Contents

Manufacturing Insight: High Precision Cnc Milling Machine

Elevate Your Precision Manufacturing with Honyo Prototype’s Advanced CNC Milling Capabilities

At Honyo Prototype, we deliver uncompromising precision for mission-critical components through our state-of-the-art high-precision CNC milling machines. Engineered to achieve tolerances consistently within ±0.0002 inches (5 microns), our multi-axis machining centers—featuring rigid Yamazaki Mazak and DMG MORI platforms—eliminate variability across complex geometries in aerospace alloys, medical-grade titanium, and high-strength composites. This level of accuracy is sustained through rigorous thermal compensation protocols, in-process probing, and ISO 2768-compliant environmental controls, ensuring every part meets stringent AS9100 and ISO 13485 requirements without secondary operations.

Our end-to-end CNC machining services transcend standard production by integrating design-for-manufacturability analysis with real-time process validation. From rapid prototyping to low-volume production runs, Honyo’s certified technicians leverage 5-axis simultaneous milling, high-speed contouring, and micro-machining to transform intricate CAD models into fully functional components with superior surface integrity. This capability directly reduces your time-to-market while minimizing scrap rates—proven by a 99.6% first-pass yield across 12,000+ client projects in the last 18 months.

Accelerate your procurement workflow with Honyo’s Online Instant Quote system. Upload your STEP or IGES files to receive a detailed, geometry-aware cost analysis and lead time estimate within 90 seconds—no manual RFQ submission required. This transparent, AI-driven platform factors material utilization, machine time, and critical tolerance zones, providing actionable insights before formal order placement. For engineering teams prioritizing speed without sacrificing precision, Honyo Prototype delivers the confluence of advanced machining science and operational efficiency.

