Introduction: Navigating the Global Market for granite engraving machine price

In today’s competitive landscape, sourcing granite engraving machines at the right price can be a daunting task for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe experience a surge in demand for personalized stone products, understanding the nuances of granite engraving machine prices becomes essential. This comprehensive guide will delve into various types of machines, including CNC routers and laser engravers, to help buyers identify the best options for their specific needs.

We will explore the diverse applications of these machines, from monument engraving to decorative arts, while also addressing critical factors such as supplier vetting, warranty offerings, and shipping logistics. With price ranges varying significantly based on specifications and features, this guide aims to empower buyers to make informed purchasing decisions, ensuring they invest in equipment that enhances operational efficiency and meets quality standards.

By providing insights into the global market trends and pricing strategies, this resource equips businesses with the knowledge necessary to navigate the complexities of sourcing granite engraving machines, ultimately leading to improved profitability and market competitiveness. Whether you are based in Germany, Brazil, or beyond, this guide serves as your roadmap to successfully acquiring the right engraving technology for your business.

Understanding granite engraving machine price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Engraving Machines | High precision, uses CO2 lasers, suitable for detailed designs | Monument industry, personalized gifts, advertising | Pros: High detail, fast engraving. Cons: Higher initial cost, requires skilled operation. |

| CNC Router Machines | Mechanical engraving, customizable sizes, versatile material use | Stone tablet processing, art relief, decoration | Pros: Versatile, can handle various materials. Cons: Slower than laser machines, more maintenance needed. |

| Handheld Engraving Tools | Portable, manual operation, ideal for small projects | Crafting, small-scale personalization | Pros: Cost-effective, easy to use. Cons: Limited precision, labor-intensive. |

| 3D Stone Carving Machines | Capable of creating three-dimensional designs | Art installations, high-end monuments | Pros: Unique designs, adds value. Cons: Expensive, requires skilled operators. |

| Multi-Function Engraving Machines | Combines various functions (cutting, engraving) | Diverse industries, including advertising and art | Pros: Multi-purpose, saves space. Cons: Complexity may lead to higher maintenance costs. |

What Are the Key Characteristics of Laser Engraving Machines?

Laser engraving machines are characterized by their high precision and ability to create intricate designs on granite and other materials using CO2 lasers. They are ideal for applications that require detailed engravings, such as personalized gifts and memorial stones. B2B buyers should consider the initial investment cost and the need for skilled personnel to operate these machines effectively.

How Do CNC Router Machines Differ in Functionality?

CNC router machines use mechanical engraving methods and can be customized in size to accommodate various projects. They are versatile, capable of processing not only granite but also other materials like glass and ceramics. B2B buyers must evaluate the speed of operation and the potential for higher maintenance compared to laser machines, especially when considering large-scale production needs.

What Are the Advantages of Handheld Engraving Tools?

Handheld engraving tools offer portability and ease of use, making them suitable for small projects or crafts. Their affordability appeals to startups and small businesses looking to enter the engraving market. However, buyers should be aware that these tools provide limited precision and require more manual labor, which may affect scalability.

Why Consider 3D Stone Carving Machines?

3D stone carving machines excel in producing three-dimensional designs, making them a valuable asset for artists and high-end monument manufacturers. These machines enhance the aesthetic value of products, attracting discerning customers. However, their cost and the necessity for skilled operators can be significant considerations for B2B buyers.

What Makes Multi-Function Engraving Machines Attractive?

Multi-function engraving machines combine several capabilities, such as cutting and engraving, into one device. This versatility is beneficial for businesses that operate across different sectors, allowing them to save space and reduce the need for multiple machines. Buyers should consider the complexity of these machines, as it may lead to increased maintenance costs and operational challenges.

Key Industrial Applications of granite engraving machine price

| Industry/Sector | Specific Application of granite engraving machine price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Monument & Gravestone | Custom engraving of headstones and memorial plaques | Enhances personalization, drives customer satisfaction | Quality of engraving precision, machine durability, and after-sales support |

| Construction & Architecture | Stone signage and decorative elements | Adds aesthetic value, promotes brand visibility | Material compatibility, machine size, and engraving depth capabilities |

| Interior Design & Decor | Customized stone features for homes and businesses | Unique offerings that differentiate from competitors | Versatility in material handling, software compatibility, and maintenance services |

| Art & Crafts | Artistic stone sculptures and reliefs | Expands product range and creative options | Artistic capabilities, engraving speed, and precision control |

| Advertising & Promotions | Promotional items made of engraved stone | Creates memorable branding opportunities | Cost-effectiveness, production speed, and customization options |

How is the granite engraving machine price utilized in the monument and gravestone industry?

In the monument and gravestone sector, granite engraving machines are used to create custom engravings on headstones and memorial plaques. This application addresses the need for personalization in memorial services, allowing families to commemorate loved ones with unique designs and inscriptions. Buyers in this sector should prioritize machines that offer high precision and durability, as they often work with hard materials and require consistent quality. Additionally, after-sales support is crucial to ensure ongoing operational efficiency.

What role does the granite engraving machine price play in construction and architecture?

