Guide Contents

Project Insight: Gray Plastic Sheet

Manufacturing Insight: Why Speed and Precision Define Gray Plastic Sheet Success

Speed: The Engine of Innovation

Time-to-market is everything: Hardware startups face relentless competition—delays mean lost opportunities. Honyo’s rapid tooling accelerates iteration cycles, letting you validate designs in days, not weeks.

Bridge tooling for low-volume production (100–10,000+ parts): Skip costly high-volume tooling. Produce functional prototypes and small batches quickly, then scale seamlessly as demand grows.

No more “wait-and-see”: From CAD to delivery, our end-to-end digital workflow slashes lead times while maintaining quality control at every step.

Precision: Engineering Excellence in Every Detail

Tight tolerances, zero compromises: Gray plastic sheet applications demand consistent material properties and micron-level accuracy for fit, function, and aesthetics.

Steel/aluminum molds engineered for perfection: High-precision tooling ensures dimensional stability, surface finish, and repeatability—even for complex geometries.

Advanced overmolding & insert molding capabilities: Integrate metal, rubber, or electronics seamlessly into your plastic components—reducing assembly steps and boosting product reliability.

Honyo Prototype: Your Digital Manufacturing Partner

⚡ Online Instant Quote: Get real-time pricing in seconds via our AI-powered platform—no manual quotes, no delays.

🤖 AI-Driven DFM Analysis: Our platform proactively optimizes designs for manufacturability, flagging issues before production begins.

🚀 5–7 Day Prototyping Turnaround: From concept to physical part, we deliver speed without sacrificing quality.

Trusted by hardware innovators: Product engineers and procurement managers rely on Honyo to turn ambitious designs into market-ready solutions—faster, smarter, and more cost-effectively.

Let’s build what’s next—together.

