Guide Contents

Project Insight: Heat Treat Steel Plate

Why Speed and Precision Matter in Heat-Treated Steel Plate Manufacturing

The Hidden Costs of Traditional Heat Treatment Methods

Inconsistent results from manual or makeshift setups (e.g., propane torches and refractory bricks) compromise material integrity and product reliability

Manual cost estimation leads to budget overruns and delays in procurement planning

Extended lead times stall iterative design cycles, delaying market entry for hardware startups

Honyo’s Digital Manufacturing Ecosystem: Precision Engineered for Speed

Online Instant Quote: Get real-time pricing in seconds—no back-and-forth emails or delays

AI-Powered Parameter Optimization: Automatically adjust heating/cooling cycles for consistent hardness, microstructure, and structural integrity

Seamless Integration: From prototype to high-volume production, our platform synchronizes heat treatment with CNC machining, welding, and finishing in a single workflow

Accelerate Time-to-Market with Unmatched Turnaround

24-48 Hour Prototyping: Heat-treated steel parts ready in days, not weeks—ideal for rapid design validation

Real-Time Quality Assurance: Automated inspection at every stage ensures compliance with ISO 9001 standards and material specifications

Scalable Solutions: Effortlessly transition from 1 unit to 10,000+ with zero setup delays or retooling costs

At Honyo Prototype, we don’t just treat steel—we engineer outcomes. Our digital ecosystem turns your design into a high-performance part, faster and more reliably than ever before.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Heat Treatment for Steel Plates: Engineered for Performance and Scalability

Online Instant Quote System

Real-time pricing for any volume—scale from 1 prototype to 10,000+ production parts with zero retooling or cost spikes.

Transparent, AI-optimized cost breakdowns (materials, processing, logistics) delivered in seconds—no manual estimates, no hidden fees.

AI-Powered Digital Manufacturing Ecosystem

Machine learning algorithms dynamically adjust heat treatment parameters (temperature, soak time, cooling rates) based on steel grade and part geometry for optimal hardness and minimal distortion.

Digital twin simulation validates process parameters pre-production, eliminating trial-and-error and reducing lead times by up to 40%.

Seamless CAD/CAM integration ensures end-to-end digital workflow from design to delivery with zero data gaps.

Fast Turnaround with ISO-Certified Quality

24–72 hour lead times for standard orders—expedited options available for urgent prototypes or production runs.

Rigorous ISO 9001-compliant QC: hardness testing, microstructure analysis, and dimensional verification with full traceability.

IoT-enabled real-time monitoring ensures 100% conformity to specifications, even at scale.

Powered by Honyo Prototype’s Shenzhen-based digital ecosystem—where innovation meets precision for hardware startups and engineering teams.

Materials & Surface Finishes

Material Options & Finishes for Heat-Treated Steel Plates

Material Selection for Heat Treatment

Metals (Heat-Treatable Grades):

AISI 1045: Ideal for general industrial use with balanced strength and machinability.

4140 Alloy Steel: High hardenability for high-stress components (e.g., gears, shafts).

4340 High-Strength Alloy: Superior fatigue resistance for aerospace and automotive applications.

17-4PH Stainless Steel: Combines corrosion resistance with high strength via precipitation hardening.

Tool Steels (D2, A2, H13): Extreme wear resistance for molds, dies, and cutting tools.

Plastics Note:

Heat treatment is not applicable to plastics due to thermal degradation. For plastic components requiring thermal processing, explore our [Plastic Prototyping Services].

Surface Finishes for Heat-Treated Steel

Corrosion Protection & Durability:

Powder Coating: Customizable colors with exceptional UV and chemical resistance.

Zinc Plating: Cost-effective rust prevention for outdoor or marine environments.

Black Oxide: Minimal dimensional change + aesthetic enhancement for mild corrosion resistance.

Electroless Nickel: Uniform coating for complex geometries and high-wear surfaces.

Shot Peening: Boosts fatigue life for cyclic-loading applications (e.g., springs, axles).

Passivation (Stainless Steel): Removes surface contaminants to maximize corrosion resistance.

Note on Anodizing:

This process is exclusive to aluminum alloys. For anodized components, see our [Aluminum Machining Services].

How to Choose the Right Material for Heat-Treated Steel Plates

🔍 Application-Driven Decisions

Strength & Hardness Needs:

High-stress parts → 4140 or 4340 (optimal toughness and hardenability).

Wear-critical tools → D2 or H13 tool steel (retains hardness under extreme loads).

Corrosion Resistance:

Marine or chemical exposure → 17-4PH stainless steel (heat-treatable + corrosion-resistant).

Machinability & Cost:

Budget-friendly prototypes → AISI 1045 (easy to machine pre-heat treatment).

