Introduction: Navigating the Global Market for high impact polystyrene sheet

As global markets evolve, sourcing high impact polystyrene sheets (HIPS) presents unique challenges for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. The demand for HIPS continues to rise due to its versatility, affordability, and robust performance in various applications, from signage and displays to packaging and prototypes. However, navigating the complexities of supplier selection, material specifications, and pricing can be daunting.

This comprehensive guide is designed to empower B2B buyers by providing in-depth insights into the diverse types of high impact polystyrene sheets available, their applications across industries, and essential criteria for vetting suppliers. Buyers will find valuable information on cost considerations, material properties, and best practices for sourcing, ensuring that they make informed purchasing decisions tailored to their specific needs.

By addressing key challenges and offering actionable strategies, this guide aims to streamline the procurement process for HIPS, helping businesses enhance their operational efficiency and product offerings. With a focus on the unique requirements of international markets, readers can leverage this resource to navigate the global landscape effectively, fostering successful partnerships and driving growth in their respective industries.

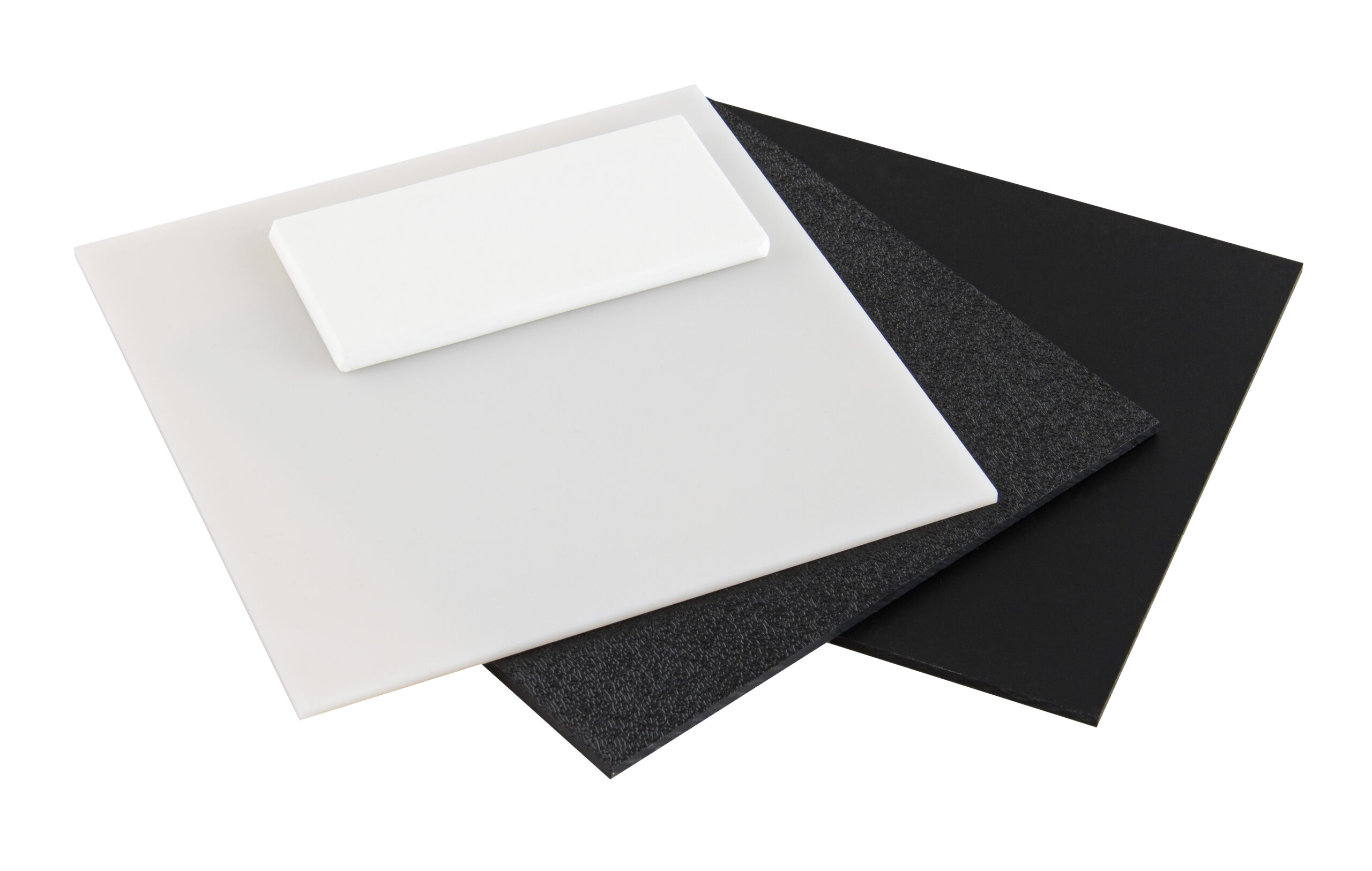

Understanding high impact polystyrene sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard HIPS | Cost-effective, good impact resistance, easy to fabricate | Signage, prototypes, displays | Pros: Affordable, versatile. Cons: Limited color options. |

| Renovo-HIPS™ | 25% post-consumer recycled content, same properties as virgin | Eco-friendly applications, retail displays | Pros: Sustainable choice. Cons: May have higher initial costs. |

| High-Gloss HIPS | Smooth, glossy finish, excellent for printing | Point-of-purchase displays, advertising graphics | Pros: Enhanced aesthetics, vibrant prints. Cons: Scratches easily. |

| Low-Gloss HIPS | Matte finish, non-reflective surface | Medical packaging, food containers | Pros: Reduced glare, easy to clean. Cons: Color options may be limited. |

| Colored HIPS | Available in various colors, custom thicknesses | Toys, decorative items, educational materials | Pros: Customizable for branding. Cons: Higher costs for custom orders. |

What Are the Characteristics of Standard HIPS?

