Contents

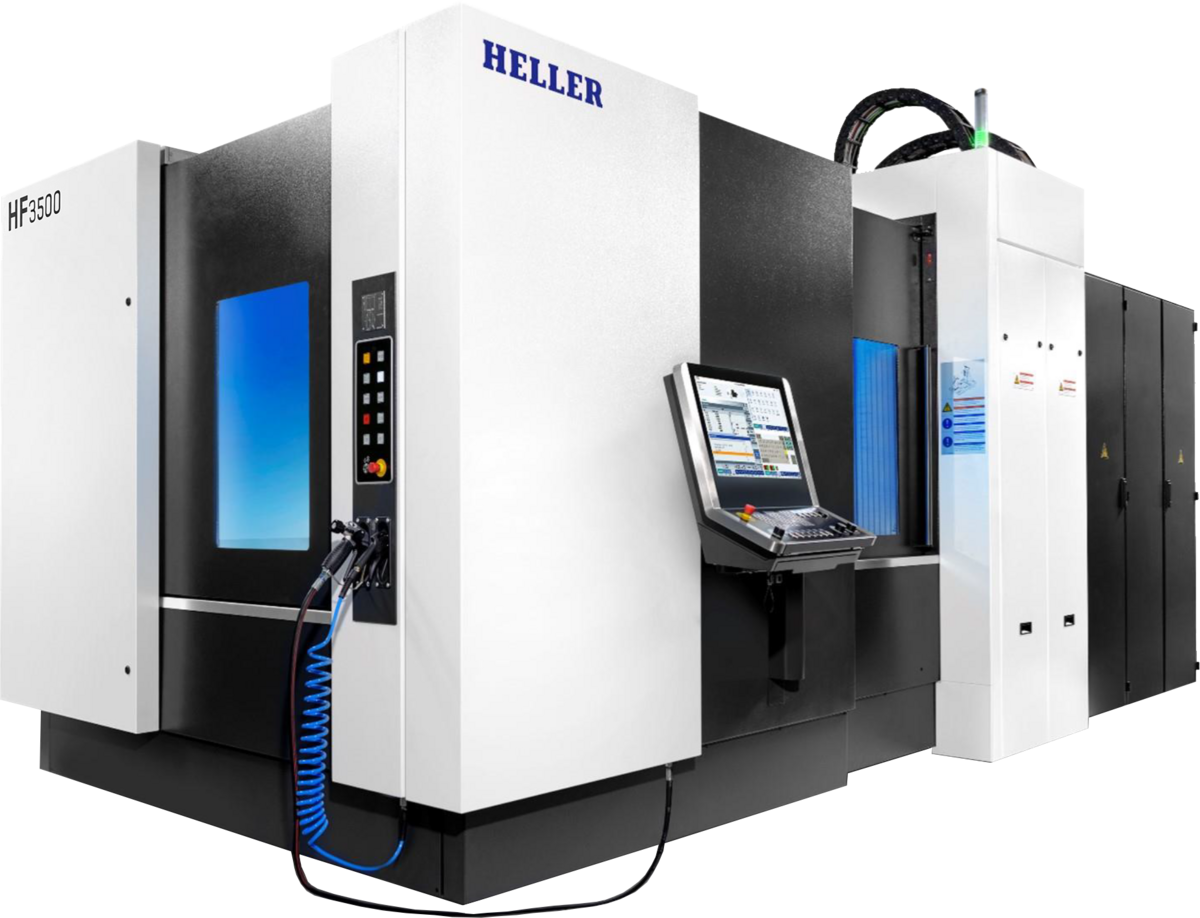

Manufacturing Insight: Heller Cnc Price

Precision CNC Machining Services at Honyo Prototype: Clarity on Heller CNC Capabilities and Pricing

When sourcing high-integrity machined components requiring the precision associated with Heller CNC platforms, understanding the true cost drivers is essential for informed procurement. Honyo Prototype delivers advanced CNC machining services utilizing a strategically selected fleet of multi-axis machining centers, including equipment comparable to Heller in capability and control, focused on producing complex, tight-tolerance parts for demanding industries like aerospace, medical, and industrial automation. Our expertise ensures optimal process selection, material utilization, and throughput for your specific geometry and volume requirements, directly impacting final part cost.

Unlike generic online calculators, Honyo provides actionable pricing transparency through our engineered approach. We recognize that quoting complex CNC work, especially for parts demanding Heller-level precision, requires evaluating detailed CAD data, material specifications, tolerances, surface finishes, and secondary operations. To eliminate quoting delays and accelerate your project timeline, we offer an Online Instant Quote system. Simply upload your 3D CAD model (STEP, IGES, Parasolid) and specify critical requirements; our system, backed by decades of manufacturing experience, generates a detailed, reliable cost estimate within hours, not days. This immediate visibility into Heller-class CNC pricing empowers faster decision-making and project initiation without sacrificing the engineering rigor your components demand. Partner with Honyo for precision machining where cost certainty meets uncompromising quality.