In construction and architecture, granite engraving machines facilitate the creation of stone signage and decorative elements that enhance the visual appeal of buildings and public spaces. This application not only adds aesthetic value but also promotes brand visibility through custom engravings. International buyers should consider the machine’s compatibility with various stone types, its size for handling large materials, and the depth of engraving capabilities to meet specific project requirements.

Why are granite engraving machines essential for interior design and decor?

Granite engraving machines are pivotal in the interior design and decor industry for producing customized stone features, such as countertops, wall art, and decorative panels. This application allows designers to offer unique, personalized products that stand out in a competitive market. Buyers should look for machines that can handle various materials and offer versatility in engraving styles, as well as reliable maintenance services to minimize downtime.

How do granite engraving machines benefit the art and crafts sector?

In the art and crafts sector, granite engraving machines enable artists to create intricate sculptures and reliefs from stone. This application expands the creative options available to artists and crafters, allowing for the production of unique pieces that can command higher prices. Buyers in this industry should focus on machines that provide artistic capabilities, such as customizable engraving patterns and speed controls, to meet their specific artistic visions.

What advantages do granite engraving machines offer in advertising and promotions?

Granite engraving machines are utilized in the advertising and promotions industry to create engraved promotional items, such as awards and corporate gifts. This application enhances branding efforts by providing memorable, tangible items that resonate with customers. When sourcing machines for this purpose, businesses should consider cost-effectiveness, production speed, and the ability to customize designs to align with brand identities and campaign goals.

3 Common User Pain Points for ‘granite engraving machine price’ & Their Solutions

Scenario 1: Unexpected Price Variability in Granite Engraving Machines

The Problem: B2B buyers often encounter significant price fluctuations when seeking granite engraving machines. A manufacturer might quote a price that seems attractive, but after adding shipping fees, import duties, and additional options, the final cost can exceed budget expectations. This unpredictability can lead to project delays and strained supplier relationships, particularly for businesses operating in cost-sensitive markets like Africa and South America.

The Solution: To mitigate these issues, buyers should adopt a comprehensive sourcing strategy. Start by obtaining quotes from multiple suppliers and consider using a standardized request for proposal (RFP) template to ensure consistency in responses. This allows for a clearer comparison of prices and specifications. Additionally, inquire about all potential extra costs during the initial discussions—such as warranty extensions, training, and installation fees. Engaging with suppliers who offer transparent pricing models can help buyers avoid unexpected costs. Building a relationship with a single reliable supplier can also yield better pricing and terms over time, as they may offer discounts for repeat business or bulk purchases.

Scenario 2: Complexity in Understanding Machine Specifications and Their Impact on Price

The Problem: Many buyers struggle with understanding how different specifications of granite engraving machines—such as laser power, table size, and additional features—affect the overall price. This lack of clarity can lead to purchasing a machine that either exceeds their needs or fails to meet their operational demands, resulting in wasted resources and dissatisfaction.

The Solution: Buyers should invest time in educating themselves about the specifications that matter most for their specific applications. Engaging with technical sales representatives or industry experts can provide valuable insights into what features are essential for their business needs. Furthermore, creating a checklist of must-have specifications based on their engraving projects can guide the purchasing process. For example, if a business primarily engraves large granite slabs, investing in a machine with a larger table size and higher power might be justified despite the higher price. Additionally, attending industry trade shows or webinars can provide firsthand experience with different models and a better understanding of the price-performance relationship.

Scenario 3: Limited Availability of Machines and Spare Parts in Specific Regions

The Problem: In regions like the Middle East and parts of Europe, buyers often face difficulties in sourcing granite engraving machines and spare parts. Limited local availability can lead to long lead times, which can severely impact project timelines and operational efficiency. This situation is compounded when machines require maintenance or repair, and parts must be imported, leading to increased downtime.

The Solution: To address this challenge, B2B buyers should prioritize working with suppliers who have a strong international presence and a reliable logistics network. This includes verifying that the supplier has local representatives or service centers that can provide timely support and spare parts. Buyers should also explore partnerships with local distributors who can stock essential spare parts and offer maintenance services. Additionally, consider investing in training for in-house technicians to perform routine maintenance, which can reduce reliance on external support. Establishing a comprehensive inventory management system for critical spare parts can also help maintain operational continuity and minimize downtime.

Strategic Material Selection Guide for granite engraving machine price

What Are the Key Materials for Granite Engraving Machines?

When considering the purchase of granite engraving machines, the selection of materials plays a crucial role in determining performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in granite engraving machines, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Granite

Key Properties: Granite is a natural stone known for its hardness and durability. It can withstand high temperatures and is resistant to wear and tear, making it ideal for engraving applications.

Pros & Cons: The primary advantage of using granite is its exceptional durability and aesthetic appeal, which enhances the final product’s quality. However, granite can be expensive due to its sourcing and processing requirements. Additionally, its weight can complicate handling and installation.

Impact on Application: Granite is commonly used for high-end products, such as memorials and decorative items. Its compatibility with various engraving techniques, including laser and CNC, allows for intricate designs.

Considerations for International Buyers: Compliance with local standards (e.g., ASTM in the US, DIN in Germany) is essential. Buyers should also consider the availability of granite in their region and the associated shipping costs.

