Introduction: Navigating the Global Market for heat resistant sheet

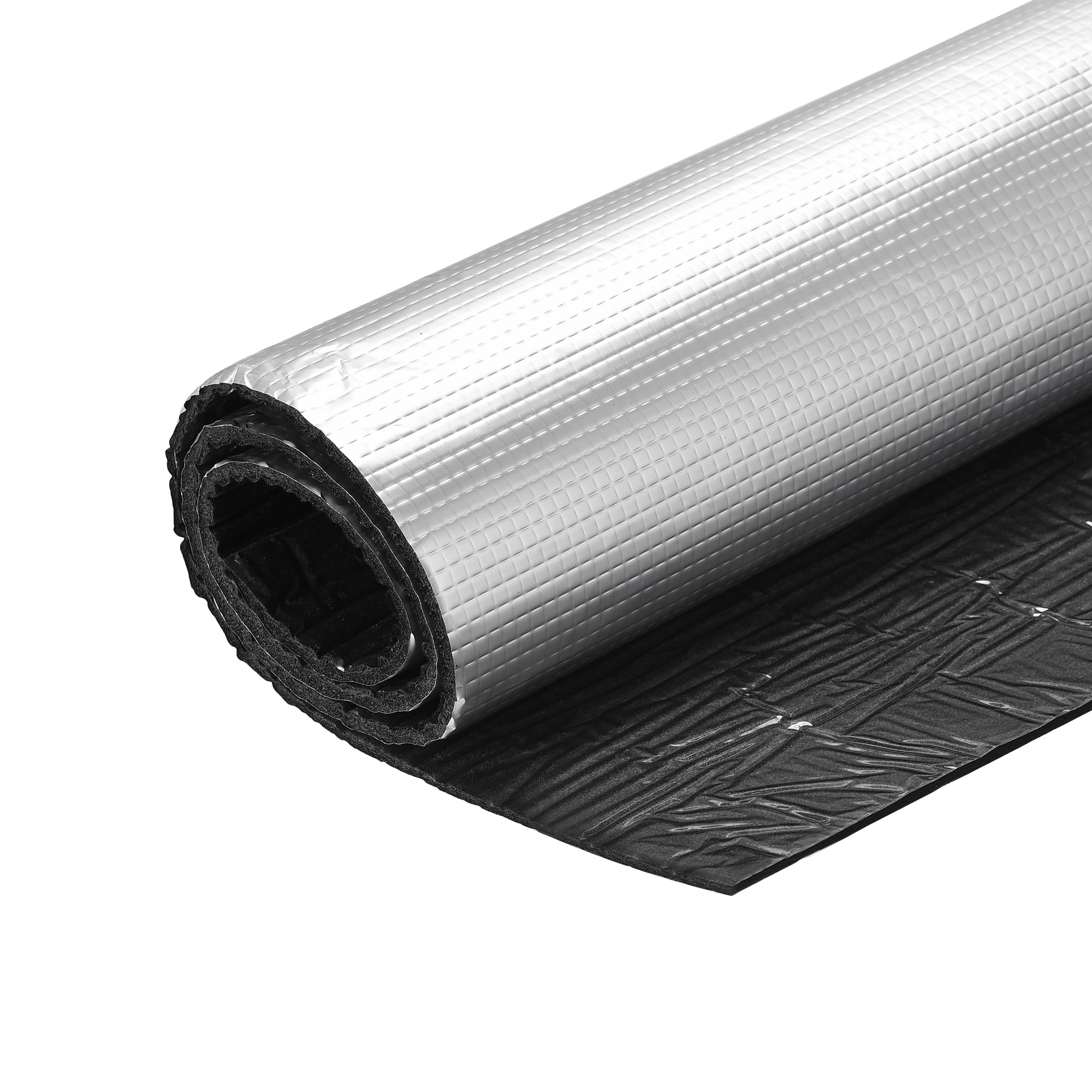

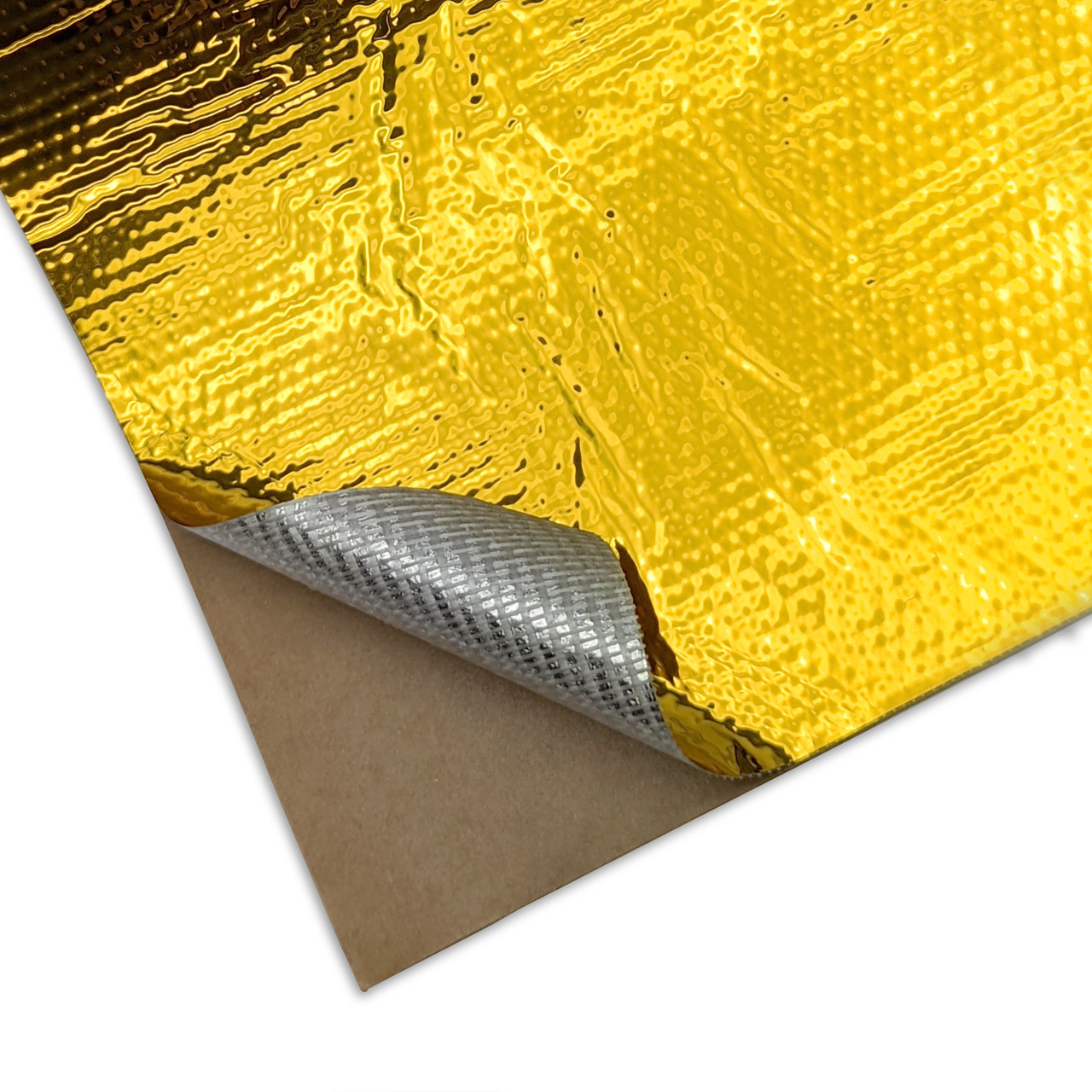

In today’s rapidly evolving industrial landscape, sourcing the right heat resistant sheet can be a daunting challenge for international B2B buyers. The demand for materials that can withstand extreme temperatures is surging across various sectors, including automotive, aerospace, and manufacturing. However, identifying high-quality suppliers and understanding the diverse types of heat resistant sheets available can significantly impact production efficiency and product longevity. This guide aims to demystify the complexities of the global market for heat resistant sheets, providing essential insights into the various materials, their applications, and how to effectively vet suppliers.

We will explore the different types of heat resistant sheets—ranging from silicone and rubber to advanced plastic composites—highlighting their unique properties and suitability for specific applications. Additionally, this guide will address critical factors such as pricing structures, sourcing strategies, and the importance of establishing long-term supplier relationships. For international buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—this comprehensive resource will empower you to make informed purchasing decisions, streamline your procurement processes, and ultimately enhance your operational capabilities. By leveraging the insights provided in this guide, you can navigate the complexities of the heat resistant sheet market with confidence, ensuring that your business stays competitive and resilient.

Understanding heat resistant sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Rubber Sheets | High temperature resistance, flexibility | Automotive seals, gaskets, insulation | Pros: Durable, versatile; Cons: Can be costly. |

| Polycarbonate Sheets | Impact-resistant, lightweight, high clarity | Safety shields, machine guards, signage | Pros: Strong, transparent; Cons: Prone to scratching. |

| Melamine Sheets | Hard surface, chemical resistance | Furniture surfaces, cabinetry | Pros: Aesthetic, easy to clean; Cons: Limited heat tolerance. |

| PTFE (Teflon) Sheets | Extremely low friction, non-stick properties | Food processing, chemical equipment | Pros: High chemical resistance; Cons: Expensive, may require special handling. |

| Acrylic Sheets | Lightweight, good optical clarity | Displays, protective barriers, lighting fixtures | Pros: Versatile, easy to fabricate; Cons: Less heat resistant than others. |

