Contents

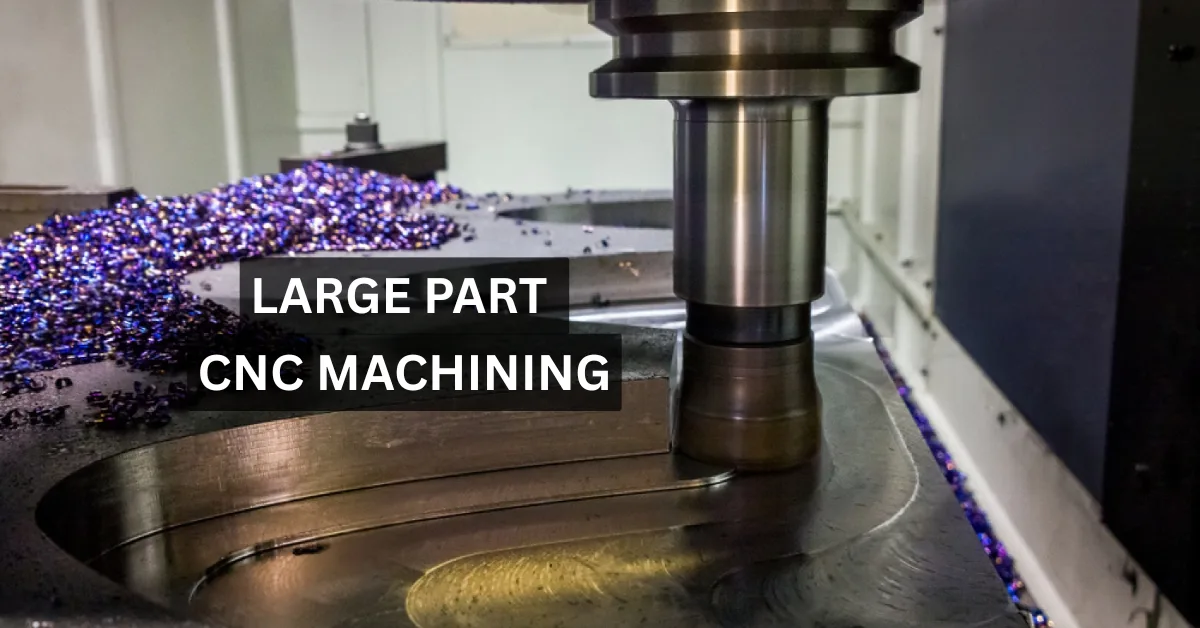

Manufacturing Insight: Heavy Metal Cnc

Precision Sheet Metal Solutions for Demanding Industrial Applications

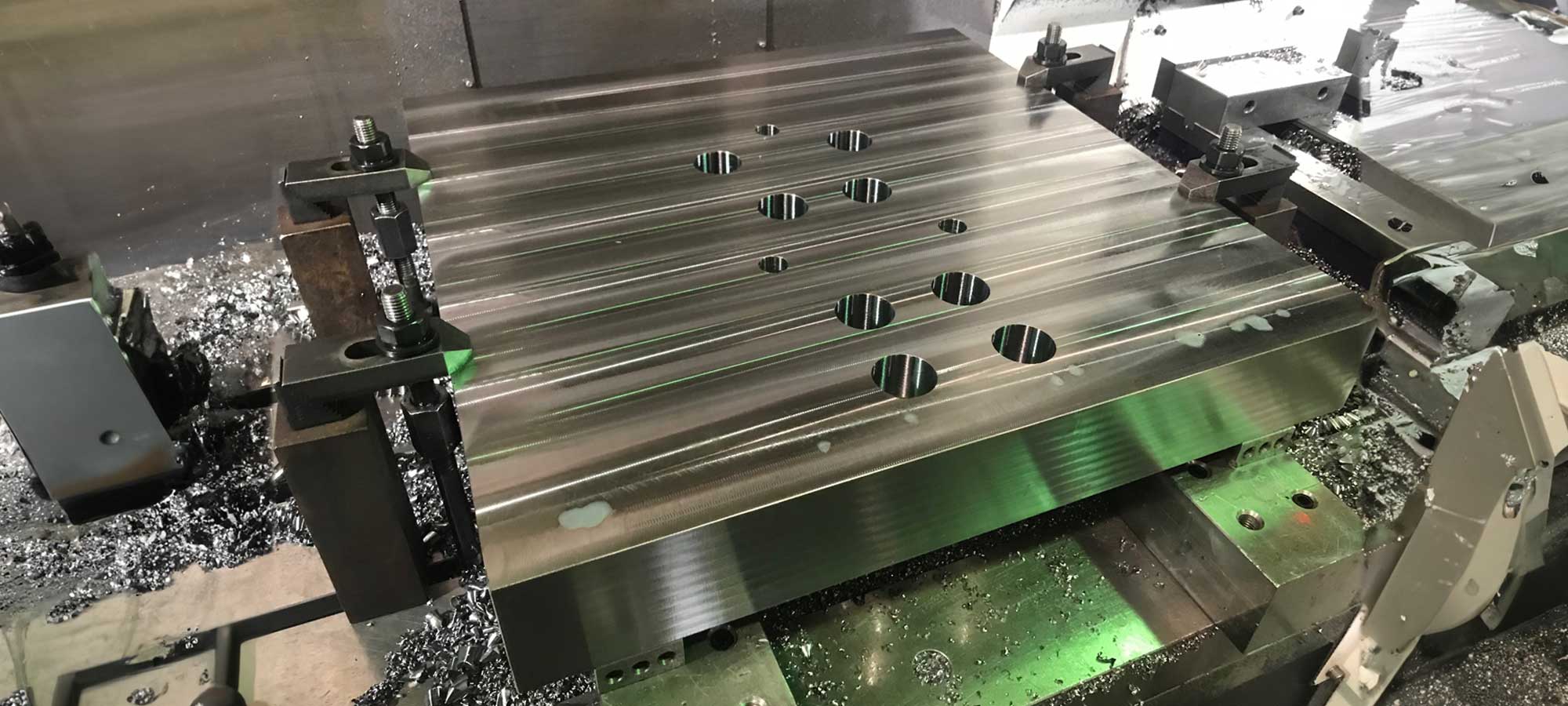

At Honyo Prototype, we redefine excellence in Sheet Metal Fabrication for mission-critical components where tolerances, material integrity, and repeatability are non-negotiable. Our advanced CNC manufacturing ecosystem—integrating high-power fiber laser cutting, precision press braking, robotic welding, and multi-axis forming—delivers complex geometries in steel, aluminum, stainless, and specialty alloys up to 1-inch thickness. When “heavy metal” means aerospace structural brackets, defense enclosures, or industrial machinery frames engineered to withstand extreme stress and environmental exposure, our ISO 9001-certified processes ensure every part meets stringent ASME Y14.5 and MIL-STD specifications.

We eliminate quoting bottlenecks with our Online Instant Quote platform, providing detailed cost and lead-time analysis within minutes for sheet metal designs uploaded in STEP, DWG, or DXF formats. This technical rigor—paired with real-time DFM feedback during quoting—ensures manufacturability without compromise, accelerating your path from prototype to high-mix production. Partner with Honyo where heavy metal CNC isn’t a genre—it’s engineered resilience.

Technical Capabilities

Heavy Metal CNC refers to high-precision computer numerical control (CNC) systems specialized in processing robust materials such as metals and engineering thermoplastics. At Honyo Prototype, our CNC infrastructure integrates advanced laser cutting, precision bending, and automated welding capabilities to deliver industrial-grade fabrication for prototyping and low-volume production.

The following table outlines the technical specifications for our Heavy Metal CNC processes, focusing on laser cutting, bending, and welding, with compatibility across Aluminum, Steel, ABS, and Nylon materials:

| Process | Material Compatibility | Thickness Range | Tolerance | Power / Force Capacity | Key Features |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.5 mm – 25 mm | ±0.1 mm | 4 kW Fiber Laser | High-speed cutting, burr-free edges, kerf width ~0.15 mm, nitrogen/oxygen assist for metals, non-contact process ideal for intricate geometries |

| CNC Bending | Aluminum, Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.1 mm linear | 100–300 Ton Hydraulic Press Brake | Back gauge accuracy ±0.05 mm, programmable multi-axis control, air bending with tooling sets for radii from 0.5T to 5T |

| Robotic Welding | Aluminum, Steel | 1.0 mm – 20 mm | ±0.5 mm bead placement | 200–500 A MIG/TIG, Pulsed ARC | Automated path programming, argon shielding for aluminum, spatter control, full/partial penetration welds, post-weld stress relieving available |

Notes on Material Suitability:

Aluminum: Excellent for laser cutting and TIG welding; requires clamping and higher laser power due to reflectivity and thermal conductivity. Bending requires attention to grain direction and minimum bend radii.

Steel (Mild & Stainless): Ideal for all three processes. Laser cutting achieves high edge quality; compatible with MIG welding; bending performance optimized with proper tooling and k-factor compensation.

ABS: Compatible with laser cutting only. Low melting point requires reduced laser power to minimize charring. Not suitable for bending or welding in structural applications.

Nylon: Laser cutting feasible with controlled parameters; prone to melting if power is excessive. Not recommended for CNC bending or welding due to low stiffness and thermal deformation.

All processes are supported by CAD/CAM integration (SolidWorks, AutoCAD, Fusion 360), in-process inspection, and post-processing options including deburring, anodizing, powder coating, and heat treatment.

