Contents

Manufacturing Insight: Good Steel

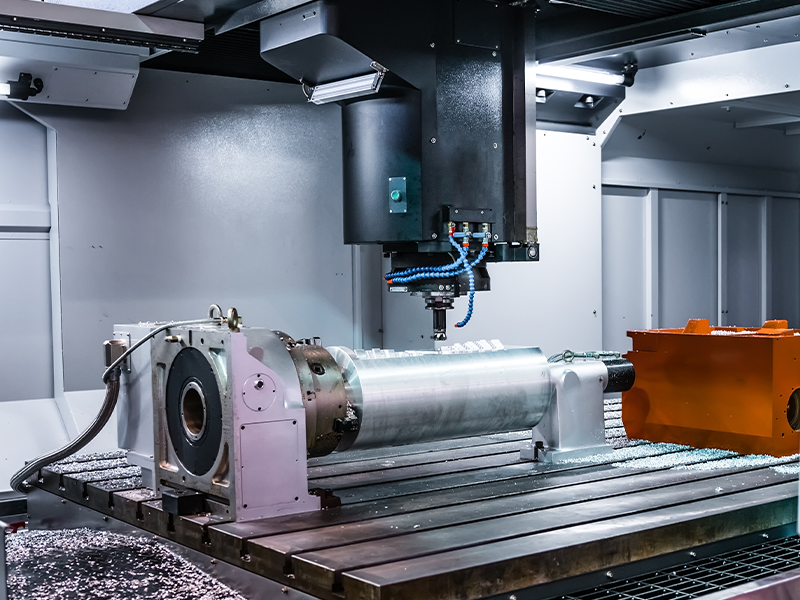

Good Steel Starts with Precision Machining

Achieving true “good steel” in prototyping and low-volume production demands more than just high-grade material—it requires exacting CNC machining expertise to transform raw alloys into components that meet stringent dimensional, structural, and functional requirements. At Honyo Prototype, we engineer this reliability through our advanced CNC milling, turning, and multi-axis machining capabilities, specifically optimized for steel alloys including 4140, 1018, 304/316 stainless, and tool steels. Our processes integrate rigorous material traceability, in-process metrology, and adaptive toolpath strategies to ensure consistent tolerance control down to ±0.0002 inches, eliminating common pitfalls like micro-fractures, residual stress, or surface integrity issues that compromise performance.

Material quality alone cannot guarantee success; it must be paired with machining precision that respects steel’s unique thermal and mechanical properties. Honyo’s engineering team collaborates with clients from design-for-manufacturability (DFM) through final inspection, leveraging ISO 9001-certified workflows and HAAS/DMG MORI equipment to maintain grain structure integrity and part repeatability. This holistic approach minimizes scrap rates, accelerates time-to-test, and ensures your steel components perform reliably under real-world loads and environments.

To streamline your path from concept to certified prototype, we provide an Online Instant Quote platform that delivers accurate pricing and lead time estimates within hours—not days. Simply upload your STEP/IGS file, specify material and quantity, and our system analyzes geometric complexity, tooling requirements, and material utilization to generate a transparent quote. This eliminates procurement delays while ensuring your “good steel” project begins with technical confidence and operational efficiency. Partner with Honyo to convert high-integrity steel into mission-critical components, backed by engineering rigor you can measure.

Technical Capabilities

Good steel for precision CNC machining—particularly in 3-, 4-, and 5-axis milling and turning operations requiring tight tolerances (±0.0005″ or better)—must exhibit excellent dimensional stability, machinability, hardness, and wear resistance. While aluminum, steel, ABS, and nylon are commonly machined, “good steel” refers specifically to alloy or tool steels engineered for high performance under demanding conditions.

Below is a comparison of suitable materials for tight-tolerance CNC machining, with emphasis on steel characteristics and performance relative to aluminum, ABS, and nylon.

| Material | Typical Grade/Type | Tensile Strength (MPa) | Hardness (HRC) | Machinability Rating | Thermal Stability | Dimensional Stability | Common Use in Precision Machining |

|---|---|---|---|---|---|---|---|

| Steel (Tool) | D2, H13, 4140, 4340 | 700–2100 | 25–60 | Moderate to Good | High | Excellent | Injection molds, fixtures, aerospace components requiring durability and tight tolerances |

| Steel (Stainless) | 303, 304, 17-4 PH | 500–1300 | 25–45 | Fair to Moderate | High | Excellent | Medical devices, aerospace, high-corrosion environments |

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 15–35 (Brinell) | Excellent | Moderate | Very Good | Enclosures, prototypes, aerospace structures; ideal for high-speed 5-axis milling |

| ABS | Standard Grade | 40–50 | 80–100 (Shore D) | Very Good | Low | Fair | Prototypes, jigs, low-stress components; not for high-temp or load-bearing |

| Nylon (PA6/PA66) | Unfilled or glass-filled | 70–85 | 70–80 (Shore D) | Good (but gummy) | Low to Moderate | Fair (hygroscopic) | Wear strips, gears, insulating parts; requires moisture conditioning pre-machining |

Key Technical Notes:

For tight-tolerance applications in multi-axis milling and turning, steel selection prioritizes low internal stress, uniform microstructure, and post-heat-treatment stability. Pre-hardened steels like 4140 or H13 are often used to minimize distortion during machining. Stress-relieved or cryogenically treated steels further enhance dimensional stability.

