Introduction: Navigating the Global Market for high precision machine shop

In an increasingly competitive global market, sourcing high precision machine shop services that meet stringent quality standards can be a daunting challenge for international B2B buyers. As industries evolve and demand for intricate components rises, the need for reliable suppliers capable of delivering consistent, high-tolerance parts becomes paramount. This guide serves as a comprehensive resource for businesses looking to navigate the complexities of high precision machining, addressing critical areas such as types of machining processes, diverse applications across various sectors, effective supplier vetting strategies, and cost considerations.

Our aim is to empower you, the international buyer, with actionable insights that enhance your procurement decisions. Whether you are in Africa seeking precision components for the automotive industry, in South America looking for reliable machining partners in aerospace, or in Europe needing tailored solutions for medical devices, this guide is tailored to your specific needs. By understanding the landscape of high precision machining, you can confidently engage with suppliers who not only meet your specifications but also align with your operational goals. Let this guide be your roadmap to sourcing excellence in the world of high precision machine shops, ensuring that your business stays ahead in innovation and quality.

Understanding high precision machine shop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining Shops | Utilize computer-controlled machines for precision parts. | Aerospace, automotive, medical devices | Pros: High accuracy, scalability. Cons: Initial setup cost can be high. |

| Multi-Spindle Machining Shops | Employ multiple spindles for high-volume production. | Mass production of small parts like screws and bolts | Pros: Increased productivity, lower per-unit cost. Cons: Limited to simpler geometries. |

| 5-Axis CNC Machining Shops | Capable of machining complex geometries with multiple axes. | Aerospace components, intricate medical devices | Pros: High precision for complex shapes. Cons: Higher operational costs. |

| Precision EDM Shops | Use electrical discharge machining for intricate designs. | Tooling, aerospace, and defense applications | Pros: Exceptional precision, ideal for hard materials. Cons: Slower production rates. |

| Precision Assembly Shops | Combine machining with assembly services for complete products. | Automotive, electronics, and medical devices | Pros: Streamlined processes, reduced lead times. Cons: May lack specialized machining capabilities. |

What Are the Characteristics of CNC Machining Shops?

CNC (Computer Numerical Control) machining shops leverage advanced technology to produce precision parts with minimal human intervention. These shops are ideal for a wide range of industries, including aerospace and automotive, where accuracy is paramount. Buyers should consider the machine shop’s capabilities in handling various materials and its ability to scale production based on project demands. While initial setup costs can be significant, the long-term benefits of efficiency and precision often outweigh these expenses.

How Do Multi-Spindle Machining Shops Operate?

Multi-spindle machining shops are designed for high-volume production, employing multiple spindles to manufacture parts simultaneously. This method is particularly suited for producing small components like screws and bolts. For B2B buyers, the primary consideration is the volume of parts needed; these shops excel in mass production but may not be suitable for complex designs. While they offer lower per-unit costs, the simplicity of parts produced can be a limiting factor for some projects.

What Makes 5-Axis CNC Machining Shops Unique?

5-axis CNC machining shops are equipped to handle intricate designs that require multiple angles of machining. This capability is crucial for industries such as aerospace and medical devices, where precision and complexity are essential. B2B buyers should assess the shop’s experience with complex geometries and the types of materials they can process. Although these shops provide exceptional precision, the costs associated with their operations can be higher, which is a vital consideration for budget-conscious buyers.

Why Choose Precision EDM Shops for Intricate Designs?

Precision EDM (Electrical Discharge Machining) shops specialize in creating intricate designs that may be challenging for traditional machining methods. This technique is particularly beneficial in tooling and aerospace applications where precision is critical. Buyers should consider the shop’s turnaround times and expertise in handling hard materials. While EDM offers unmatched precision, it typically has slower production rates, making it less suitable for high-volume needs.

What Benefits Do Precision Assembly Shops Offer?

Precision assembly shops not only provide machining services but also integrate assembly capabilities, resulting in complete products. This approach is particularly advantageous for industries like automotive and electronics, where time-to-market is crucial. Buyers should evaluate the shop’s ability to streamline processes, as this can significantly reduce lead times. However, it’s essential to ensure that the shop maintains specialized machining capabilities, as this may impact the overall quality of the final product.

Key Industrial Applications of high precision machine shop

| Industry/Sector | Specific Application of High Precision Machine Shop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of aircraft components | Ensures safety and compliance with stringent regulations | Certifications, material specifications, lead times |

| Medical Devices | Production of surgical instruments | High precision reduces risk in critical applications | Quality assurance, biocompatibility, traceability |

| Automotive | Engine and transmission parts fabrication | Enhances performance and longevity of vehicles | Tolerance levels, cost efficiency, scalability |

| Oil & Gas | Custom parts for drilling equipment | Increases operational efficiency and safety | Material durability, sourcing of exotic materials |

| Defense & Military | Components for defense systems | Critical for mission success and reliability | Security clearances, compliance with military standards |

How is High Precision Machining Used in Aerospace Applications?

In the aerospace industry, high precision machine shops are essential for manufacturing critical aircraft components such as turbine blades and landing gear. These components must meet rigorous safety standards and tolerances, often requiring advanced machining techniques like 5-axis milling. For international B2B buyers, particularly those in Europe and the Middle East, sourcing from a high precision machine shop ensures compliance with aviation regulations and enhances product reliability, thereby reducing the risk of costly recalls or failures.

What Role Does High Precision Machining Play in Medical Device Production?

High precision machining is vital in the medical device sector, where precision components like surgical instruments and implants are produced. These items must be manufactured to exact specifications to ensure patient safety and device efficacy. Buyers from regions such as Africa and South America should prioritize suppliers with robust quality assurance processes and certifications that demonstrate compliance with international health standards. The ability to provide traceability and biocompatibility data is also crucial for these buyers.

