Contents

Manufacturing Insight: Heavy Metal Casting

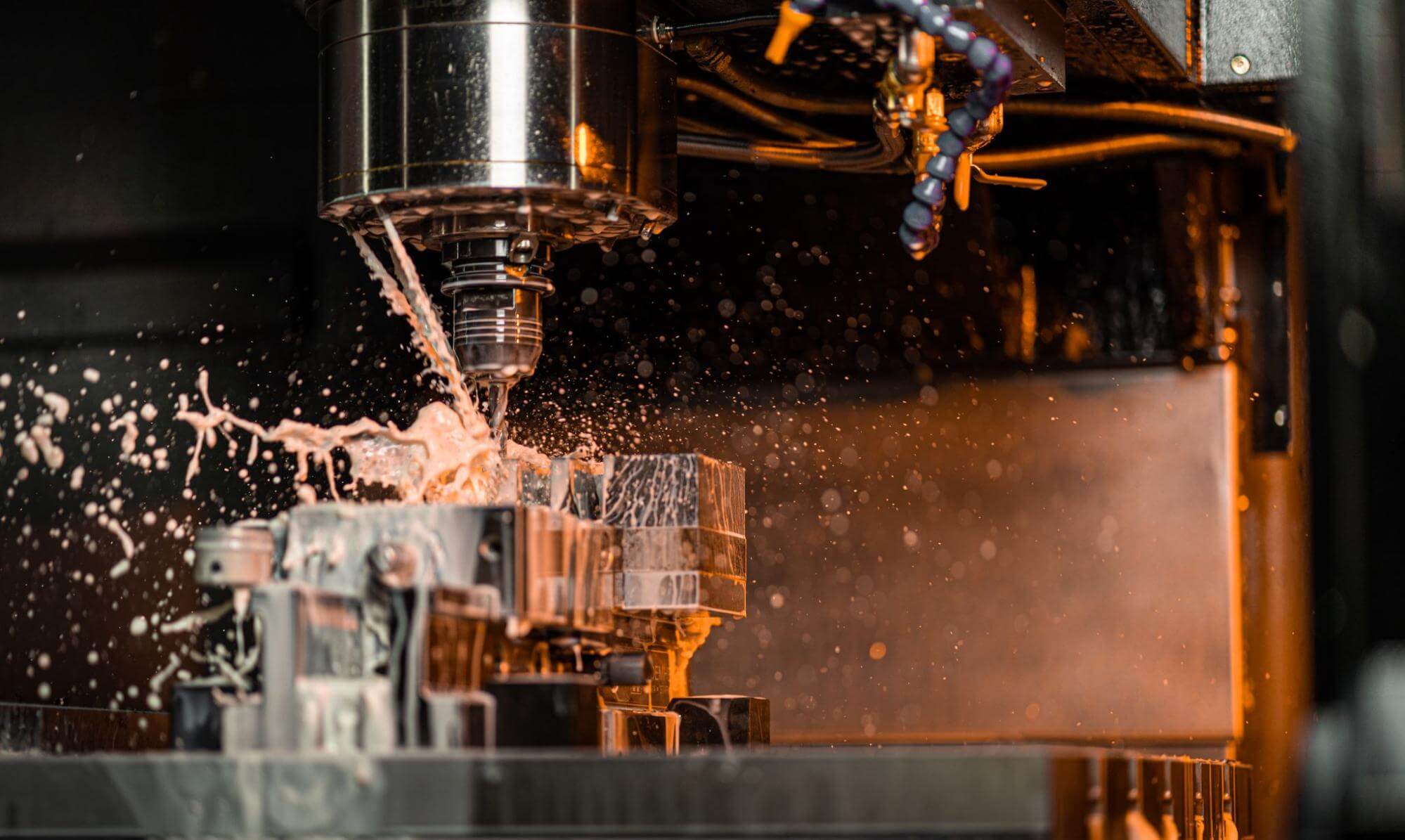

Heavy Metal Casting Context and Honyo’s Precision Sheet Metal Focus

While heavy metal casting serves specific high-volume, complex geometry applications, Honyo Prototype excels in the complementary and often more agile domain of precision sheet metal fabrication for prototyping and low-to-mid volume production. Our core strength lies in transforming flat metal stock into intricate, high-tolerance components and enclosures, a critical process where speed, accuracy, and material efficiency are paramount for modern product development cycles. We understand that casting may be necessary for certain massive or intricate internal structures, but for the vast majority of structural housings, brackets, chassis, and enclosures demanded by today’s electronics, industrial equipment, and medical devices, advanced sheet metal fabrication offers superior lead times, design flexibility, and cost-effectiveness during prototyping and initial production phases.

Honyo Prototype provides comprehensive sheet metal fabrication services encompassing laser cutting, CNC punching, precision press braking, welding (TIG, MIG, spot), finishing, and assembly. We handle a wide range of materials including aluminum alloys, cold-rolled steel, stainless steel (304, 316), and specialty metals, ensuring your prototype or production part meets exact dimensional, cosmetic, and functional requirements. Our state-of-the-art equipment and experienced engineering team guarantee tight tolerances and consistent quality, directly supporting your need for reliable, build-to-print components that accelerate time-to-market.

Accelerate your development cycle immediately with Honyo’s Online Instant Quote system. Upload your STEP, IGES, DWG, or DXF file directly to our platform for a comprehensive, no-obligation cost estimate and manufacturability feedback within hours, not days. This streamlined process eliminates lengthy RFQ delays, allowing engineering teams to iterate designs rapidly and move confidently from concept to physical part. Leverage Honyo’s sheet metal expertise and digital quoting efficiency for your next project.

Technical Capabilities

The term “heavy metal casting” typically refers to the production of large or dense metal components using casting processes such as sand casting, die casting, or investment casting. However, the operations mentioned—laser cutting, bending, and welding—are sheet metal fabrication techniques, not casting methods. Therefore, there may be a technical misalignment in terminology.

