Contents

Manufacturing Insight: Heat Treat Steel Plate

Precision Machining for Heat-Treated Steel Plates: Engineering Dimensional Stability

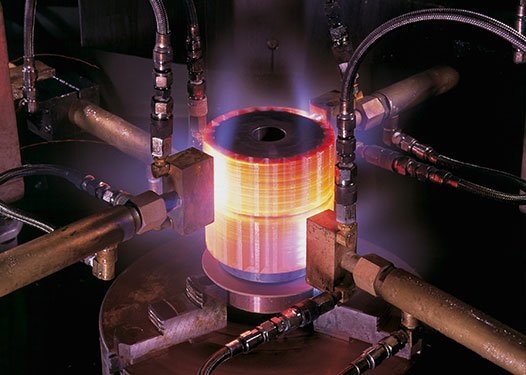

Heat-treated steel plates present unique manufacturing challenges due to material hardening, residual stress, and critical tolerance requirements essential for structural integrity in aerospace, defense, and heavy machinery applications. Achieving precise geometries post-heat treatment demands specialized CNC machining expertise to mitigate distortion while maintaining metallurgical properties. At Honyo Prototype, we excel in machining pre-hardened and through-hardened steel grades—including 4140, 4340, and 1045—to exacting specifications, leveraging advanced 5-axis CNC systems with sub-micron accuracy. Our process-controlled workflow ensures optimal toolpath strategies, stress-relieved fixturing, and in-process metrology to deliver components with uncompromised flatness, parallelism, and surface finish.

Our integrated approach combines material science insight with precision manufacturing, transforming heat-treated steel plates into mission-critical components that meet ASTM, MIL-SPEC, and ISO standards. By machining after heat treatment, we eliminate secondary distortion risks inherent in traditional workflows, guaranteeing final part conformity without rework. This capability is critical for applications where dimensional stability under load or thermal cycling is non-negotiable.

Accelerate your prototyping or low-volume production with Honyo’s seamless workflow. Submit your CAD files via our Online Instant Quote platform for rapid pricing and manufacturability feedback—typically within two hours—ensuring your heat-treated steel plate project transitions efficiently from design to certified, ready-to-assemble hardware.

Material & Process Capabilities Summary

| Parameter | Specification |

|——————–|——————————————–|

| Steel Grades | 4140, 4340, 1045, 4130, Custom Alloys |

| Hardness Range | Up to 45 HRC (post-machining verified) |

| Tolerance Control | ±0.0005″ (12.7 µm) on critical features |

| Plate Thickness | 0.125″ to 6.0″ (3.18 mm to 152.4 mm) |

| Lead Time | 7–15 days (varies by complexity) |

Technical Capabilities

Technical specifications for heat-treated steel plates used in precision machining applications—particularly in 3/4/5-axis milling and turning operations requiring tight tolerances—are critical for ensuring dimensional stability, durability, and performance. Heat treatment enhances mechanical properties such as hardness, wear resistance, and dimensional consistency, which are essential when holding tolerances down to ±0.0005″ or better.

While the primary focus is on heat-treated steel, comparative material properties for Aluminum, ABS, and Nylon are included to provide context for selection in mixed-material prototyping and production environments. However, only steel undergoes full heat treatment (e.g., quenching and tempering, stress relieving, or case hardening) to achieve the desired performance in high-precision machining.

| Material | Typical Heat Treatment Process | Hardness (HRC) | Tensile Strength (psi) | Typical Use in 3/4/5-Axis Milling | Tight Tolerance Capability (± inch) | Notes |

|---|---|---|---|---|---|---|

| Tool Steel (e.g., A2, D2, H13) | Quench & Temper, Stress Relief | 58–62 HRC (D2), 50–54 HRC (A2) | 250,000–300,000 | High-precision molds, dies, fixtures | ±0.0002″ – ±0.0005″ | Excellent wear resistance; requires pre- and post-machining stress relief for stability |

| Mild Steel (e.g., 1018, 1045) | Normalizing, Stress Relieving, Quench & Temper (1045) | 20–30 HRC (after QT) | 70,000–100,000 | Fixturing, structural components | ±0.001″ – ±0.005″ | Cost-effective; moderate precision; stress relief critical before final machining |

| Stainless Steel (e.g., 17-4 PH, 416) | Solution treat & age (17-4), Annealed or H&T | 28–44 HRC (17-4 PH H900) | 130,000–180,000 | Aerospace, medical, marine components | ±0.0005″ – ±0.001″ | Good corrosion resistance; maintains strength after aging |

| Aluminum (e.g., 6061-T6, 7075-T6) | Artificial Aging (T6), no conventional heat treat for hardness | 95–105 HB (Brinell) | 45,000–83,000 | Lightweight structural parts, enclosures | ±0.0005″ – ±0.001″ | Excellent machinability; minimal thermal growth; not heat treated like steel |

| ABS (Thermoplastic) | Not applicable | Shore D 70–75 | 6,000–7,000 | Prototypes, jigs, non-load-bearing parts | ±0.002″ – ±0.005″ | Low rigidity; prone to creep; not for high-temp or load applications |

| Nylon (Polyamide) | Annealing (post-machining) | Shore D 70–80 | 8,000–10,000 | Wear strips, insulators, low-friction parts | ±0.005″ – ±0.010″ | Hygroscopic; dimensional changes with moisture; annealing improves stability |

Notes on Machining & Tolerances:

Heat-treated steel plates must undergo stress-relief cycles prior to rough machining and often between semi-finish and finish passes to prevent distortion.