How is High Precision Machining Applied in the Automotive Sector?

In the automotive industry, high precision machine shops produce engine components, transmission parts, and other critical systems that enhance vehicle performance. The demand for durability and efficiency in automotive parts makes precision machining indispensable. B2B buyers in markets like Germany, known for its automotive excellence, must consider machining capabilities that can handle tight tolerances and provide scalability for large production runs, ensuring both cost-effectiveness and high-quality output.

What Benefits Does High Precision Machining Offer in Oil & Gas?

The oil and gas sector relies heavily on custom parts for drilling and extraction equipment, where precision machining plays a key role. Components must withstand extreme conditions, requiring materials that offer exceptional durability and resistance to wear. Buyers from South America and Africa should focus on machine shops that can source exotic materials and provide solutions tailored to their specific operational challenges, ensuring longevity and reliability in their equipment.

How Does High Precision Machining Support Defense & Military Applications?

In defense and military applications, high precision machining is critical for producing components used in various systems, from weapons to communication devices. The reliability of these components can directly impact mission success. For international buyers, particularly from the Middle East, sourcing components from machine shops that adhere to strict security and compliance standards is essential. Ensuring that suppliers have the necessary certifications and a proven track record in defense contracting is crucial for maintaining operational integrity.

3 Common User Pain Points for ‘high precision machine shop’ & Their Solutions

Scenario 1: Tight Deadlines for Complex Projects

The Problem: B2B buyers often find themselves in situations where they need high precision components produced within exceptionally tight deadlines. This is particularly common in industries such as aerospace and medical devices, where delays can lead to costly production halts or compliance issues. For instance, a buyer may require a custom part that involves intricate geometries and stringent tolerances, but the chosen machine shop may not have the capacity or expertise to deliver on time, leaving the buyer scrambling for alternatives.

The Solution: To mitigate this issue, buyers should conduct thorough research on potential machine shops before committing to a partnership. Look for shops that specialize in quick turnaround times and have a proven track record in handling complex projects. When submitting requests for quotes, clearly communicate your timeline and specifications, and ask for examples of similar projects they have completed on time. Establishing a collaborative relationship with the machine shop can also facilitate faster production; consider involving them early in the design process to leverage their expertise in optimizing the part for manufacturability.

Scenario 2: Quality Assurance and Tolerance Challenges

The Problem: Achieving the required quality and tolerances in high precision machining can be a significant challenge, especially for international B2B buyers sourcing from different regions. Variability in machining processes, tools, and materials can lead to parts that do not meet specifications, resulting in rework, waste, and increased costs. A buyer may receive components that are just outside the specified tolerance, which could compromise the integrity of their final product.

The Solution: Buyers should prioritize machine shops that implement rigorous quality assurance processes, including the use of advanced measurement technologies such as CMM (Coordinate Measuring Machines) and laser scanning. Before finalizing a vendor, request details about their quality control protocols and certifications, such as ISO 9001 or AS9100, which indicate adherence to high standards. Additionally, it is wise to engage in pilot runs or prototype testing before large-scale production. This allows buyers to verify the machining quality and tolerances and make any necessary adjustments to the design or specifications before full production begins.

Scenario 3: Communication Barriers and Technical Misalignment

The Problem: In an increasingly globalized market, B2B buyers often face communication barriers when working with high precision machine shops located in different countries. Misunderstandings regarding technical specifications, material requirements, or production capabilities can lead to misaligned expectations and unsatisfactory results. A buyer from Europe, for instance, may struggle to convey complex design specifications to a shop in Africa, resulting in delays and potential project failure.

The Solution: To overcome communication challenges, buyers should invest time in establishing clear and comprehensive documentation for their projects. This includes detailed drawings, specifications, and any relevant industry standards. Utilizing digital platforms for real-time collaboration and feedback can also enhance communication. Consider appointing a liaison or project manager who is fluent in both the technical language of machining and the local language of the machine shop to facilitate smoother interactions. Additionally, video conferencing can be a valuable tool for discussing project nuances and troubleshooting issues as they arise, ensuring all parties are aligned throughout the production process.

Strategic Material Selection Guide for high precision machine shop

What Are the Key Properties of Aluminum in High Precision Machining?

Aluminum is a widely used material in high precision machining due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It typically performs well under moderate temperatures and pressures, making it suitable for a variety of applications. Aluminum alloys, such as 6061 and 7075, are particularly popular for their enhanced mechanical properties.

Pros: Aluminum is lightweight, which reduces shipping costs and makes it ideal for applications where weight is a critical factor, such as aerospace and automotive components. Its good thermal and electrical conductivity also makes it suitable for electrical applications.

Cons: However, aluminum can be less durable than some metals, especially under high-stress conditions. It is also more expensive than some alternative materials, such as steel, which can impact overall project budgets.

Impact on Application: Aluminum is compatible with various media, including water, air, and certain chemicals. However, it may not be suitable for high-temperature applications without specific alloying.

Considerations for International Buyers: B2B buyers should ensure compliance with regional standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) when sourcing aluminum components. Additionally, understanding local market preferences for specific aluminum alloys can influence procurement decisions.

How Does Stainless Steel Perform in Precision Machining Applications?

Stainless steel is renowned for its exceptional corrosion resistance, high strength, and durability, making it a go-to material for high precision machining. It typically withstands elevated temperatures and pressures, which is crucial for industries like oil and gas, aerospace, and medical devices.

Pros: The material’s resistance to rust and staining makes it ideal for applications requiring hygiene, such as food processing and medical equipment. Stainless steel also maintains its strength at high temperatures, making it suitable for high-performance applications.