Honyo Capabilities & Technology

Gray Plastic Sheet Manufacturing Capabilities

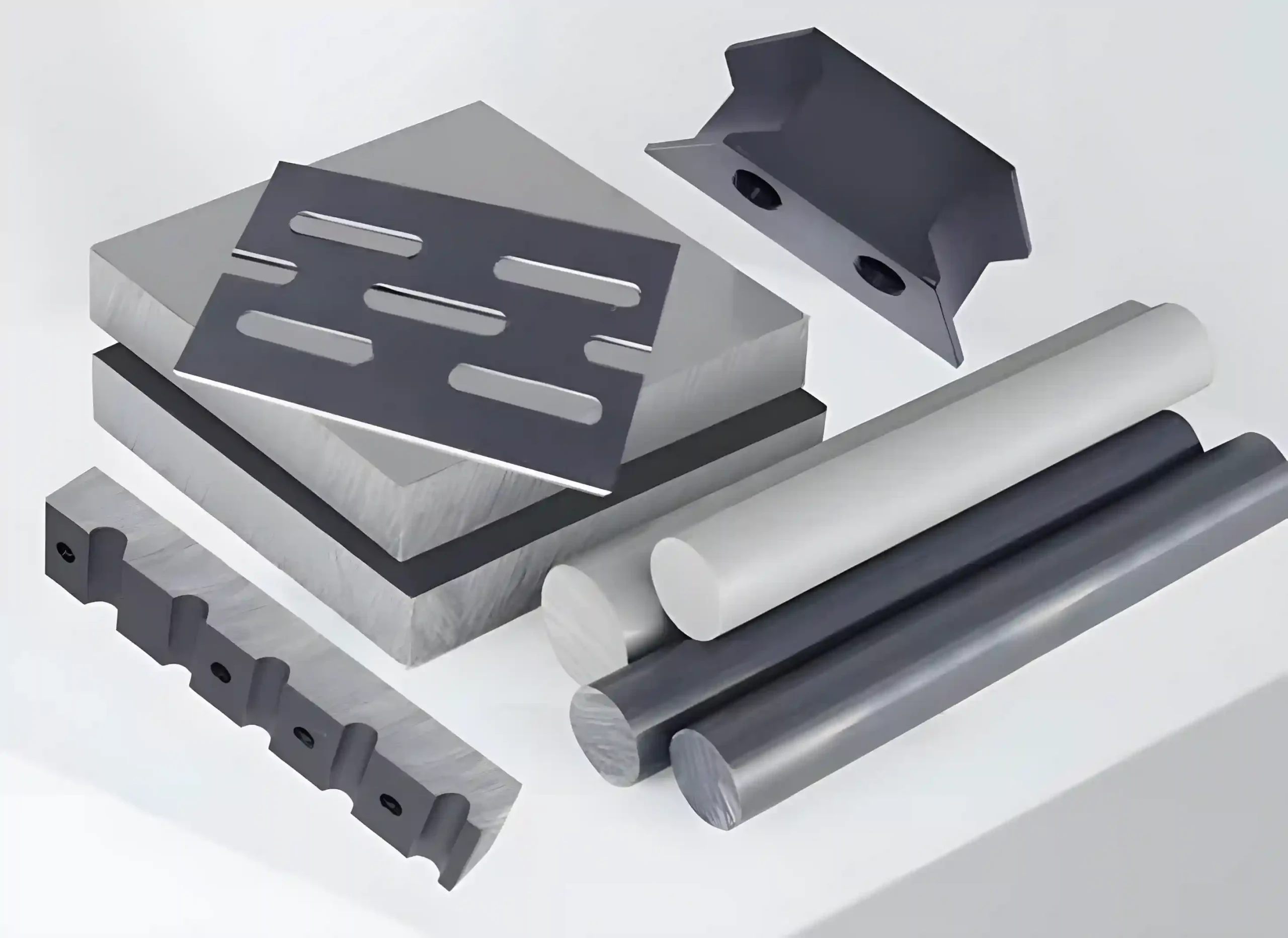

At Honyo Prototype, we engineer high-performance gray plastic sheet solutions that transform your ideas into reality—faster, smarter, and with unparalleled precision. Whether you’re a hardware startup scaling prototypes or an enterprise optimizing production, our capabilities are built to accelerate your innovation cycle.

Precision Tooling & Molding Expertise

Steel/Aluminum Molds: Precision-engineered molds for consistent part quality, durability, and thermal efficiency—ideal for low-volume bridge tooling (100–10,000+ parts).

Advanced Overmolding & Insert Molding: Seamlessly integrate multiple materials (e.g., rigid plastics with rubber or metal components) to reduce assembly steps and enhance product functionality.

Bridge Tooling Optimization: Rapid tooling solutions that bridge prototyping and full-scale production, cutting costs by up to 40% while maintaining tight tolerances (±0.05mm).

Material Versatility & Customization

Grade-Specific Gray Sheets: Premium-grade PP, PPH, PVC, ABS, and engineered polymers tailored to mechanical, thermal, and chemical requirements.

Full Customization: Thicknesses from 1mm to 50mm+, surface finishes (matte, gloss, textured), and color consistency for design-specific applications.

Free Sample Program: Request no-cost material samples with 24-hour turnaround to validate performance before production.

Scalable Production Capacity

Prototype-to-Volume Flexibility: Scale from single prototypes to high-volume runs (10,000+ parts) with zero minimum order quantities—perfect for startups testing market demand.

On-Demand Scheduling: Agile production workflows that adapt to urgent deadlines without compromising quality or precision.

Global Supply Chain Integration: Shenzhen-based manufacturing hub ensures rapid access to raw materials and seamless logistics for worldwide delivery.

ISO-Certified Quality Assurance

End-to-End Traceability: Rigorous in-process inspections and final part verification aligned with ISO 9001 standards.

Defect-Free Guarantee: 99.8% first-pass yield rate for all molded components, with detailed quality documentation for compliance.

Sustainability Focus: Recycled material options and waste-reduction protocols to support eco-conscious product development.

Digital-First Manufacturing Platform

AI-Powered Instant Quotes: Real-time pricing and lead time estimates via our cloud platform—no manual quotes, no delays.

Automated DFM Analysis: AI-driven design feedback to optimize geometries, reduce material waste, and prevent costly manufacturing issues pre-production.

Lightning-Fast Turnaround:

Cut-to-size orders: 2–3 business days

Prototypes: 3–5 days

Production runs: 2–3 weeks (with expedited options for critical projects)

All backed by 24/7 digital support and transparent project tracking.

Materials & Surface Finishes

Material Options & Finishes for Gray Plastic Sheets

Material Selection Guide

Optimize performance, cost, and aesthetics with Honyo’s precision-engineered thermoplastic solutions. Our gray plastic sheets are tailored for demanding applications across industries:

ABS (Acrylonitrile Butadiene Styrene)

Key Properties: High impact resistance, dimensional stability, and excellent paintability.