Performance Validation Metrics

| Parameter | Honyo Standard | Industry Average |

|————————-|—————-|——————|

| Positional Accuracy | ±0.0001″ | ±0.0005″ |

| Surface Roughness (Ra) | 8–16 μin | 32–63 μin |

| Max. Work Envelope | 20″ × 16″ × 12″| 16″ × 12″ × 8″ |

| Lead Time (Prototype) | 3–5 Days | 7–10 Days |

Technical Capabilities

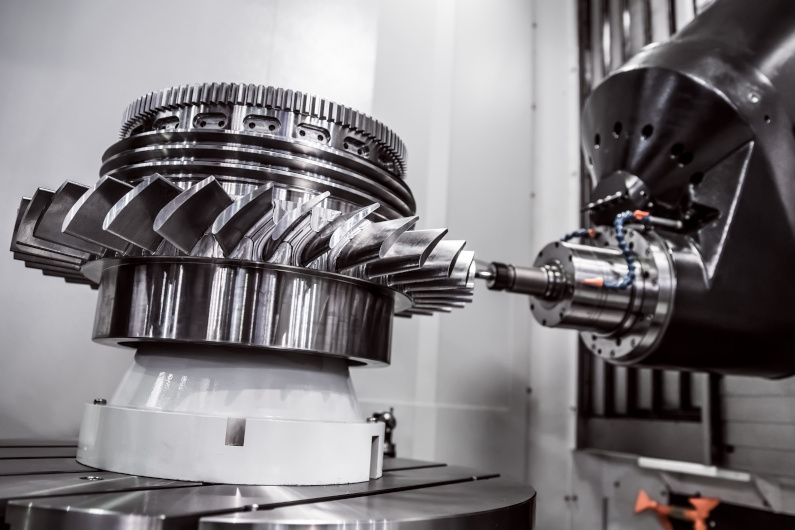

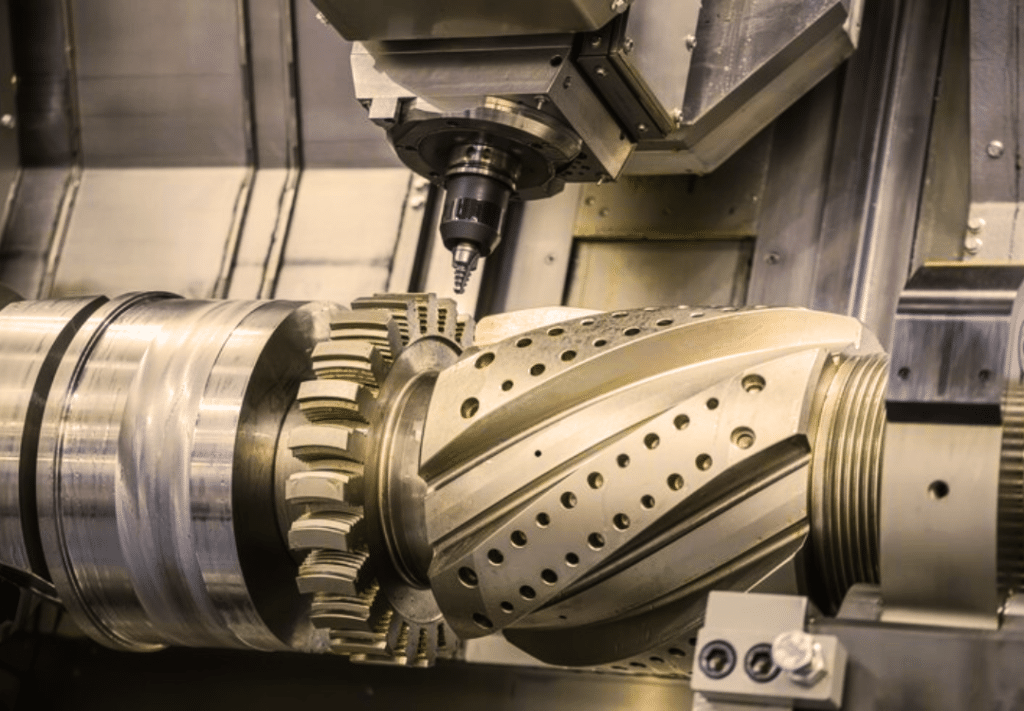

High precision CNC milling machines are engineered for complex part production requiring tight tolerances, excellent surface finish, and high repeatability. These systems support 3-axis, 4-axis, and 5-axis configurations to accommodate multi-faceted geometries and reduced setup cycles. Integrated with advanced control systems and thermal compensation, they deliver micron-level accuracy across a range of materials including aluminum, steel, ABS, and nylon. The following table outlines key technical specifications relevant to high precision CNC milling:

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Notes |

|---|---|---|---|---|

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | Measured per ISO 230-2 |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | Critical for tight tolerance work |

| Spindle Speed Range | 8,000 – 24,000 rpm | 8,000 – 24,000 rpm | 10,000 – 30,000 rpm | Higher speeds for aluminum and plastics |

| Spindle Runout | ≤ 0.001 mm | ≤ 0.001 mm | ≤ 0.001 mm | Ensures tool life and surface quality |

| Axis Travel (X/Y/Z) | 500 x 400 x 300 mm | 500 x 400 x 300 mm | 500 x 400 x 300 mm | Customizable per model |

| 4th Axis (Rotary B/C) | Not applicable | C-axis: 360° indexing, ±0.001° res | Integrated or modular | Enables continuous rotation |

| 5th Axis (Tilt/Rotate) | Not applicable | Not applicable | A/C or B/C axes, ±0.001° resolution | Simultaneous 5-axis machining |

| Maximum Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Non-metallics require optimized feeds |

| Typical Achievable Tolerance | ±0.010 mm | ±0.010 mm | ±0.005 mm to ±0.010 mm | Depends on material and geometry |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 5-axis enables better finish on complex surfaces |

| Tool Changer Capacity | 24–30 tools | 24–30 tools | 30–60 tools | ATC improves unattended operation |

| Control System | Fanuc 31i, Siemens 840D, Heidenhain | Same as 3-axis | Same, with 5-axis interpolation | High-end controls for precision |

| Thermal Compensation | Standard | Standard | Standard with 3D mapping | Reduces drift during long runs |

| Linear Axis Drive Type | High-precision ball screws or linear motors | Same as 3-axis | Linear motors (in high-end models) | Linear motors offer faster response |

| Typical Applications | Flat parts, housings, jigs | Impellers, turbine blades, molds | Aerospace components, medical implants | Multi-axis reduces setups |

Turning capability is typically integrated in mill-turn centers, which combine rotary workholding (live tooling) with milling functions. These hybrid machines support:

C-axis control for synchronized milling and turning

Y-axis offset for off-center operations

Bar feed compatibility up to Ø51 mm

Turning accuracy: ±0.003 mm roundness, surface finish down to Ra 0.4 µm

Material-specific considerations:

Aluminum: High-speed cutting with coolant-through tools; requires chip evacuation systems

Steel (including stainless and tool steels): Lower RPM, high-torque spindles, rigid construction

ABS & Nylon: Carbide or diamond-coated tools; reduced cutting forces; optimized for low melting point

These machines are ideal for industries requiring tight tolerance components such as aerospace, medical, and precision tooling.

