Introduction: Navigating the Global Market for gloss black chrome powder coat

In the ever-evolving landscape of industrial finishes, sourcing high-quality gloss black chrome powder coat presents a unique challenge for B2B buyers. As manufacturers and suppliers in regions like Africa, South America, the Middle East, and Europe seek to enhance their product offerings, understanding the nuances of gloss black chrome powder coat becomes crucial. This guide aims to demystify the complexities surrounding this versatile coating solution, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

From automotive components to architectural features, the applications of gloss black chrome powder coat are vast and varied, appealing to a wide array of industries. Buyers will benefit from insights on how to effectively assess supplier credibility and ensure compliance with local regulations, which is particularly important in diverse markets like Vietnam and Saudi Arabia. Additionally, this guide provides an in-depth analysis of pricing structures and market trends, enabling informed purchasing decisions.

By equipping international B2B buyers with the knowledge they need to navigate the global market for gloss black chrome powder coat, this comprehensive resource empowers businesses to make strategic choices that align with their operational goals. With the right information at their fingertips, buyers can confidently select the best products to elevate their offerings and meet the demands of their customers.

Understanding gloss black chrome powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Black Chrome II | Transparent charcoal black; high gloss finish | Automotive, Industrial, Design | Pros: Striking appearance; versatile applications. Cons: Requires specific base coat for optimal results. |

| Ultra Black Chrome | Deep black with chrome-like sheen; high durability | Decorative, Automotive, Retail | Pros: Excellent wear resistance; eye-catching. Cons: Higher cost; may need specialized application. |

| Gloss Black Metallic Sparkle | Metallic finish with sparkle effect; high gloss | Consumer Goods, Automotive | Pros: Unique aesthetic appeal; enhances product value. Cons: Can be more expensive than standard options. |

| Super Durable Gloss Black | High durability; resistant to chipping and fading | Heavy Machinery, Automotive | Pros: Long-lasting finish; suitable for harsh environments. Cons: Limited color variations; may require a specific application process. |

| Candy Black Chrome | Translucent finish; depth varies with substrate color | Custom Fabrication, Art Projects | Pros: Customizable appearance; unique visual effects. Cons: Requires careful substrate selection; complex application process. |

What Are the Key Features of Black Chrome II Powder Coat?

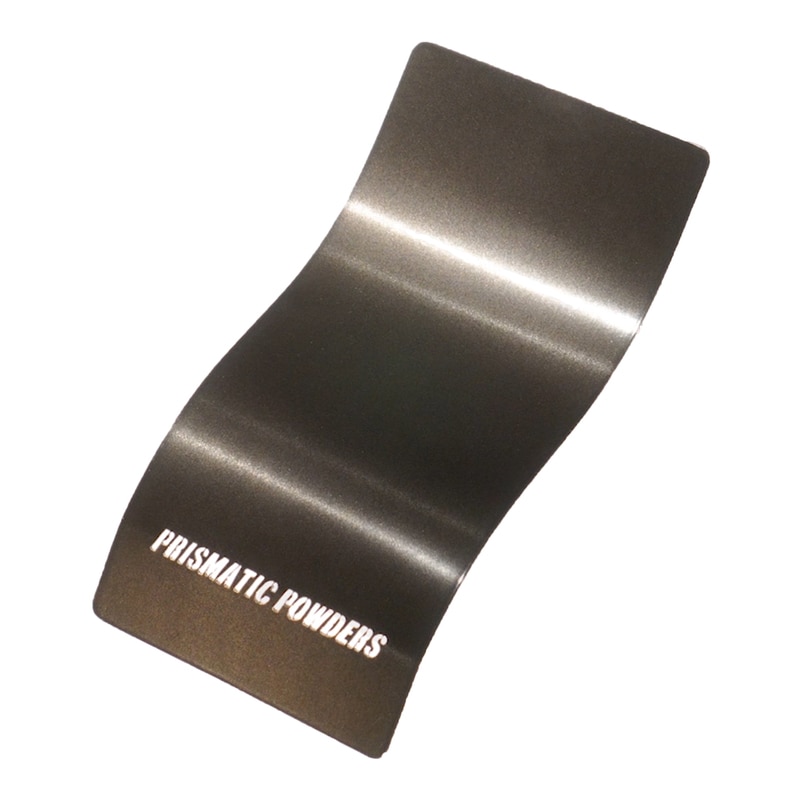

Black Chrome II is recognized for its transparent charcoal black color and high gloss finish, making it a popular choice in industries such as automotive and industrial design. Its unique aesthetic can significantly enhance the visual appeal of products. However, to achieve the best results, this powder coat must be applied over a bright silver substrate, which may require additional planning during the purchasing process.