Gray Applications: Automotive interiors, consumer electronics housings, medical device components.

Why Choose: Ideal for prototyping and end-use parts requiring durability and a professional finish.

PC (Polycarbonate)

Key Properties: Superior strength, heat resistance (up to 135°C), and optical clarity.

Gray Applications: Safety shields, aerospace components, optical lenses.

Why Choose: Best for high-temperature environments where clarity and structural integrity are critical.

PP (Polypropylene)

Key Properties: Chemical resistance, fatigue resistance, and FDA-compliant for food contact.

Gray Applications: Food containers, automotive bumpers, living hinges.

Why Choose: Cost-effective for high-volume, low-cost parts with chemical exposure needs.

TPE (Thermoplastic Elastomer)

Key Properties: Rubber-like flexibility, shock absorption, and recyclability.

Gray Applications: Gaskets, ergonomic grips, medical seals.

Why Choose: Combines flexibility with injection molding efficiency for complex, flexible components.

Surface Finishes for Enhanced Performance

Elevate functionality and aesthetics with Honyo’s advanced finishing capabilities:

Precision Polishing: Mirror-like finishes for optical clarity and premium aesthetics—perfect for display components.

Custom Texturing: Matte, brushed, or patterned surfaces for improved grip and design versatility.

High-Quality Painting: Durable, color-consistent coatings with precise Pantone matching for brand alignment.

UV Stabilization: Protect against degradation for outdoor applications (e.g., automotive exteriors, outdoor equipment).

Anodizing (for metal inserts): Corrosion-resistant finishes for integrated metal components in multi-material assemblies.

Why Choose Honyo for Your Project

Online Instant Quote: Get real-time pricing in seconds via our AI-powered platform—no waiting for manual quotes.

Fast Turnaround: Bridge tooling for low-volume production (100–10,000+ parts) with lead times up to 50% faster than traditional methods.

Expert Guidance: Our Shenzhen-based engineering team works with you to select the optimal material and finish for your specific application, ensuring cost-efficiency and performance.

End-to-End Integration: From concept to production, we handle everything—mold design, tooling, and finishing—so you get high-quality parts with minimal lead time.

Innovate faster. Produce smarter. Partner with Honyo Prototype to turn your vision into reality.