Cons: On the downside, stainless steel is more challenging to machine than aluminum, often requiring specialized tools and techniques. This can lead to increased manufacturing costs and longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, which is vital for chemical processing applications.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 or JIS G4303 is essential for stainless steel products. Buyers should also consider the availability of specific grades, as preferences may vary by region.

What Are the Advantages of Using Titanium in High Precision Machining?

Titanium is celebrated for its high strength-to-weight ratio and exceptional corrosion resistance, making it a preferred choice in aerospace and medical applications. It can withstand extreme temperatures and pressures, which is critical for high-performance components.

Pros: Titanium’s biocompatibility makes it ideal for medical implants, while its strength allows for lightweight designs in aerospace applications. Its resistance to corrosion extends the lifespan of components, reducing maintenance costs.

Cons: However, titanium is significantly more expensive than aluminum and stainless steel, which can limit its use in cost-sensitive applications. Additionally, machining titanium is more complex and requires specialized equipment, leading to longer production times.

Impact on Application: Titanium is compatible with a variety of media, including seawater and aggressive chemicals, making it suitable for marine and chemical processing applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B348 or ISO 5832 for titanium components. Understanding the supply chain for titanium, especially in regions like Africa or South America, is crucial due to potential sourcing challenges.

What Role Does Brass Play in High Precision Machining?

Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It performs well in applications requiring good electrical conductivity and is often used in plumbing and electrical components.

Pros: Brass is easy to machine, allowing for intricate designs and tight tolerances. Its antimicrobial properties make it suitable for applications in healthcare and food processing.

Cons: However, brass is less strong than steel and may not be suitable for high-stress applications. Additionally, it can be more expensive than aluminum and carbon steel.

Impact on Application: Brass is compatible with water and many chemicals, but it may corrode in harsh environments, limiting its use in certain applications.

Considerations for International Buyers: Buyers should be aware of the different grades of brass and their corresponding standards, such as ASTM B16 or JIS H3250. Understanding local preferences for brass applications can also inform purchasing decisions.

Summary Table of Material Selection for High Precision Machining

| Material | Typical Use Case for high precision machine shop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Stainless Steel | Medical devices, oil and gas components | Exceptional corrosion resistance | Challenging to machine | High |

| Titanium | Aerospace, medical implants | High strength-to-weight ratio | Expensive and complex to machine | High |

| Brass | Plumbing fixtures, electrical components | Excellent machinability and antimicrobial | Less strong than steel | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for high precision machine shop

What Are the Key Stages of Manufacturing in a High Precision Machine Shop?

In high precision machining, the manufacturing process is meticulously structured to ensure that each component meets stringent quality and accuracy requirements. The primary stages of manufacturing typically include material preparation, forming, assembly, and finishing. Each stage employs specific techniques designed to optimize precision and efficiency.

How Is Material Prepared in High Precision Machining?

Material preparation begins with the selection of appropriate raw materials, such as aluminum, stainless steel, titanium, or exotic alloys. This selection is crucial because the material properties will directly influence the performance of the final part. Once chosen, materials undergo rigorous inspection for quality and conformity to specifications. This may include checking for defects, verifying dimensions, and ensuring that the material meets relevant industry standards.

After inspection, the materials are cut to size using precision techniques like laser cutting or waterjet cutting. This initial step ensures that the materials are ready for subsequent machining operations, laying the groundwork for high precision outcomes.

What Forming Techniques Are Commonly Used?

The forming stage is where the bulk of the machining takes place. High precision machine shops utilize various techniques, including CNC milling, turning, and multi-axis machining. CNC (Computer Numerical Control) technology allows for highly accurate machining operations that can achieve tolerances of ±0.0001 inches or better.

Multi-axis machining, such as 5-axis CNC milling, enables the creation of complex geometries in a single setup, reducing the need for multiple operations and minimizing potential errors. This is particularly beneficial for industries that require intricate parts, such as aerospace and medical devices.

How Is Assembly Conducted for Precision Parts?

Once individual components are machined, the assembly stage involves bringing these parts together to form a complete product. This can include the integration of various sub-components and may require additional processes such as welding, fastening, or adhesive bonding. Precision in assembly is critical; therefore, assembly operations are often conducted in controlled environments to prevent contamination and ensure that tolerances are maintained.

Some high precision machine shops also offer assembly services that include functional testing of the assembled product, ensuring that it meets all operational requirements before it reaches the client.

What Finishing Techniques Enhance Quality and Performance?

The finishing stage is essential for achieving the desired surface quality and performance characteristics of machined parts. Techniques such as grinding, polishing, and anodizing are commonly employed to enhance the surface finish. This not only improves the aesthetic appeal of the components but also contributes to their durability and resistance to wear.

Finishing processes may also include heat treatment or surface hardening to improve material properties. Each of these techniques must be carefully monitored and controlled to ensure that they do not compromise the precision achieved in earlier stages.

What Quality Assurance Measures Are Essential in High Precision Machining?

Quality assurance (QA) is a cornerstone of high precision machining, ensuring that all products meet or exceed customer expectations and regulatory requirements. Implementing a robust QA program involves adhering to international standards and conducting thorough inspections throughout the manufacturing process.

Which International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 are critical in establishing a quality management system within high precision machine shops. ISO 9001 provides a framework for consistent quality in manufacturing processes, focusing on customer satisfaction and continuous improvement. Furthermore, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications add an additional layer of compliance that is often required by B2B buyers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor critical dimensions and tolerances, ensuring that deviations are detected early.

- Final Quality Control (FQC): After machining and finishing, a comprehensive inspection is carried out to validate that the finished product meets all specifications before shipment.

