Contents

Manufacturing Insight: Hem In Sheet Metal

Precision Hemming in Sheet Metal: A Critical Fabrication Process

Hemming in sheet metal fabrication transforms basic bends into structurally reinforced, safety-critical features by folding the edge of a workpiece back onto itself. This process eliminates sharp edges, enhances rigidity, improves cosmetic finish, and creates secure attachment points for assemblies. Achieving consistent, burr-free hems demands exacting control over material behavior, tooling geometry, and process parameters—particularly for complex contours or high-strength alloys where springback and deformation must be precisely compensated. At Honyo Prototype, our sheet metal fabrication services integrate advanced hemming capabilities within a comprehensive suite of precision manufacturing solutions, including laser cutting, CNC punching, precision bending, and automated welding.

Our engineered approach leverages proprietary process validation protocols and real-time in-process metrology to ensure hem integrity across diverse materials—from aluminum and stainless steel to specialty composites—meeting stringent aerospace, medical, and industrial equipment specifications. Unlike standard bending operations, hemming requires iterative prototyping to optimize radii, flange widths, and force distribution; Honyo’s technical team collaborates early in DFM to mitigate risks like material splitting or dimensional drift before production. For projects requiring this specialized capability, our Online Instant Quote system delivers rapid, transparent pricing with material-specific cost drivers clearly itemized, enabling faster design validation and procurement cycles without sacrificing technical rigor.

Engineers seeking hemming expertise backed by certified quality systems can initiate a quote in under two minutes, receiving actionable feedback on manufacturability alongside cost and lead time data—all within a secure B2B portal designed for professional fabrication workflows.