Why Choose Ultra Black Chrome for Your B2B Needs?

Ultra Black Chrome offers a deep black finish with a chrome-like sheen, making it a favored option for decorative applications in retail and automotive sectors. Its high durability ensures that the finish withstands wear and tear, making it suitable for items that require a long-lasting appearance. However, the higher cost and specialized application methods may be a consideration for budget-conscious buyers.

What Makes Gloss Black Metallic Sparkle Stand Out?

Gloss Black Metallic Sparkle features a metallic finish with a unique sparkle effect that enhances the product’s aesthetic appeal. This type of powder coat is particularly effective in consumer goods and automotive applications where visual impact is crucial. While it can elevate product value, the cost is typically higher than standard black options, which buyers should weigh against the potential benefits.

How Does Super Durable Gloss Black Benefit Heavy Machinery?

Super Durable Gloss Black is designed for heavy-duty applications, offering high resistance to chipping and fading. This makes it ideal for use in heavy machinery and automotive components that are exposed to harsh conditions. While it provides a robust finish, buyers may find limited color variations and a need for specific application processes, which can influence procurement decisions.

What Are the Advantages of Candy Black Chrome in Custom Projects?

Candy Black Chrome provides a translucent finish that varies in depth based on the substrate color, allowing for a high degree of customization in art projects and custom fabrication. This versatility can create unique visual effects, appealing to designers and artists. However, careful substrate selection and a more complex application process can complicate purchasing and application, making it essential for buyers to evaluate their project requirements.

Key Industrial Applications of gloss black chrome powder coat

| Industry/Sector | Specific Application of gloss black chrome powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wheel rims and chassis components | Enhances aesthetic appeal and corrosion resistance | Ensure compatibility with various substrates and regulations |

| Aerospace | Aircraft interior fittings | Lightweight finish that provides durability and a premium look | Compliance with aviation standards and weight specifications |

| Architectural & Design | Decorative elements and furniture | Adds a luxurious finish while maintaining structural integrity | Availability of custom colors and finishes |

| Electronics | Housing for electronic devices | Provides a sleek appearance while ensuring protection from wear | Consider thermal properties and electrical conductivity |

| Powersports | Motorcycle frames and accessories | Increases durability against environmental factors and wear | Assess UV stability and impact resistance |

How Is Gloss Black Chrome Powder Coat Used in Automotive Applications?

In the automotive sector, gloss black chrome powder coat is commonly applied to wheel rims and chassis components. This coating enhances the aesthetic appeal of vehicles while providing a robust layer of corrosion resistance, which is vital for components exposed to harsh environmental conditions. International buyers, particularly in regions like Africa and the Middle East, should ensure the coatings comply with local regulations and are suitable for various substrates used in vehicle manufacturing.

What Are the Aerospace Applications of Gloss Black Chrome Powder Coat?

The aerospace industry utilizes gloss black chrome powder coat for aircraft interior fittings, where aesthetics and functionality are paramount. This lightweight finish not only provides a premium look but also ensures durability, which is crucial for components subjected to extreme conditions. Buyers must prioritize suppliers that meet strict aviation standards and can provide coatings that adhere to weight specifications, particularly in Europe and South America.

How Is Gloss Black Chrome Powder Coat Beneficial in Architectural & Design?

In architectural and design applications, gloss black chrome powder coat is often used for decorative elements and furniture. This finish adds a luxurious touch while maintaining the structural integrity of the items. For B2B buyers in Europe and the Middle East, sourcing considerations include the availability of custom colors and finishes to match specific design aesthetics, as well as ensuring long-term durability against wear and tear.

What Role Does Gloss Black Chrome Powder Coat Play in Electronics?

In the electronics industry, gloss black chrome powder coat is applied to housings for electronic devices, providing a sleek appearance while ensuring protection from wear. This application is particularly important for manufacturers looking to enhance product appeal while maintaining functionality. Buyers should consider the thermal properties and electrical conductivity of the coating, especially in regions like South America where climate conditions can vary significantly.

How Is Gloss Black Chrome Powder Coat Used in Powersports?