2. Marble

Key Properties: Marble is another natural stone, characterized by its softer texture compared to granite. It is easier to engrave but requires careful handling to avoid chipping.

Pros & Cons: The main advantage of marble is its versatility and the wide range of colors available, making it suitable for various artistic applications. However, its softness can lead to quicker wear and tear, reducing the longevity of engraved products.

Impact on Application: Marble is often used for decorative items, sculptures, and architectural details. Its compatibility with both traditional and modern engraving techniques makes it a popular choice.

Considerations for International Buyers: Buyers should be aware of the differences in marble quality and sourcing. Compliance with international standards is also crucial to ensure product quality and safety.

3. Slate

Key Properties: Slate is a fine-grained metamorphic rock that is relatively softer than granite and marble, making it easier to engrave. It has good resistance to weathering and is often used in outdoor applications.

Pros & Cons: The primary advantage of slate is its affordability and ease of use in engraving. However, its softer nature may limit the intricacy of designs compared to harder stones.

Impact on Application: Slate is commonly used for signage, tiles, and decorative pieces. Its compatibility with laser engraving makes it a favorite for personalized gifts and home décor.

Considerations for International Buyers: Buyers should consider the sourcing of slate, as it may vary in quality. Understanding local preferences and regulations regarding slate products is also important.

4. Acrylic

Key Properties: Acrylic is a synthetic material that mimics the appearance of glass and stone. It is lightweight, shatter-resistant, and available in various colors.

Pros & Cons: The main advantage of acrylic is its cost-effectiveness and ease of handling. It can be engraved quickly, allowing for fast production times. However, it is less durable than natural stones and may scratch more easily.

Impact on Application: Acrylic is widely used for awards, signage, and decorative items. Its compatibility with laser engraving allows for detailed designs and personalization.

Considerations for International Buyers: Buyers should ensure that the acrylic meets local safety and quality standards. Additionally, understanding the environmental impact of acrylic production may influence purchasing decisions.

Summary Table of Material Selection for Granite Engraving Machines

| Material | Typical Use Case for granite engraving machine price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Granite | Memorials, decorative items | Exceptional durability and aesthetic appeal | High cost and heavy weight | High |

| Marble | Sculptures, architectural details | Versatile and available in various colors | Softer, leading to quicker wear | Medium |

| Slate | Signage, tiles, decorative pieces | Affordable and easy to engrave | Limited intricacy due to softness | Low |

| Acrylic | Awards, signage, decorative items | Cost-effective and lightweight | Less durable and prone to scratches | Low |

This analysis provides B2B buyers with essential insights into material selection for granite engraving machines, helping them make informed purchasing decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for granite engraving machine price

What Are the Main Stages in the Manufacturing Process of Granite Engraving Machines?

The manufacturing process of granite engraving machines involves several critical stages, each contributing to the overall quality and functionality of the final product. Here’s a breakdown of the main stages:

Material Preparation

The first step in the manufacturing process is material preparation. This involves sourcing high-quality materials, such as steel for the frame, electronic components for the control system, and precision laser tubes for engraving. Suppliers often conduct rigorous quality checks to ensure that materials meet specific standards, which is crucial for durability and performance.

In the context of international trade, especially for buyers from Africa, South America, the Middle East, and Europe, it’s vital to verify that suppliers maintain robust sourcing practices. This could involve requesting documentation regarding material certification and compliance with international standards.

Forming Techniques

Once materials are prepared, the forming stage begins. This stage typically employs techniques like CNC machining, welding, and laser cutting. CNC machining allows for high precision in creating parts that fit together seamlessly, while laser cutting ensures clean edges and shapes.

For granite engraving machines, the frame and base must be robust to withstand the vibrations and forces generated during operation. Buyers should inquire about the specific machining processes used and their tolerances to ensure that components will align correctly and function as intended.

Assembly Process

The assembly stage is where all individual components come together. This process often involves both automated and manual operations. Skilled technicians assemble the machine’s frame, install the laser tubes, connect the electrical systems, and integrate software controls.

Quality assurance at this stage is crucial. Manufacturers typically conduct initial checks to ensure all components are assembled correctly and meet specifications. B2B buyers should consider asking for assembly checklists or reports to verify that assembly processes adhere to best practices.

Finishing Techniques

Finishing involves applying protective coatings, such as powder coating or painting, and conducting final adjustments. This stage is essential for enhancing the machine’s aesthetics and protecting it from environmental factors.

Buyers should be aware of the types of finishes used, as these can affect the machine’s longevity and maintenance needs. Requesting samples or photos of finished products can help buyers assess the quality of the manufacturer’s finishing techniques.

How Is Quality Assurance Implemented in Granite Engraving Machine Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for granite engraving machines. A robust QA system ensures that each machine meets specific quality standards before it reaches the buyer.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers of granite engraving machines often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with this standard indicates that the manufacturer has processes in place to ensure consistent quality and customer satisfaction.

