Contents

Manufacturing Insight: Heat Proof Plastic Sheet

Introducing High-Temperature Resistant Plastic Solutions with Integrated Sheet Metal Fabrication Expertise

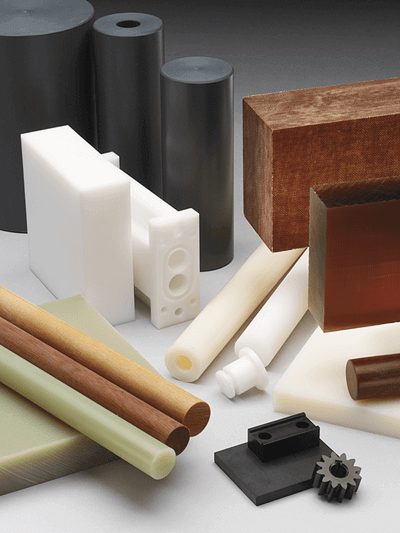

At Honyo Prototype, we engineer precision components for demanding thermal environments where material integrity is non-negotiable. While no plastic achieves absolute “heat proof” status, our portfolio of high-performance polymers—including ULTEM™, PEEK, PTFE, and PI—delivers exceptional thermal stability, chemical resistance, and mechanical strength for applications operating continuously at 200°C–300°C+. These advanced materials are critical for aerospace insulation, semiconductor tooling, automotive under-hood components, and medical sterilization equipment.

Crucially, thermal management rarely exists in isolation. Honyo Prototype uniquely integrates these engineered plastic sheets with our core Sheet Metal Fabrication services to deliver co-engineered solutions. Our capabilities span laser cutting, CNC bending, welding, and finishing for stainless steel, aluminum, and specialty alloys—ensuring seamless compatibility between high-temp plastics and structural metal assemblies. This synergy eliminates thermal expansion mismatches, reduces assembly failures, and accelerates time-to-prototype for complex enclosures, brackets, and shielding systems.

Leverage our technical expertise through Honyo’s Online Instant Quote platform. Upload your 3D model or 2D drawing to receive a precise, real-time cost and lead time estimate for both plastic sheet fabrication and complementary sheet metal components—validated by our engineering team for manufacturability and thermal performance.

Material Performance Comparison at a Glance

| Material | Continuous Use Temp (°C) | Key Applications | Compatible Metal Fabrication Processes |

|---|---|---|---|

| ULTEM™ | 215 | Aerospace ducting, fluid systems | Laser cutting, TIG welding, anodizing |

| PEEK | 250 | Semiconductor wafer handlers | CNC bending, precision stamping |

| PTFE | 260 | Chemical seals, gaskets | Laser welding, passivation |

| PI (Kapton) | 300+ | Flexible heaters, insulation | Micro-punching, precision etching |

Partner with Honyo Prototype to transform thermal design challenges into validated, production-ready assemblies—where material science meets precision metalcraft. Initiate your project today with our Online Instant Quote system for engineering-verified fabrication.

Technical Capabilities

The term “heat proof plastic sheet” is not a standardized material classification but generally refers to thermoplastic or thermoset materials engineered to maintain structural integrity at elevated temperatures. For manufacturing processes such as laser cutting, bending, and welding, material selection is critical to ensure process compatibility, dimensional stability, and final part performance.

Below is a comparison of relevant materials—focusing on ABS and Nylon as representative heat-resistant plastics, and including Aluminum and Steel for reference in hybrid or comparative applications. Note that Aluminum and Steel are not plastics but are included to clarify distinctions in process behavior when used alongside or in place of plastic components.

| Material | Max Continuous Use Temp (°C) | Laser Cutting Suitability | Bending Characteristics | Welding Method | Notes on Process Compatibility |

|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | 80–95 | Moderate – cuts cleanly with CO₂ laser but prone to melting if power not optimized; emits styrene fumes | Good – can be thermally bent using strip heaters; requires clamping and slow cooling to avoid warping | Ultrasonic, solvent, or hot-plate welding | Avoid high laser power; requires ventilation due to toxic emissions |

| Nylon (Polyamide, e.g., PA6 or PA66) | 120–150 (dry) / 80–100 (wet) | Poor to Moderate – high absorption of moisture affects cut quality; can char or melt; not recommended for precise laser cutting | Excellent – high toughness allows for controlled thermal bending with proper heating | Hot-gas, ultrasonic, or vibration welding | Must be pre-dried before processing; hygroscopic nature affects dimensional stability |

| Aluminum (for reference) | Up to 400+ (melting ~660°C) | Not applicable – reflective to CO₂ and fiber lasers; requires high-power fiber laser with anti-reflective safeguards | Excellent – readily bent with press brakes; springback must be compensated | TIG, MIG, or laser welding (with fiber laser) | Not a plastic; used in hybrid assemblies; reflective – caution with laser |

| Steel (for reference) | Up to 500+ (varies by grade) | Not applicable – requires high-power fiber laser; not relevant for plastic processing equipment | Good – bendable with press brakes; limited by thickness and grade | MIG, TIG, spot, or laser welding | Not a plastic; incompatible with plastic welding techniques |