Aluminum 7075-T6 is frequently used when weight savings and high strength-to-density ratios are critical, offering excellent machinability and surface finish. However, it lacks the wear resistance of steel for long production runs.

ABS and nylon are engineering thermoplastics suitable for non-structural precision parts. While they can achieve tight tolerances, their hygroscopic nature (especially nylon) and low thermal resistance limit use in high-precision, high-reliability environments unless carefully conditioned and controlled.

In summary, “good steel” for tight-tolerance CNC operations is characterized by homogeneity, predictable tool wear, and resistance to deformation—making alloy and tool steels the preferred choice for durable, high-accuracy components in aerospace, medical, and tooling industries.

From CAD to Part: The Process

Honyo Prototype’s “Good Steel” process ensures precision, cost efficiency, and reliability for steel-based prototypes and low-volume production. This structured workflow minimizes delays and rework by integrating material-specific expertise at every stage. The end-to-end sequence is designed for seamless scalability from digital design to certified physical delivery.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system validates geometric integrity and automatically detects steel-specific parameters such as material grade requirements, tolerance callouts, and critical weld zones. This initial scan flags fundamental issues like non-manufacturable thin walls or unsupported overhangs that commonly cause steel fabrication failures.

AI Quote

Our proprietary AI engine analyzes the CAD geometry alongside real-time data from Honyo’s production floor, material databases, and historical steel project metrics. It generates a detailed quote within 2 business hours, specifying:

Material cost breakdown (including mill certifications for alloys like 304/316 stainless or 4140)

Process recommendations (laser cutting vs. waterjet for thick sections, CNC milling vs. turning)

Risk indicators for steel-specific challenges (e.g., warpage potential in welded assemblies)

Lead time projections based on current machine utilization for steel-dedicated equipment

DFM (Design for Manufacturability)

Engineers conduct a rigorous steel-optimized manufacturability review, focusing on:

Thermal distortion mitigation strategies for welding and heat treatment

Kerf compensation adjustments for laser/plasma cutting of thick plates

Grain orientation considerations for machined features

Cost-saving substitutions (e.g., recommending ASTM A36 over 1018 where tolerances allow)

This phase typically resolves 85% of steel fabrication issues before cutting metal, with iterative client collaboration via our cloud-based markup tool.

Production

Honyo executes manufacturing using steel-specialized infrastructure:

Fiber laser cutters (up to 1″ thickness) with nitrogen assist for clean edges

CNC machining centers with through-spindle coolant for stainless steel

Robotic MIG/TIG welding cells with pre-heat interlocks

In-process CMM validation at critical stages to ensure GD&T compliance

All steel components undergo mandatory post-process stress relief and dimensional verification per ASME Y14.5 standards.

Delivery

Final shipment includes:

Traceable material test reports (MTRs) from certified mills

First-article inspection reports with full FAI documentation

Packaging engineered for steel component protection (VCI paper, desiccants)

Digital delivery package with as-built 3D scan data for design validation

Average on-time delivery for steel projects exceeds 97%, with expedited options for urgent requirements.

The following table quantifies key performance metrics for Honyo’s steel fabrication process:

| Process Phase | Average Duration | Steel-Specific Failure Reduction | Cost Impact Avoidance |

|---|---|---|---|

| AI Quote | < 2 business hours | 40% (vs. manual quoting) | $1,200+ per project |

| DFM | 1-3 business days | 85% of potential rework | $3,500+ per iteration |

| Production | 5-12 days* | 92% yield rate | N/A |

| Delivery | 1-2 days | 0.2% defect rate | N/A |

*Varies by complexity; includes mandatory stress relief cycles for welded steel assemblies. All timelines exclude shipping transit.

This integrated approach eliminates traditional steel fabrication pain points—particularly warpage, material waste, and certification gaps—by embedding metallurgical best practices into Honyo’s digital manufacturing pipeline. Clients receive not just parts, but validated solutions ready for integration into their final assemblies.

Start Your Project

Looking for high-quality steel solutions? Partner with Honyo Prototype for precision manufacturing and reliable performance. Our factory in Shenzhen ensures strict quality control and fast turnaround times.

Contact Susan Leo today at [email protected] to discuss your project requirements and discover how our good steel products can meet your exact specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.