Standard High Impact Polystyrene (HIPS) sheets are recognized for their affordability and excellent impact resistance. These sheets are easy to fabricate and thermoform, making them suitable for a variety of applications such as signage, prototypes, and displays. When considering procurement, B2B buyers should note the limited color options, which may not align with specific branding needs. However, their cost-effectiveness makes them a popular choice across industries.

Why Choose Renovo-HIPS™ for Eco-Friendly Applications?

Renovo-HIPS™ is a sustainable option made from 25% post-consumer recycled material, offering the same performance characteristics as virgin HIPS. This type is particularly appealing to companies aiming to enhance their eco-credentials. B2B buyers should consider the potential for higher initial costs against long-term sustainability benefits. Its application in eco-friendly retail displays and packaging positions it as a forward-thinking choice for environmentally-conscious businesses.

How Does High-Gloss HIPS Enhance Visual Appeal?

High-Gloss HIPS is characterized by its smooth, glossy surface, making it ideal for applications requiring vibrant visuals, such as point-of-purchase displays and advertising graphics. This type is particularly suited for businesses focused on aesthetics and brand representation. Buyers should be aware that while it enhances visual appeal, it may be more prone to scratches and damage, necessitating careful handling and storage.

What Are the Benefits of Low-Gloss HIPS in Medical Packaging?

Low-Gloss HIPS features a matte finish that minimizes glare, making it suitable for medical packaging and food containers. Its surface is easy to clean, which is essential in hygiene-sensitive applications. B2B buyers should consider the reduced glare benefits for environments where visibility is crucial, though they may encounter limitations in color options. This type is particularly beneficial for companies in the healthcare and food industries looking for reliable, safe materials.

Why Opt for Colored HIPS for Custom Applications?

Colored HIPS sheets are available in a variety of hues and can be customized in thickness, making them ideal for toys, decorative items, and educational materials. This type allows for branding opportunities and creative designs, appealing to businesses looking to differentiate their products. However, B2B buyers should factor in the higher costs associated with custom orders, ensuring that the investment aligns with their marketing strategy and target audience.

Key Industrial Applications of high impact polystyrene sheet

| Industry/Sector | Specific Application of high impact polystyrene sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Signage and Display | Production of indoor and outdoor signage | Cost-effective, durable signage that withstands weather conditions | Ensure UV resistance and color stability for longevity |

| Packaging | Food and medical packaging solutions | Lightweight, hygienic, and customizable packaging options | Compliance with food safety regulations and recyclability |

| Prototyping and Model Making | Creation of prototypes for product development | Quick turnaround for design iterations, easy to machine | Availability of various thicknesses and surface finishes |

| Point-of-Purchase (POP) Displays | Development of retail displays and merchandising units | Enhances visibility and branding, easy to transport and assemble | Custom cut sizes and printing capabilities for branding |

| Automotive and Appliance Components | Use in non-structural automotive parts and appliance casings | Cost-effective alternative to heavier materials, good impact resistance | Consideration of thermal properties and dimensional stability |

How is High Impact Polystyrene Sheet Used in Signage and Display?

High impact polystyrene (HIPS) is widely utilized in the signage and display industry due to its excellent durability and weather resistance. It is ideal for creating both indoor and outdoor signs, as it can withstand harsh environmental conditions while maintaining its structural integrity. B2B buyers in this sector should prioritize sourcing HIPS sheets that offer UV resistance and color stability to ensure longevity and vibrancy of their signage.

What are the Benefits of Using High Impact Polystyrene in Packaging?

In the packaging industry, high impact polystyrene sheets are favored for food and medical applications, providing lightweight, hygienic, and customizable solutions. HIPS is non-toxic and can be thermoformed into various shapes, making it suitable for food trays, containers, and medical packaging. International buyers must ensure compliance with local food safety regulations and consider the recyclability of the material to meet sustainability goals.

How Does High Impact Polystyrene Facilitate Prototyping and Model Making?

For prototyping and model making, high impact polystyrene serves as an excellent material due to its ease of machining and fabrication. Designers and engineers can quickly create prototypes, allowing for faster iterations and adjustments during the development process. Buyers in this sector should look for suppliers that offer a range of thicknesses and surface finishes to meet specific project requirements.

Why is High Impact Polystyrene Ideal for Point-of-Purchase Displays?

High impact polystyrene is extensively used in point-of-purchase (POP) displays due to its lightweight nature and ease of assembly. Retailers benefit from HIPS’s ability to enhance product visibility and branding while providing a cost-effective solution for merchandising units. When sourcing HIPS for POP displays, businesses should consider custom cut sizes and printing capabilities to align with their branding strategies.

How is High Impact Polystyrene Applied in Automotive and Appliance Components?

In the automotive and appliance sectors, high impact polystyrene is commonly used for non-structural components, such as casings and interior parts. Its lightweight nature and good impact resistance make it a viable alternative to heavier materials, contributing to overall energy efficiency. Buyers should pay attention to the thermal properties and dimensional stability of the HIPS sheets to ensure they meet the specific requirements of their applications.