Technical Capabilities

Hem in Sheet Metal – Technical Specifications

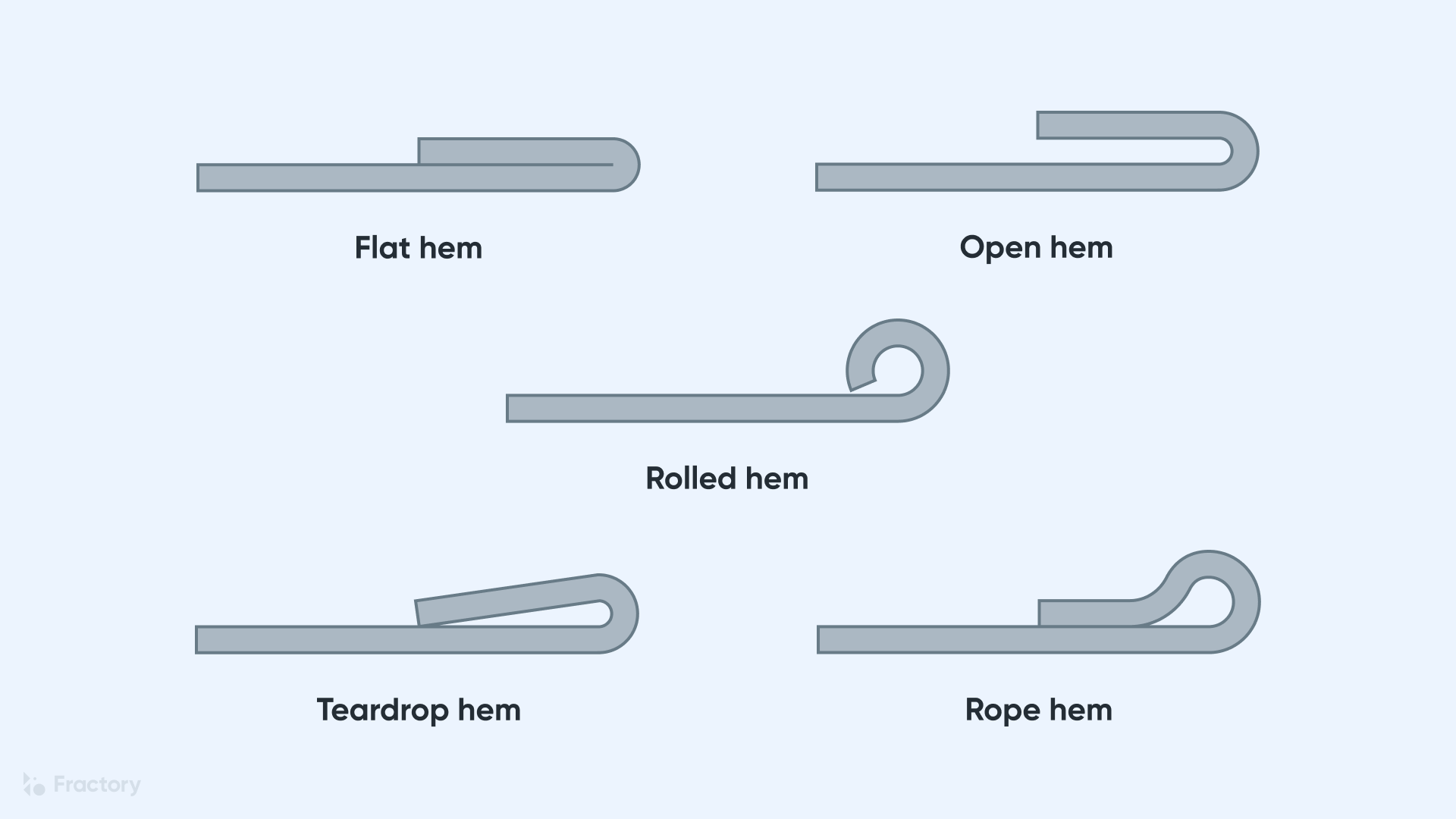

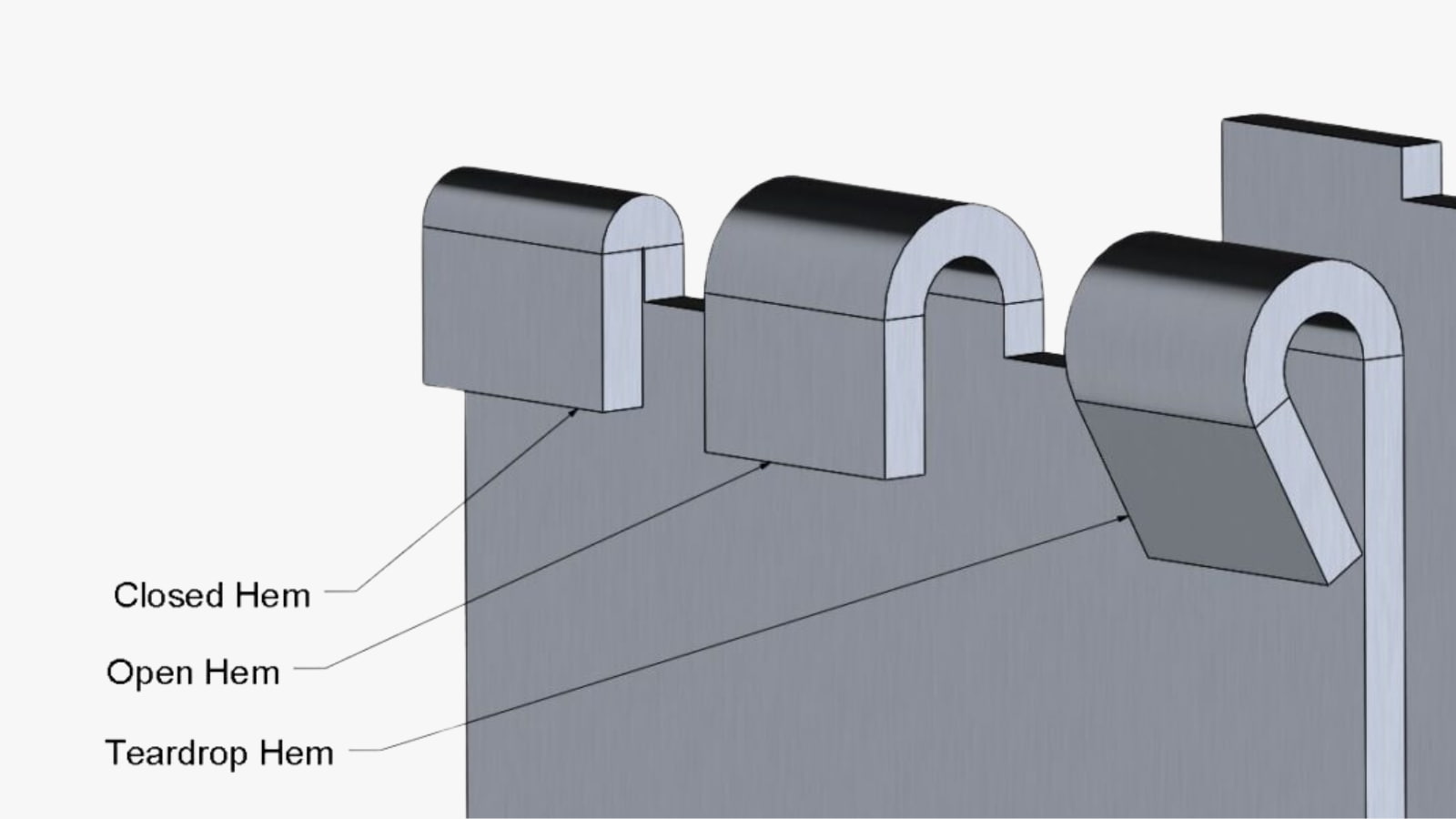

A hem refers to a sheet metal feature where the edge of the material is folded back onto itself, creating a smooth, rounded, or flattened closed edge. Hems are used to improve edge safety, increase stiffness, or prepare parts for welding or joining. The following technical specifications outline key parameters and considerations for hems in the context of laser cutting, bending, and welding processes, with material-specific details for Aluminum, Steel, ABS, and Nylon.

| Parameter | Aluminum (e.g., 5052, 6061) | Steel (e.g., 304 SS, Mild Steel) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Laser Cutting | Compatible; requires high-power fiber lasers. Reflective nature demands controlled assist gas (N₂ or O₂). Kerf tolerance: ±0.1 mm. | Easily cut using CO₂ or fiber lasers. Oxygen assist enhances edge quality on mild steel. Kerf tolerance: ±0.1 mm. | Can be laser cut with CO₂ lasers; may produce charring or melting if power is not optimized. Tolerance: ±0.2 mm. | Possible with CO₂ lasers; high melting point and thermal deformation risk. Requires low power and high speed. Tolerance: ±0.25 mm. |

| Minimum Hem Radius | 1.0 × material thickness (min) | 0.8 × material thickness (min) | Not applicable (thermoplastic, not hemmed like metal) | Not applicable (flexible, not formed via hemming) |

| Minimum Material Thickness for Hem | 0.5 mm | 0.4 mm | N/A | N/A |

| Maximum Material Thickness for Hem | 3.0 mm | 4.0 mm | N/A | N/A |

| Bending Process | Air bending or bottoming; tooling must accommodate springback (7–12°). Use hemming dies for final flattening. | Low springback (2–5°); compatible with standard press brakes and hemming dies. | Cannot be bent into hems using metal-style tooling; heat-assisted forming possible but not typical. | Not suitable for conventional hemming; thermoforming required for edge treatments. |