What are the characteristics of Silicone Rubber Sheets for B2B buyers?

Silicone rubber sheets are renowned for their exceptional heat resistance, capable of withstanding temperatures ranging from -60°C to 250°C. Their flexibility and durability make them ideal for applications requiring sealing and insulation, particularly in the automotive and aerospace industries. When purchasing, buyers should consider the thickness and grade of silicone, as these factors influence performance and cost. Additionally, the ability to withstand various environmental conditions further enhances their appeal in diverse applications.

How do Polycarbonate Sheets meet the needs of B2B applications?

Polycarbonate sheets are highly valued for their impact resistance and lightweight nature, offering a superior alternative to glass. With a high level of clarity, they are often used in safety shields and machine guards, making them a popular choice in manufacturing and construction sectors. Buyers should evaluate the sheet’s thickness and UV resistance, as these attributes determine its suitability for outdoor applications. While polycarbonate is durable, its susceptibility to scratching may necessitate protective coatings for certain uses.

What advantages do Melamine Sheets provide in industrial settings?

Melamine sheets feature a hard surface that is resistant to scratches and stains, making them a practical choice for furniture and cabinetry in commercial environments. Their aesthetic appeal, combined with easy maintenance, positions them favorably in retail and office design. When considering melamine sheets, buyers should assess the color and finish options available, as well as the sheet’s resistance to heat and chemicals. However, it is important to note that melamine has a lower heat tolerance compared to other materials, which may limit its application in high-temperature areas.

Why are PTFE (Teflon) Sheets essential for specific industries?

PTFE sheets, commonly known by the brand name Teflon, are prized for their non-stick and low friction properties, making them ideal for food processing and chemical equipment applications. Their ability to withstand extreme temperatures and resist chemical degradation adds to their versatility. B2B buyers should focus on the thickness and purity of PTFE sheets, as these factors can significantly impact performance in specialized applications. However, the higher cost and potential handling challenges associated with PTFE should be considered in the procurement process.

