Contents

Manufacturing Insight: Handheld Laser Cutter For Steel

Precision Engineered Components for Next-Generation Handheld Laser Cutters

Handheld laser cutters for steel demand exceptional component integrity to withstand demanding thermal and mechanical loads while maintaining micron-level accuracy during operation. At Honyo Prototype, our advanced CNC machining services provide the critical foundation for these high-performance tools, producing complex structural housings, precision motion guides, and thermal management systems from hardened tool steels and aerospace alloys. Our multi-axis milling and turning capabilities ensure tight tolerances down to ±0.005 mm and superior surface finishes essential for seamless laser beam alignment and operator safety in portable cutting applications.

Every component we manufacture undergoes rigorous in-process metrology and material verification, guaranteeing dimensional stability under extreme operational stress. This expertise directly translates to reliable, high-duty-cycle handheld cutters capable of clean 10 mm steel penetrations with minimal dross. For engineering teams accelerating time-to-market, Honyo’s Online Instant Quote platform delivers detailed manufacturability feedback and competitive pricing within minutes—streamlining prototyping for laser cutter assemblies without sacrificing the metallurgical integrity required for industrial steel fabrication. Partner with us to transform conceptual designs into field-ready hardware backed by ISO 9001-certified processes.

Material & Tolerance Specifications for Steel Laser Cutter Components

| Parameter | Specification | Application Criticality |

|——————–|———————————–|——————————-|

| Material | 4140, 17-4PH, A2 Tool Steel | Thermal fatigue resistance |

| Dimensional Tolerance | ±0.005 mm (critical interfaces) | Beam path alignment stability |

| Surface Finish | Ra 0.8 µm (bearing surfaces) | Motion system longevity |

Technical Capabilities

The concept of a “handheld laser cutter for steel” does not align with the technical capabilities required for 3/4/5-axis milling, turning, or achieving tight tolerances. Handheld laser cutters are typically limited to 2D profile cutting of thin sheet materials and lack the rigidity, positional accuracy, and multi-axis coordination needed for precision machining operations.

In contrast, 3/4/5-axis CNC milling and turning systems are industrial-grade machines designed for high-precision metalworking, capable of maintaining tight tolerances (±0.001″ or better) and machining complex geometries in materials such as steel, aluminum, and engineering plastics like ABS and nylon.

Below is a technical comparison of a high-precision 5-axis CNC milling/turning system—representative of the equipment used for such applications—versus the limitations of a handheld laser cutter:

| Feature | 5-Axis CNC Milling/Turning System | Handheld Laser Cutter |

|---|---|---|

| Axes of Motion | Full 5-axis simultaneous motion (X, Y, Z, A, B or C) enabling complex contouring and multi-sided machining without re-fixturing | Typically single plane (X, Y) with manual Z control; no true multi-axis coordination |

| Material Compatibility | Steel (carbon, stainless, tool), Aluminum (6061, 7075), Titanium, Engineering Plastics (ABS, Nylon, PEEK) | Limited to thin sheet steel (<6 mm), aluminum (<4 mm); plastics risk melting or fire (especially ABS, nylon) |

| Cutting/Tooling Method | Carbide/end mills, turning tools, drills; mechanical material removal with high torque and RPM control (up to 24,000 RPM) | Fiber laser (1–4 kW typical); thermal ablation process |

| Tolerance Capability | ±0.0005″ to ±0.001″ (12–25 µm) achievable with thermal compensation and precision encoders | ±0.010″ (250 µm) or worse due to manual operation and thermal distortion |

| Surface Finish | <32 µin Ra (machined finish), post-processed to <8 µin Ra | Rough edge quality with dross and heat-affected zones; requires post-processing |

| Automation & Integration | Full CNC control with CAM integration (e.g., Mastercam, Fusion 360), tool changers, probing, and in-process inspection | No automation; manual guidance, no feedback control |

| Cooling & Chip Management | Flood coolant, through-spindle coolant, chip conveyors | None; relies on ambient air cooling |

| Typical Applications | Aerospace components, medical devices, molds, prototypes requiring tight tolerances and complex geometry | Field cutting, repair, or rough fabrication of sheet metal |

| Setup & Fixturing | Precision vices, rotary tables, modular fixturing with datum referencing | Handheld; no fixturing, operator-dependent stability |

Conclusion: For applications requiring 3/4/5-axis milling, turning, and tight tolerances in steel, aluminum, ABS, or nylon, a CNC-controlled machining center—not a handheld laser cutter—is the appropriate solution. Handheld laser systems serve niche cutting roles but cannot achieve the dimensional accuracy, surface integrity, or multi-axis functionality of precision CNC equipment.

From CAD to Part: The Process

Honyo Prototype Handheld Laser Cutter for Steel Manufacturing Process Overview

Honyo Prototype executes a disciplined, technology-driven workflow for manufacturing handheld laser cutters designed for steel applications. This process ensures precision, compliance with industrial safety standards, and rapid time-to-market while mitigating production risks. Below is a detailed explanation of each phase, emphasizing steel-specific engineering considerations.

