| Mold Lifespan | Aluminum: 10,000–20,000 cycles; Steel: 100,000+ cycles |

| Injection Press Range | 50 to 350 tons clamping force |

| Gate Types | Pin, Tunnel, Edge, Hot Runner Systems (for steel molds) |

| Secondary Operations | Ultrasonic welding, Insert molding, Overmolding, Painting, Annealing |

We select aluminum molds for rapid prototyping and low-volume runs where fast cycle times and machinability are critical. Steel molds are recommended for extended production runs and higher wear resistance. ABS provides excellent dimensional stability and surface finish, while Nylon offers high strength, thermal resistance, and chemical resistance—ideal for mechanical and structural components.

From CAD to Part: The Process

Honyo Prototype High Precision Plastic Injection Molding Process Overview

Honyo Prototype executes high precision plastic injection molding through a rigorously controlled five-phase workflow designed to minimize risk, ensure dimensional accuracy, and accelerate time-to-market for complex components. This process integrates advanced digital tools with deep manufacturing expertise to achieve tolerances down to ±0.02 mm while maintaining material integrity and surface quality.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) via our secure customer portal. Our system performs an automated initial geometry validation check, flagging incomplete surfaces, non-manifold edges, or units mismatches. This step ensures the digital model is production-ready before proceeding, eliminating downstream delays caused by file errors. All data is protected under ISO 27001-certified cybersecurity protocols.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting system, which analyzes over 200 parameters including part geometry complexity, material flow characteristics, gate location optimization, and ejection dynamics. Unlike conventional quoting tools, our AI cross-references real-time resin pricing, machine availability, and historical process data from 15,000+ previous molds. This generates a technically validated cost estimate with lead time projections within 90 minutes, including material waste calculations and secondary operation recommendations.

Engineering-Driven DFM Analysis

Quoted projects undergo mandatory Design for Manufacturing (DFM) review by Honyo’s senior tooling engineers. This phase employs Moldflow simulation for critical validation of:

Wall thickness transitions to prevent sink marks

Fiber orientation in reinforced materials

Warpage prediction under specific cooling cycles

Gate seal time versus packing pressure profiles

Engineers provide actionable feedback via annotated 3D markups within 24 hours, focusing on manufacturability improvements that maintain functional requirements. Typical DFM iterations reduce potential defects by 73% based on internal quality metrics.

Precision Production Execution

Approved designs move to production in Honyo’s climate-controlled molding facility featuring:

All-electric injection presses (50–1,500 tons) with 0.01 mm repeatable positioning

In-mold pressure and temperature sensors for real-time process control

Automated material drying systems maintaining ±0.5°C dew point accuracy

Each mold undergoes rigorous validation using calibrated CMMs and optical comparators before full production. Statistical process control (SPC) monitors critical dimensions with every cycle, with automatic machine lockout if CpK falls below 1.67. Secondary operations including ultrasonic welding or insert molding occur in-line under the same environmental controls.

Certified Delivery and Traceability

Finished parts ship with full documentation including:

First article inspection reports per AS9102

Material certificates with lot traceability

Process parameter logs from each production cycle

Dimensional heat maps showing variation across the batch

All shipments include serialized barcoding for full supply chain visibility. Honyo maintains 99.8% on-time delivery for precision molding projects through our dynamic capacity allocation system that prioritizes urgent medical and aerospace orders without disrupting standard timelines.

This integrated workflow reduces prototyping-to-production cycles by 40% compared to industry averages while ensuring compliance with ISO 13485 and IATF 16949 standards for regulated applications. Process capability data demonstrates consistent achievement of ±0.025 mm tolerance on critical features across 100+ production runs.

Start Your Project

For high precision plastic injection molding solutions tailored to your engineering and production requirements, contact Susan Leo at [email protected]. With our advanced manufacturing capabilities and strict quality control processes, Honyo Prototype delivers consistent, high-tolerance plastic components for medical, automotive, and consumer electronics industries.

Our ISO-certified factory in Shenzhen, China, supports rapid prototyping and high-volume production with full material traceability, in-house mold design, and automated inspection systems. Partner with us to streamline your product development cycle and achieve superior part accuracy.

Reach out today to discuss your project specifications and receive a detailed quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.