How do Acrylic Sheets serve various business needs?

Acrylic sheets are lightweight and provide excellent optical clarity, making them a versatile material for displays, protective barriers, and lighting fixtures. Their ease of fabrication allows businesses to customize shapes and sizes to fit specific applications. Buyers should consider the thickness and type of acrylic, as well as its heat resistance capabilities, which may vary. While acrylic offers many advantages, its lower heat resistance compared to other materials may limit its use in high-temperature environments, necessitating careful evaluation based on the intended application.

Key Industrial Applications of heat resistant sheet

| Industry/Sector | Specific Application of Heat Resistant Sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Insulation for High-Temperature Equipment | Reduces energy costs and enhances equipment lifespan | Temperature tolerance, thickness, and compliance with safety standards |

| Food Processing | Protective Barriers in Cooking Equipment | Ensures food safety and hygiene while withstanding heat | FDA compliance, material durability, and ease of cleaning |

| Automotive | Heat Shields for Engine Components | Protects sensitive parts from heat damage, improving reliability | Material specifications, weight, and performance under stress |

| Electronics | Heat Sinks in Circuit Boards | Enhances performance and longevity of electronic devices | Thermal conductivity, size, and compatibility with existing designs |

| Construction and HVAC | Thermal Barriers in Building Applications | Improves energy efficiency and comfort in structures | Insulation properties, fire resistance, and local building codes |

How is Heat Resistant Sheet Used in Manufacturing?

In manufacturing, heat resistant sheets are integral for insulating high-temperature equipment, such as furnaces and boilers. These sheets help maintain optimal operating temperatures, thus reducing energy costs and prolonging equipment life. For international buyers, especially those in regions with varying climatic conditions, it is crucial to consider the temperature tolerance and thickness of the sheets, along with adherence to local safety standards.

What Role Does Heat Resistant Sheet Play in Food Processing?

In the food processing industry, heat resistant sheets are employed as protective barriers in cooking equipment. They not only ensure food safety and hygiene by preventing contamination but also withstand high temperatures during cooking processes. Buyers must prioritize materials that are FDA-compliant, durable, and easy to clean, particularly in regions with strict food safety regulations, such as Europe and North America.

How Are Heat Resistant Sheets Beneficial in the Automotive Sector?

Automotive manufacturers utilize heat resistant sheets for heat shields in engine components. These sheets protect sensitive parts from the intense heat generated during operation, thus improving the reliability and performance of vehicles. Buyers in this sector should focus on material specifications, weight, and performance under stress, especially in markets like South America and Africa, where vehicle durability is paramount.

What is the Application of Heat Resistant Sheet in Electronics?

In the electronics industry, heat resistant sheets are used as heat sinks in circuit boards, helping to dissipate heat generated by electronic components. This application enhances the performance and longevity of devices, making them more reliable for consumers. International B2B buyers should consider thermal conductivity, size, and compatibility with existing designs to ensure optimal performance in their products.

How Do Heat Resistant Sheets Contribute to Construction and HVAC?

In construction and HVAC applications, heat resistant sheets serve as thermal barriers, significantly improving energy efficiency and comfort within buildings. They are essential in reducing heat transfer, which can lead to lower energy costs. Buyers need to evaluate insulation properties, fire resistance, and compliance with local building codes, particularly in regions prone to extreme weather conditions, such as the Middle East and parts of Europe.

3 Common User Pain Points for ‘heat resistant sheet’ & Their Solutions

Scenario 1: Inconsistent Product Quality Leading to Production Delays

The Problem: One significant challenge faced by B2B buyers of heat-resistant sheets is the inconsistency in product quality from different suppliers. This inconsistency can manifest in varying thicknesses, heat tolerances, or even material defects. For manufacturers, this can lead to production delays, as they may need to reorder materials or stop production lines to address quality issues. The stakes are high—production delays can result in lost contracts, strained client relationships, and diminished reputation in competitive markets.

The Solution: To mitigate this problem, B2B buyers should establish rigorous quality standards and specifications that align with their operational needs. It’s essential to work closely with suppliers who can provide certifications and detailed product specifications. Conducting initial sample tests before placing bulk orders can help assess the quality of the heat-resistant sheets. Additionally, consider establishing a long-term partnership with a reliable supplier who has a proven track record in quality assurance. This can foster better communication and quicker resolutions for any issues that arise.

Scenario 2: Difficulty in Selecting the Right Material Type for Specific Applications

The Problem: Another common pain point is the difficulty in selecting the appropriate type of heat-resistant sheet for specific applications. With various materials available—such as silicone, rubber, and plastic—buyers may struggle to determine which option offers the best performance under their unique conditions. For instance, using a sheet that can’t withstand the required temperatures can lead to product failure, safety hazards, and additional costs related to replacement and downtime.

The Solution: To address this challenge, buyers should invest time in understanding the specific thermal requirements of their applications. This includes analyzing the operational environment, such as temperature ranges, exposure to chemicals, and physical stressors. Collaborating with material scientists or engineers during the selection process can provide valuable insights. Additionally, suppliers often have technical support teams that can assist in recommending the best materials based on application-specific parameters. Creating a checklist of necessary attributes (e.g., thermal stability, chemical resistance) will streamline the selection process and ensure compatibility with operational needs.

Scenario 3: High Costs Associated with Procurement and Shipping

The Problem: High procurement and shipping costs can significantly impact the overall budget for B2B buyers purchasing heat-resistant sheets. Many buyers find that shipping costs for bulky materials can eat into profit margins, particularly when ordering from international suppliers. Additionally, sudden price hikes or hidden fees can disrupt financial planning and project timelines, leading to frustration and potential project cancellations.