In addition, certifications like CE mark indicate compliance with European safety, health, and environmental protection standards. For buyers from Europe, particularly Germany, this certification is crucial. It’s advisable for B2B buyers to request copies of these certifications to confirm compliance.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the QA process and typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are conducted to monitor the production quality. This includes measuring tolerances and ensuring that assembly processes are followed correctly.

-

Final Quality Control (FQC): Before shipment, the finished machines undergo a comprehensive inspection. This may involve functional testing, performance evaluations, and aesthetic checks to ensure that everything is up to par.

B2B buyers should inquire about these checkpoints and request documentation that demonstrates the results of these inspections.

What Common Testing Methods Are Employed?

Manufacturers utilize various testing methods to ensure the reliability and performance of granite engraving machines. Common methods include:

-

Functional Testing: This involves running the machine to ensure all components work as intended. This is particularly important for laser engravers, where precision is crucial.

-

Performance Testing: Machines are tested for speed, accuracy, and durability under operational conditions. This helps ensure they can handle the demands of engraving hard materials like granite.

-

Safety Testing: Compliance with safety standards is assessed, ensuring that the machine operates without posing risks to the user.

B2B buyers should ask about the specific tests performed and request test reports to verify that the machines have passed all necessary evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are some methods to consider:

Conducting Audits

Buyers can conduct audits of potential suppliers to assess their manufacturing processes, quality control systems, and overall operational practices. This hands-on approach can provide insights into the supplier’s commitment to quality.

Requesting Quality Assurance Reports

Buyers should not hesitate to request quality assurance reports and certifications from suppliers. These documents should detail the QA processes in place, results from testing, and compliance with international standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct pre-shipment inspections, ensuring that products meet the buyer’s specifications before leaving the factory.

What Nuances Should International Buyers Consider in Quality Control?

When engaging with suppliers from different regions, international buyers should consider various nuances in quality control:

-

Cultural Differences: Understanding local practices and attitudes towards quality can help buyers navigate potential challenges in communication and expectations.

-

Regulatory Compliance: Different regions may have unique regulatory requirements that affect quality standards. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Logistics and Shipping: Quality can be compromised during transportation. Buyers should discuss packaging and shipping methods with suppliers to ensure that products arrive in optimal condition.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when purchasing granite engraving machines, ensuring they select suppliers that meet their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘granite engraving machine price’

To assist B2B buyers in sourcing granite engraving machines effectively, this guide provides a structured approach to ensure informed decision-making. By following these steps, you can streamline your procurement process and secure a machine that meets your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before exploring options. Consider the types of materials you will engrave, the desired engraving depth, and the machine’s working area. Additionally, think about the power requirements and software compatibility to ensure the machine integrates seamlessly into your operations.

- Material Types: Identify whether you will work with granite, marble, or other stone types.

- Engraving Depth: Determine the maximum depth you need based on your projects.

Step 2: Research Market Prices

Understanding the price range for granite engraving machines will help you budget effectively. Prices can vary significantly based on brand, features, and specifications. Generally, you can expect prices to range from $2,500 to over $7,000 depending on the machine’s capabilities.

- Price Variability: Be aware that additional features or higher specifications may increase costs.

- Total Cost of Ownership: Factor in not just the purchase price, but also maintenance and operational costs.

Step 3: Evaluate Supplier Certifications

Before proceeding with a purchase, verify the certifications and standards met by potential suppliers. Look for compliance with international safety and quality standards, such as CE certification, which indicates a commitment to quality manufacturing.

- Supplier Reputation: Research the supplier’s history and customer reviews to gauge reliability.

- Warranty and Support: Ensure that suppliers offer adequate warranties and post-purchase support.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. This should include the price, specifications, warranty terms, and any additional costs such as shipping or installation fees. A transparent quotation will help you make a direct comparison between different suppliers.

- Breakdown of Costs: Look for clarity in the pricing structure to avoid unexpected charges.

- Inclusions: Ensure that the quote covers all necessary components and services.

Step 5: Assess After-Sales Support and Training

The effectiveness of your granite engraving machine will depend significantly on the support provided after purchase. Evaluate what kind of training and technical support is available to your team. This is crucial for maximizing the machine’s capabilities and addressing any operational issues promptly.

- Technical Support: Confirm the availability of support channels such as phone, email, or online chat.

- Training Programs: Look for suppliers that offer training sessions for your staff on machine operation and maintenance.

Step 6: Consider Shipping and Logistics

Logistics can significantly impact the total procurement process. Ensure that you understand the shipping options available, including costs, timelines, and insurance. International shipping can be complex, so clarity on these aspects is vital.

- Shipping Costs: Factor these into your overall budget.

- Delivery Timeline: Confirm expected delivery dates to align with your project schedules.

Step 7: Finalize Your Purchase with a Contract

Before making a final decision, ensure that all terms are documented in a formal contract. This should cover payment terms, delivery schedules, warranty details, and any service agreements. A well-defined contract protects both parties and clarifies expectations.

- Review Terms Carefully: Ensure you understand all clauses and conditions.

- Seek Legal Advice: If necessary, consult with a legal expert to review the contract before signing.

By following these steps, B2B buyers can navigate the complexities of sourcing granite engraving machines with greater confidence, ensuring they select a machine that best fits their operational needs and budget.