Common testing methods employed during these checkpoints include dimensional inspections, non-destructive testing (NDT), and functional testing, depending on the application and industry requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control processes of potential suppliers. This can be achieved through various methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing capabilities, quality management systems, and adherence to industry standards.

- Quality Reports: Requesting detailed quality reports and certifications can provide insight into the supplier’s QC practices and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can help validate the integrity of the products and ensure they meet specified requirements.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers must be aware of specific nuances related to QC and certifications. Different countries may have unique regulatory requirements, and understanding these can help mitigate risks associated with international procurement.

For example, European buyers may require CE certification for certain products, while Middle Eastern markets might demand compliance with local standards. It is essential for buyers to communicate their quality expectations clearly and ensure that suppliers are equipped to meet these standards.

In conclusion, the manufacturing processes and quality assurance measures in high precision machine shops are integral to delivering components that meet the rigorous demands of various industries. By understanding these processes and verifying supplier capabilities, B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘high precision machine shop’

In the competitive landscape of high precision machining, sourcing the right supplier can significantly impact your project’s success. This guide provides a structured checklist to help B2B buyers navigate the complexities of procuring services from a high precision machine shop, ensuring that you make informed decisions that align with your technical and business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements. This includes dimensions, tolerances, material types, and any specific finishing processes needed. Defining these parameters upfront helps suppliers assess their capabilities and ensures you receive accurate quotes tailored to your needs.

- Consider the complexity of your designs: Complex geometries may require advanced machining techniques, such as 5-axis machining.

- Detail any regulatory or industry standards: Compliance with specific standards can impact both the choice of materials and the machining process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable high precision machine shops. Look for suppliers with a proven track record in your industry and positive customer reviews. This step is essential to ensure that potential partners possess the necessary expertise and reliability.

- Utilize online directories and industry forums: Platforms like ThomasNet or industry-specific groups can provide insights into supplier capabilities.

- Check for case studies or testimonials: Look for evidence of successful projects similar to yours.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of suppliers, assess their machining capabilities in detail. This includes understanding their equipment, technologies used, and the range of materials they can handle. A supplier’s capabilities directly influence the quality and precision of your parts.

- Inquire about their machining technologies: Advanced CNC machinery and software can significantly enhance precision and efficiency.

- Ask about their experience with specific materials: Different materials may require unique machining approaches.

Step 4: Verify Quality Assurance Processes

Quality control is crucial in high precision machining. Ensure that potential suppliers have robust quality assurance processes in place, including certifications such as ISO 9001 or AS9100. This step is vital to guarantee that the parts produced meet your specifications and industry standards.

- Request information on their inspection methods: This may include equipment used for measuring tolerances and surface finishes.

- Inquire about their corrective action processes: Understanding how they handle defects can give insight into their commitment to quality.

Step 5: Assess Lead Times and Flexibility

Understanding a supplier’s lead times and flexibility is essential for project planning. Evaluate their ability to meet your deadlines, especially if your project requires rapid prototyping or high-volume production. This consideration can be a deciding factor in supplier selection.

- Discuss their capacity for urgent requests: Some suppliers may have the ability to expedite orders or increase production capacity.

- Check for their history with on-time delivery: Reliable suppliers can significantly reduce project delays.

Step 6: Request Quotes and Compare

Once you’ve narrowed down your options, request detailed quotes from each supplier. Ensure that the quotes include all relevant costs, such as tooling, materials, and any additional services. Comparing quotes allows you to evaluate not only pricing but also the overall value offered by each supplier.

- Look for transparency in pricing: Hidden costs can lead to budget overruns, so clarity is crucial.

- Consider the total cost of ownership: Evaluate the long-term implications of choosing a supplier based on factors like quality and service.

Step 7: Establish Communication and Support

Effective communication is vital for successful collaboration. Assess how responsive and supportive potential suppliers are during the inquiry process. A partner who communicates clearly and promptly can help resolve issues quickly and ensure a smoother workflow.

- Evaluate their customer service approach: A dedicated account manager or support team can enhance the partnership experience.

- Discuss how they handle project updates: Regular updates can help you stay informed about project progress and any potential issues.

By following this checklist, B2B buyers can confidently navigate the sourcing process for high precision machine shops, ensuring they choose a partner that aligns with their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for high precision machine shop Sourcing

What Are the Key Cost Components of High Precision Machine Shop Sourcing?

Understanding the cost structure of high precision machine shops is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials like stainless steel and aluminum may be less expensive compared to exotic metals such as titanium or Waspaloy. The quality and sourcing of these materials can also affect prices.

-

Labor: Skilled labor is essential for high precision machining. Labor costs can vary based on the region and the expertise required. Countries with a high cost of living, such as Germany, may have higher labor costs compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Efficient machine shops optimize these overhead costs, potentially lowering the final price for buyers.

-

Tooling: Custom tooling can be a significant upfront investment. The complexity of the parts being produced often dictates tooling costs. Buyers should discuss tooling requirements upfront to avoid unexpected expenses.

-

Quality Control (QC): High precision machining demands rigorous QC processes to ensure that parts meet strict tolerances. This can add to the overall cost but is crucial for maintaining product integrity, especially in industries like aerospace and medical.

-

Logistics: Shipping costs can vary significantly depending on the destination and the volume of parts being sourced. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Finally, suppliers will add a profit margin to cover their business risks and to reinvest in operations. This margin can vary widely based on market competition and the complexity of the service offered.

How Do Price Influencers Impact High Precision Machining Costs?

Several factors influence pricing in the high precision machining sector:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their production needs while maximizing cost efficiency.