The Solution: To combat high costs, buyers should explore bulk purchasing options or establish long-term contracts with suppliers to lock in prices. Negotiating shipping terms and exploring multiple logistics partners can also help reduce expenses. Consider sourcing heat-resistant sheets from local or regional suppliers to minimize shipping costs and lead times. Additionally, leveraging technology to analyze total cost of ownership—including procurement, shipping, and potential downtime—can provide a clearer financial picture and help justify sourcing decisions. Implementing a centralized procurement process can also facilitate better negotiation and coordination, ultimately driving down costs.

Strategic Material Selection Guide for heat resistant sheet

What Are the Key Materials for Heat Resistant Sheets in B2B Applications?

When selecting heat resistant sheets for industrial applications, understanding the properties and suitability of various materials is crucial. Here, we analyze four common materials used in heat resistant sheets: silicone rubber, polycarbonate, PTFE (Teflon), and fiberglass. Each material has unique characteristics that can impact performance, cost, and application compatibility.

How Does Silicone Rubber Perform in Heat Resistance?

Silicone rubber is well-known for its excellent thermal stability, typically rated for continuous use at temperatures up to 200°C (392°F) and short-term exposure to higher temperatures. Its inherent flexibility and elasticity make it suitable for applications requiring a tight seal, such as gaskets and seals in high-temperature environments.

Pros: Silicone rubber is durable, resistant to UV light, and does not degrade easily in extreme temperatures. It also exhibits good chemical resistance, making it versatile for various industries.

Cons: The primary limitation is its higher cost compared to other rubber materials. Additionally, it may not be suitable for applications requiring high mechanical strength.

Impact on Application: Silicone rubber is ideal for food processing and pharmaceutical industries due to its non-toxic nature and compliance with FDA standards.

What Advantages Does Polycarbonate Offer?

Polycarbonate sheets are known for their high impact resistance and clarity. They can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F), making them suitable for applications that require both heat resistance and transparency, such as protective shields and safety glazing.

Pros: Polycarbonate is lightweight, easy to fabricate, and offers excellent durability against impacts and UV radiation.

Cons: However, polycarbonate can be more expensive than traditional glass and may scratch more easily unless treated with a hard coating.

Impact on Application: Its high clarity makes it a preferred choice in applications where visibility is critical, such as in safety equipment or display cases.

How Does PTFE (Teflon) Compare for High-Temperature Applications?

PTFE, commonly known by the brand name Teflon, is renowned for its exceptional heat resistance, withstanding temperatures up to 260°C (500°F). It is also chemically inert, making it suitable for applications involving corrosive substances.

Pros: PTFE has an extremely low friction coefficient, which makes it ideal for applications requiring non-stick properties.

Cons: The main drawback is its high cost and complexity in manufacturing, as PTFE requires specialized processes for shaping and forming.

Impact on Application: PTFE is widely used in the chemical processing industry, where exposure to aggressive chemicals and high temperatures is common.

What Role Does Fiberglass Play in Heat Resistant Sheets?

Fiberglass sheets are composed of woven glass fibers and resin, providing excellent thermal insulation and heat resistance, typically rated for use up to 300°C (572°F). They are commonly used in applications requiring structural integrity combined with heat resistance.

Pros: Fiberglass is lightweight, strong, and offers good electrical insulation properties.

Cons: It can be brittle and may not perform well under mechanical stress, leading to potential cracking.

Impact on Application: Fiberglass is often used in the aerospace and automotive industries for insulation and structural components due to its strength-to-weight ratio.

Summary of Material Selection for Heat Resistant Sheets

| Material | Typical Use Case for heat resistant sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Gaskets and seals in high-temperature environments | Excellent thermal stability and flexibility | Higher cost, lower mechanical strength | Medium |

| Polycarbonate | Protective shields and safety glazing | High impact resistance and clarity | Higher cost, prone to scratching | Medium |

| PTFE (Teflon) | Chemical processing applications | Extremely low friction and chemical inertness | High cost, complex manufacturing | High |

| Fiberglass | Aerospace and automotive insulation | Lightweight and strong | Brittle, potential for cracking | Medium |

In summary, the choice of material for heat resistant sheets should align with specific application requirements, cost considerations, and compliance with international standards. B2B buyers in regions such as Africa, South America, the Middle East, and Europe should prioritize materials that meet local regulations and industry standards to ensure optimal performance and safety.

In-depth Look: Manufacturing Processes and Quality Assurance for heat resistant sheet

What Are the Key Stages in the Manufacturing Process of Heat Resistant Sheets?

The manufacturing process of heat resistant sheets encompasses several critical stages, each designed to ensure the final product meets the stringent requirements of various industries. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials used for heat resistant sheets include silicone, rubber, and various polymers. These materials are chosen for their thermal stability and durability under high temperatures. During this stage, suppliers must ensure that the materials are free from contaminants and meet specific industry standards. This often involves sourcing materials from reputable suppliers and conducting initial quality checks.

How Are Heat Resistant Sheets Formed?

Once the materials are prepared, they undergo forming, which can involve several techniques such as extrusion, molding, or casting.

- Extrusion: This method involves forcing heated material through a die to create sheets of desired thickness. It is commonly used for producing continuous lengths of heat resistant sheets.

- Molding: In this technique, the material is poured into a mold and allowed to cool and solidify. This is particularly useful for creating complex shapes or large sheets.

- Casting: This method involves pouring liquid material into a mold, where it hardens into the desired shape. Casting is often used for thicker sheets that require high durability.

Each technique offers distinct advantages, and the choice depends on the specific application and properties required for the final product.

What Quality Control Measures Are Implemented During Manufacturing?