Powersports applications, such as motorcycle frames and accessories, frequently employ gloss black chrome powder coat due to its durability and resistance to environmental factors. This coating helps maintain the appearance of components while providing a protective layer against wear. Buyers should assess the UV stability and impact resistance of the coatings, particularly in sunny regions like Africa, where outdoor exposure is significant.

3 Common User Pain Points for ‘gloss black chrome powder coat’ & Their Solutions

Scenario 1: Difficulty Achieving Desired Finish Quality

The Problem: B2B buyers often face challenges in achieving the desired finish quality when applying gloss black chrome powder coat. Variability in substrate quality, application technique, and environmental conditions can lead to inconsistent results, such as uneven gloss or a lackluster appearance. This inconsistency can be particularly frustrating for businesses that rely on high-quality aesthetics for branding and customer satisfaction, such as automotive parts manufacturers or decorative item producers.

The Solution: To overcome this challenge, buyers should prioritize a thorough understanding of the application process and invest in proper training for their applicators. It is essential to start with a high-quality substrate, as the underlying material significantly influences the final appearance. For optimal results, a bright silver base coat, such as Super Chrome, should be applied prior to the gloss black chrome top coat. This combination will enhance the finish and ensure a reflective quality. Conducting trial runs on test pieces before full-scale production can help identify any potential issues with application techniques or environmental factors. Additionally, maintaining consistent oven temperatures and ensuring proper curing times will help achieve a uniform finish.

Scenario 2: Limited Availability of Specialized Powders

The Problem: Many international B2B buyers, particularly those in regions such as Africa and South America, may struggle to find reliable suppliers for gloss black chrome powder coat. Limited access to specialized products can hinder production timelines and increase costs due to shipping delays or the need to source from multiple vendors. This is especially critical for industries that operate under tight schedules or have specific aesthetic requirements.

The Solution: To mitigate this issue, buyers should establish relationships with reputable suppliers who specialize in powder coatings and have a global distribution network. Conducting thorough market research to identify suppliers with a proven track record in delivering gloss black chrome powder coat can streamline sourcing. Additionally, consider negotiating long-term contracts with suppliers to secure consistent availability and potentially better pricing. Utilizing local distributors who can provide timely access to a variety of powder coat options can also enhance supply chain efficiency. Regular communication with suppliers regarding stock levels and lead times can further ensure that production schedules remain on track.

Scenario 3: Environmental and Regulatory Compliance Challenges

The Problem: B2B buyers in the powder coating industry face mounting pressure to comply with environmental regulations and safety standards, especially concerning the chemicals used in gloss black chrome powder coat formulations. Buyers may find themselves navigating complex regulatory landscapes that vary by region, complicating their purchasing decisions and potentially leading to compliance issues.

The Solution: To address compliance challenges, it is crucial for buyers to remain informed about local and international regulations pertaining to powder coatings. Working closely with suppliers who provide comprehensive safety data sheets (SDS) and technical data sheets (TDS) is essential. These documents should detail the chemical composition and any associated hazards. Buyers should also seek out products labeled as compliant with regulations such as Proposition 65 in California or REACH in Europe, ensuring that the powders they purchase meet safety standards. Implementing regular training for staff on handling and applying powder coatings safely can further minimize risks and enhance compliance. Additionally, buyers should consider participating in industry groups or forums that focus on regulatory updates and best practices to stay ahead of potential changes in compliance requirements.

Strategic Material Selection Guide for gloss black chrome powder coat

What Are the Key Materials for Gloss Black Chrome Powder Coating?

When selecting materials for gloss black chrome powder coating, it is essential to consider various substrates that can enhance the performance and aesthetic appeal of the finished product. Below are four common materials used in conjunction with gloss black chrome powder coat, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it suitable for various applications. It can withstand temperatures up to 600°F (316°C) without losing structural integrity.

Pros & Cons: The primary advantage of aluminum is its excellent strength-to-weight ratio, which is beneficial for automotive and aerospace applications. However, it can be more expensive than steel and may require additional surface preparation to achieve optimal adhesion with the powder coat.

Impact on Application: Aluminum substrates provide a smooth finish that enhances the gloss of the black chrome powder coat. However, they may require a pre-treatment process to ensure proper powder adhesion.

International Considerations: Buyers in regions like Europe or the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys. Additionally, local preferences for lightweight materials in automotive sectors may drive demand for aluminum substrates.