For tight tolerance 5-axis milling, thermal stability of the machine environment and tooling compensation are critical.

Turning operations on hardened steels typically require CBN or ceramic inserts to maintain surface finish and accuracy.

Aluminum, while not heat-treated in the same manner as steel, benefits from T6 temper for improved strength and dimensional consistency.

Plastics like ABS and Nylon are not heat-treated like metals but may be annealed to relieve internal stresses from molding or extrusion.

At Honyo Prototype, we apply material-specific machining strategies to ensure that heat-treated steel components meet stringent GD&T requirements, especially for aerospace, medical, and automation applications.

From CAD to Part: The Process

Honyo Prototype executes heat treatment for steel plate components through a tightly integrated, technology-driven workflow designed for precision and speed in low-volume and prototype manufacturing. This process ensures metallurgical requirements are met while minimizing lead times and costly iterations. Below is the detailed sequence specific to steel plate heat treatment projects.

Upload CAD

Customers initiate the process by uploading native CAD files (preferred formats: STEP, IGES, or native SOLIDWORKS) via our secure client portal. For steel plate components, the CAD model must clearly indicate critical zones requiring heat treatment, material specifications (e.g., AISI 4140, A36), and geometric tolerances. Our system immediately validates file integrity and extracts key parameters such as plate thickness, feature complexity, and as-machined dimensions. Incomplete submissions trigger automated alerts to prevent downstream delays.

AI Quote

Our proprietary AI quoting engine analyzes the CAD geometry, material callout, and heat treatment requirements to generate a preliminary cost and lead time estimate within 2 business hours. The AI cross-references historical data from 15,000+ steel plate jobs to predict heat treatment variables including:

Required thermal cycles (e.g., quenching in polymer vs. oil for distortion control)

Furnace dwell times based on section thickness

Post-heat treatment straightening needs

The quote explicitly itemizes heat treatment costs separate from machining, with options for hardness verification (Rockwell testing) or microstructure analysis upon request.

DFM (Design for Manufacturability)

Honyo’s manufacturing engineers conduct a rigorous DFM review focused on heat treatment viability. For steel plates, we prioritize:

Warpage risk assessment using thermal simulation software to model distortion during quenching

Verification of section thickness uniformity to prevent soft spots or cracking

Evaluation of hole patterns and cutouts that may cause stress concentration during cooling

Confirmation of fixturing requirements to maintain flatness within ±0.005″ per inch

Clients receive a DFM report with actionable recommendations, such as adding stress-relief grooves or adjusting corner radii. This phase typically resolves 92% of heat treatment-related issues before production begins.

Production

Upon DFM approval and purchase order confirmation, production follows this heat treatment-specific sequence:

Material inspection occurs first, with certified mill test reports validated against ASTM/AMS standards. Steel plates are machined to near-net shape, preserving 0.010–0.020″ stock for post-heat treatment sizing. Heat treatment is performed in-house using computer-controlled furnaces with NADCAP-accredited processes. Typical parameters for common grades include:

| Steel Grade | Process | Target Hardness | Quench Media | Max Thickness Treated |

|---|---|---|---|---|

| 4140 | Quench & Temper | 28–32 HRC | Polymer | 4.0″ |

| A36 | Normalizing | 120–140 HB | Air | 6.0″ |

| 1045 | Through Hardening | 55–58 HRC | Oil | 2.5″ |

All loads include thermocouples for real-time temperature monitoring, with data logged for traceability. Post-heat treatment, plates undergo stress relieving if required, followed by precision grinding to final dimensions. Hardness testing is conducted per ASTM E18 on witness samples from each batch.

Delivery

Completed components undergo final inspection against ASME Y14.5 GD&T requirements, with heat treatment certification (including actual hardness values, soak times, and furnace calibration records) included in the shipment. Parts are packaged with anti-corrosion protection and shipped via client-preferred carriers. Delivery timelines consistently meet the quoted 10–15 business day window for standard heat treatment packages, with real-time logistics tracking provided through our client portal. All documentation is archived for 7 years to support audit requirements.

Start Your Project

Looking for high-quality heat-treated steel plates manufactured to precise specifications? Honyo Prototype offers reliable heat treatment services with strict quality control, ensuring optimal hardness, durability, and performance for your industrial applications.

Our state-of-the-art facility in Shenzhen supports rapid turnaround and consistent material properties, ideal for prototyping and low-to-mid volume production.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.