Quality assurance is a crucial aspect of the manufacturing process for heat resistant sheets, ensuring that products not only meet specifications but also comply with international standards.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers typically adhere to several international standards to ensure product quality. ISO 9001 is a widely recognized standard for quality management systems that ensures a consistent approach to production. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications are critical for ensuring compliance with regional regulations.

How Are Quality Control Checkpoints Structured?

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): This final inspection occurs before shipping the product. It includes comprehensive testing to ensure that the heat resistant sheets meet all specified requirements.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to validate the performance of heat resistant sheets, including:

- Thermal Testing: This evaluates the material’s ability to withstand high temperatures without degrading.

- Mechanical Testing: This assesses properties such as tensile strength and flexibility to ensure the sheets can perform under stress.

- Chemical Resistance Testing: This is crucial for applications in environments where exposure to harsh chemicals is likely.

These tests provide critical data that manufacturers can use to adjust processes and improve product quality.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers. Here are several methods to ensure reliability:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality management systems.

- Quality Assurance Reports: Requesting detailed quality assurance reports can help assess the supplier’s adherence to quality standards and testing results.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s production and quality processes.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing heat resistant sheets from international suppliers, buyers must be aware of various nuances related to quality control:

- Cultural Differences: Different regions may have varying standards and practices. Understanding these cultural differences can help in negotiating and ensuring compliance.

- Regulatory Compliance: Buyers should ensure that the products meet local regulations in their respective markets. This may involve additional testing or certifications.

- Documentation and Traceability: Ensuring that suppliers provide complete documentation for materials used and processes followed can facilitate smoother transactions and compliance checks.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing heat resistant sheets, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat resistant sheet’

Introduction

Sourcing heat resistant sheets requires careful consideration to ensure that you select the right materials for your specific applications. This guide offers a step-by-step checklist designed for B2B buyers, focusing on essential actions to take when procuring these materials. By following this checklist, you can streamline the sourcing process, mitigate risks, and make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the heat resistant sheets you need. Consider factors such as temperature resistance, thickness, and material type (e.g., silicone, rubber, or plastic). This step is crucial as it establishes a baseline for your procurement, ensuring that you communicate your needs effectively to potential suppliers.

- Temperature Range: Specify the maximum and minimum temperatures the sheets must withstand.

- Thickness and Dimensions: Determine the required thickness and sizes based on your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in heat resistant sheets. Look for companies with a strong reputation and experience in your industry. This step is important to ensure that you partner with reliable suppliers who can meet your quality and delivery expectations.

- Online Reviews: Check platforms like Google and industry-specific forums for customer feedback.

- Industry Presence: Evaluate their presence in your target regions, such as Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers have the necessary certifications and quality assurances. This step is vital to ensure that the materials meet international standards and regulations, which can vary significantly across regions.

- ISO Certifications: Look for suppliers with ISO 9001 or similar certifications that indicate quality management systems.

- Material Safety Data Sheets (MSDS): Request MSDS for assurance on safety and compliance.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of the heat resistant sheets to assess their quality firsthand. This step is essential to ensure that the products meet your technical specifications and performance expectations.

- Testing Conditions: Conduct tests under real-world conditions to evaluate performance.

- Durability Assessment: Check for wear and tear resistance, especially if used in high-stress environments.

Step 5: Compare Pricing and Terms

After evaluating the quality of samples, compare pricing and terms from different suppliers. This step helps you identify competitive offers while ensuring that you are not compromising on quality for cost.

- Bulk Discounts: Inquire about pricing for bulk orders, as many suppliers offer discounts for larger quantities.

- Payment Terms: Clarify payment conditions to avoid any future misunderstandings.

Step 6: Assess Lead Times and Delivery Options

Understanding the lead times and delivery options is crucial for planning your operations. This step helps you ensure that the supplier can meet your timelines and that their delivery logistics align with your needs.

- Shipping Methods: Evaluate the shipping methods they offer and their reliability.

- Flexibility: Check if they can accommodate urgent orders or changes in demand.

Step 7: Establish a Long-Term Relationship

Finally, consider establishing a long-term partnership with your chosen supplier. This step can lead to better pricing, priority service, and enhanced collaboration over time.

- Regular Communication: Maintain open lines of communication for ongoing support and feedback.

- Performance Reviews: Periodically review the supplier’s performance to ensure continued alignment with your business needs.

By following this checklist, B2B buyers can effectively navigate the sourcing process for heat resistant sheets, ensuring that they make informed and strategic decisions that support their operational goals.

Comprehensive Cost and Pricing Analysis for heat resistant sheet Sourcing

Understanding the cost structure and pricing dynamics of heat resistant sheets is crucial for international B2B buyers looking to optimize their procurement strategies. This analysis delves into the various components that influence costs, key price influencers, and provides actionable tips for buyers.

What Are the Key Cost Components in Heat Resistant Sheet Production?

The cost structure for heat resistant sheets typically encompasses several components:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials include silicone, rubber, and various plastics, each with distinct properties and price points. For example, silicone sheets may command higher prices due to their superior heat resistance compared to standard rubber sheets.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the production process. Countries with lower labor costs may offer competitive pricing, but buyers should consider the potential trade-offs in quality.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative support. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs for custom shapes or sizes can be significant. Buyers should evaluate whether the tooling costs are justified by the volume of production and the expected lifespan of the tooling.

-

Quality Control (QC): Implementing stringent QC processes ensures that the sheets meet industry standards. While this may add to the cost, it can prevent costly returns or failures in application.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the supplier to the buyer, as well as the mode of transportation. International buyers should consider logistics when calculating total costs.

-

Margin: Suppliers typically include a profit margin, which varies based on market competition and the supplier’s positioning. Understanding these margins can assist buyers in negotiating better deals.