3 Common User Pain Points for ‘high impact polystyrene sheet’ & Their Solutions

Scenario 1: Sourcing Quality High Impact Polystyrene Sheets

The Problem:

B2B buyers often face challenges when sourcing high-quality high impact polystyrene (HIPS) sheets that meet their specific application requirements. In regions like Africa and South America, inconsistent product quality can lead to unreliable performance in critical applications such as signage, packaging, or prototypes. Buyers may find themselves receiving sheets that do not have the expected dimensions, impact resistance, or printability, resulting in wasted time and resources. This inconsistency can be particularly damaging for businesses that rely on timely delivery and high standards to maintain customer satisfaction.

The Solution:

To overcome sourcing challenges, B2B buyers should establish relationships with reputable suppliers who can provide certifications and detailed product specifications. Look for suppliers that offer sample packs of HIPS sheets, allowing you to test the material before committing to a larger order. It’s also advisable to check customer reviews and request testimonials that speak to the quality and reliability of the supplier’s products. Additionally, considering suppliers that offer customization options can ensure the sheets are tailored to your specific needs, such as thickness and color. Engaging in direct communication with suppliers to discuss your project requirements can also foster trust and help ensure the consistency of your orders.

Scenario 2: Difficulty in Thermoforming High Impact Polystyrene Sheets

The Problem:

Thermoforming high impact polystyrene sheets can be a daunting task for many businesses, especially those new to the process. Buyers may struggle with achieving the right temperatures and techniques, leading to issues such as warping, poor detail reproduction, or even material wastage. This can be particularly frustrating for companies in the packaging or display industries that depend on precise shapes and forms for their products. Missteps in this process can also lead to increased production costs and time delays, hampering overall operational efficiency.

The Solution:

To effectively thermoform HIPS sheets, it’s crucial to invest in the right equipment and training. Start by conducting thorough research on the specific thermoforming techniques that best suit your application. Consider collaborating with experienced partners or consultants who specialize in thermoforming processes. Additionally, utilizing HIPS sheets that have been specifically designed for thermoforming can simplify the process; these sheets often have enhanced properties that allow for better shaping and detail retention. Regularly monitoring the temperature and adjusting it based on the thickness of the sheet will also contribute to achieving optimal results. Providing training for your team on best practices in thermoforming can further ensure consistency and quality in the final products.

Scenario 3: Challenges in Adhesive Bonding of High Impact Polystyrene Sheets

The Problem:

Another common pain point for B2B buyers is the effective bonding of high impact polystyrene sheets using adhesives. Many businesses face issues with adhesives not providing a strong bond, resulting in joint failures during application. This is particularly relevant for industries that require reliable, durable assemblies, such as construction or product displays. The challenge is often compounded by the variety of adhesives available, which can leave buyers confused about the best options for HIPS sheets.

The Solution:

To achieve successful adhesive bonding, it is essential to select adhesives specifically formulated for use with HIPS sheets. Research and consult with adhesive manufacturers to identify products that offer compatibility, strength, and ease of use. It is also beneficial to conduct adhesion tests to determine the best adhesive for your specific application. Proper surface preparation—such as cleaning and roughening the edges of the HIPS sheets—can significantly enhance adhesion. Providing training for staff on the correct application techniques will also help ensure that the bonding process is executed properly, leading to stronger, more reliable assemblies. Regularly reviewing and updating bonding practices based on material advancements and supplier recommendations can keep your processes efficient and effective.

Strategic Material Selection Guide for high impact polystyrene sheet

What Are the Key Properties of High Impact Polystyrene Sheet?

High Impact Polystyrene (HIPS) sheets are known for their excellent dimensional stability, impact resistance, and ease of fabrication. They typically exhibit a specific gravity of around 1.04, a flexural strength of approximately 6200 psi, and a heat deflection temperature of around 189°F at 66 psi. These properties make HIPS suitable for a variety of applications, including signage, prototypes, and packaging. Additionally, HIPS is non-toxic and odorless, which enhances its appeal for industries such as food packaging and medical applications.

What Are the Advantages and Disadvantages of High Impact Polystyrene?

HIPS offers several advantages, particularly in terms of cost-effectiveness and versatility. It is relatively inexpensive compared to other materials, making it an attractive option for businesses looking to optimize their budgets. The material is easy to paint, print, and assemble using adhesives or solvents, which simplifies the manufacturing process. However, HIPS does have limitations, including lower heat resistance compared to some alternatives, which may restrict its use in high-temperature environments. Additionally, while it has good impact resistance, it may not be suitable for applications requiring extreme durability.

How Does High Impact Polystyrene Affect Application Performance?

The performance of HIPS can significantly impact its application suitability. For instance, its excellent thermoforming characteristics allow it to be shaped into complex designs, making it ideal for point-of-purchase displays and food containers. However, businesses should consider the specific media compatibility, as HIPS may not perform well with certain chemicals or solvents. International buyers need to be aware of local regulations and standards, such as ASTM or DIN, that may dictate the suitability of HIPS for specific applications.

What Should International B2B Buyers Consider When Selecting High Impact Polystyrene?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, compliance with local regulations is paramount. Buyers should ensure that the selected HIPS products meet relevant safety and environmental standards. Additionally, understanding the preferences of local markets can guide material selection, as certain regions may favor recycled or eco-friendly options. It is also essential to consider logistics and supply chain factors, including shipping costs and availability of local suppliers.