-

Specifications and Customization: Custom parts require more labor and specialized tooling, raising costs. Clear communication of specifications can help avoid misunderstandings that lead to costly revisions.

-

Material Selection: The choice of materials not only affects price but also the machining processes involved. For example, harder materials may require more advanced tooling and longer machining times.

-

Quality and Certifications: Parts requiring specific certifications (e.g., aerospace or medical) may incur additional costs due to the stringent QC processes involved. Buyers should consider the long-term benefits of sourcing certified parts, even if initial costs are higher.

-

Supplier Factors: The experience and reputation of the supplier can also influence pricing. Established suppliers may charge more but offer superior quality and reliability.

-

Incoterms: Understanding Incoterms is vital for managing logistics costs and responsibilities. For instance, choosing DDP (Delivered Duty Paid) can simplify the shipping process, albeit at a potentially higher cost.

What Are the Best Practices for Negotiating with High Precision Machine Shops?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing from high precision machine shops:

-

Negotiate Terms: Engaging suppliers in discussions about pricing, payment terms, and MOQs can yield better deals. Building a long-term relationship often leads to more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, consider TCO, which includes quality, durability, and maintenance costs over the product lifecycle. This approach often highlights the value of investing in higher-quality components.

-

Understand Pricing Nuances for International Sourcing: When dealing with suppliers from diverse regions, be aware of currency fluctuations, import duties, and local market conditions. For buyers in Africa, South America, and the Middle East, these factors can significantly impact overall costs.

-

Conduct Market Research: Familiarize yourself with industry pricing standards and competitor offerings. This knowledge can empower negotiations and help identify the best suppliers for your needs.

Disclaimer on Indicative Prices

Pricing in the high precision machining sector can fluctuate based on various factors, including market demand, material availability, and technological advancements. Therefore, it is essential for buyers to seek tailored quotes from suppliers to ensure accurate budgeting for their specific projects.

Alternatives Analysis: Comparing high precision machine shop With Other Solutions

When considering high precision machining solutions, it’s essential to explore various alternatives that can meet specific production requirements. Different methods can provide similar outcomes in terms of part quality and performance, but they may differ significantly in cost, implementation complexity, and maintenance needs. This analysis aims to compare high precision machine shops with other viable alternatives, providing insights that can aid B2B buyers in making informed decisions.

| Comparison Aspect | High Precision Machine Shop | 3D Printing | Manual Machining |

|---|---|---|---|

| Performance | Exceptional precision (±0.0001 inches) for complex geometries | Good for complex designs, but can struggle with high volume | Varies widely; high skill can lead to precision, but often less consistent |

| Cost | Higher upfront costs due to advanced machinery | Generally lower for low-volume production but can be expensive for large batches | Lower initial investment but can be costlier over time due to labor and inefficiencies |

| Ease of Implementation | Requires specialized knowledge and tooling | Easier for rapid prototyping; software-driven | Requires skilled labor; setup time can vary greatly |

| Maintenance | Regular maintenance needed for precision tools | Minimal maintenance; depends on printer type | High maintenance due to wear and tear of manual tools |

| Best Use Case | Complex, high-tolerance parts in industries like aerospace and medical | Prototyping, custom parts, and small batch production | Simple parts, low-volume runs, or when budget constraints are significant |

What Are the Advantages and Disadvantages of 3D Printing as an Alternative?

3D printing has emerged as a popular alternative to traditional machining, particularly for rapid prototyping and small batch production. The primary advantage of 3D printing is its ability to produce complex geometries that would be difficult or impossible to achieve through machining. Additionally, it generally has lower upfront costs, making it accessible for startups and small businesses. However, the performance can vary, especially for high-volume runs, where traditional machining excels due to its precision and speed. Furthermore, material limitations and slower production speeds can be drawbacks for certain applications.

How Does Manual Machining Compare to High Precision Machine Shops?

Manual machining is another alternative that can be considered, especially for businesses with tight budgets. It typically involves lower initial investments in equipment and can be performed by skilled laborers. Manual machining can produce high-quality parts, but achieving consistent precision across multiple units can be challenging. This method is best suited for simple parts or low-volume runs where the cost of high-precision equipment cannot be justified. However, the reliance on human skill can lead to variability in quality and efficiency, making it less suitable for high-tolerance applications.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting a machining solution, B2B buyers should assess their specific requirements, including the complexity of parts, volume, budget constraints, and required precision. High precision machine shops are ideal for industries requiring stringent tolerances and complex designs, such as aerospace and medical manufacturing. Conversely, 3D printing is better suited for rapid prototyping and low-volume custom parts, while manual machining can serve as a cost-effective solution for simpler projects. By carefully evaluating these alternatives, businesses can choose the most suitable solution that aligns with their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for high precision machine shop

What Are the Key Technical Properties of a High Precision Machine Shop?

When engaging with a high precision machine shop, understanding critical specifications is essential for making informed purchasing decisions. Here are some of the most vital technical properties:

1. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. In high precision machining, tolerances can be as tight as ±0.0001 inches. This level of precision is crucial for industries such as aerospace and medical, where even minute discrepancies can lead to failures or safety hazards. B2B buyers should prioritize suppliers who can consistently meet tight tolerances to ensure product reliability.

2. Material Grade

The grade of material used in manufacturing impacts the strength, durability, and performance of the final product. Common materials include stainless steel, titanium, and aluminum, each with specific properties suited for different applications. For example, aerospace components often require high-strength alloys to withstand extreme conditions. Understanding material grades helps buyers select the right machining partner capable of sourcing and working with the necessary materials.