From Quote to Part: Our Process

How It Works: From CAD to Part

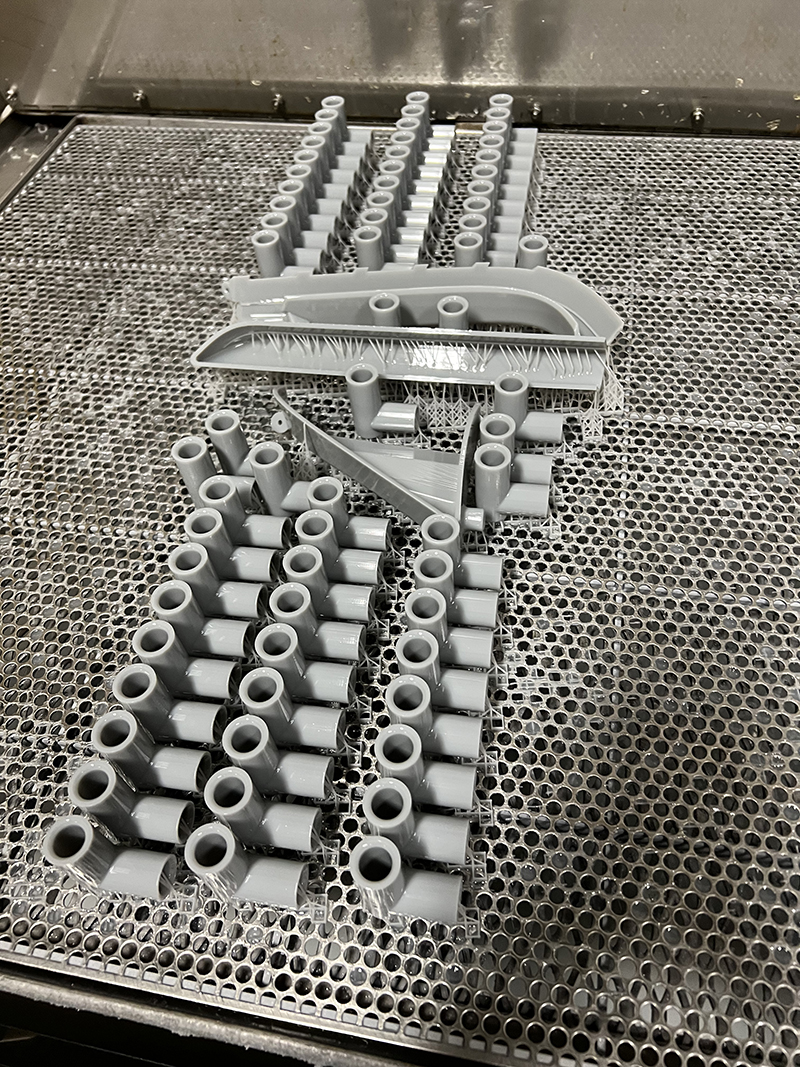

At Honyo Prototype, we’ve redefined rapid manufacturing with an AI-driven workflow that turns your design into production-ready parts in record time. Whether you’re prototyping a new hardware product or scaling low-volume production with bridge tooling (100–10,000+ parts), our seamless process ensures transparency, speed, and precision—every step of the way.

Step 1: Upload Your CAD File

Submit 3D models (STL, STEP, IGES) via our cloud platform—no software installation needed

Instant validation checks ensure your design is thermoforming-ready

Real-time feedback on material compatibility (e.g., gray PP, ABS, PVC sheets) and geometry feasibility

Step 2: Get Instant AI-Powered Quote

Our AI engine analyzes geometry, material specs, and quantity in under 60 seconds

Transparent pricing breakdown with no hidden fees—see exact costs before committing

AI suggests optimizations (e.g., wall thickness adjustments, draft angles) to reduce costs without compromising performance

Step 3: Expert DFM Analysis

Our manufacturing engineers review your design for thermoforming feasibility and structural integrity

Receive actionable feedback on undercuts, draft angles, and material flow—collaborate directly via our platform

Iterate faster with real-time design refinements tailored to your project’s needs

Step 4: Rapid Production & Delivery

Bridge tooling optimized for 100–10,000+ parts—aluminum molds enable prototypes in as little as 5 days

Precision thermoforming of gray plastic sheets with ±0.1mm tolerances and consistent surface finishes

End-to-end tracking from production to delivery—global shipping with guaranteed timelines and real-time updates

Why Honyo?

We eliminate guesswork with AI-driven efficiency and human expertise. From your first upload to your first part, we deliver faster iteration, lower costs, and zero supply-chain delays—so you can focus on innovation, not logistics.

Designed for hardware startups and product engineers who need speed without compromise.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision-Driven Solutions for Gray Plastic Components

While thermoforming suits simple sheet applications, Honyo’s injection molding expertise delivers superior strength, dimensional accuracy, and functional performance for gray plastic components—perfect for end-use parts in automotive, medical, and consumer electronics.

Bridge Tooling for Low-Volume Efficiency: Steel/aluminum molds reduce costs by 40%+ vs. traditional high-cavitation tools—ideal for 100–10,000+ parts without sacrificing quality.

Advanced Material Integration: Overmolding and insert molding capabilities enable seamless bonding of metals, elastomers, or multi-material designs—unachievable with standard thermoformed sheets.

Engineering-Grade Consistency: Tight tolerances (±0.05mm) and uniform wall thickness ensure reliability for high-stress applications, unlike thermoformed alternatives prone to warping.

Streamlined, AI-Powered Production Workflow

From concept to delivery—faster, smarter, and transparent.

Instant Online Quote: Get real-time pricing in 60 seconds via our AI-driven platform—no back-and-forth emails or delays.

DFM Optimization: Our AI analyzes your design for manufacturability, suggesting material upgrades, geometry tweaks, or cost-saving adjustments before production starts.

7–10 Day Turnaround: Bridge tooling projects shipped in record time with 24/7 progress tracking and proactive quality checks.

Ready to Build Smarter? Let’s Talk.

Founder Susan Leo and our Shenzhen/Dongguan engineering team are ready to optimize your project—whether you’re prototyping a medical device, scaling consumer electronics, or solving a complex manufacturing challenge.

Contact: [email protected] | +86 139 2843 8620

Visit Us: Explore our state-of-the-art facilities in Shenzhen/Dongguan for hands-on collaboration.

Next Step: Request an Instant Quote Now → See how Honyo turns gray plastic into high-performance solutions.

Innovation isn’t just in our name—it’s in every mold we build. 🚀

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.