Summary Table of Material Selection for High Impact Polystyrene Sheet

| Material | Typical Use Case for high impact polystyrene sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Impact Polystyrene (HIPS) | Signage, prototypes, food packaging, displays | Cost-effective and easy to fabricate | Limited heat resistance | Low |

| ABS (Acrylonitrile Butadiene Styrene) | Consumer products, automotive parts | Excellent impact resistance | Higher cost compared to HIPS | Med |

| Polycarbonate | Safety glasses, electronic housings | Superior impact strength and clarity | More expensive and harder to machine | High |

| PVC (Polyvinyl Chloride) | Pipes, medical devices, signage | Good chemical resistance | Less impact resistance than HIPS | Low |

This table provides a concise overview of various materials relevant to high impact polystyrene sheets, highlighting their typical use cases, advantages, disadvantages, and cost considerations. By understanding these factors, international B2B buyers can make informed decisions that align with their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for high impact polystyrene sheet

What are the Key Stages in the Manufacturing Process of High Impact Polystyrene Sheets?

The manufacturing of high impact polystyrene (HIPS) sheets involves several critical stages that ensure product quality and performance. Understanding these stages can help B2B buyers assess suppliers and make informed purchasing decisions.

Material Preparation: What Goes Into HIPS Production?

The process begins with the preparation of raw materials. High impact polystyrene is produced by polymerizing styrene with a rubber modifier, typically polybutadiene, to enhance its impact resistance. This mixture is compounded with additives to improve properties like UV resistance and processing characteristics. The raw materials undergo rigorous quality checks to ensure they meet specifications before proceeding to the next stage.

Forming: How are HIPS Sheets Made?

Once the materials are prepared, the next step is forming. The raw polystyrene is heated until it reaches a molten state and then extruded through a die to create sheets of various thicknesses. This process can be adjusted to create different widths and lengths, depending on customer requirements. Techniques such as thermoforming can also be employed, where heated sheets are shaped into specific forms using molds. This versatility makes HIPS suitable for a wide range of applications, from signage to packaging.

Assembly: What Techniques Are Used?

While HIPS sheets may not require complex assembly, they often need to be cut, bonded, or printed upon for specific applications. Techniques such as solvent bonding, mechanical fastening, or adhesive application are commonly used to assemble components. The ease of machining HIPS allows for quick adaptation to various project requirements, which is particularly advantageous for B2B buyers looking for custom solutions.

Finishing: What Quality Enhancements Are Applied?

The finishing stage involves processes that enhance the aesthetic and functional qualities of the HIPS sheets. This may include surface treatment to improve printability or coating to provide additional protection against wear and tear. Quality control measures are employed throughout this stage to ensure the final product meets the desired specifications for appearance and performance.

How is Quality Assurance Ensured in HIPS Manufacturing?

Quality assurance (QA) is critical in the production of high impact polystyrene sheets, as it directly impacts product performance and customer satisfaction. Adhering to international standards is essential for establishing credibility and trust in the global marketplace.

What International Standards Should B2B Buyers Be Aware Of?

Key international standards include ISO 9001, which outlines the requirements for a quality management system, and CE marking, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Additionally, industry-specific standards such as ASTM D5926 (for plastic sheets) may be relevant, depending on the application.

What Are the Key Quality Control Checkpoints?

Quality control in HIPS manufacturing typically involves several checkpoints, including:

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet predefined specifications before production begins.

- In-Process Quality Control (IPQC): Monitoring during the manufacturing process helps identify any deviations from quality standards. This can include checks on temperature, pressure, and material consistency.

- Final Quality Control (FQC): This stage involves a thorough inspection of the finished product, including physical tests for impact resistance, dimensional accuracy, and surface quality.

What Testing Methods Are Commonly Used in HIPS Quality Assurance?

Common testing methods for HIPS include:

- Impact Testing: To assess the toughness and durability of the material.

- Tensile Testing: To measure the strength and elasticity of the sheets.

- Thermal Analysis: To determine heat resistance and thermal properties.

- Dimensional Inspection: To ensure that the sheets meet specified dimensions.

By understanding these methods, B2B buyers can better evaluate the quality of the HIPS products they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of suppliers is crucial. Here are some effective strategies:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing process and quality control measures in place. This includes examining documentation, processes, and employee training.

- Quality Reports: Requesting detailed quality reports can help buyers understand the testing methods used and the results obtained.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of the supplier’s quality assurance practices.

What Are the QC and Certification Nuances for International Buyers?

International buyers must navigate various certification requirements based on their location and the intended market for the HIPS products. For example, products entering the European market must comply with CE marking, while buyers in North America may prioritize compliance with ASTM standards. Understanding these nuances can help buyers avoid regulatory issues and ensure product acceptance in their target markets.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for high impact polystyrene sheets is essential for B2B buyers. By focusing on these aspects, companies can make informed decisions, ensuring they source high-quality materials that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘high impact polystyrene sheet’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring high impact polystyrene (HIPS) sheets. Understanding the nuances of this material and the procurement process can help ensure that you select the right product and supplier for your specific needs.

Step 1: Define Your Technical Specifications

Before beginning your search for HIPS sheets, clearly define the technical specifications required for your application. Consider factors such as thickness, color, and size, as well as any specific properties like impact resistance and heat tolerance. This initial step ensures that you narrow down your options to products that meet your exact requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in HIPS sheets. Look for companies with a solid reputation in the industry and positive reviews from previous clients. Utilize online directories, trade shows, and industry publications to gather a list of credible suppliers.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers. Ensure that they meet international quality standards, such as ISO certifications, which reflect their commitment to quality and reliability. This step is crucial to mitigate risks associated with product quality and safety.