Comprehensive Cost and Pricing Analysis for granite engraving machine price Sourcing

What Are the Key Cost Components in Sourcing Granite Engraving Machines?

When sourcing granite engraving machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of materials used in the construction of granite engraving machines significantly affects the overall cost. High-quality steel and precision components will naturally increase the price. Machines designed for heavy-duty use will have higher material costs due to their enhanced durability.

-

Labor: Labor costs encompass both direct and indirect labor involved in the manufacturing process. Skilled labor is essential for assembly and quality assurance, especially in high-precision machines. Labor costs can vary based on geographic location and the level of expertise required.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to consider suppliers’ operational efficiencies.

-

Tooling: The cost of tooling, including molds and dies used in machine production, can be significant. Custom tooling for specific machine configurations or features will add to the cost, particularly if the order volume is low.

-

Quality Control (QC): Ensuring that machines meet industry standards requires a robust QC process, which adds to overall costs. Buyers should consider suppliers who prioritize quality, as this can reduce long-term operational issues.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International buyers must consider duties, taxes, and insurance, which can add to the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition and the supplier’s positioning.

How Do Price Influencers Affect Granite Engraving Machine Costs?

Several factors can influence the pricing of granite engraving machines, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Minimum order quantities (MOQ) play a critical role in pricing. Larger orders often qualify for bulk pricing discounts, making it advantageous for businesses to consolidate their purchases.

-

Specifications and Customization: Custom features or specifications tailored to specific applications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts the machine’s durability and performance. High-quality components may be more expensive initially but can lead to lower maintenance and replacement costs over time.

-

Quality and Certifications: Machines that meet international quality standards (e.g., CE certification) may have higher upfront costs. However, investing in certified machinery can lead to fewer operational issues and greater reliability.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Well-established suppliers may charge a premium for their products due to their proven track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance, impacting the overall cost.

What Buyer Tips Can Help Optimize Costs for International Purchases?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs when sourcing granite engraving machines.

-

Negotiate Terms: Always negotiate payment terms and pricing with suppliers. Flexibility in payment terms can improve cash flow and reduce financial pressure.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also ongoing operational costs, including maintenance, energy consumption, and potential downtime. A lower initial price may not always equate to lower TCO.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing differences. For instance, suppliers in Europe may offer advanced technology but at a higher price point compared to manufacturers in Asia.

-

Leverage Partnerships: Establish long-term relationships with suppliers. This can lead to better pricing, priority service, and insights into future discounts or offers.

-

Research Market Trends: Stay informed about industry trends and technological advancements, which can impact pricing and availability. Being proactive can help in making timely purchasing decisions.

Disclaimer on Indicative Prices

Prices for granite engraving machines can vary widely based on the aforementioned factors. The figures provided are indicative and should be confirmed with suppliers to obtain the most accurate and current pricing information.

Alternatives Analysis: Comparing granite engraving machine price With Other Solutions

Exploring Alternative Solutions to Granite Engraving Machines

In the quest for effective solutions in the stone engraving industry, it’s crucial to evaluate alternatives to granite engraving machines. By comparing these options, B2B buyers can make informed decisions that align with their operational needs, budget constraints, and production goals. This analysis focuses on two viable alternatives: laser engraving machines and CNC routers, which offer unique advantages and challenges in the engraving process.

| Comparison Aspect | Granite Engraving Machine Price | Laser Engraving Machine | CNC Router |

|---|---|---|---|

| Performance | High precision for deep engraving | Excellent detail for surface etching | Versatile for various materials |

| Cost | $2,500 – $7,200 | $6,000 – $7,200 | $2,500 – $7,500 |

| Ease of Implementation | Moderate; requires training | Easy setup; user-friendly software | Moderate; CAD/CAM knowledge needed |

| Maintenance | Regular upkeep; parts replacement | Low maintenance; consumables needed | Moderate; requires calibration |

| Best Use Case | High-quality gravestones, sculptures | Decorative items, signage | Custom designs, art pieces |

What Are the Advantages and Disadvantages of Laser Engraving Machines?

Laser engraving machines excel in providing high-detail etching on the surface of granite and other materials. They are particularly suited for applications requiring intricate designs, such as personalized gifts or decorative stonework. The user-friendly software and minimal setup make them accessible for businesses looking to diversify their offerings quickly. However, laser machines can be limited in depth of engraving compared to traditional granite engraving machines, which may restrict their use for specific applications like gravestones or deep relief work.

How Do CNC Routers Compare in the Granite Engraving Market?

CNC routers present a versatile alternative to granite engraving machines, capable of handling a wide range of materials beyond stone, including wood and plastics. They are excellent for custom designs and can achieve complex carvings with high precision. The cost-effectiveness of CNC routers makes them an attractive option for businesses aiming to expand their production capabilities without significant investment. Nevertheless, they may require a higher level of expertise in CAD/CAM software, which could necessitate additional training for staff.

