Contents

Manufacturing Insight: Gun Cnc Machine

Honyo Prototype delivers precision CNC machining services engineered for demanding manufacturing applications, including highly regulated sectors requiring strict compliance and exceptional part integrity. With decades of experience and ISO-certified processes, we specialize in producing complex, high-tolerance components from a wide range of materials, ensuring every part meets rigorous quality and safety standards. Our advanced 5-axis CNC machining centers, coupled with stringent quality control protocols, guarantee repeatability and accuracy down to sub-micron tolerances, making us a trusted partner for critical applications where failure is not an option.

Precision CNC Machining Capabilities

Our facility leverages state-of-the-art CNC technology to handle intricate geometries and challenging materials, from aerospace alloys to medical-grade polymers. We support full production lifecycles—from rapid prototyping to low-volume production—with dedicated engineering oversight at every stage. This commitment to technical excellence ensures components perform reliably under extreme conditions, adhering to all relevant regulatory frameworks without compromise.

Streamlined Quoting for Urgent Project Timelines

Accelerate your path to production with Honyo Prototype’s Online Instant Quote system. Simply upload your CAD file, specify materials and quantities, and receive a detailed, transparent cost estimate within minutes—no manual submission delays. This digital workflow eliminates bottlenecks, allowing engineering teams to validate designs and secure approvals faster while maintaining full traceability. For projects requiring specialized expertise, our engineering team remains available for immediate consultation to optimize manufacturability and reduce time-to-market.

Partner with Honyo Prototype for CNC machining solutions where precision, compliance, and speed converge. Initiate your project today through our instant quoting platform and experience how advanced manufacturing execution supports your most critical component requirements.

Technical Capabilities

Technical Specifications for High-Precision CNC Machine (Gun CNC Machine) – 3/4/5-Axis Milling and Turning

The term “gun CNC machine” typically refers to high-precision CNC machining centers used in the production of firearm components, where tight tolerances, complex geometries, and material consistency are critical. These machines are commonly configured as 3-axis, 4-axis, or 5-axis milling systems, often integrated with turning capabilities (mill-turn centers) to support complete part fabrication in a single setup.

Below are the key technical specifications and capabilities relevant to such machines when applied to firearm component manufacturing:

| Parameter | Specification / Description |

|---|---|

| Machine Type | 5-Axis CNC Mill-Turn Center (also available in 3-axis and 4-axis configurations) |

| Axis Configuration | X, Y, Z linear axes with A and B rotary axes (5-axis); optional C-axis for live tooling in turning |

| Spindle Speed | 12,000 – 24,000 RPM (high-speed spindle for precision finishing) |

| Positioning Accuracy | ±0.0025 mm (±0.0001”) |

| Repeatability | ±0.001 mm (±0.00004”) |

| Tolerance Capability | Achieves tight tolerances down to ±0.005 mm (±0.0002”) with proper fixturing and process control |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 – supporting high-speed machining and 5-axis interpolation |

| Tool Changer | Automatic Tool Changer (ATC) with 24–60 tool capacity; tool probing and wear compensation |

| Work Envelope (Typical) | 500 mm (X) × 400 mm (Y) × 350 mm (Z) – varies by model |

| Rapid Traverse Rate | 30–60 m/min across axes |

| Turning Capability | Integrated main and sub-spindle for backworking; live tooling for milling on turned parts |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) for deep hole drilling and chip evacuation |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 4340, Stainless 17-4 PH), ABS, Nylon (6/66), and other engineering plastics and alloys |

| Surface Finish | Capable of achieving Ra < 0.8 µm (32 µin) with finishing passes |

| Fixturing Compatibility | Modular fixturing, hydraulic or pneumatic chucks, zero-point systems for rapid changeover |

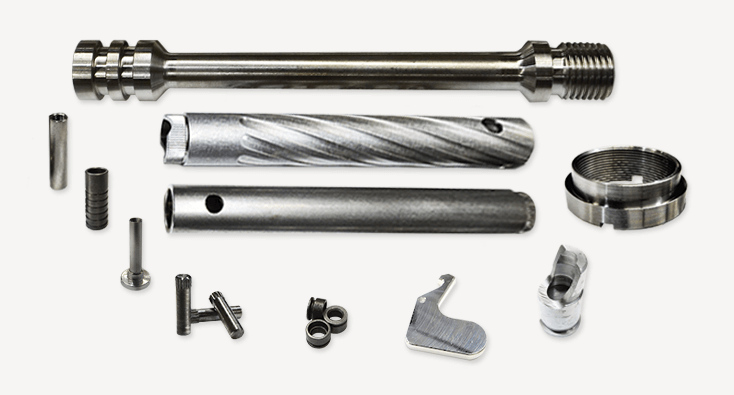

| Applications | Firearm receivers, barrels, bolt carriers, trigger components, suppressor parts, and accessories |

Material Notes:

Aluminum (6061, 7075): Lightweight and easily machinable; commonly used for receivers and frames. Requires sharp tooling and proper chip evacuation.