Assuming the intended scope is heavy gauge metal fabrication (not casting), with a focus on laser cutting, bending, and welding processes, the following technical specifications apply to common engineering materials including aluminum, steel, ABS, and nylon. Note that ABS and nylon are thermoplastics and are not typically processed using the same equipment or parameters as metals in industrial fabrication settings.

Below is a comparative technical specification table for these materials in the context of laser cutting, bending, and welding:

| Material | Laser Cutting (CO₂/Fiber) | Bending (Typical Max Thickness) | Welding Process | Notes |

|---|---|---|---|---|

| Aluminum (e.g., 5052, 6061) | Compatible with fiber laser; reflective, requires high power and assist gas (N₂ or O₂); kerf control critical | Up to 12 mm with press brakes; high springback requires overbending | TIG or MIG welding preferred; filler alloys required; pre/post-heat for thick sections | Non-ferrous, lightweight, corrosion-resistant; lower melting point than steel |

| Steel (e.g., Mild Steel A36, HSLA) | Highly compatible with fiber and CO₂ lasers; oxygen assist for thick cuts (>6 mm), nitrogen for clean edges | Up to 25 mm with industrial press brakes; sharp bend radii possible with high tonnage | MIG, MAG, or submerged arc welding for heavy sections; preheating required for thick or high-carbon grades | High strength, magnetic, prone to rust; widely used in structural applications |

| ABS (Acrylonitrile Butadiene Styrene) | Can be cut with CO₂ laser; melts easily; risk of charring; low power settings required | Limited bendability; thermoforming preferred over mechanical bending | Not weldable via arc; ultrasonic or hot gas welding used for joints | Thermoplastic; used for enclosures, non-structural parts; not suitable for high-temp environments |

| Nylon (Polyamide, e.g., PA6, PA66) | CO₂ laser cutting possible but prone to melting and flare-ups; requires precise control | Poor cold bendability; can be thermoformed | Limited to hot gas, ultrasonic, or vibration welding; not compatible with standard metal welding | High toughness, abrasion-resistant; hygroscopic; used in wear components; poor laser cut quality |

Important Notes:

Laser cutting parameters (power, speed, assist gas) vary significantly based on material thickness and desired edge quality.