💡 Honyo’s Digital Advantage

Online Instant Quote:

Get real-time pricing for your exact material, thickness, and finish—no manual calculations.

AI-Powered Platform:

Our algorithm analyzes your design specs to recommend the optimal material grade and process parameters—cutting prototyping cycles by 40%.

Fast Turnaround:

Heat treatment + finishing completed in 72 hours via automated workflow. From prototype to production—seamlessly integrated.

“At Honyo, we don’t just heat-treat steel—we engineer solutions. Our digital ecosystem ensures your components meet exacting standards, faster and smarter than ever.”

— Susan Leo, Founder

Ready to optimize your steel components? [Get Your Instant Quote Now] →

From Quote to Part: Our Process

Seamless Workflow: From CAD to Heat-Treated Steel Plate in Record Time

Honyo Prototype’s digital manufacturing ecosystem redefines efficiency for heat-treated steel plate production. Our end-to-end process eliminates traditional bottlenecks, delivering precision-engineered components with unmatched speed and transparency—no guesswork, no third-party handoffs, just engineering excellence from day one.

1. Upload CAD File in Seconds

Drag-and-drop your design (STEP, IGES, STL, or native CAD formats) into our cloud-based platform

Real-time validation checks ensure file compatibility before processing

Zero software installation required—access your project from anywhere, anytime

2. Instant AI-Powered Quote

Proprietary algorithm analyzes geometry, material specs, and heat treatment requirements in <60 seconds

Transparent pricing with no hidden fees—breakdown includes material, processing, and logistics

Compare scenarios instantly (e.g., AISI 1045 vs. 4140 steel, quenching vs. tempering parameters)

3. Proactive DFM Analysis

AI flags potential issues before production (e.g., thermal stress risks, uneven cooling zones, distortion hotspots)

Engineer-reviewed recommendations optimize design for cost-effective heat treatment