Steel (4140, 4340, Stainless): Used for high-strength components like bolts and barrels. Requires rigid setups and lower speeds with high torque.

ABS & Nylon: Used for non-structural parts such as grips, housings, and rail covers. Machining requires reduced feed rates and sharp tools to avoid melting or burring.

This class of machine supports full 5-axis simultaneous machining, enabling complex internal features and compound angles common in firearm design. The integration of milling and turning allows for complete part fabrication without secondary operations, critical for maintaining tight tolerances across multiple features.

From CAD to Part: The Process

Honyo Prototype executes precision CNC machining for firearm components through a rigorously controlled, client-centric workflow designed for defense and aerospace-grade compliance. Our process strictly adheres to ITAR and ISO 9001:2015 standards, ensuring traceability and security at every phase. Below is the technical breakdown of our integrated workflow for firearm-related CNC projects.

CAD Upload and Initial Validation

Clients submit native CAD files (STEP, IGES, or native SolidWorks formats) via our encrypted client portal. Our system performs immediate validation checks for geometric integrity, unit consistency, and manufacturability flags. For firearm components, we verify alignment with ITAR-controlled data protocols, requiring client authorization codes before processing begins. Unvalidated files trigger automated notifications for correction, minimizing downstream delays.

AI-Powered Preliminary Quoting

Our proprietary AI engine analyzes validated CAD geometry, material specifications, and surface finish requirements to generate a preliminary quote within 2 business hours. The algorithm factors in:

Material waste metrics based on stock size optimization

Machine time estimates using historical cycle data from similar firearm components (e.g., bolt carriers, receivers)

Secondary operation costs (heat treating, Mil-Spec coatings)

Compliance overhead for ITAR-controlled parts

This quote includes clear disclaimers noting it as a baseline estimate subject to DFM refinement, with no binding commitments until DFM sign-off.

Engineering-Driven DFM Analysis

DFM is our value-add phase where Senior Manufacturing Engineers collaborate directly with client design teams. For firearm parts, we focus on:

Critical tolerance validation against MIL-STD-810G vibration/shock requirements

Material substitution analysis (e.g., recommending 4140 chrome-moly steel over 7075-T6 aluminum for barrel extensions)

Fixture strategy optimization to prevent distortion in thin-walled components

Geometric feature adjustments to eliminate manual deburring in internal chambers

Typical DFM feedback includes actionable recommendations like:

| DFM Issue Type | Firearm Component Example | Honyo Recommendation | Impact |

|---|---|---|---|

| Wall Thickness | Magazine well | Increase from 1.8mm to 2.5mm | Prevents deformation during polymer overmolding |

| Internal Radius | Bolt lug | Add 0.5mm corner radius | Eliminates micro-crack initiation points |

| Tolerance Stack | Barrel extension | Relax non-critical ±0.005″ to ±0.010″ | Reduces machining time by 22% |

Clients receive annotated 3D models with markups and a formal DFM report requiring written approval before production.

ITAR-Compliant Production Execution

Approved designs move to dedicated CNC cells with:

Machines isolated in secure zones with biometric access

Material traceability via laser-etched batch numbers matching mill certificates

In-process CMM validation at critical stages (e.g., headspace dimensions on receivers)

Real-time SPC monitoring of key characteristics like chamber concentricity

All firearm components undergo final inspection per AS9102 forms, with first-article reports including full GD&T documentation. We maintain segregated inventory for ITAR-controlled parts with dual-custody chain-of-custody logs.

Certified Delivery and Traceability

Shipments include:

DFARS-compliant material certifications with heat numbers

ITAR-mandated end-use statements

Full inspection documentation in PPAP Level 3 format

Serialized part tracking via QR codes linking to digital twin records

We utilize bonded freight forwarders for international shipments, with all logistics documentation pre-verified by our compliance team. Typical lead time from CAD approval to delivery is 15-20 business days for complex firearm assemblies, with expedited options available for urgent defense contracts.

This workflow ensures firearm components meet stringent defense industry requirements while minimizing time-to-market through embedded compliance protocols. All projects include a dedicated Manufacturing Engineer for continuous technical liaison from quote to delivery.

Start Your Project

Looking for high-precision CNC machining solutions for firearm components? Honyo Prototype specializes in advanced gun CNC machining with tight tolerances and repeatable accuracy, ideal for prototypes and low-volume production.

Our manufacturing facility is based in Shenzhen, leveraging state-of-the-art equipment and quality control systems to ensure every component meets rigorous performance standards.

For project inquiries or technical specifications, contact Susan Leo at [email protected]. Let’s engineer reliability together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.