Conclusion: Choosing the Right Engraving Solution for Your Business

When selecting the most suitable engraving technology, B2B buyers should consider their specific operational requirements, including the types of materials they work with, the complexity of designs, and budget constraints. Granite engraving machines are ideal for businesses focused on deep engraving and high-quality stone work, while laser engraving machines are perfect for detailed surface etching. CNC routers offer flexibility and broader material compatibility, making them suitable for businesses looking to diversify. By weighing the advantages and disadvantages of each option, buyers can align their choice with their strategic goals and enhance their production capabilities.

Essential Technical Properties and Trade Terminology for granite engraving machine price

What Are the Key Technical Properties of Granite Engraving Machines?

When evaluating granite engraving machines, several technical specifications are crucial to ensure that the equipment meets industry standards and operational needs. Here are some key properties:

-

Working Area

The working area, typically measured in millimeters or feet, defines the maximum size of the material that can be engraved. For instance, a common size is 1300mm x 2500mm (approximately 4×8 feet). A larger working area allows for more extensive projects without needing to reposition the material, which is critical for efficiency in production environments. -

Laser Power

Measured in watts (W), laser power directly impacts the machine’s ability to engrave different materials. For granite engraving machines, typical laser powers range from 60W to 80W. Higher power enables deeper and more intricate engravings, thereby enhancing the machine’s versatility across various applications, from art to industrial use. -

Cooling System

A reliable cooling system, often water-cooled, is essential for maintaining optimal operational temperatures during long engraving sessions. This ensures the longevity of the laser tube and consistent engraving quality. In a B2B context, understanding the cooling requirements helps buyers anticipate maintenance needs and operational costs. -

Drive System

The drive system, which can include stepper motors or servo motors, is pivotal for precision and speed. For example, a machine with a high-quality drive system can achieve better accuracy in engraving, which is vital for detailed designs. Buyers should consider the type of drive system when assessing the machine’s performance and suitability for their specific engraving needs. -

Compatible Software

Compatibility with design software such as CorelDraw, Photoshop, or AutoCAD is essential for seamless workflow integration. This allows for flexibility in design and ease of use, which is particularly important for businesses that require quick turnaround times on custom projects.

What Are Common Trade Terms Related to Granite Engraving Machines?

Understanding trade terminology is vital for B2B transactions, especially in international contexts. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of granite engraving machines, knowing the OEM can provide insights into the quality and reliability of the machine components, which is crucial for long-term investment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For granite engraving machines, MOQs can vary significantly depending on the manufacturer and the complexity of the machine. Understanding MOQs helps buyers plan their purchasing strategy and manage inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products. For B2B buyers, issuing an RFQ for granite engraving machines allows for price comparisons and helps negotiate better deals, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. For granite engraving machines, knowing the applicable Incoterms can clarify shipping responsibilities, costs, and risks, which is particularly important for international buyers from regions like Africa, South America, and Europe. -

Warranty and Support

Warranty terms define the period and conditions under which a machine is covered for repairs or replacements. Understanding warranty options and support services is essential for B2B buyers to mitigate risks associated with machine failure and ensure ongoing operational efficiency.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when investing in granite engraving machines, ensuring they choose the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the granite engraving machine price Sector

What are the Global Drivers Influencing Granite Engraving Machine Prices?

The granite engraving machine market is currently experiencing dynamic shifts driven by technological advancements and changing buyer preferences. One of the primary global drivers is the increasing demand for personalized products across various industries, including construction, arts, and crafts. This demand is prompting manufacturers to innovate, leading to the emergence of advanced CNC and laser engraving technologies that enhance precision and efficiency. Additionally, as urbanization accelerates in regions such as Africa and South America, the need for high-quality engraving machines to produce decorative elements and memorials is on the rise.

Current trends also reflect a growing interest in automation and digitalization in manufacturing processes. International B2B buyers are increasingly seeking machines that integrate with CAD/CAM software, enabling seamless design and production workflows. Moreover, the availability of machines with enhanced features, such as customizable engraving heads and adjustable working tables, is appealing to businesses looking to diversify their product offerings.

In terms of pricing, fluctuations can occur based on the specifications, brand reputation, and warranty offerings. For instance, entry-level models may start around $2,500, while high-end, feature-rich machines can reach upwards of $7,200. Understanding these market dynamics is essential for buyers to make informed decisions and negotiate favorable terms.

How is Sustainability and Ethical Sourcing Impacting Granite Engraving Machine Pricing?

Sustainability is becoming a critical factor in the purchasing decisions of international B2B buyers in the granite engraving machine sector. The environmental impact of manufacturing processes and the sourcing of materials is under scrutiny, pushing companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and ensuring the ethical sourcing of components.

Incorporating eco-friendly materials and technologies not only aligns with global sustainability goals but can also influence pricing structures. Machines that use energy-efficient components or are constructed from recycled materials may come at a premium, yet they offer long-term cost savings and appeal to environmentally conscious consumers.

Furthermore, certifications such as ISO 14001 for environmental management systems can enhance a supplier’s credibility and attract buyers looking for responsible sourcing options. By investing in sustainable machinery, B2B buyers can enhance their brand reputation and meet the growing consumer demand for environmentally friendly products.

What is the Historical Context of Granite Engraving Machines in the B2B Sector?