What Influences Pricing for Heat Resistant Sheets?

Several factors can influence the pricing of heat resistant sheets:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Buyers should assess their needs carefully to avoid excess inventory while maximizing savings.

-

Specifications and Customization: Custom specifications such as thickness, size, and color can affect pricing. Buyers should clearly define their requirements to receive accurate quotes.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can increase costs but may be necessary for specific applications, especially in regulated industries.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Long-term relationships with reputable suppliers may yield better pricing and terms.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect shipping costs and responsibilities. Understanding these terms is essential for managing overall expenses.

How Can Buyers Optimize Costs When Sourcing Heat Resistant Sheets?

To maximize cost efficiency, international buyers should consider the following strategies:

-

Negotiate Pricing: Engage in open discussions with suppliers regarding pricing structures and potential discounts for larger orders or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider factors such as durability, maintenance costs, and potential downtime to get a comprehensive view of the total cost.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across regions due to local market conditions, tariffs, and logistical challenges. Buyers from Africa, South America, the Middle East, and Europe should conduct regional market analyses to identify the best sourcing options.

-

Request Multiple Quotes: Gathering quotes from several suppliers can provide leverage in negotiations and help identify competitive pricing.

Disclaimer on Pricing

It is important to note that the prices for heat resistant sheets can fluctuate based on market conditions, material availability, and supplier pricing strategies. Buyers should always request current quotes and consider all cost factors before making purchasing decisions.

Alternatives Analysis: Comparing heat resistant sheet With Other Solutions

Exploring Alternatives to Heat Resistant Sheets

When selecting materials for heat resistance, it’s essential to evaluate not only the capabilities of heat resistant sheets but also the alternatives that may better suit specific operational needs. This analysis will compare heat resistant sheets with two viable alternatives: ceramic tiles and heat resistant coatings. Each option presents unique advantages and challenges, making it crucial for B2B buyers to assess their specific applications and requirements.

Comparison Table

| Comparison Aspect | Heat Resistant Sheet | Ceramic Tiles | Heat Resistant Coatings |

|---|---|---|---|

| Performance | Excellent thermal insulation; withstands high temperatures | High durability; good thermal resistance | Varies by formulation; effective under moderate heat |

| Cost | Moderate cost; often more economical for large areas | Higher upfront investment; long-term durability | Generally lower cost; depends on application |

| Ease of Implementation | Easy to cut and install; requires basic tools | Requires skilled labor for installation | Simple application; often requires curing time |

| Maintenance | Low maintenance; resistant to moisture and chemicals | Requires periodic cleaning; durable | May need reapplication; susceptible to wear |

| Best Use Case | Industrial settings, kitchens, and laboratories | Flooring, countertops, and decorative surfaces | Protective layering on various substrates |

Detailed Breakdown of Alternatives

Ceramic Tiles

Ceramic tiles are known for their robustness and aesthetic appeal. They offer excellent thermal resistance and durability, making them suitable for high-traffic areas and environments exposed to heat, such as kitchens or industrial settings. However, the initial installation cost can be significantly higher compared to heat resistant sheets, and they require skilled labor for proper fitting. While maintenance is relatively straightforward, ceramic tiles may become slippery when wet, necessitating additional safety measures.

Heat Resistant Coatings

Heat resistant coatings provide a versatile solution for protecting various surfaces from heat damage. They can be easily applied to metals, plastics, and other substrates, allowing for customization based on specific operational needs. The application process is generally straightforward, though it often involves a curing period that can delay usability. While coatings can be a cost-effective solution, their performance varies significantly depending on the formulation and exposure conditions. Regular maintenance and reapplication may be necessary to ensure continued protection, which can add to long-term costs.

How to Choose the Right Solution for Your Needs

In selecting between heat resistant sheets and their alternatives, B2B buyers should consider several factors, including the specific environmental conditions, budget constraints, and long-term maintenance requirements. Heat resistant sheets are ideal for straightforward applications where cost efficiency and ease of installation are priorities. In contrast, ceramic tiles may be more suitable for areas requiring a blend of aesthetics and durability, while heat resistant coatings offer flexibility for diverse applications. By assessing these factors, businesses can make informed decisions that align with their operational goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for heat resistant sheet

What Are the Key Technical Properties of Heat Resistant Sheets?

When sourcing heat resistant sheets, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that buyers should consider:

1. Material Grade

The material grade indicates the type of polymer or rubber used in manufacturing the heat resistant sheet. Common materials include silicone, neoprene, and PTFE. Each material has unique thermal resistance capabilities and applications. For instance, silicone sheets can withstand temperatures up to 300°C, making them ideal for high-heat applications. Selecting the right material grade ensures compatibility with specific operational environments, reducing the risk of product failure.

2. Temperature Tolerance

Temperature tolerance defines the maximum and minimum temperatures the sheet can endure without degrading. This property is vital for industries where sheets are exposed to extreme heat, such as automotive, aerospace, and food processing. Understanding the temperature tolerance helps buyers avoid costly downtime and maintenance by ensuring the sheets can withstand the operational conditions they will face.

3. Thickness

The thickness of a heat resistant sheet can significantly affect its performance and application suitability. Thicker sheets typically offer better insulation and resistance to wear, while thinner sheets may provide more flexibility. Buyers should consider the specific requirements of their application when selecting sheet thickness, as it impacts durability, heat resistance, and ease of installation.

4. Chemical Resistance

Heat resistant sheets often encounter various chemicals in industrial settings. Chemical resistance refers to the sheet’s ability to withstand exposure to acids, bases, oils, and solvents without degrading. This property is particularly important in industries like manufacturing and chemical processing. Selecting sheets with appropriate chemical resistance helps prevent material failure and prolongs the lifespan of the product.