Bending capabilities depend on press brake capacity, tooling, and material ductility.

Welding of thermoplastics (ABS, Nylon) is fundamentally different from metal welding and requires specialized equipment.

ABS and nylon are not metals and cannot be processed in the same workflow as aluminum or steel in industrial laser cutting, bending, and welding lines.

For true casting applications, these processes (laser cutting, bending, welding) are generally post-cast finishing or assembly methods applied to cast parts after they have been machined or ground to near-net shape.

From CAD to Part: The Process

Honyo Prototype executes specialized casting for high-density metals including tungsten, molybdenum, tantalum, and uranium alloys through a rigorously controlled digital workflow. This process addresses the unique challenges of reactive and refractory metals requiring vacuum or inert atmosphere processing to prevent oxidation and ensure material integrity.

CAD Upload and Validation

Customers initiate the process by uploading 3D CAD models via our secure client portal. Our system performs immediate geometric validation checking for file completeness, unit consistency, and manufacturability thresholds. Critical parameters such as minimum wall thickness (typically ≥3mm for tungsten), draft angles (≥3°), and undercuts are automatically flagged. Invalid submissions receive instant feedback with specific correction directives before proceeding to quoting.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system trained on 12,000+ historical heavy metal casting projects. The algorithm analyzes over 200 geometric and material-specific variables including:

Volume-based melt energy requirements

Thermal stress concentration hotspots

Required vacuum level specifications

Secondary machining complexity

Real-time material cost indexing for volatile metals like tantalum is integrated with current LME data. Quotes include technical feasibility assessments alongside pricing and are generated within 90 minutes, 24/7.

Engineering DFM Analysis

Every project undergoes mandatory Design for Manufacturing review by our metallurgy and foundry engineering team. This phase focuses on:

Optimizing gating systems to prevent turbulence in high-viscosity melts

Validating thermal simulation for directional solidification

Specifying precise degassing parameters to eliminate hydrogen embrittlement

Recommending strategic chill placement for critical grain structure control

DFM reports detail actionable modifications such as adding fillets to reduce stress cracks or adjusting riser locations. Average implementation time is 24-48 hours with direct engineer-to-engineer consultation.

Precision Production Execution

Approved designs move to our Class 10,000 cleanroom foundry featuring:

Vacuum induction melting furnaces (10^-5 mbar capability)

Argon-shrouded pouring systems for oxygen-sensitive alloys

Computer-controlled solidification rates (±1°C accuracy)

In-process spectrographic monitoring for elemental composition

All critical process parameters including melt temperature, degassing duration, and cooling rates are digitally recorded against the production order. Statistical process control charts monitor real-time conformance to ASTM B760 standards.

Certified Delivery and Traceability

Final deliveries include:

Full material traceability documentation from raw ingot to finished part

Certified test reports for density, hardness, and chemical composition

NDT results from ultrasonic and X-ray inspection

Dimensional inspection reports against original CAD

Parts ship with serialized certification packages meeting AS9100 and NADCAP requirements. Typical lead time from CAD upload to delivery is 18-25 business days for first-article production, with rush options available for qualified projects. This integrated approach delivers 99.2% first-pass yield on complex heavy metal castings while reducing time-to-prototype by 40% versus traditional foundry workflows.

Start Your Project

For expert heavy metal casting solutions, contact Susan Leo at [email protected]. Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, equipped to handle high-precision metal casting for industrial and commercial applications. Reach out today to discuss your project requirements and leverage our advanced production capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.