The evolution of granite engraving machines can be traced back to traditional manual engraving techniques, which were labor-intensive and limited in precision. The introduction of CNC technology in the late 20th century revolutionized the industry, allowing for greater accuracy and the ability to replicate designs efficiently. This shift not only increased production rates but also expanded the scope of applications, making it feasible to engrave intricate designs on hard materials like granite.

As the industry progressed, laser engraving technology emerged as a game-changer, offering even higher precision and versatility. This technological advancement has enabled engravers to explore new creative avenues, catering to the growing consumer desire for personalized and unique products. Today, the market for granite engraving machines continues to innovate, integrating advanced software and automation to meet the demands of a diverse range of industries. Understanding this historical context is crucial for B2B buyers as they navigate the evolving landscape of engraving technology and pricing.

Frequently Asked Questions (FAQs) for B2B Buyers of granite engraving machine price

-

How do I determine the right granite engraving machine for my business needs?

To select the appropriate granite engraving machine, assess your specific requirements such as the types of materials you will engrave, the volume of production, and the level of detail required. Consider machine specifications like working area size, laser power, and compatible software. Additionally, evaluate the machine’s versatility in handling different materials and engraving styles. Engaging with suppliers and requesting demonstrations can also provide insights into the machine’s capabilities and help you make an informed decision. -

What is the typical price range for granite engraving machines?

The price of granite engraving machines can vary significantly based on features, brand, and specifications. Generally, entry-level machines start around $2,500, while more advanced models can cost upwards of $7,200. Factors influencing price include the machine’s technology (laser vs. CNC), warranty terms, and additional features like automatic tool changers or advanced cooling systems. It’s advisable to compare multiple suppliers and consider the total cost of ownership, including maintenance and operational costs. -

What payment terms should I expect when purchasing a granite engraving machine?

Payment terms can vary by supplier and region, but common options include T/T (Telegraphic Transfer), credit cards, and payment through platforms like PayPal. Some suppliers may require a deposit (usually 30%) upfront, with the balance due before shipping. Ensure you clarify terms regarding currency, payment timelines, and any potential financing options available to help manage cash flow. It’s also wise to confirm that the payment method offers adequate buyer protection. -

What should I look for when vetting suppliers of granite engraving machines?

When vetting suppliers, consider their reputation, experience, and customer reviews. Verify their certifications, such as ISO or CE, which indicate compliance with international quality standards. Request references from past clients and inquire about their after-sales support, warranty services, and availability of spare parts. Additionally, assess their responsiveness and willingness to provide technical assistance, as strong support is crucial for maintaining operational efficiency. -

What is the minimum order quantity (MOQ) for granite engraving machines?

The MOQ for granite engraving machines can vary widely among manufacturers. Some suppliers may allow single unit purchases, while others may set a minimum of 2-5 units to qualify for bulk pricing. If you are new to the industry or unsure about your needs, inquire about flexible purchasing options or trial periods. Establishing a good relationship with suppliers can also lead to more favorable terms over time. -

How do I ensure the quality of the granite engraving machine I am purchasing?

To ensure quality, request detailed specifications and certifications from the supplier. It’s beneficial to review the machine’s design and components, such as the type of laser or spindle used, and to ask about the manufacturing process. Conducting a factory visit or requesting a live demonstration can provide insights into the machine’s performance. Additionally, inquire about the supplier’s quality assurance processes and after-sales service to address any issues post-purchase. -

What logistics considerations should I keep in mind when importing a granite engraving machine?

When importing a granite engraving machine, consider shipping costs, customs duties, and delivery timelines. Research the regulations and import duties applicable in your country to avoid unexpected fees. Collaborate with a reliable logistics partner familiar with machinery imports to ensure proper handling and documentation. Confirm the supplier’s shipping methods and insurance coverage to safeguard your investment during transit. -

Can I customize my granite engraving machine based on my specific requirements?

Many manufacturers offer customization options for granite engraving machines to meet specific business needs. Customizations may include modifications to the working area size, laser power, or additional features like automated tool changers or specialized software. When discussing options with suppliers, be clear about your requirements and budget. It’s essential to understand how these customizations may affect the lead time and overall cost of the machine.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Granite Engraving Machine Price Manufacturers & Suppliers List

1. STYLECNC – 4×8 Marble, Granite, Stone Laser Engraving Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Product Name: 4×8 Marble, Granite, Stone Laser Engraving Machine

Brand: STYLECNC

Model: STJ1325S

Working Area: 1300mm x 2500mm (4×8 feet)

Laser Power: 60W/80W

Laser Type: Sealed CO2 Glass Laser Tube

Cooling Mode: Water Cooling and Protection System

Compatible Software: CorelDraw, Photoshop, AutoCAD

Position System: Red Light Pointer

Graphic Format Supported: PLT, DXF, BMP, AI, DST, JPG

Driving Sys…

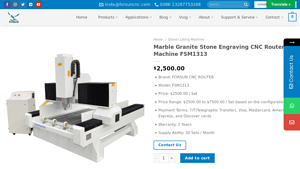

2. FORSUN – Marble Granite Stone Engraving CNC Router Machine FSM1313

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Marble Granite Stone Engraving CNC Router Machine FSM1313”, “Brand”: “FORSUN”, “Price”: “$2500.00”, “Price Range”: “$2500.00 to $7500.00”, “Payment Terms”: “T/T, Visa, Mastercard, American Express, Discover”, “Warranty”: “2 Years”, “Supply Ability”: “30 Sets / Month”, “Applications”: [“Stone industry”, “stone tablet processing”, “art relief”, “advertising”, “decoration”, “ceramic…