2. Steel

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: Steel is generally more cost-effective than aluminum and provides a robust substrate. However, it is prone to corrosion if not properly coated or treated, which can affect the longevity of the gloss black chrome finish.

Impact on Application: Steel’s surface can be treated to enhance adhesion for the powder coat, but it may require a primer or base coat to prevent rusting and ensure a long-lasting finish.

International Considerations: Compliance with standards like ASTM A123 for hot-dip galvanizing is crucial for buyers in North America and Europe. Buyers from regions like South America may also need to consider local corrosion resistance standards due to varying environmental conditions.

3. Stainless Steel

Key Properties: Stainless steel is highly resistant to corrosion, heat, and staining. It can endure temperatures exceeding 1000°F (538°C) and is available in various grades, each with unique properties.

Pros & Cons: The primary advantage of stainless steel is its aesthetic appeal and durability, making it ideal for decorative applications. However, it is more expensive than both aluminum and regular steel, which may impact budget considerations.

Impact on Application: The smooth surface of stainless steel enhances the gloss finish of the black chrome powder coat. However, it may require specialized pre-treatment to ensure proper adhesion.

International Considerations: Buyers should be aware of compliance with standards such as ASTM A240 for stainless steel. In regions like the Middle East, where humidity can affect metal durability, selecting the right grade of stainless steel is critical.

4. Plastic Composites

Key Properties: Plastic composites are lightweight, corrosion-resistant, and can be molded into complex shapes. They typically have a lower thermal resistance compared to metals.

Pros & Cons: The key advantage of plastic composites is their versatility and lower manufacturing costs. However, they may not withstand high temperatures as effectively as metals, which can limit their use in certain applications.

Impact on Application: Gloss black chrome powder coating can significantly enhance the appearance of plastic composites, but they may require specific formulations to ensure compatibility and adhesion.

International Considerations: Buyers should consider compliance with standards such as ASTM D638 for tensile properties of plastics. In regions like Africa, where UV exposure is high, selecting UV-stable formulations is essential.

Summary Table of Material Selection for Gloss Black Chrome Powder Coat

| Material | Typical Use Case for gloss black chrome powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, aerospace components | Lightweight with excellent strength-to-weight ratio | Higher cost than steel | Medium |

| Steel | Heavy machinery, structural components | Cost-effective and durable | Prone to corrosion without proper treatment | Low |

| Stainless Steel | Decorative items, high-end appliances | Corrosion-resistant and aesthetically appealing | Higher cost than aluminum and steel | High |

| Plastic Composites | Consumer goods, automotive interiors | Versatile and lower manufacturing costs | Limited temperature resistance | Low |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions regarding material selection for gloss black chrome powder coating applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gloss black chrome powder coat

What Are the Key Stages in the Manufacturing Process of Gloss Black Chrome Powder Coat?

The manufacturing process of gloss black chrome powder coat involves several crucial stages, each designed to ensure the final product meets both aesthetic and functional standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage begins with the selection of high-quality raw materials. The primary components for gloss black chrome powder coat typically include resins, pigments, and additives. The materials undergo rigorous testing to confirm their purity and suitability for the intended application. Proper storage and handling are essential to prevent contamination that could affect the final product’s performance.

-

Forming: The raw materials are then blended to create a homogeneous mixture. This process may involve various techniques, such as extrusion or mixing, to achieve the desired particle size and distribution. The formulation is critical; for instance, the glossiness of the final product often depends on the ratio of pigments and the type of resin used.

-

Assembly: Once the powder is produced, it is packaged for distribution. This involves filling bags or containers while ensuring that the powder remains free from moisture and impurities. Proper labeling is also crucial for identifying the product and its specifications, which is particularly important for international shipments.

-

Finishing: The final stage of manufacturing includes applying the powder coat to the substrate (the surface to be coated). This is typically done using electrostatic spray deposition (ESD), where the powder is charged and sprayed onto the grounded substrate. The coated items are then cured in an oven, which melts the powder and forms a durable, glossy finish. The curing process is critical to achieving the desired gloss and adhesion properties.

How Is Quality Assurance Implemented in Gloss Black Chrome Powder Coat Production?

Quality assurance (QA) is integral to the manufacturing process of gloss black chrome powder coat, ensuring consistency and compliance with international standards. Effective QA protocols typically involve several key components, including adherence to recognized standards, inspection checkpoints, and testing methodologies.