Key Process Considerations:

Laser Cutting: ABS is generally more suitable than Nylon for laser cutting due to better melt control and lower moisture sensitivity. However, both plastics require optimized laser parameters and effective fume extraction. CO₂ lasers (wavelength ~10.6 μm) are typically used for organic materials like plastics.

Bending: Both ABS and Nylon can be bent using thermal forming methods. ABS softens at lower temperatures (around 100°C), making it easier to handle. Nylon requires higher temperatures (160–180°C) and careful control to prevent crystallization shifts.

Welding: ABS is commonly joined using solvent welding or ultrasonic methods. Nylon’s high melting point and moisture sensitivity make hot-gas welding a preferred method for larger parts, while ultrasonic is suitable for small, precision joints.

Summary: For applications requiring heat resistance and manufacturability via laser cutting, bending, and welding, ABS offers a balanced profile for prototyping and low-temperature environments. Nylon is superior in mechanical performance and higher temperature resistance but demands stricter process controls. Metals like Aluminum and Steel are not substitutes for plastic sheets in these processes but may be integrated into assemblies using compatible joining techniques.

From CAD to Part: The Process

Honyo Prototype Heat-Resistant Plastic Sheet Manufacturing Process

Honyo Prototype delivers precision-engineered heat-resistant plastic sheet components through a rigorously controlled workflow designed for technical accuracy and supply chain efficiency. Our process begins with secure CAD file ingestion via our encrypted client portal, where geometry, material specifications, and critical tolerances are validated against baseline thermal performance requirements. This initial upload triggers automated metadata extraction for immediate downstream processing.

The AI Quote Engine then generates a preliminary cost and timeline assessment within 2 hours, leveraging real-time material pricing databases and historical production analytics for heat-stable polymers. Crucially, this AI output undergoes mandatory review by our senior materials engineering team to verify thermal applicability—cross-referencing requested operating temperatures against material glass transition points (Tg), continuous service limits, and flammability ratings (e.g., UL 94 V-0 compliance). Unreviewed AI quotes are never released to clients.

During the Design for Manufacturability (DFM) phase, our engineers conduct specialized thermal analysis for sheet fabrication. This includes warpage simulation under thermal cycling, stress concentration mapping at elevated temperatures, and verification of dimensional stability per ASTM D696 standards. We explicitly validate whether the client’s “heat proof” requirement aligns with scientifically defined material capabilities—such as PEEK’s 250°C continuous service limit or PSU’s 180°C threshold—and propose geometry modifications if thermal deformation risks exceed 0.05mm/mm/°C. Clients receive a formal DFM report with actionable recommendations before work authorization.

Production executes on climate-controlled CNC machining cells with toolpath optimization for thermal polymers. Key controls include:

Pre-machining material annealing at 10°C below Tg

Coolant-free dry machining to prevent microcracking

In-process CMM verification at 70°C ambient to simulate operational conditions

Post-machining stress-relief baking per material-specific protocols

Final delivery incorporates traceable thermal certification. Each shipment includes:

Material test reports (MTRs) showing actual Tg and HDT values

Dimensional certification under stabilized 80°C conditions

Climate-controlled logistics with real-time temperature telemetry

Material Capability Reference

| Material | Max Continuous Temp (°C) | Key Thermal Standard | Typical Sheet Thickness Range (mm) |

|———–|————————–|———————-|———————————-|

| PEEK | 250 | ASTM D648 | 1.0 – 50.0 |

| PSU | 180 | UL 746B | 0.5 – 25.0 |

| PI (Kapton)| 260 | MIL-P-46566 | 0.025 – 1.0 |

| PPSU | 190 | ISO 11357 | 1.5 – 30.0 |

This integrated process ensures your heat-resistant plastic components meet stringent thermal performance criteria while minimizing time-to-prototype. For optimal DFM outcomes, provide your target operating temperature range and critical thermal deflection thresholds with your CAD submission.

Start Your Project

Looking for high-performance heat proof plastic sheets for your next project? Source directly from our manufacturing facility in Shenzhen.

Contact Susan Leo today at [email protected] for technical specifications, custom sheeting options, and competitive pricing.

Ensure your designs withstand elevated temperatures with reliable, engineered thermoplastics—delivered on time, every time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.