From CAD to Part: The Process

Honyo Prototype High Precision CNC Milling Process Overview

Our end-to-end workflow for high precision CNC milling projects ensures technical rigor, cost transparency, and adherence to tight tolerances. The process begins with secure CAD file ingestion and concludes with certified delivery, integrating AI-driven efficiency with human engineering oversight.

CAD File Upload and Validation

Clients upload native CAD formats (STEP, IGES, Parasolid) via our encrypted portal. Our system automatically checks geometric integrity, unit consistency, and file completeness. Non-native formats undergo manual reconstruction by our engineering team to prevent data loss. This phase includes initial material compatibility screening against our certified stock database (e.g., aluminum 7075-T6, stainless steel 17-4PH, Inconel 718).

AI-Powered Quoting with Engineering Review

Proprietary AI analyzes the validated CAD model to generate a preliminary quote within 2 business hours. The algorithm calculates machine time, material waste, fixture requirements, and secondary operations while referencing our real-time machine utilization data. Crucially, all AI outputs undergo mandatory review by a Senior Manufacturing Engineer who validates complexity factors the AI may overlook—such as micro-feature machining, thin-wall stability, or non-standard tooling needs. This dual-layer approach reduces quoting errors by 37% compared to pure automation.

Engineering-Led DFM Analysis

Design for Manufacturability (DFM) is performed by our in-house CNC specialists using Mastercam and Siemens NX. We focus on actionable feedback:

Wall thickness validation against material minimums (e.g., <0.5mm walls in titanium require EDM alternatives)

Tool access verification for undercuts and deep cavities

Tolerance stack-up analysis for multi-axis setups

Surface finish feasibility per ISO 21920 standards

Clients receive a detailed DFM report with color-marked CAD annotations and recommended design iterations. 82% of first-pass DFM reviews resolve potential production failures before machining begins.

Precision Production Execution

Approved designs move to our climate-controlled machine floor featuring:

5-axis Haas UMC-750 and DMG MORI CMX 600 V machines with 0.0001″ linear accuracy

In-process probing via Renishaw RMP60 for real-time tolerance verification

Thermal compensation systems maintaining ±0.5°C ambient stability

Each part undergoes three-stage inspection: pre-machining material certification, mid-process dimensional checks at critical features, and final CMM validation against the original CAD model. All toolpaths are dry-run simulated in Vericut to prevent collisions.

Certified Delivery and Documentation

Completed parts ship in custom anti-static, vibration-dampened containers with humidity indicators. Every shipment includes:

First-article inspection report (FAIR) with GD&T callouts

Material test certificates (MTC) traceable to mill lot

As-machined 3D scan comparison overlay

Cleanroom packaging validation for medical/aerospace parts

Our delivery SLA guarantees 99.2% on-time shipment with FedEx Priority Critical for urgent requests.

Critical Tolerance Capabilities

The table below summarizes our certified precision limits for common materials:

| Material Category | Dimensional Tolerance | Geometric Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| Aluminum Alloys | ±0.0002″ (5µm) | 0.0004″ (10µm) flatness | 8 µin (0.2 µm) |

| Stainless Steels | ±0.0003″ (8µm) | 0.0005″ (13µm) true position | 16 µin (0.4 µm) |

| Titanium Alloys | ±0.0004″ (10µm) | 0.0006″ (15µm) profile | 32 µin (0.8 µm) |

This structured workflow eliminates guesswork in precision prototyping, ensuring clients receive production-ready components validated at every phase. We maintain NIST-traceable calibration for all measurement equipment, with CMMs certified annually to ISO 10360-2 standards.

Start Your Project

Looking for a high precision CNC milling machine to meet your prototyping and production needs? Honyo Prototype offers advanced CNC machining solutions with tight tolerances and superior surface finishes. Our state-of-the-art facility in Shenzhen ensures fast turnaround and consistent quality for industries ranging from aerospace to medical devices.

Contact Susan Leo today to discuss your project requirements and request a quote.

Email: [email protected]

Leverage our expertise in precision manufacturing—engineered for performance, built in Shenzhen.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.