Technical Capabilities

Honeyo Prototype provides high-precision CNC machining services utilizing advanced 3-axis, 4-axis, and 5-axis milling centers, as well as CNC turning systems. Our equipment is optimized for tight-tolerance production across a range of engineering materials, including aluminum, steel, ABS, and nylon. Below are the key technical specifications relevant to our CNC machining capabilities and pricing structure based on complexity, axes used, and tolerance requirements.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary) | X, Y, Z + A & B (dual rotary) | Main spindle + X/Z linear axes |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

| Tight Tolerance Capability | ±0.01 mm typical, down to ±0.005 mm | ±0.01 mm typical, down to ±0.005 mm | ±0.005 mm standard, achievable down to ±0.003 mm | ±0.01 mm typical, down to ±0.005 mm |

| Surface Finish (Typical) | Ra 1.6 µm (standard), down to Ra 0.8 µm | Ra 1.6 µm, with options to Ra 0.8 µm | Ra 1.6 µm, achievable to Ra 0.4 µm with polishing | Ra 1.6 µm, down to Ra 0.8 µm |

| Max Work Envelope (mm) | 1000 x 600 x 500 | 800 x 600 x 500 | 600 x 500 x 400 | Diameter: 300 mm, Length: 500 mm |

| Spindle Speed (RPM) | Up to 24,000 | Up to 24,000 | Up to 30,000 | Up to 6,000 (high-torque) |

| Tooling System | BT30 or HSK-63 | BT30 or HSK-63 | HSK-63 or HSK-A63 | Live tooling capable |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Same as 3-axis | Same as 3-axis, optimized for complex geometries | Aluminum, Steel, ABS, Nylon (bar stock compatible) |

| Typical Applications | Flat parts, housings, jigs | Index-rotated features, mid-complexity parts | Aerospace components, medical devices, molds | Shafts, bushings, threaded components |

| Relative Cost Factor (Base = 1.0) | 1.0 | 1.4 | 2.0 | 1.1 |

Notes on Pricing and Tolerances

Base pricing is influenced by machine time, setup complexity, tool wear, and inspection requirements.

Tighter tolerances (below ±0.005 mm) require additional metrology (CMM or laser probing), increasing cost by 15–25%.

5-axis jobs incur higher programming (CAM) and fixturing costs due to simultaneous motion and 3D toolpath validation.

Non-metallic materials such as ABS and nylon are machined with specialized cutters to prevent melting or burring, slightly affecting cycle time and tooling cost.

All parts undergo first-article inspection for critical dimensions when tight tolerances are specified.

For quotation purposes, detailed CAD models and tolerance callouts (per ISO 2768 or specific GD&T) are required to accurately assess machining time and process planning.

From CAD to Part: The Process

Honyo Prototype employs a streamlined digital workflow for CNC machining quotations and production, specifically optimized for precision components often associated with high-end machinery like Heller CNC systems. Our process ensures accuracy, manufacturability, and rapid turnaround while maintaining strict quality control. Below is a detailed explanation of each phase:

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SOLIDWORKS) via our secure web portal. Our system validates file integrity and extracts critical geometric data, material specifications, and requested tolerances. This step eliminates manual data entry errors and establishes a digital thread for the entire project lifecycle. We support complex geometries typical of aerospace, medical, and industrial automation components requiring Heller-grade precision.

AI Quote Generation

Within minutes, our proprietary AI engine analyzes the CAD model against real-time parameters including material availability, machine capacity, tooling requirements, and geometric complexity. The algorithm cross-references historical production data from our 50+ CNC machines (including DMG MORI, Mazak, and Heller systems) to generate a firm price quote. Unlike basic calculators, our AI factors in secondary operations, fixturing needs, and surface finish requirements. Clients receive a transparent breakdown showing material costs, machine hours, and value-added services with no hidden fees. Typical quote accuracy exceeds 95% against final invoicing.

DFM Analysis

Before order confirmation, our engineering team conducts a comprehensive Design for Manufacturability review. This phase identifies potential issues such as non-optimal wall thicknesses, inadequate tool clearance, or tolerance stack-ups that could increase costs or cause failures. We provide actionable feedback within 72 hours, including suggested modifications to reduce lead time by 15–30% while maintaining functional requirements. All DFM recommendations are validated against AS9100 and ISO 13083 standards for critical applications. Clients approve the final manufacturable design before production begins.

Production Execution

Approved designs move to our climate-controlled manufacturing floor where CNC programmers generate optimized toolpaths using Mastercam and Siemens NX CAM. Parts are machined on appropriate equipment—Heller MC 250/5-axis centers for complex multi-sided work or high-speed vertical mills for simpler geometries. In-process inspections occur at critical stages using Zeiss CMMs and optical comparators, with full first-article inspection reports provided upon request. We maintain NIST-traceable calibration across all metrology equipment.

Delivery Assurance

Finished parts undergo final QA verification against the original CAD model and client specifications. We package components using ESD-safe materials and ship via DHL/FedEx with real-time tracking. Standard lead times are 5–10 business days for 1–100 units, with expedited options available. All shipments include certified material test reports, dimensional reports, and RoHS compliance documentation where applicable. International clients receive customs documentation pre-verified to prevent clearance delays.

Key Process Parameters

| Parameter | Standard Capability | Precision Tier (Heller-grade) |

|——————–|—————————|——————————-|

| Tolerance Control | ±0.025 mm | ±0.005 mm (repeatability) |

| Surface Finish | 3.2 μm Ra | 0.8 μm Ra (critical surfaces) |

| Max Work Envelope | 1200 x 600 x 500 mm | 800 x 400 x 300 mm |

| Material Range | Aluminum, Steel, Titanium | Inconel 718, MP35N, CFRP |

| Lead Time | 7 business days | 10 business days |

This integrated approach minimizes quotation-to-shipment cycles while ensuring components meet the stringent demands of advanced machinery applications. By leveraging AI-driven quoting and mandatory DFM validation, we reduce client rework costs by an average of 22% compared to industry benchmarks. All processes are certified to ISO 9001:2015 with Nadcap accreditation for non-destructive testing.

Start Your Project

Looking for competitive pricing on Heller CNC machines? Contact Susan Leo at [email protected] for detailed quotes and technical specifications. Our manufacturing facility is based in Shenzhen, ensuring high-quality production and efficient lead times. Reach out today to discuss your precision machining needs and discover how Honyo Prototype delivers reliable, cost-effective CNC solutions tailored to your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.