Contents

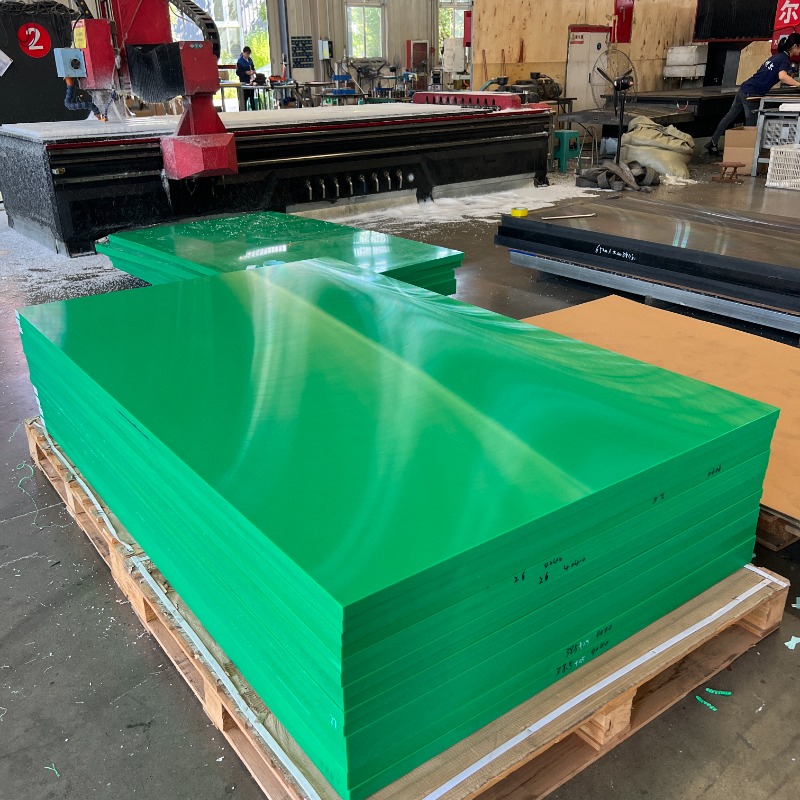

Manufacturing Insight: Hdpe Plastic Sheeting

Honyo Prototype delivers precision sheet metal fabrication services for demanding industrial applications, leveraging advanced capabilities in laser cutting, CNC bending, welding, and finishing. While HDPE plastic sheeting serves distinct purposes in containment and lining, our core expertise lies in transforming industrial-grade metals—including stainless steel, aluminum, and carbon steel—into mission-critical components with tight tolerances and repeatable quality. We support rapid prototyping through low-volume production runs, ensuring your designs meet functional and structural requirements without compromising on manufacturability. To accelerate your project timeline, utilize our Online Instant Quote system for transparent, real-time pricing on sheet metal parts—simply upload your STEP or DWG files to receive a detailed quote within hours, backed by engineering feedback to optimize your design for production efficiency.

Technical Capabilities

HDPE (High-Density Polyethylene) plastic sheeting is a thermoplastic material known for its high strength-to-density ratio, chemical resistance, and low moisture absorption. It is commonly used in industrial, packaging, and prototyping applications. When considering fabrication processes such as laser cutting, bending, and welding, HDPE presents unique characteristics that differ significantly from materials like aluminum, steel, ABS, and nylon. Below is a comparative technical specification table focusing on these processes.

| Property / Material | HDPE Plastic Sheeting | Aluminum | Steel | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|---|

| Laser Cutting | Poorly suited; high thermal conductivity and low laser absorption cause melting, charring, and poor edge quality. CO₂ lasers may cut thin sheets with careful parameter tuning but often produce melted edges. Requires high power and inert assist gas for minimal oxidation. | Excellent; clean, precise cuts with fiber lasers. Minimal dross with proper settings. | Excellent; fiber lasers provide high-speed, high-precision cutting. Nitrogen or oxygen assist depending on finish requirements. | Good; CO₂ lasers cut cleanly with smooth edges. Low melting point requires controlled power to avoid melting. | Moderate; prone to melting and charring. Requires precise power and speed control. May produce hazardous fumes. |

| Bending | Limited; poor bendability due to low stiffness and high springback. Can be thermoformed with heated bending tools. Not suitable for sharp or cold bends. | Excellent; high ductility allows for precise V-bending and roll forming. Minimal springback with proper tooling. | Good; bendable with press brakes. Higher springback than aluminum. Requires higher tonnage. | Good; can be heat-bent using strip heaters or ovens. Limited to moderate bend radii. | Good; can be thermoformed or heat-bent. High toughness allows for tight bends if preheated. |

| Welding | Excellent via hot gas welding, extrusion welding, or friction methods. Solvent and ultrasonic welding also effective. Cannot be arc or resistance welded. | Excellent; weldable via TIG, MIG, and laser welding. High thermal conductivity requires preheating for thick sections. | Excellent; compatible with MIG, TIG, spot, and laser welding. Requires shielding gas and proper joint prep. | Good; ultrasonic, vibration, and hot-plate welding effective. Solvent welding not applicable. | Excellent; weldable via hot gas, ultrasonic, and laser methods. High melt temperature requires controlled energy input. |