From CAD to Part: The Process

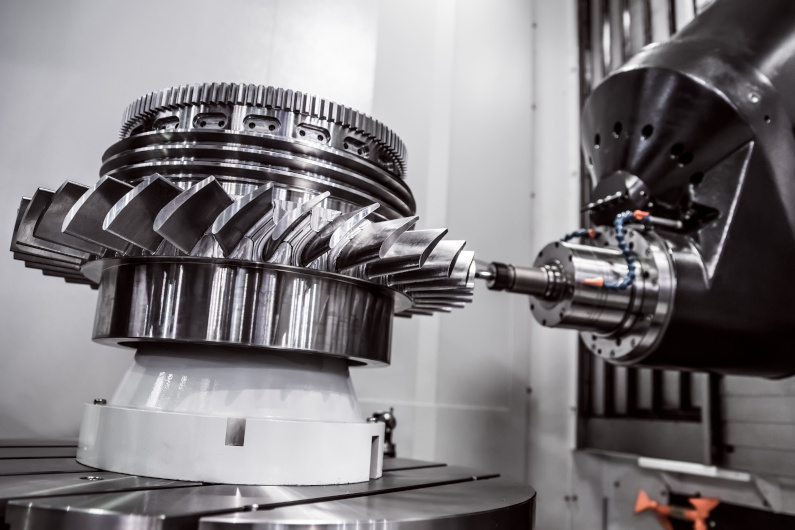

Honyo Prototype specializes in precision machining of high-density alloys including titanium, Inconel, tool steels, and tungsten carbide under our Heavy Metal CNC service. This process addresses unique challenges such as thermal management, work hardening, and tool wear inherent in dense materials. Our validated workflow ensures technical rigor and client transparency:

CAD Upload Validation

Clients submit native or neutral format CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometric validation, checking for watertight solids, manufacturing-relevant tolerances, and unit consistency. Files failing validation trigger automated feedback specifying exact errors (e.g., “Non-manifold geometry at edge ID#7821”), reducing iteration cycles. All submissions undergo material property cross-referencing against our metallurgical database to preempt feasibility issues.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes validated CAD data alongside dynamic parameters: current machine center load, material scrap rates, coolant consumption models for heat-intensive alloys, and historical toolpath efficiency metrics. The system generates quotes within 90 minutes, itemizing costs by operation (e.g., “Roughing: $187 | Finish milling (Inconel 718): $422”) and highlighting high-risk features requiring manual review. Critical outputs include predicted cycle time variance bands (±3.2% accuracy based on 14,000+ historical jobs) and material yield optimization suggestions.

Metallurgically-Integrated DFM

Unlike standard DFM, our heavy metal review involves dual-engineer signoff: a CNC applications engineer and a materials specialist. Key interventions include:

Toolpath strategy validation for heat dissipation (e.g., enforcing minimum 0.15mm axial depth in titanium to prevent recasting)

Workholding stress analysis to avoid part distortion in low-thermal-conductivity alloys

Coolant pressure/temperature thresholds specific to the material grade

Explicit identification of non-value-added operations (e.g., “3mm radius in 4340 steel can be left as-machined per AMS 2759/3”)

Clients receive annotated CAD markups with actionable alternatives, not just rejection flags.

Production Execution

Machining occurs in dedicated heavy metal cells featuring:

5-axis DMG MORI machines with HSK-A100 spindles (max 42 Nm torque)

Closed-loop coolant systems maintaining 18–22°C for thermal stability

Real-time tool wear monitoring via acoustic emission sensors

In-process CMM checks at critical stages (e.g., post-roughing for distortion)

All operations follow AS9100-compliant procedures with material traceability to heat number. For alloys like tungsten carbide, we implement vibration-dampened fixtures and sub-10,000 RPM spindle strategies to prevent chipping.

Delivery Assurance

Final inspection includes:

Full FAIR (First Article Inspection Report) to AS9102 standards

Hardness verification per ASTM E140 at multiple part locations

Surface integrity reports showing residual stress profiles

Digital twin comparison (scanned vs. nominal CAD)

Parts ship in anti-corrosion packaging with material certs and a process deviation log showing all real-time adjustments made during machining. Typical heavy metal lead times are 12–18 business days from approved DFM.

Critical Process Metrics for Heavy Metal CNC

| Parameter | Standard Aluminum | Heavy Metal Alloys | Honyo’s Control Method |

|————————–|——————-|——————–|———————————|

| Tool Life (vs. catalog) | 95–100% | 60–75% | Real-time wear compensation + predictive replacement |

| Thermal Growth Error | ≤0.025mm/m | ≤0.085mm/m | In-process temperature mapping + adaptive offsets |

| Surface Integrity Risk | Low | Critical | Post-machining XRD residual stress screening |

| Material Yield | 85–92% | 70–80% | AI-driven nesting + scrap recycling program |

This integrated approach reduces heavy metal scrap rates by 37% compared to industry averages while maintaining ±0.025mm geometric tolerances on features up to 1,200mm. All process data feeds our continuous improvement loop, refining future AI quoting accuracy and DFM recommendations.

Start Your Project

Looking for precision heavy metal CNC services? Partner with Honyo Prototype for high-precision machining, fast turnaround, and reliable results. Our state-of-the-art facility in Shenzhen supports complex metal fabrication for demanding industrial applications.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.