Step 4: Request Samples

Before making a bulk order, request samples of the HIPS sheets to assess their quality firsthand. Examine the samples for consistency in color, texture, and physical properties. This allows you to evaluate whether the product aligns with your specifications and expectations.

Step 5: Understand Pricing Structures

Engage in discussions with suppliers to gain a clear understanding of their pricing structures. Inquire about minimum order quantities, bulk discounts, and shipping costs. This knowledge helps in budgeting and ensures that you can negotiate favorable terms.

Step 6: Assess Logistics and Delivery Options

Evaluate the logistics and delivery capabilities of your shortlisted suppliers. Confirm their lead times and shipping methods to ensure timely delivery of your order. Consider suppliers that offer reliable shipping options, especially if you are sourcing internationally.

Step 7: Negotiate Payment Terms

Once you have selected a supplier, negotiate payment terms that suit your financial situation. Discuss options such as payment in advance, net terms, or letters of credit. Clear payment agreements can help build a strong relationship with your supplier and ensure smooth transactions.

By following this checklist, you can streamline your procurement process for high impact polystyrene sheets, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for high impact polystyrene sheet Sourcing

What Are the Key Cost Components in High Impact Polystyrene Sheet Sourcing?

When sourcing high impact polystyrene (HIPS) sheets, understanding the underlying cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The price of raw polystyrene resin significantly influences overall costs. Market fluctuations, driven by crude oil prices and supply chain dynamics, can lead to variability in material costs. Buyers should monitor resin price trends and consider sourcing from multiple suppliers to mitigate risks.

-

Labor: Labor costs encompass wages for production workers and other personnel involved in manufacturing and quality assurance. Labor rates can vary significantly by region, impacting the final price of HIPS sheets. For instance, sourcing from countries with lower labor costs may offer savings, but this must be balanced against quality and lead times.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility operations. Efficient manufacturing processes can help reduce overhead, thus lowering the cost of HIPS sheets. Buyers should inquire about a supplier’s operational efficiencies when discussing pricing.

-

Tooling: Custom tooling can add to the initial investment costs. If specific dimensions or features are required, buyers may need to factor in the cost of molds and dies, which can be substantial. Understanding these costs upfront is essential for accurate budgeting.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to production costs. However, investing in quality checks can prevent costly returns and defects. Buyers should assess a supplier’s QC measures and certifications, as these can impact both cost and reliability.

-

Logistics: Shipping and handling costs, including freight and insurance, are critical in the total cost calculation. Buyers should explore various shipping options and consider factors such as distance, shipping terms, and Incoterms to optimize logistics costs.

-

Margin: Finally, supplier margins will vary based on market positioning and competition. Understanding typical markups in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect High Impact Polystyrene Sheet Costs?

Several factors can influence the pricing of HIPS sheets:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for bulk orders. Understanding the MOQ can help buyers negotiate favorable terms and achieve cost savings.

-

Specifications and Customization: Custom sizes, colors, and thicknesses can increase production costs. Buyers should clearly define their specifications to avoid unexpected charges later in the sourcing process.

-

Material Quality and Certifications: Higher-quality HIPS sheets may come at a premium. Certifications such as ISO can assure buyers of consistent quality but may also increase costs.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can all affect pricing. Established suppliers may charge more due to their reliability and service levels.

-

Incoterms: The agreed-upon Incoterms can significantly affect total landed costs. Understanding who bears the cost and risk at each stage of transport is essential for accurate budgeting.

What Are Some Effective Buyer Tips for Sourcing High Impact Polystyrene Sheets?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiation: Leverage volume orders and long-term relationships to negotiate better pricing and terms. Establishing a partnership with suppliers can lead to more favorable conditions.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) by considering all cost components, including logistics and potential defects. A lower upfront price may lead to higher long-term costs if quality issues arise.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs that can affect final costs. Building these factors into your pricing strategy can prevent budget overruns.

-

Supplier Diversification: Engaging multiple suppliers can enhance negotiating power and reduce dependence on a single source, mitigating risks associated with supply chain disruptions.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of high impact polystyrene sheets enables buyers to make informed decisions, optimize their sourcing strategies, and ultimately enhance their bottom line.

Alternatives Analysis: Comparing high impact polystyrene sheet With Other Solutions

When evaluating materials for various applications, it’s crucial to consider alternatives to High Impact Polystyrene (HIPS) sheets. Understanding the different options available allows B2B buyers to make informed decisions based on their specific needs and operational constraints. Below is a comparative analysis of HIPS sheets against alternative materials.

| Comparison Aspect | High Impact Polystyrene Sheet | Polycarbonate Sheet | Acrylic Sheet |

|---|---|---|---|

| Performance | Excellent impact resistance, good dimensional stability | Very high impact resistance, excellent thermal stability | Good impact resistance, excellent clarity |

| Cost | Cost-effective, lower price point | Higher cost, premium material | Moderate cost, generally more expensive than HIPS |

| Ease of Implementation | Easy to cut, drill, and assemble | Requires specialized tools for cutting | Easy to cut and fabricate, but can crack if mishandled |

| Maintenance | Low maintenance, durable in various environments | Low maintenance, resistant to UV degradation | Requires regular cleaning to maintain clarity |

| Best Use Case | Prototyping, signage, models | Safety shields, high-impact applications | Displays, lighting fixtures, decorative applications |

What Are the Pros and Cons of Polycarbonate Sheets as an Alternative to HIPS?