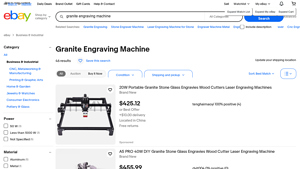

3. eBay – Granite Engraving Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Granite Engraving Machine listings on eBay include various models and specifications. Key products include: 1. A5 PRO 40W DIY Granite Stone Glass Engraving Machine priced at $455.99 (was $479.99, 5% off) with $99.99 delivery from China. 2. 20W Portable Granite Stone Glass Engraving Machine priced at $425.12 with $59.50 delivery from China, offering free returns. 3. 3D Desktop Carving Cutting Metal…

4. Mirtels – Laser Stone Engraving Machines

Domain: mirtels.com

Registered: 2015 (10 years)

Introduction: Mirtels Laser Stone Engraving Machines offer advanced engraving technologies for creating photorealistic images on stone surfaces. Key features include:

– **Models Available**: L5060, L60120, L90170

– **Engraving Area**:

– L5060: 500×600 mm

– L60120: 600×1200 mm

– L90170: 900×1700 mm

– **Maximum Speed of Engraving**: 1000 mm/sec

– **Image Reading**: Supports USB-Flash memory and PC con…

5. Elephant CNC – Automatic Tool Change 2113 Granite Engraving Machine

Domain: elephant-cnc.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Automatic Tool Change 2113 Granite Engraving Machine with Rotary Device”, “features”: [“Automatic tool change system”, “Granite engraving capabilities”, “Includes rotary device for cylindrical engraving”, “High precision and efficiency”, “User-friendly interface”], “applications”: [“Granite engraving”, “Stone carving”, “Cylindrical engraving”], “dimensions”: “Not specified”, “wei…

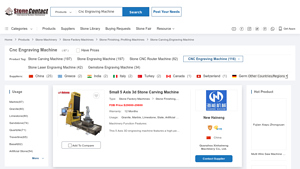

6. StoneContact – Custom ATC 2113 Granite Engraving Machine

Domain: stonecontact.com

Registered: 2003 (22 years)

Introduction: This company, StoneContact – Custom ATC 2113 Granite Engraving Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. AP Lazer – CNC Granite and Marble Engraving Machine

Domain: aplazer.com

Registered: 2009 (16 years)

Introduction: CNC Granite and Marble Engraving Machine by AP Lazer is designed for precision and reliability in engraving granite, marble, and other natural stone surfaces. It features a generous working area to accommodate various stone sizes and is capable of producing durable, detailed engravings. The machine allows for personalization of items such as memorials, plaques, coasters, and more. Advantages inclu…

8. Shot Blasting Machines – Granite Engraving Machine

Domain: shotblastingmachines.in

Registered: 2019 (6 years)

Introduction: Granite Engraving Machine Price Range: ₹ 30k – 15 Lakh Specifications: Material: Mild Steel, Type of Nozzle: Tungsten / Boron Carbide, Blast nozzle diameter: 6 – 10 mm, Compressed air requirement: 25 – 90 CFM, Blast hose and recovery hose: 6 – 8 Mtr., Storage Capacity: 28 Lit, Blasting Capacity: Approx 3 to 5 Sq. Mtr/Hr. Payment Method: 100% T/T NEFT RTGS IMPS. Transportation Mode: Air Transport, …

9. Gravotech – LS100 Laser Engraver

Domain: gravotech.us

Registered: 2007 (18 years)

Introduction: Slate, granite and stone engraving products from Gravotech include various laser tables and engraving machines designed for personalization, signage, and creative applications. Key products include:

1. **LS100**: Small CO2 laser engraver with a marking area of 460 x 305 mm, suitable for plastics, wood, glass, and other organic materials.

2. **LS100EX**: Medium CO2 or Fiber laser engraving and c…

Strategic Sourcing Conclusion and Outlook for granite engraving machine price

In the evolving landscape of granite engraving machines, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the price range—from affordable options around $2,500 to advanced models priced up to $7,200—enables businesses to align their investment with operational needs and market demands. Factors such as machine specifications, warranty provisions, and supplier reliability play a pivotal role in decision-making.

Buyers should prioritize partnerships with manufacturers that offer not only competitive pricing but also comprehensive support, including warranties and technical assistance. This approach minimizes risks and enhances the overall value derived from the investment.

Looking ahead, the demand for granite engraving machines is expected to grow, driven by trends in personalization and artistic applications across various industries. For international buyers from regions like Africa, South America, the Middle East, and Europe, now is the opportune time to engage with suppliers, explore customization options, and secure favorable purchasing agreements. By doing so, businesses can position themselves to capitalize on emerging opportunities and drive innovation in their respective markets.