3. Surface Finish

Surface finish describes the texture and smoothness of a machined part’s surface. It is critical for both aesthetic and functional reasons, especially in applications where friction or contact is involved. A smoother finish can reduce wear and improve the performance of moving parts. B2B buyers should inquire about the machining shop’s capabilities in achieving specific surface finishes to align with their project requirements.

4. Production Volume

Production volume refers to the quantity of parts that can be manufactured in a given timeframe. High precision machine shops often cater to both low-volume prototype runs and high-volume OEM (Original Equipment Manufacturer) projects. Understanding the shop’s capacity to handle varying production volumes is essential for buyers who may require scalability in their manufacturing processes.

5. Lead Time

Lead time is the duration from the initial order to the delivery of the finished product. In fast-paced industries, such as automotive or electronics, shorter lead times can provide a competitive advantage. Buyers should assess the machine shop’s ability to meet tight deadlines without compromising quality, ensuring that their supply chain remains efficient.

What Are Common Trade Terms Used in High Precision Machining?

Familiarity with industry jargon can facilitate smoother communications with suppliers. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of high precision machining, buyers often seek shops that can produce components tailored to their specifications for integration into their own products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and can influence purchasing decisions. High precision machine shops may have different MOQs based on the type of material or complexity of the part.

3. RFQ (Request for Quote)

An RFQ is a document sent to suppliers to solicit price quotes for specific quantities and types of products. It is an essential tool for buyers to compare costs and capabilities of different machining shops, ensuring they select the best value for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers navigate shipping costs, risk management, and delivery responsibilities, which are crucial when sourcing from global suppliers.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by a computer. This technology enhances precision and efficiency in the manufacturing process. Buyers should inquire about a shop’s CNC capabilities, as they directly impact the quality and consistency of the machined parts.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when collaborating with high precision machine shops, ensuring that their specific requirements are met effectively.

Navigating Market Dynamics and Sourcing Trends in the high precision machine shop Sector

What Are the Current Market Dynamics and Key Trends in the High Precision Machine Shop Sector?

The high precision machine shop sector is experiencing robust growth, driven by increasing demand across various industries, including aerospace, automotive, medical, and defense. As global supply chains become more interconnected, international buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly sourcing precision components to meet stringent quality standards and tight delivery schedules. Key trends include the adoption of advanced manufacturing technologies like CNC machining, 3D printing, and automation, which enhance production efficiency and precision.

Emerging technologies are reshaping sourcing strategies, with many firms investing in digital solutions for inventory management and order tracking. Furthermore, the rise of Industry 4.0 is prompting machine shops to integrate IoT (Internet of Things) technologies, allowing for real-time monitoring of machine performance and predictive maintenance. This shift not only optimizes operations but also significantly reduces downtime, making it crucial for international B2B buyers to partner with shops that are technologically adept.

In addition to technological advancements, there’s a growing emphasis on customization and flexibility. High precision machine shops are increasingly offering tailored solutions to meet the unique requirements of diverse industries. This trend aligns well with the needs of buyers who require specific tolerances and materials, underscoring the importance of establishing strong relationships with suppliers that can adapt to fluctuating demands.

How Is Sustainability and Ethical Sourcing Shaping the High Precision Machine Shop Industry?

Sustainability is becoming a critical concern for B2B buyers in the high precision machine shop sector. The environmental impact of manufacturing processes, including waste generation and energy consumption, is prompting companies to seek suppliers who prioritize eco-friendly practices. This shift is not just about compliance; it reflects a broader market trend where sustainability is becoming a competitive differentiator.

Ethical sourcing plays a vital role in building trust and transparency within supply chains. Buyers are increasingly looking for suppliers that adhere to social responsibility standards, ensuring fair labor practices and safe working conditions. The demand for ‘green’ certifications, such as ISO 14001, is on the rise, encouraging machine shops to adopt environmentally friendly materials and processes. This includes using recyclable materials and reducing the carbon footprint of their operations.

Moreover, the integration of sustainable practices can lead to cost savings in the long term. By optimizing resource use and minimizing waste, machine shops can enhance their operational efficiency, which translates into better pricing for international buyers. As the market evolves, prioritizing suppliers with sustainable practices will not only meet regulatory requirements but also align with the values of increasingly conscious consumers.

What Is the Historical Context of High Precision Machine Shops and Their Evolution?

The high precision machine shop sector has its roots in the early 20th century, driven by advancements in industrial machinery and manufacturing techniques. Initially focused on basic machining processes, the industry has evolved significantly over the decades. The introduction of Computer Numerical Control (CNC) technology in the late 20th century marked a pivotal transformation, allowing for unprecedented precision and complexity in machining.

As globalization took hold, many precision machine shops expanded their capabilities to cater to international markets. This evolution has been characterized by a shift from traditional manufacturing methods to advanced technologies, including 5-axis machining and automation. Today, the sector is defined by its ability to produce highly intricate components with minimal lead times, aligning with the demands of a fast-paced global economy.

This historical context underscores the importance of technological adaptation and innovation in maintaining competitiveness. For international B2B buyers, understanding this evolution can inform their sourcing decisions, highlighting the need to partner with machine shops that are not only experienced but also forward-thinking in their approach to precision manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of high precision machine shop

-

How do I choose the right high precision machine shop for my project?

Choosing the right high precision machine shop involves several key factors. First, evaluate the shop’s experience and capabilities, ensuring they align with your specific requirements, such as material types and complexity of parts. Look for certifications that indicate quality standards, like ISO 9001. Assess their technology, such as CNC capabilities and machine types, to ensure they can meet your precision needs. Finally, consider customer reviews and case studies to gauge their reliability and service quality. -

What is the typical lead time for high precision machining projects?