5. Surface Texture

The surface texture of heat resistant sheets can influence their performance in specific applications. Smooth surfaces are easier to clean and maintain, while textured surfaces may provide better grip or adhesion. Understanding the desired surface characteristics is essential for ensuring optimal functionality in applications such as gaskets, seals, or protective coverings.

Which Trade Terminology Should B2B Buyers Be Aware Of?

Familiarity with industry jargon can enhance communication with suppliers and streamline the purchasing process. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of heat resistant sheets, understanding OEM relationships can help buyers identify reputable suppliers and ensure they receive high-quality products that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage their inventory effectively and avoid overcommitting to large orders that may not be needed. This can also affect pricing, as larger orders may qualify for discounts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting detailed pricing and terms for specific products. It’s a critical step in the procurement process, allowing buyers to compare offers and negotiate better deals. An effective RFQ should include detailed specifications of the heat resistant sheets required.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and obligations associated with the delivery of heat resistant sheets.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their projects effectively and avoid production delays. It’s important for buyers to communicate their timelines clearly to suppliers to ensure timely delivery.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, fostering stronger supplier relationships and enhancing operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the heat resistant sheet Sector

What Are the Current Market Dynamics and Key Trends in the Heat Resistant Sheet Sector?

The heat resistant sheet market is experiencing significant growth driven by various global factors, including the increasing demand from the automotive, aerospace, and manufacturing sectors. Emerging economies in Africa and South America, alongside established markets in Europe and the Middle East, are key players in this expansion. Key trends include the adoption of advanced materials such as silicone and thermoplastics, which offer superior durability and thermal resistance. Furthermore, the rise of Industry 4.0 technologies is transforming sourcing practices, enabling international buyers to leverage data analytics for better decision-making and supply chain optimization.

Another notable trend is the growing emphasis on customization. B2B buyers are increasingly seeking tailored solutions to meet specific operational needs, prompting suppliers to enhance their product offerings. Additionally, e-commerce platforms are becoming vital for sourcing heat resistant sheets, allowing buyers to access a broader range of suppliers and competitive pricing. This digital shift is particularly important for buyers in regions like Vietnam and Germany, where online procurement can significantly streamline operations and reduce lead times.

How Is Sustainability Influencing the Sourcing of Heat Resistant Sheets?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers in the heat resistant sheet sector. The environmental impact of manufacturing processes is under scrutiny, leading to a demand for sustainable practices across the supply chain. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and using eco-friendly materials.

Ethical sourcing is paramount, with businesses seeking suppliers who adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Green Seal for product sustainability are becoming essential for suppliers aiming to attract international buyers. By opting for heat resistant sheets made from recycled or biodegradable materials, companies can not only enhance their sustainability profile but also meet regulatory requirements in various markets.

What Is the Evolution of the Heat Resistant Sheet Market and Its Significance for B2B Buyers?

The evolution of the heat resistant sheet market dates back several decades, initially dominated by rubber and basic plastic materials. Over the years, advancements in polymer chemistry and manufacturing technologies have led to the development of high-performance materials that can withstand extreme temperatures and harsh conditions. This evolution is significant for B2B buyers as it opens up new possibilities for applications in diverse industries, from food processing to aerospace.

Today, the market is characterized by a wide array of options, including silicone sheets, thermoplastics, and composite materials, each offering unique benefits. Understanding this historical context allows buyers to make informed decisions based on the performance characteristics and long-term viability of different materials. As the market continues to innovate, staying abreast of these changes will be crucial for B2B buyers looking to optimize their procurement strategies and enhance operational efficiencies.

Frequently Asked Questions (FAQs) for B2B Buyers of heat resistant sheet

-

How do I choose the right heat resistant sheet for my application?

Selecting the appropriate heat resistant sheet involves considering factors such as temperature tolerance, material composition, and application requirements. Common materials include silicone, PTFE, and various plastics, each with different heat resistance capabilities. Assess your specific needs, including mechanical strength and chemical exposure, to determine the best fit. Consulting with suppliers for samples or technical specifications can also provide valuable insights. -

What types of heat resistant sheets are available in the market?

Heat resistant sheets come in various materials including rubber, silicone, and plastics like polycarbonate and acrylic. Each type offers unique properties; for example, silicone sheets excel in high-temperature applications, while polycarbonate provides excellent impact resistance. Evaluate your project’s specific requirements, such as thermal stability and durability, to select the appropriate type. -

What are the minimum order quantities (MOQs) for heat resistant sheets?

Minimum order quantities can vary significantly among suppliers and are often influenced by the type of material and customization options. Generally, MOQs may range from a few square meters to several hundred, depending on the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially for large or recurring orders. -

What payment terms should I expect when sourcing heat resistant sheets internationally?

Payment terms for international transactions typically include options like advance payment, letter of credit, or payment upon delivery. Suppliers may also offer net payment terms based on your credit history or relationship. Always clarify payment methods, currency, and any potential fees before finalizing orders to avoid surprises and ensure smooth transactions. -

How do I ensure quality assurance for my heat resistant sheet orders?

To ensure quality assurance, request samples or certifications from suppliers that indicate compliance with international standards such as ISO or ASTM. Conducting factory visits or third-party inspections can also provide peace of mind regarding manufacturing processes. Additionally, establishing clear specifications and quality metrics in your purchase agreements can help maintain product consistency. -

What shipping options are available for heat resistant sheets?

