Contents

Manufacturing Insight: Granite Cnc Router

Precision Granite CNC Routing: Engineered for Demanding Applications

Honyo Prototype delivers industry-leading CNC machining services specifically engineered for granite and other challenging stone materials. Our granite CNC routers integrate high-torque spindles, vibration-damped gantry systems, and proprietary dust management to overcome the unique abrasiveness and thermal sensitivity of granite. Unlike standard machining centers, our dedicated stone platforms maintain sub-micron positional accuracy across extended production runs, ensuring dimensional stability for precision components in semiconductor tooling, metrology bases, and aerospace fixtures. This capability stems from our ISO 9001-certified processes and in-house engineering team’s deep material science expertise, which optimizes feed rates, tool geometry, and coolant strategies to prevent micro-fracturing and surface degradation.

Our end-to-end service encompasses CAD/CAM programming, 5-axis contouring, fine-detail engraving, and post-machining surface finishing—all executed on equipment calibrated for granite’s exacting requirements. We support grades from absolute black to exotic crystalline variants, with tolerance capabilities down to ±0.005 mm and surface finishes as fine as Ra 0.8 µm.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within minutes—not days—eliminating traditional RFQ bottlenecks while maintaining full engineering transparency. For mission-critical granite components where precision cannot be compromised, partner with a manufacturer that merges material-specific mastery with digital procurement efficiency. Request your quote today to experience engineered accuracy from concept to delivery.

Technical Capabilities

Granite CNC Router – Technical Specifications

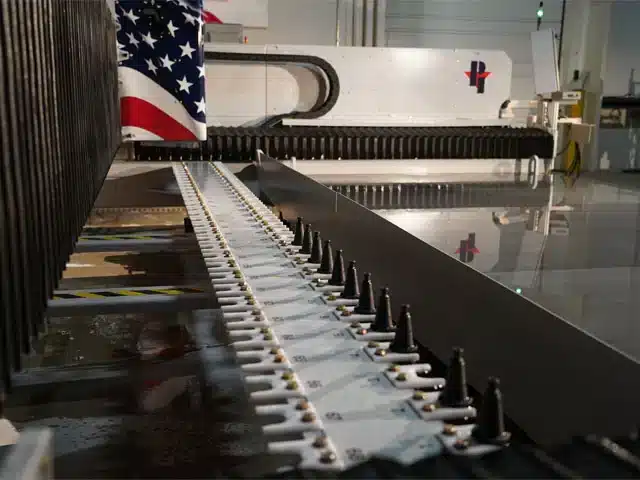

A high-precision granite CNC router is engineered for superior stability, vibration damping, and long-term accuracy, making it ideal for 3, 4, and 5-axis milling and turning operations. The granite base structure ensures minimal thermal expansion and exceptional surface finish, critical for achieving tight tolerances in demanding applications across a range of materials including aluminum, steel, ABS, and nylon.

| Parameter | Specification |

|---|---|

| Machine Type | CNC Router with Granite Bed |

| Axes Configuration | 3-axis, 4-axis (rotary A or B), 5-axis (simultaneous XYZAB or XYZBC) |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.0001 in) |

| Spindle Speed Range | 8,000 – 24,000 RPM (air-cooled or liquid-cooled options) |

| Spindle Power | 5 – 15 kW (depending on configuration) |

| Tool Changer | Automatic Tool Changer (ATC) with 8–30 tool capacity |

| Control System | Siemens SINUMERIK, Fanuc, or Heidenhain iTNC |

| Maximum Traverse (X/Y/Z) | X: 1000–3000 mm, Y: 600–1500 mm, Z: 200–500 mm (custom sizes available) |

| Rapid Traverse Rate | 30–60 m/min |

| Linear Axis Drive | High-precision ball screws or linear motors |

| Rotary Axis (4th/5th) | High-torque direct drive or precision worm-gear (±5 arc-sec accuracy) |

| Tolerance Capability | ±0.01 mm (±0.0004 in) typical; down to ±0.005 mm with thermal compensation |

| Surface Finish | Ra < 0.8 µm (machined), achievable with proper toolpath and spindle control |

| Materials Processed | Aluminum (6061, 7075), Mild and Stainless Steel (up to 4140), ABS, Nylon, PEEK |

| Coolant System | Mist, flood, or high-pressure coolant (optional for steel and high-temp plastics) |

| Workholding Compatibility | Vacuum table, T-slots, custom fixtures, rotary chucks |

| Machine Frame | Epoxy granite composite base with steel gantry for rigidity and damping |

| Thermal Compensation | Optional real-time thermal error correction |

| Software Compatibility | Mastercam, Fusion 360, HyperMill, PowerMill, SolidWorks CAM |

This granite CNC router platform delivers consistent performance in high-tolerance environments, supporting complex multi-axis machining of metals and engineering plastics. The inherent damping properties of granite reduce chatter, enabling finer finishes and tighter tolerances—especially beneficial when finishing aluminum molds or machining wear-resistant nylon components.