| Hem Type Compatibility | Closed, open, and tear-dropped hems achievable with multi-stage bending. | Full hems (closed), open hems standard. High strength after hemming. | Not applicable | Not applicable |

| Welding for Hem Joining | TIG or laser welding preferred for closed hems. Fillet or seam welds used for structural attachment. Avoid warping with controlled heat input. | MIG, TIG, or resistance welding effective. Seam welding common for hemmed joints (e.g., enclosures). Strong, conductive joints. | Ultrasonic or vibration welding for edge joining; not hem-specific. Adhesives more common. | Hot plate or vibration welding possible; not applicable to traditional hem structures. |

| Surface Finish Consideration | Oxide layer may affect weld quality; cleaning or pre-treatment recommended. Anodizing incompatible post-hemming. | Zinc coating (on galvanized) may affect weld integrity; ventilation required. Paint or powder coat typically applied post-forming. | Surface may melt or degrade during thermal joining. Solvent bonding preferred. | Prone to moisture absorption; pre-drying required for welding. |

Notes:

Hems are primarily a metal forming technique; ABS and Nylon are not typically processed using hemming due to their thermoplastic behavior and lack of ductile cold-forming characteristics.

For Aluminum and Steel, hem design must include allowance for springback and tooling progression (pre-bend, final fold).

Laser cutting must precisely define the blank edge prior to bending; edge quality affects hem integrity.

In welded hem applications, joint accessibility and fit-up are critical; automated welding benefits from consistent hem geometry.