Polycarbonate sheets stand out for their exceptional impact resistance, making them ideal for applications requiring durability, such as safety shields and protective enclosures. Their thermal stability allows them to perform well in extreme temperatures, which is beneficial for outdoor applications. However, the higher cost of polycarbonate can be a drawback for budget-conscious buyers. Additionally, while they are easy to maintain, they may require specialized cutting tools, which can complicate implementation in some scenarios.

How Does Acrylic Compare to High Impact Polystyrene Sheets?

Acrylic sheets offer excellent clarity and can be an attractive option for applications where visibility is paramount, such as in displays and lighting fixtures. They are relatively easy to cut and fabricate, similar to HIPS; however, they can be more prone to cracking if not handled carefully. Acrylic typically comes at a higher price point than HIPS, which may limit its use in cost-sensitive projects. Maintenance is another consideration, as acrylic requires regular cleaning to keep its transparency, while HIPS maintains its appearance with less effort.

Conclusion: How Should B2B Buyers Choose Between HIPS and Its Alternatives?

When selecting the right material, B2B buyers should assess their specific application needs, budget constraints, and operational capabilities. High Impact Polystyrene is a solid choice for cost-effective solutions where impact resistance and ease of fabrication are priorities. However, for applications that demand superior durability or clarity, polycarbonate or acrylic might be more suitable despite their higher costs. Ultimately, a thorough evaluation of performance, cost, and application requirements will guide buyers in making the best decision for their projects.

Essential Technical Properties and Trade Terminology for high impact polystyrene sheet

What Are the Key Technical Properties of High Impact Polystyrene Sheet?

High Impact Polystyrene (HIPS) is a versatile material widely used in various industries, particularly for applications requiring durability and ease of fabrication. Understanding its critical technical properties is essential for B2B buyers to make informed purchasing decisions.

1. Material Grade

Material grade refers to the specific formulation of HIPS, impacting its performance characteristics such as impact resistance and thermal stability. High-quality grades ensure better performance in demanding applications, which is crucial for manufacturers aiming for product longevity and reliability.

2. Flexural Strength

Flexural strength measures the material’s ability to resist deformation under load. For HIPS, this is typically around 6200 psi. A higher flexural strength indicates better performance in applications where the material may be subjected to bending or stress, making it ideal for signs, displays, and structural components.

3. Tensile Strength

Tensile strength, measured in psi, indicates how much pulling force a material can withstand before breaking. HIPS generally exhibits a tensile strength of approximately 2800 psi at yield and 3500 psi at break. This property is vital for applications such as packaging and prototypes, where the material must endure various handling and usage conditions.

4. Impact Resistance

Impact resistance is a critical property for HIPS, often evaluated using Izod impact strength tests. HIPS typically shows values around 2.1 ft-lb/in at 73°F and 1.2 ft-lb/in at 0°F. This measure is essential for buyers in industries like food packaging and medical supplies, where the material must withstand accidental drops or collisions without breaking.

5. Thermal Stability

Thermal stability is indicated by the Heat Deflection Temperature (HDT), which for HIPS is about 189°F at 66 psi. This property is crucial for applications exposed to heat, ensuring that the material maintains its shape and strength under elevated temperatures.

6. Dimensional Stability

Dimensional stability describes the material’s ability to maintain its shape and size under varying environmental conditions. HIPS is known for its excellent dimensional stability, making it suitable for precision applications such as model making and signage, where exact measurements are critical.

What Are Common Trade Terms Used in High Impact Polystyrene Transactions?

Navigating the procurement of HIPS involves understanding specific trade terminology that can significantly impact the purchasing process.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For HIPS, OEMs often require custom specifications, making it essential for buyers to communicate their needs clearly.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. Understanding MOQ is vital for buyers, particularly small businesses, as it influences inventory management and cash flow. Negotiating favorable terms can lead to cost savings.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific quantities of HIPS. It’s a critical step in the procurement process, enabling buyers to compare options and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, specifying who pays for shipping, insurance, and tariffs. Familiarity with these terms helps buyers manage logistics and avoid unexpected costs.

5. Thermoforming

Thermoforming is a manufacturing process where plastic sheets are heated to a pliable forming temperature, then molded into specific shapes. Understanding this term is essential for buyers who intend to use HIPS in applications such as packaging or product displays.

6. Machinability

Machinability refers to how easily a material can be cut, shaped, or finished. HIPS is known for its excellent machinability, making it a preferred choice for fabricators and manufacturers requiring precise components.

By grasping these technical properties and trade terms, B2B buyers can effectively navigate the high impact polystyrene market, ensuring they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the high impact polystyrene sheet Sector

What Are the Key Market Dynamics and Trends Influencing High Impact Polystyrene Sheets?

The high impact polystyrene (HIPS) sheet market is currently experiencing significant growth driven by various global factors. The increasing demand for lightweight and durable materials across multiple sectors, including packaging, automotive, and electronics, is propelling market expansion. Additionally, the rise of e-commerce has led to an uptick in demand for effective packaging solutions, where HIPS sheets are favored for their high impact resistance and versatility. Emerging technologies in manufacturing, such as 3D printing and advanced thermoforming techniques, are also reshaping the sourcing landscape, allowing for custom solutions tailored to specific industry needs.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that can offer a diverse range of HIPS products, including custom sizes and thicknesses. The trend towards online sourcing platforms is making it easier for buyers to access a global pool of suppliers, facilitating price comparisons and product availability checks. Furthermore, the focus on digital supply chain management tools is enhancing transparency and efficiency in procurement processes, allowing buyers to make informed decisions based on real-time data.