Collaborative platform enables real-time feedback—no email chains or delays

4. Precision Production & Fast Delivery

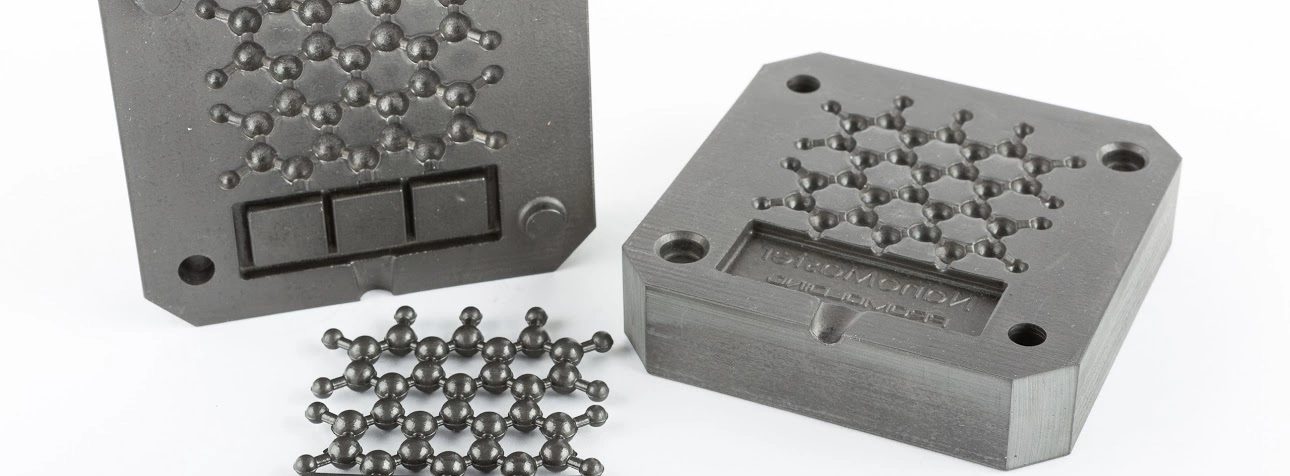

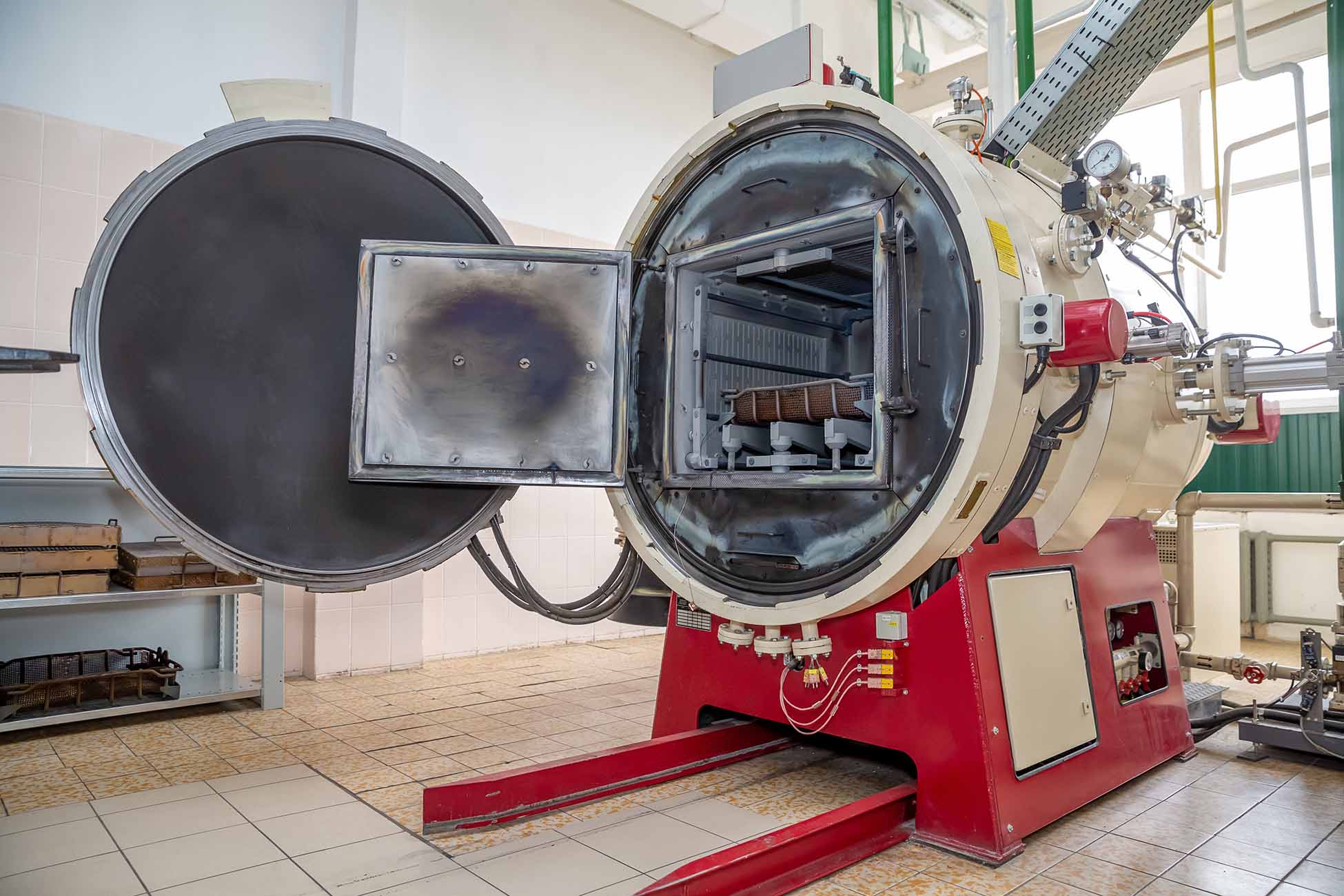

Integrated in-house capabilities: CNC machining → controlled atmosphere heat treatment → final finishing

Automated quality control with real-time monitoring at every stage

Track your order from production to doorstep with live shipment updates—prototypes in 24h, production batches in 3–5 days

“At Honyo, we don’t just process steel—we engineer solutions. Our digital ecosystem turns your design into a heat-treated part faster than traditional suppliers can quote.”

— Susan Leo, Founder & Chief Innovation Officer

Ready to transform your heat treatment workflow? [Upload Your CAD Now] → Get a quote in 60 seconds.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Heat Treatment, Simplified

Instant, AI-Powered Cost Estimation

Get real-time quotes in seconds—no manual calculations or delays

Dynamic pricing based on material grade, dimensions, and treatment type (quenching, tempering, case hardening)

Transparent cost breakdown with zero hidden fees—see exactly what you’re paying for

End-to-End Digital Manufacturing Ecosystem

Seamlessly integrate heat treatment into your full production workflow—from design to delivery

Automated process control ensures consistent hardness, structural integrity, and compliance with industry standards

One-stop solution: Coordinate heat treatment with machining, welding, or finishing in a single platform

48-Hour Turnaround Guarantee

Rapid heat treatment cycles without compromising precision or quality

Expedited shipping options for urgent prototyping or production runs

Real-time project tracking via our digital dashboard—monitor progress from anywhere

Founder Susan Leo and our Shenzhen/Dongguan engineering team are ready to bring your vision to life.

📞 Contact us: [email protected] | +86 139 2843 8620

📍 Visit our facilities in Shenzhen and Dongguan for hands-on collaboration

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.