From CAD to Part: The Process

Honyo Prototype Hemming Process for Sheet Metal Components

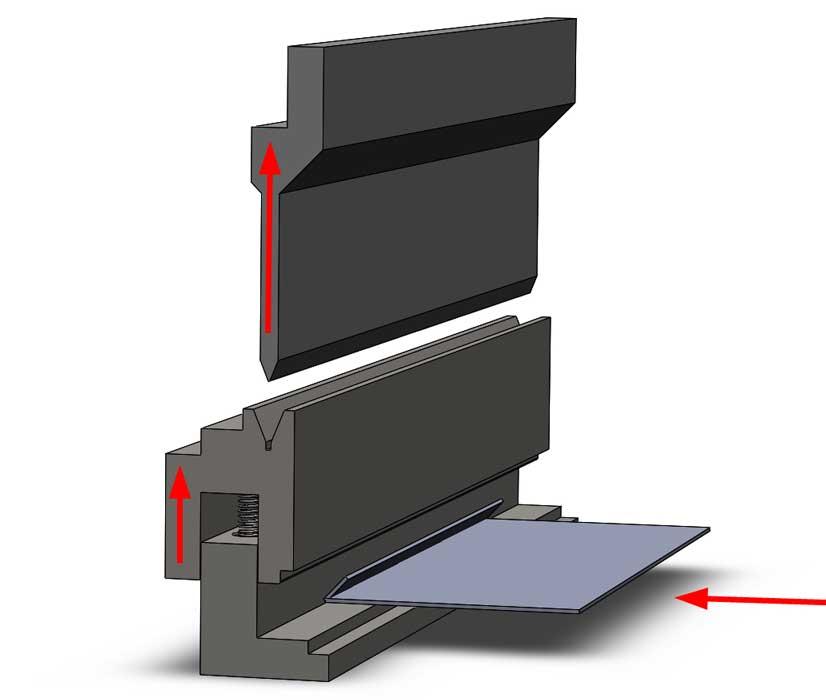

Honyo executes hemming operations—where sheet metal edges are folded over themselves to reinforce strength, eliminate sharp edges, or prepare for welding—with a structured workflow ensuring precision and efficiency from design to delivery. The process begins when a client uploads a CAD file containing hem-specific geometry, such as flange widths, hem radii, and material thickness. Our system validates file integrity and extracts critical hem parameters, including minimum bend radii relative to material ductility and hem length tolerances.

The AI quoting engine then generates a real-time cost estimate by analyzing hem complexity factors: material grade (e.g., aluminum 5052 vs. steel SPCC), hem type (teardrop, open, or blunt), and secondary operations like pre-piercing for spot welds. For instance, hems under 3mm width or requiring multiple-stage folding trigger cost adjustments due to specialized tooling needs. All quotes include lead time projections based on hemming method selection—robotic press brake hemming for high-volume runs or CNC turret press hemming for prototypes.

During DFM analysis, our engineers rigorously review hem feasibility. Key checks include verifying that the hem radius exceeds 0.8x material thickness to prevent cracking, confirming adequate flange width for tool clearance (typically ≥4x material thickness), and identifying interference risks between hems and adjacent features like louvers or embossments. If a hem violates these rules—such as a 0.5mm hem on 1.2mm steel—the DFM report details actionable revisions, like increasing flange width or suggesting alternative hem types. Clients receive annotated 3D models highlighting adjustments before approval.

Production leverages precision hemming equipment calibrated for tight tolerances. For small batches, hydraulic press brakes with custom hemming dies form edges in sequential bends; for volumes >500 units, progressive dies on turret presses automate the process. In-process checks measure hem width consistency (±0.2mm) and edge smoothness via profilometer scans to ensure no burrs exceed 0.05mm. Material grain direction is aligned with the hem path to minimize springback, particularly for stainless steel.

Final delivery includes comprehensive documentation: CMM reports validating hem geometry against CAD, material certificates, and first-article inspection records. All hemed parts undergo functional testing—such as pull tests for welded hems—to confirm structural integrity. Standard lead time is 7–10 days for prototypes and 12–15 days for production runs, with expedited options available.

Typical Hemming Tolerances at Honyo Prototype

| Parameter | Standard Tolerance | Tight Tolerance Option |

|———————|——————–|————————|

| Hem Width | ±0.3 mm | ±0.15 mm |

| Hem Height | ±0.4 mm | ±0.2 mm |

| Edge Smoothness | ≤0.1 mm burr | ≤0.05 mm burr |

| Angular Deviation | ±1.5° | ±0.8° |

This integrated approach minimizes iteration risks while maintaining hem-specific quality benchmarks critical for enclosures, automotive panels, and medical housings. Clients receive real-time production updates via our portal, including stage completion timestamps and QC data access.

Start Your Project

For expert hemming solutions in sheet metal fabrication, contact Susan Leo at [email protected]. Leverage our precision manufacturing capabilities from our Shenzhen factory for high-quality, reliable results.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.