How Is Sustainability Shaping Sourcing Decisions for High Impact Polystyrene Sheets?

Sustainability has become a pivotal factor in sourcing high impact polystyrene sheets. As environmental concerns rise, B2B buyers are prioritizing suppliers that adopt sustainable practices and offer eco-friendly products. The introduction of post-consumer recycled HIPS sheets is a prime example of how manufacturers are responding to this demand. These products maintain the performance characteristics of virgin HIPS while reducing environmental impact, making them attractive to sustainability-conscious buyers.

Additionally, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ sourcing practices, looking for certifications that validate their commitment to environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and the use of materials with recognized ‘green’ certifications can significantly influence purchasing decisions. By aligning sourcing strategies with sustainability goals, businesses can enhance their brand image and meet the growing consumer demand for responsible products.

What Is the Historical Context of High Impact Polystyrene Sheets in B2B Markets?

The evolution of high impact polystyrene sheets dates back to the mid-20th century, when the material was first developed as a cost-effective alternative to other plastics. Initially used in various consumer products, its superior impact resistance and ease of fabrication quickly made it a popular choice in industrial applications. Over the decades, advancements in polymer chemistry have improved HIPS properties, making it suitable for a wider range of applications, including medical packaging and point-of-purchase displays.

As global markets began to prioritize efficiency and sustainability in the late 20th and early 21st centuries, the HIPS sector adapted accordingly. The incorporation of recycled materials into the production process not only addressed environmental concerns but also provided businesses with competitive advantages in a rapidly changing marketplace. Today, high impact polystyrene sheets are integral to numerous industries, reflecting a robust history of innovation and adaptability that continues to shape their market presence.

Frequently Asked Questions (FAQs) for B2B Buyers of high impact polystyrene sheet

-

How do I choose the right high impact polystyrene sheet for my application?

Selecting the appropriate high impact polystyrene (HIPS) sheet involves evaluating the specific requirements of your project. Consider factors such as thickness, color, and surface finish, as these can affect both functionality and aesthetics. Review the mechanical properties like impact resistance and tensile strength, which are crucial for durability. Additionally, assess compatibility with your manufacturing processes, whether it’s for thermoforming, machining, or printing. Consulting with suppliers for recommendations based on your intended application can also provide valuable insights. -

What are the common applications of high impact polystyrene sheets in various industries?

High impact polystyrene sheets are versatile and utilized across numerous sectors. They are commonly found in signage, point-of-purchase displays, packaging, and model-making. In the food industry, HIPS is used for containers and trays, while in healthcare, it’s often employed for medical packaging. Their excellent machinability and thermoforming capabilities make them ideal for prototypes and custom designs. Understanding your industry’s specific needs can help you leverage HIPS sheets effectively. -

What are the minimum order quantities (MOQ) for high impact polystyrene sheets?

Minimum order quantities for high impact polystyrene sheets can vary significantly between suppliers. Generally, MOQs can range from a few sheets to several hundred, depending on the supplier’s policies and the specific product specifications. When sourcing internationally, it’s advisable to inquire about MOQs upfront to ensure they align with your project needs. Some suppliers may offer flexibility for first-time orders or smaller businesses, so it’s worth negotiating if necessary. -

How can I ensure the quality of high impact polystyrene sheets when sourcing internationally?

To ensure the quality of high impact polystyrene sheets, start by vetting suppliers through references, reviews, and industry certifications. Request material samples to evaluate the product’s physical properties firsthand. Additionally, inquire about quality assurance processes, including testing for impact resistance and dimensional stability. It can also be beneficial to establish clear specifications and expectations in your purchase agreement, including penalties for non-compliance with quality standards. -

What payment terms should I expect when purchasing high impact polystyrene sheets from international suppliers?

Payment terms can vary widely among international suppliers. Common arrangements include advance payment, net 30, or net 60 terms, where the buyer pays within 30 or 60 days after receiving the invoice. It’s crucial to discuss and agree on payment methods—such as wire transfers, letters of credit, or PayPal—before finalizing any purchase. Understanding these terms can help manage cash flow and ensure a smooth transaction process. -

What shipping options are available for high impact polystyrene sheets, and how do they impact delivery times?

Shipping options for high impact polystyrene sheets generally include air freight, sea freight, and courier services. Air freight is faster but more expensive, suitable for urgent orders. Sea freight is more economical for bulk orders but can take longer, potentially several weeks. The choice of shipping method will impact delivery times, so it’s essential to plan accordingly based on your project deadlines. Always clarify shipping terms, including responsibilities for customs and duties, with your supplier. -

Can high impact polystyrene sheets be customized for specific projects?

Yes, many suppliers offer customization options for high impact polystyrene sheets. Customization can include cutting to specific dimensions, color matching, and surface treatments such as printing or texturing. When discussing your project with suppliers, provide detailed specifications to ensure the final product meets your requirements. Custom solutions can enhance the usability of HIPS sheets for specialized applications, making them a valuable option for businesses looking for tailored solutions. -

What are the environmental considerations when sourcing high impact polystyrene sheets?