Lead times can vary significantly based on the complexity of the parts, the machine shop’s capacity, and current demand. Generally, simple projects might take a few days to a couple of weeks, while complex, high-tolerance parts could take several weeks or longer. It’s essential to communicate your timeline during the initial discussions to ensure the shop can meet your deadlines. Always request a clear timeline in the quote to avoid any surprises. -

What are the minimum order quantities (MOQs) for high precision machining services?

Minimum order quantities can differ widely among machine shops. Some may accommodate low MOQs for prototyping or small-batch production, while others might require higher quantities for cost-effectiveness. When negotiating, clarify your needs and discuss flexibility in order quantities, especially if you’re testing a new product. Many shops are willing to collaborate on initial orders to foster long-term partnerships. -

How can I ensure quality assurance in my machining projects?

Quality assurance (QA) is critical in high precision machining. Inquire about the shop’s QA processes, including inspection methods and equipment used for measuring tolerances. Look for certifications that demonstrate a commitment to quality, such as AS9100 for aerospace applications. Request documentation on their QA procedures, including how they handle non-conformities and their approach to continuous improvement. A reliable shop should be transparent about their QA practices. -

What payment terms should I expect when working with a high precision machine shop?

Payment terms can vary based on the shop’s policies and your relationship with them. Common terms include a deposit upfront, with the balance due upon completion or delivery. Some shops may offer net-30 or net-60 terms for established clients. It’s crucial to discuss payment expectations early in the negotiation process to ensure both parties are aligned and to prevent any cash flow issues during the project. -

How do I vet a high precision machine shop as an international buyer?

Vetting a high precision machine shop requires thorough research. Start by checking their certifications, customer testimonials, and case studies related to your industry. Use platforms like LinkedIn to connect with previous clients and gather feedback. Additionally, consider visiting the facility if possible, or request a virtual tour to assess their capabilities firsthand. Establishing clear communication and understanding their export compliance and logistics processes is also vital for international transactions. -

What customization options are available for precision machined parts?

Customization options in high precision machining can include specific material choices, custom geometries, surface finishes, and assembly services. Many machine shops offer design collaboration to optimize parts for performance and manufacturability. When discussing your project, clearly outline your specifications and any unique requirements. A reputable shop will work with you to ensure the final product meets your exact needs while leveraging their expertise to suggest improvements. -

What logistical considerations should I keep in mind when sourcing internationally?

When sourcing high precision machining services internationally, consider logistics such as shipping costs, customs duties, and import regulations specific to your country. Factor in delivery times and potential delays due to customs clearance. It’s advisable to work with a machine shop that has experience in international shipping to ensure compliance and timely delivery. Establishing clear communication regarding tracking and updates throughout the shipping process will help mitigate any logistical challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 High Precision Machine Shop Manufacturers & Suppliers List