-

International and Industry-Specific Standards: Compliance with ISO 9001 is essential for manufacturers aiming to provide consistent quality. This standard outlines requirements for a quality management system that can enhance customer satisfaction and operational efficiency. In addition, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the powder coat. These certifications help buyers verify that products meet safety and performance criteria.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established. These typically include:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Monitoring occurs during manufacturing to detect any deviations from quality standards.

– Final Quality Control (FQC): The finished product undergoes a thorough inspection before shipment, focusing on visual defects, gloss levels, and adhesion properties. -

Common Testing Methods: Various testing methods are employed to validate the quality of the gloss black chrome powder coat. These may include:

– Gloss Measurement: Using gloss meters to quantify the sheen of the finish.

– Adhesion Tests: Conducting tape tests to evaluate how well the powder coat adheres to the substrate.

– Durability Testing: Assessing resistance to scratches, chemicals, and environmental conditions to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is paramount. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. Audits should assess compliance with international standards, cleanliness of the production environment, and overall manufacturing capabilities.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand the measures taken during production. These reports should include information on testing methodologies, inspection results, and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control systems. This is particularly beneficial when dealing with suppliers in regions where direct audits may be challenging.

-

Certifications and Documentation: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking, and request copies of these documents. This ensures that the supplier adheres to recognized quality standards.

-

Feedback from Previous Clients: Gathering references or testimonials from other B2B clients who have previously worked with the supplier can provide insights into their reliability and quality performance.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges and considerations when it comes to quality control in gloss black chrome powder coat manufacturing. Understanding these nuances can enhance buyer confidence and ensure successful procurement.

-

Regulatory Compliance: Different countries have varying regulations concerning environmental impact and safety standards. Buyers must ensure that suppliers comply with local regulations in their target markets, especially concerning hazardous materials and waste disposal.

-

Cultural and Language Barriers: Communication can be a challenge when dealing with suppliers from different regions. Buyers should ensure that quality control documentation is available in a language they understand and that there are clear lines of communication regarding quality expectations.

-

Logistical Considerations: International shipping can complicate quality control processes. Buyers should be aware of how transportation conditions might affect product quality, particularly for sensitive finishes like gloss black chrome. Suppliers should provide guidance on storage and handling to maintain quality during transit.

-

Market-Specific Preferences: Different regions may have specific preferences regarding color, gloss level, and finish durability. Buyers should communicate these preferences clearly to suppliers and ensure that products are tailored to meet local market demands.

In conclusion, understanding the manufacturing processes and quality assurance measures for gloss black chrome powder coat is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensure product quality, and establish successful partnerships with suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gloss black chrome powder coat’

In the competitive landscape of powder coating, sourcing a high-quality gloss black chrome powder coat requires a systematic approach. This guide provides actionable steps for B2B buyers to ensure they make informed purchasing decisions that meet their specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is crucial for successful sourcing. Consider factors such as the desired gloss level, substrate compatibility, and application methods. For instance, gloss black chrome typically requires a bright silver substrate to achieve the desired finish. This helps in identifying products that will meet your quality and aesthetic requirements.

Step 2: Research Potential Suppliers

Begin by compiling a list of potential suppliers who specialize in powder coatings. Look for companies with a strong reputation in the industry, particularly those that serve your geographical region. Check online reviews and testimonials to gauge customer satisfaction and reliability.

- Tip: Utilize industry-specific platforms and directories to find suppliers who focus on gloss black chrome coatings.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001 or other relevant quality management system certifications. This ensures that the supplier adheres to strict quality control processes, which is critical for maintaining product consistency.

- Check for: Safety Data Sheets (SDS) and Technical Data Sheets (TDS) to understand product handling and application guidelines.

Step 4: Request Samples for Testing

Once you have narrowed down potential suppliers, request samples of the gloss black chrome powder coat. Testing these samples allows you to evaluate the finish, durability, and compatibility with your substrates. Ensure that the samples replicate the desired aesthetic and performance standards before making a bulk order.

- Consider: Conducting a test application in your production environment to assess how the coating behaves under actual working conditions.

Step 5: Review Pricing and Terms of Sale

Pricing can vary significantly among suppliers, so it’s essential to compare costs thoroughly. Request detailed quotes that include shipping and handling fees, as well as any bulk purchase discounts. Understanding the total cost will help you make a financially sound decision.