When sourcing high impact polystyrene sheets, consider the environmental impact of production and disposal. Look for suppliers who offer recycled options, such as post-consumer recycled HIPS, which can reduce your carbon footprint. Additionally, inquire about the supplier’s commitment to sustainability practices, such as energy-efficient manufacturing processes and waste reduction initiatives. Understanding these factors can help align your sourcing decisions with your company’s environmental responsibility goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 High Impact Polystyrene Sheet Manufacturers & Suppliers List

1. Interstate Plastics – Renovo-HIPS ™ Post-Consumer High Impact Polystyrene Sheet

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: {“Product Title”: “Renovo-HIPS ™ Post-Consumer High Impact Polystyrene Sheet – White”, “Description”: “Renovo-HIPS ™ 25% post-consumer recycled styrene sheet has the same properties as virgin styrene.”, “High Impact Styrene”: “High impact styrene is used for models, prototypes, signs, displays, enclosures, and more.”, “Template Sheet Kits”: “Styrene Template Sheet Kits (.030/.060) can be cut with …

2. Acme Plastics – High Impact Polystyrene Sheets

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: This company, Acme Plastics – High Impact Polystyrene Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Curbell Plastics – High Impact Polystyrene Sheets

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: High Impact Polystyrene (HIPS) Sheets available in various grades including standard and Orfitrans™ Stiff for orthotics and prosthetics. Key product details include:

– Thickness options: 0.02 in, 0.03 in, 0.04 in, 0.06 in, 0.08 in

– Width: 48 in

– Length options: 72 in, 96 in

– Colors: Black, White

– Surface textures: Matte/Smooth, Matte/Matte

– Pricing examples:

– 0.06 in x 48 in x 96 in Black,…

4. Evergreen – HIPS Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Evergreen (Styrene) vs. HIPS (High Impact Polystyrene): Evergreen is expensive in Canada, with a 12″ x 12″, .020″ sheet priced at $9.00. HIPS is a cheaper alternative, costing $0.75 for the same size and thickness. HIPS contains rubber, making it high-impact, but it is not a good replacement for regular styrene as plastic cements do not work on it; only CA and epoxy glues bond to HIPS. Some users …

5. Polymer Shapes – High Impact Polystyrene (HIPS)

Domain: polymershapes.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “High Impact Polystyrene (HIPS)”, “Also Known As”: “PS (Polystyrene)”, “Material Type”: “Amorphous thermoplastic”, “Applications”: “Lower heat applications”, “Category”: “Standard material”, “Benefits”: [“High impact strength”, “Printable using Digital, Screen, Flexo, and Litho inks”, “Fabricates well (guillotine cut, die-cut, punched, formed)”, “Easy to Thermoform”, “Good dimensi…

6. Rapid – High Impact Polystyrene Sheets

Domain: rapidonline.com

Registered: 2002 (23 years)

Introduction: Brand: Rapid, Product Type: High Impact Polystyrene (HIPS) Sheets, Available Sizes: 1x457x254mm, 1x457x305mm, Thickness Options: 1mm, 1.5mm, Colors Available: Red, Blue, Green, Yellow, White, Black, Clear, Pack Size: 10 sheets per pack, Tolerance: ±1.5mm, Virgin grade for consistency of moulding, Suitable for vacuum forming, Cost-effective for prototyping, Pricing: Varies by color and size, Stock …

7. Regal Plastics – HIPS Sheets

Domain: regal-plastics.com

Registered: 1997 (28 years)

Introduction: HIPS (High Impact Polystyrene) is a lightweight, cost-effective plastic sheet designed for screen-printed applications. Common names include HIPS and HIS. Key properties include impact strength, heat resistance, machinability, cost-effectiveness, and thermoformability. Popular applications are signage, point of purchase displays, electronics, models and templates, and packaging. HIPS is durable, r…

8. Plastic Craft – Polystyrene Clear Mirror Sheet

Domain: plastic-craft.com

Registered: 1997 (28 years)

Introduction: Polystyrene Clear Mirror Sheet, lightweight, shatter-resistant, versatile applications, available in various sizes, easy to cut and shape, ideal for crafts, displays, and home decor.

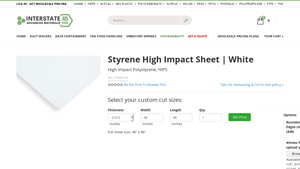

9. Interstateam – Styrene High Impact Sheet

Domain: interstateam.com

Registered: 2022 (3 years)

Introduction: Styrene High Impact Sheet | White

– SKU: STYWEH SH

– Material: High Impact Polystyrene (HIPS)

– Full sheet size: 48″ x 96″

– Thickness options: 0.015, 0.020, 0.030, 0.040, 0.060, 0.093, 0.125 inches

– Features: Good machinability, high impact strength, paintable, excellent thermoforming properties, easy to print on, easy to assemble with adhesives or solvents.

– Applications: Prototypes, signage, …

Strategic Sourcing Conclusion and Outlook for high impact polystyrene sheet

High impact polystyrene (HIPS) sheets stand out as a versatile and cost-effective material for numerous applications, including signage, packaging, and prototyping. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the unique properties and benefits of HIPS is crucial. Key takeaways include its excellent machinability, impact resistance, and thermoforming capabilities, making it an ideal choice for diverse industries from medical packaging to point-of-purchase displays.

Strategic sourcing of high impact polystyrene sheets can lead to significant cost savings and improved product quality. By establishing relationships with reliable suppliers who offer a range of options in terms of thickness, color, and custom cuts, businesses can enhance their operational efficiency and meet specific project requirements.

As the global demand for sustainable and versatile materials continues to rise, now is the opportune moment for international buyers to capitalize on the benefits of HIPS. Engage with suppliers who prioritize quality and sustainability, and consider integrating high impact polystyrene into your supply chain strategy. Embrace the potential of HIPS to drive innovation and efficiency in your operations.