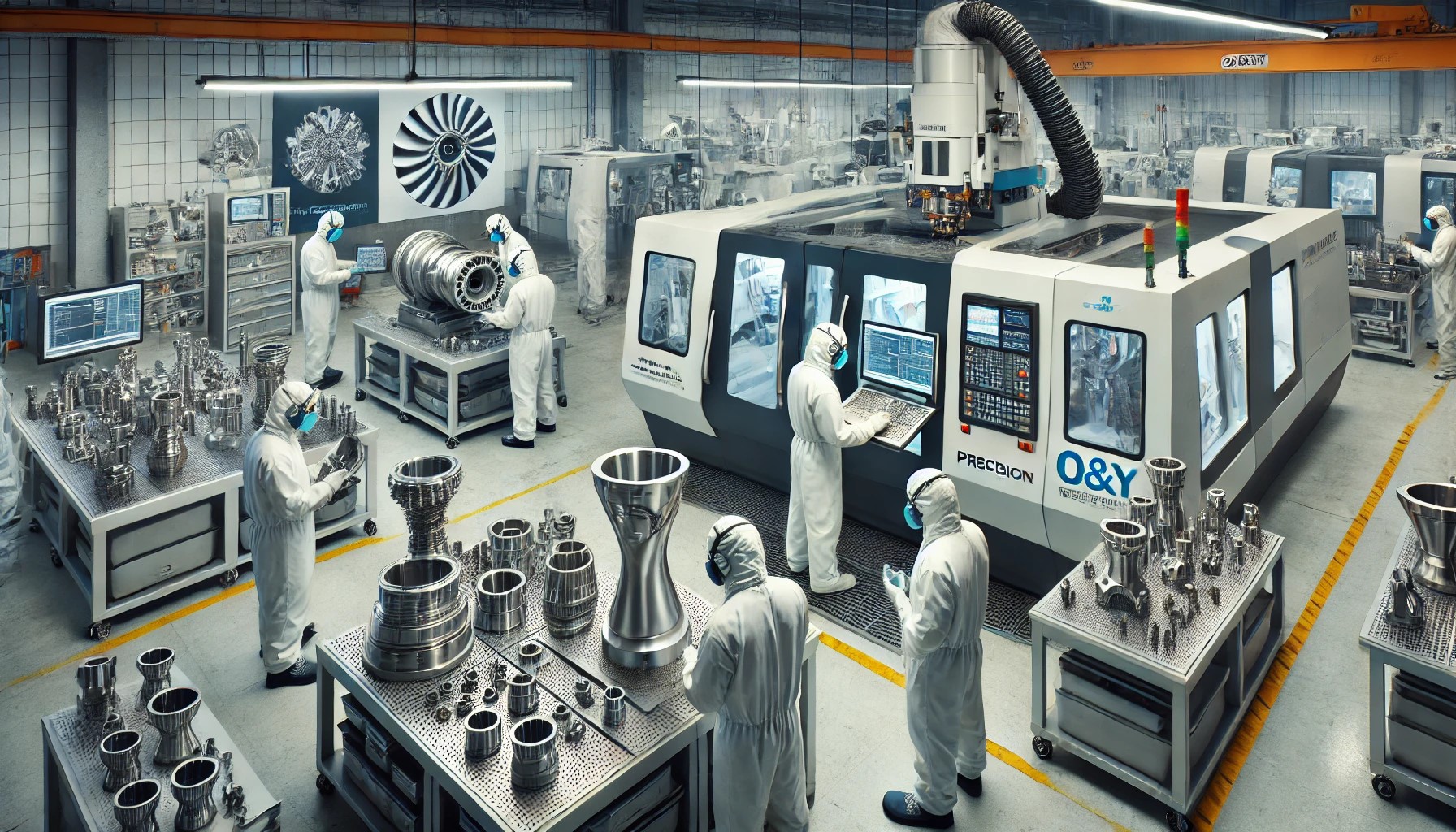

1. Intrex Aerospace – High-Precision Machined Components

Domain: intrexcorp.com

Registered: 1998 (27 years)

Introduction: Intrex Aerospace specializes in high-precision machined components for the aerospace, defense, and space industries. Key offerings include:

– Multi-axis machining capabilities, including vertical and horizontal centers and 5-axis CNC turning lathes.

– Precision CNC machining services tailored for tight tolerances required in aerospace projects.

– Integrated Logistical Supply Chain Management with …

2. Panek Precision – High Precision CNC Machining Services

Domain: panekprecision.com

Registered: 1998 (27 years)

Introduction: High Precision CNC Machining Services, CNC Turning, CNC Vertical Machining, CNC Horizontal Machining, CNC Prototyping, Multi-Spindle Screw Machining, Robotics & Automation, Tube Cutting & Forming, Precision Tube Cutting, End & Metal Forming, Fourslide Metal Stamping. Industries Served: Automotive, Medical & Healthcare, Military & Defense, Garage Access & Security, Controls & Automation, Cable & Pa…

3. High Precision Machine Shop – Precision Machining Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, High Precision Machine Shop – Precision Machining Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – NASCAR and F1 Precision Shops

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – NASCAR and F1 Precision Shops, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. GOMPC – High Precision Machining Services

Domain: gompc.net

Registered: 2002 (23 years)

Introduction: High Precision Machining Services including Swiss Screw Machining, Precision CNC Machining, Cam Precision Machining, Micro Parts Machining, Multi-Spindle Machining, and CNC Milling Service. Capable of producing parts from subminiature (.010″ diameter) to large parts (up to 1.50″ diameter) with close tolerances of ±.0005″ and capabilities of ±.0002″. Materials used include Stainless Steels, Carbon …

6. Precision CNC Machines – High Tolerance Fabrication

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: New high precision CNC machines needed for fabricating hard toleranced parts with several h6 tolerances and N1 rugosity. Parts are made from stainless steel, high temperature resistant, in tubular and flat shapes with grooves, outside and inside threads. Tubular parts are around 120mm long, and square parts are approximately 150x200x45mm. Budget is around $1,000,000 excluding tooling. Current mach…

7. Trace-A-Matic – Precision CNC Machining Services

Domain: traceamatic.com

Registered: 1998 (27 years)

Introduction: Trace-A-Matic is a precision machine shop specializing in CNC machining services for various industries including aerospace, automotive, defense, food processing, forging, foundry, heavy equipment, infrastructure, marine, medical equipment, military, mining, oil and gas, power generation, space, and transportation. Key services include: 5-Axis CNC Machining (up to 27.5″ x 120″), Horizontal Milling…

8. IS Services – Industrial Machine Shop Solutions

Domain: isservices.com

Registered: 2002 (23 years)

Introduction: Industrial Machine Shop services include custom enclosures, CNC machining, and milling. Key capabilities include CNC mills, engine lathes, vertical turret lathes, horizontal boring mills, vertical mills, AutoCad assisted pattern burn table, and sub-arc welding machines. The company has over 30 years of experience, certified welders, and trained machinists. They are certified by PRI Registrar for I…

9. DealStream – CNC & Manufacturing Businesses

Domain: dealstream.com

Registered: 1999 (26 years)

Introduction: Machine Shops for Sale | Buy CNC & Manufacturing Businesses. Categories include: Businesses For Sale, Real Estate, Funding Wanted, Financial. Industries: Manufacturing, Hospitality, Retail Stores, Services, Construction, Health Care, Finance and Insurance, Transportation, Wholesalers. Locations: United States, Canada, United Kingdom, Australia, Spain, Thailand, Mexico, Switzerland, Singapore, Chin…

Strategic Sourcing Conclusion and Outlook for high precision machine shop

In navigating the complexities of sourcing high precision machining services, international buyers must prioritize partnerships that deliver exceptional quality, rapid turnaround, and extensive capabilities. As highlighted throughout this guide, strategic sourcing is not merely a procurement process; it’s a crucial investment in the reliability and efficiency of your supply chain. By selecting a machine shop with a proven track record in diverse sectors—such as aerospace, medical, and automotive—you ensure that your components meet stringent industry standards while also enhancing your product’s market readiness.

The future of high precision machining is poised for growth, driven by advancements in technology and increasing demand for customized solutions. As markets in Africa, South America, the Middle East, and Europe expand, buyers are encouraged to leverage this momentum by forging strong relationships with reputable machining partners.

Act now to evaluate your sourcing strategies and consider how aligning with a high precision machine shop can elevate your operations. Engage with suppliers who not only understand your specific requirements but also bring innovative solutions to the table. Your path to enhanced operational excellence begins with informed, strategic sourcing decisions.