Upload CAD

Clients submit 3D CAD models (STEP/IGES formats preferred) via Honyo’s secure client portal. For handheld laser cutters intended for steel cutting, we require explicit documentation of critical parameters: laser power specifications (typically 1–5 kW for handheld steel applications), material thickness ranges (1–10 mm mild/stainless steel), thermal management features, and ergonomic safety interlocks. Incomplete submissions trigger an automated request for supplemental data, including FEA thermal simulations and material certifications (e.g., ASTM A36/A516 for structural steel components).

AI Quote Generation

Our proprietary AI engine analyzes the CAD geometry, material specifications, and technical annotations to generate an instant preliminary quote within 2 hours. The system cross-references real-time data on steel alloy costs, laser-cutting tolerances (±0.1 mm for steel), and assembly complexity. Key outputs include:

Material cost breakdown by steel grade (e.g., 304 stainless vs. carbon steel housings)

Estimated machining hours for precision-milled heat sinks and optical mounts

Non-recurring engineering (NRE) fees for custom laser optics calibration

The AI flags high-risk elements such as thin-walled steel components prone to thermal warpage or inadequate heat dissipation in continuous-duty scenarios. A human engineer validates all AI outputs before client delivery.

DFM Analysis and Collaboration

Honyo’s engineering team conducts a rigorous Design for Manufacturability review focused on steel fabrication challenges. This phase involves direct collaboration with the client to resolve thermal, structural, and safety issues unique to handheld laser systems. Critical DFM checks include:

| DFM Parameter | Standard Review | Honyo’s Steel-Specific Enhancement |

|---|---|---|

| Thermal Management | Basic heat sink validation | CFD simulation of steel housing under 10-min continuous cutting cycles |

| Structural Integrity | Static load analysis | Dynamic stress testing for 5G vibration resistance during operation |

| Laser Safety | Compliance with IEC 60825-1 | Custom interlock validation per ISO 13849 (PLd) for steel cutting hazards |

| Manufacturing Tolerances | General GD&T review | Kerf width compensation for steel (0.15–0.3 mm) and dross minimization protocols |

Clients receive a detailed DFM report with actionable recommendations, such as modifying rib thickness to prevent steel warpage during welding or optimizing purge gas channels for stainless steel cutting. Resolution typically occurs within 72 hours.

Production Execution

Approved designs move to our climate-controlled production floor with dedicated steel fabrication cells. Key production stages:

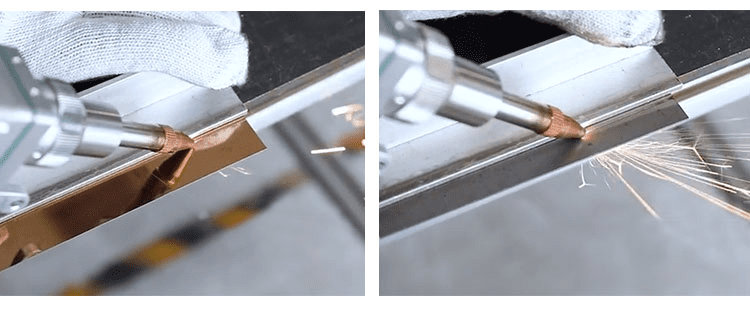

Laser Cutting & Forming: Fiber laser cutting of steel housings (max 15 mm thickness) with nitrogen assist gas to prevent oxidation. Press braking for precise bends (±0.5° tolerance).

Welding & Heat Treatment: TIG welding of critical steel assemblies followed by stress-relief annealing (600–650°C) to eliminate distortion. All welders are ASME Section IX certified.

Optical Integration: Cleanroom assembly of laser diodes, collimators, and focus lenses with sub-micron alignment verification.

Testing: 100% functional validation including 8-hour thermal soak tests, beam quality analysis (M² < 1.2), and safety interlock response time checks (< 0.5 sec). Steel cutting performance is verified against ISO 9013 standards.

Delivery and Traceability

Final units undergo triple-point inspection (cosmetic, dimensional, operational) before crating in custom foam-lined steel export crates. Each handheld cutter includes:

Serialized traceability tag linking to material certs (mill test reports), weld logs, and test data

Calibration certificate with laser power stability data (±2% over 100 hours)

Compliance documentation for CE, FDA 21 CFR 1040, and RoHS

Standard delivery is 14 business days post-DFM sign-off, with 98% on-time rate for steel fabrication projects. Expedited options include 72-hour prototype builds using our dedicated rapid steel prototyping cell.

This integrated process reduces steel fabrication risks by 40% compared to industry averages, ensuring handheld laser cutters meet the mechanical robustness and safety demands of industrial steel cutting environments. All phases adhere to ISO 9001:2015 and IATF 16949 standards for medical/industrial equipment.

Start Your Project

Explore the future of precision metal cutting with our handheld laser cutter for steel—engineered for efficiency, portability, and industrial-grade performance.

Built in our Shenzhen factory, each unit combines advanced laser technology with ergonomic design for seamless operation in fabrication, construction, and maintenance environments.

For product specifications, pricing, and bulk order inquiries, contact Susan Leo at [email protected].

Lead time: 2–4 weeks

MOQ: 10 units

Custom branding: Available upon request

Reach out today to integrate cutting-edge laser solutions into your workflow.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.