Shipping options for heat resistant sheets may include air freight, sea freight, or courier services, depending on urgency and budget. Air freight is faster but more expensive, while sea freight is economical for larger shipments. Discuss logistics with suppliers to determine the best shipping method that aligns with your delivery timelines and costs. -

How can I vet suppliers of heat resistant sheets effectively?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with international standards. Check reviews, request references, and verify certifications to ensure reliability. Additionally, consider conducting on-site audits or using third-party verification services to evaluate their facilities and quality control processes, ensuring they meet your requirements. -

Can I customize heat resistant sheets for specific applications?

Yes, many suppliers offer customization options for heat resistant sheets, including thickness, size, and material properties. Discuss your specific requirements with potential suppliers, including any unique features such as colors or additional treatments. Customization may affect pricing and lead times, so it’s crucial to clarify these aspects during negotiations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Heat Resistant Sheet Manufacturers & Suppliers List

1. Interstate Plastics – Heat Resistant & Worbla Thermoplastic Sheets

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: Heat Resistant Plastic Sheet, Worbla Hand-Formable Black Thermoplastic Sheet, Worbla Hand-Formable Beige Thermoplastic Sheet, Delrin® Plastic Sheet | Black, Acetal Plastic Sheet | Acetal Copolymer | Natural Color, Craft Plastic Mirror | Gold Acrylic Sheet, Craft Plastic Sheet | Black 2025 (Opaque), Acrylic Sheet | Clear Bullet Resistant Cast Paper-Masked Mp 1.25, Craft Plastic Sheet | Clear Cast P…

2. My Craft Source – Heat Resistant Sheets

Domain: mycraftsource.com

Registered: 2015 (10 years)

Introduction: Heat Resistant Sheets: 1. Heat Resistant Sheet – Brown: Size: 15″ x 19″, Color: Brown, Price: $3.00 2. Heat Resistant Sheet – White: Size: 19″ x 20″, Color: White, Price: $8.00 3. Siser Heat Resistant Sheet: Size: 18″ x 20″, Color: White, Price: $10.00

3. McMaster – High Temperature Plastic Sheets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – High Temperature Plastic Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. The Rubber Company – High Temperature Resistant FKM Rubber Sheeting

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: High Temperature Resistant Sheeting includes various types of FKM (Viton) rubber sheeting, specifically: RC0320 Genuine Chemours Viton® A 75° Rubber Sheeting, RC0378 Green FKM A (Viton) 75° Rubber Sheeting, RC0377 Blue FKM A (Viton) Food Contact Rubber Sheeting, RC0379 FKM B (Viton) 70° Rubber Sheeting, RC0375 White FKM A (Viton) Food Contact Rubber Sheeting, RC0374 Hydrogenated Nitrile Rubber She…

5. Pensacola Vinyl Shop – Heat Resistant Sheet

6. AB Thermal – Flexible Graphite Solutions

Domain: abthermal.com

Registered: 2010 (15 years)

Introduction: Flexible Graphite Sheet & Roll – High Temperature & Heat Resistant; Continuous Exposure: 950°F / 510°C; Higher Intermittent: up to 5400°F / 2982°C; Material: GraphTek™ Flexible graphite, available in sheets, laminate, and rolls; Applications: Extreme heat protection, thermal dissipation, lubrication.

7. Prime Pick – Heat-Resistant Sheet

Domain: primepickusa.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Heat-Resistant Sheet”, “brand”: “Prime Pick”, “description”: “Heat-resistant sheets from Prime Pick are essential when you’re working with materials that are more susceptible to higher temperatures. By placing the Teflon sheet for HTV between the press and the material, it can withstand temperatures of up to 600 degrees Fahrenheit. Protect your vinyl, materials, and sensitive fab…

8. A&C Plastics – Fire Rated Polycarbonate Sheets

Domain: acplasticsinc.com

Registered: 1997 (28 years)

Introduction: A&C Plastics offers fire rated polycarbonate sheets that are flame-inhibiting, UV-stable, and virtually unbreakable. These sheets are stronger than glass and plexiglass, easily die cut, punched, and sheared for various fabrication needs. The fire resistant plastic sheeting is produced under strict quality control and meets ISO certification guidelines. It is suitable for industries such as electri…

9. Swift Supplies – Rigid Heat Resistant Boards

Domain: swiftsupplies.com.au

Introduction: Rigid Heat Resistant Boards from Swift Supplies include various types such as Mica Insulation Board (500°C), Polyester Glass Board (220°C), and Sindanyo Cement Insulation Board (700°C). They offer high heat resistance and are available in a wide selection of sizes and thicknesses. Custom made parts can be requested. The boards are used in various applications, providing strong thermal insulation. …

Strategic Sourcing Conclusion and Outlook for heat resistant sheet

What Are the Key Takeaways for Sourcing Heat Resistant Sheets?

In the dynamic landscape of heat-resistant sheet sourcing, international B2B buyers must prioritize quality, durability, and supplier reliability. Understanding the diverse applications—from industrial settings to specialized crafts—enables businesses to make informed purchasing decisions. Leveraging strategic sourcing not only ensures access to superior materials but also fosters long-term partnerships that can enhance operational efficiency and reduce costs.

How Can Strategic Sourcing Enhance Supply Chain Efficiency?

Strategic sourcing is essential for optimizing supply chains, particularly in regions such as Africa, South America, the Middle East, and Europe. By identifying suppliers who can deliver high-performance heat-resistant sheets tailored to specific industry needs, companies can mitigate risks and ensure consistent product availability. This proactive approach also allows for better negotiation of terms, potentially leading to favorable pricing and enhanced service levels.

What Should International Buyers Consider Moving Forward?

As the market continues to evolve, staying abreast of technological advancements and emerging materials will be vital. B2B buyers should actively engage with suppliers to explore innovative solutions that meet their unique requirements. By doing so, they can secure a competitive edge in their respective markets. Embrace the opportunities that strategic sourcing presents and position your business for growth in the ever-expanding realm of heat-resistant materials.