From CAD to Part: The Process

Honyo Prototype Granite CNC Router Manufacturing Process

Our end-to-end workflow for granite CNC router production is engineered for precision, efficiency, and material-specific optimization. Granite demands specialized handling due to its abrasiveness, density, and fracture sensitivity. Below is the rigorously defined sequence:

CAD Upload & Validation

Clients submit 3D CAD models (STEP, IGES, or native formats) via our secure portal. Our system performs initial validation checks, including unit consistency, geometry integrity, and minimum feature size verification. For granite components, we immediately flag features prone to chipping (e.g., sharp internal corners < R3mm) or excessive thin-wall sections (< 8mm), as these require material-specific adjustments. Invalid submissions trigger automated feedback within 2 business hours.

AI-Powered Quoting Engine

Validated CAD files enter Honyo’s proprietary AI quoting system. The algorithm cross-references granite-specific parameters: material grade (e.g., Black Galaxy, Absolute Black), density (2.6–2.8 g/cm³), abrasion resistance, and required surface finish (typically Ra 0.8–3.2 µm for granite). Machine time calculations incorporate spindle load limits (max 15 kW for granite), diamond-coated tool wear rates, and mandatory coolant flow rates (min 15 L/min). Quotes detail cost drivers like vacuum table setup complexity and secondary operations (e.g., edge polishing). Standard quote turnaround is 4 business hours.

Design for Manufacturability (DFM) Review

Engineers conduct a targeted DFM analysis focusing on granite’s unique challenges. Common recommendations include increasing internal radii to R5mm+, specifying draft angles > 2° for undercuts, and avoiding through-holes smaller than Ø6mm. We validate fixturing feasibility using granite’s thermal expansion coefficient (7–8 µm/m·°C) to prevent distortion during milling. Clients receive a formal DFM report with actionable suggestions; approval is required before toolpath generation. This phase typically takes 1–2 business days.

Precision Production

Granite machining occurs on dedicated 5-axis CNC routers with reinforced gantries and hydrostatic bearings to dampen vibration. Key protocols include:

Tooling: Diamond-coated carbide end mills (max RPM 12,000) with adaptive toolpath strategies to minimize heat buildup

Parameters: Feed rates capped at 300 mm/min, depth of cut ≤ 2mm, constant coolant flood to suppress silica dust

In-process QA: Laser probing verifies critical dimensions after roughing and semi-finishing; granite-specific thermal compensation adjusts for ambient temperature shifts

Full production cycles for complex granite fixtures average 5–10 days depending on geometry.

Quality-Controlled Delivery

All granite components undergo final inspection per ISO 2768-mK tolerances (±0.1mm for features < 500mm). We measure flatness (max 0.05mm/m²), squareness (< 0.02°), and surface integrity using granite surface plates and CMMs. Parts are cleaned with non-acidic solutions to prevent etching, wrapped in anti-static foam, and crated with custom shock-absorbing inserts. Shipping documentation includes material certification, first-article inspection reports, and handling guidelines for stone substrates. Standard delivery is 24–72 hours post-approval via tracked freight.

Process Timeline Summary

| Phase | Typical Duration | Key Granite-Specific Focus |

|————————|——————|——————————————|

| CAD Upload & Validation| < 2 business days| Geometry fracture risk assessment |

| AI Quote | < 4 business hours| Diamond tool wear & coolant optimization |

| DFM Review | 1–2 business days| Draft angles, internal radii, fixturing |

| Production | 5–10 business days| Low-RPM machining, thermal management |

| Delivery | 1–3 business days| Silica-safe packaging, flatness validation |

This process ensures granite components meet stringent mechanical and aesthetic requirements while mitigating material-specific failure modes. All steps are audited under ISO 9001:2015, with real-time production data accessible to clients via our customer portal.

Start Your Project

Looking for a high-performance granite CNC router for your manufacturing needs? Contact Susan Leo today at [email protected] to request specifications, pricing, or a custom quote.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring precision engineering, fast turnaround times, and strict quality control for all granite CNC routing solutions.

Whether you’re prototyping or scaling production, our Shenzhen-based team delivers industrial-grade performance with global support. Reach out now to discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.