| Typical Thickness Range | 0.5 mm – 50 mm | 0.5 mm – 25 mm | 0.8 mm – 100 mm | 1 mm – 20 mm | 1 mm – 30 mm |

| Thermal Sensitivity | High; low melting point (~130°C), prone to warping under heat. Requires cooling during processing. | Moderate; high thermal conductivity dissipates heat quickly. | Low; high thermal mass, but susceptible to warping if unevenly heated. | Moderate; softens around 100°C. Sensitive to localized heating. | High; high melting point (~220–260°C) but hygroscopic—requires drying before processing. |

| Common Fabrication Tools | Hot knives, router, thermal forming, extrusion welders | Laser cutters, CNC bending, TIG/MIG welders | Laser/plasma cutters, press brakes, MIG/TIG welders | CNC routing, 3D printing, ultrasonic welders | CNC machining, injection molding, hot gas welding |

Notes for HDPE Processing:

Laser Cutting: Not recommended for precision applications due to melting and flare-up risks. If attempted, use high-speed, low-duty cycles with compressed air assist.

Bending: Requires heated bending jigs or oven-assisted forming. Sharp bends lead to cracking.

Welding: Best results with hot gas welding using HDPE filler rod. Joint design (e.g., V-groove) is critical for strength.

For hybrid assemblies, HDPE can be mechanically fastened to aluminum or steel; adhesive bonding requires surface treatment (e.g., plasma or corona) for adequate adhesion. Avoid direct fusion with metals or dissimilar thermoplastics like ABS or nylon due to incompatibility.

From CAD to Part: The Process

Honyo Prototype HDPE Plastic Sheeting Manufacturing Process

Honyo Prototype executes HDPE plastic sheeting projects through a streamlined, technology-driven workflow designed for precision and efficiency. HDPE’s semi-crystalline structure, low friction coefficient, and sensitivity to thermal gradients necessitate specialized handling at each stage. Below is our validated process flow.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. For HDPE sheeting, we require explicit material specification (e.g., HDPE 500, HDPE 1000), density (0.93–0.97 g/cm³), and critical dimensions. Our system auto-validates file integrity and flags common issues like non-manifold geometry or units mismatch. Non-conforming files trigger immediate notification for client correction, preventing downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which calculates costs using HDPE-specific parameters: material waste factors (accounting for HDPE’s 1.5–2.5% shrinkage during cooling), machining time based on toolpath complexity, and secondary operation requirements. The AI cross-references real-time HDPE sheet stock availability (standard grades: 3mm–100mm thickness) and applies dynamic pricing for expedited orders. Quotes include explicit tolerances (±0.25mm standard for HDPE sheeting) and material certifications (e.g., FDA, NSF). Clients receive detailed cost breakdowns within 2 business hours.

DFM Analysis for HDPE Critical Constraints

All approved projects undergo mandatory Design for Manufacturability (DFM) review by our engineering team, focusing on HDPE-specific challenges:

| DFM Check Category | Standard Plastics | HDPE-Specific Focus |

|---|---|---|

| Thermal Behavior | Generic cooling rates | Warpage mitigation via balanced wall thickness (min 3mm) and controlled ramp-down cycles |

| Machinability | Standard tool feeds | Low-friction coefficient adjustments: reduced spindle speeds (40–60% of ABS rates), specialized chip evacuation |

| Dimensional Stability | Linear tolerance checks | Shrinkage compensation modeling (1.5–2.5% based on grade) and stress-relief annealing protocols |

| Secondary Operations | Basic hole/slot checks | Thermal bonding feasibility assessment (HDPE requires 130–180°C for fusion) |

Clients receive annotated DFM reports with actionable recommendations (e.g., “Increase rib thickness to 4mm to prevent sink marks during cooling”). 95% of HDPE projects require ≤1 DFM iteration.

Precision Production Execution

Approved designs move to production using HDPE-optimized protocols:

Material Handling: Sheets acclimatized 24hrs in climate-controlled staging (22±2°C, 45% RH) to minimize moisture-induced warpage.

Machining: Dedicated CNC routers with polished carbide tools (no HSS) to prevent static buildup; coolant-free dry machining to avoid thermal shock.

Quality Control: In-process CMM checks at 30% and 70% completion, focusing on flatness (max 0.5mm/m²) and critical feature alignment. Final inspection includes density verification per ASTM D792.

Delivery and Traceability

Completed HDPE sheeting undergoes:

Vacuum-sealed moisture-barrier packaging with desiccant packs

Batch-specific documentation (material certs, CMM reports, DFM signoff)

Shipping via climate-controlled carriers for temperature-sensitive orders

Standard lead time is 7–10 business days from DFM approval. All shipments include QR-coded traceability linking to production logs and QC data.

This integrated process reduces HDPE project timelines by 30% versus industry averages while maintaining <0.8% defect rates. For urgent HDPE sheeting requirements, contact our engineering team directly at [email protected] to discuss material-specific acceleration options.

Start Your Project

Looking for high-quality HDPE plastic sheeting for your next project? Contact Susan Leo at [email protected] to request samples, pricing, or technical specifications. With our manufacturing facility based in Shenzhen, we deliver reliable production capacity and fast lead times for custom orders. Partner with Honyo Prototype for precision-engineered HDPE solutions built to meet your exact requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.