- Negotiate: Don’t hesitate to discuss pricing structures and payment terms to find a mutually beneficial agreement.

Step 6: Assess Customer Support and Responsiveness

Evaluate the level of customer support offered by potential suppliers. Effective communication is vital in resolving issues that may arise during the sourcing process. A responsive supplier can significantly enhance your procurement experience and ensure timely deliveries.

- Look for: Suppliers who provide dedicated account managers or technical support teams to assist you with any queries.

Step 7: Finalize the Order and Confirm Delivery Timelines

Once you have chosen a supplier, finalize your order by confirming quantities and delivery timelines. Ensure that you have a clear understanding of lead times and any potential delays that could impact your production schedule.

- Document everything: Keep a record of your order confirmation, including any agreed-upon terms, to avoid misunderstandings later.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing gloss black chrome powder coat, ensuring high-quality outcomes that meet their operational needs.

Comprehensive Cost and Pricing Analysis for gloss black chrome powder coat Sourcing

What Are the Key Cost Components for Gloss Black Chrome Powder Coat?

When sourcing gloss black chrome powder coat, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials used in the powder coating process can vary significantly based on quality and supplier. High-quality pigments and resins that provide durability and a high-gloss finish typically command a higher price. For instance, premium polyester powders may range from $15 to $18 per pound.

-

Labor: Labor costs involve not only the application of the powder but also preparation and post-coating processes. Skilled technicians are required to ensure proper application techniques and quality control, which can impact overall costs.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, utilities, and facility management. Depending on the scale of production, these costs can be distributed across larger volumes, thus reducing the per-unit cost.

-

Tooling: Specific tooling may be required for custom applications or unique product shapes. The initial investment in these tools can affect pricing, especially for low-volume orders.

-

Quality Control (QC): Ensuring that the powder coating meets industry standards and customer specifications often involves rigorous testing and inspection, contributing to the overall cost.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and volume. International buyers should be aware of potential tariffs and customs duties that could impact final pricing.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on market demand, competition, and negotiation outcomes.

How Do Price Influencers Impact Sourcing Decisions for Gloss Black Chrome Powder Coat?

Several factors can influence the price of gloss black chrome powder coat significantly:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs that align with their production needs to optimize pricing.

-

Specifications and Customization: Custom colors or specific performance characteristics (e.g., UV resistance, scratch resistance) can increase costs. Clearly defining specifications upfront can help avoid unexpected charges later.

-

Material Quality and Certifications: The use of high-quality materials can enhance the longevity and performance of the powder coat, thus justifying higher prices. Certifications such as ISO or environmental standards can also affect pricing.

-

Supplier Factors: Supplier reputation, reliability, and service levels can impact costs. Established suppliers may charge a premium for their proven track record and customer support.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for calculating total landed costs. Buyers should clarify these terms during negotiations to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Gloss Black Chrome Powder Coat?

B2B buyers looking to optimize costs when sourcing gloss black chrome powder coat should consider the following strategies:

-

Negotiate Terms: Always negotiate prices, payment terms, and delivery timelines. Suppliers may offer discounts for bulk orders or favorable payment terms to secure long-term contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond initial purchase price and consider the total cost over the product’s lifecycle, including maintenance, performance, and potential rework costs. High-quality coatings may cost more upfront but can save money in the long run.

-

Research Market Prices: Familiarize yourself with current market prices for gloss black chrome powder coats. This knowledge will empower you during negotiations and help identify fair pricing.

-

Evaluate Multiple Suppliers: Don’t settle for the first offer. Comparing quotes from various suppliers can reveal significant pricing differences and help you make a more informed decision.

-

Stay Informed About Regional Variations: Pricing can differ based on geographical location, local demand, and import regulations. Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of these factors when sourcing internationally.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. Always consult with suppliers for the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing gloss black chrome powder coat With Other Solutions

Exploring Alternatives to Gloss Black Chrome Powder Coat

When considering surface finishing solutions, gloss black chrome powder coat stands out for its sleek aesthetic and durability. However, businesses must evaluate various alternatives to determine the best fit for their specific applications and operational contexts. Below, we compare gloss black chrome powder coat with two viable alternatives: traditional liquid paint and anodizing.

| Comparison Aspect | Gloss Black Chrome Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | High gloss, excellent durability and resistance to scratches and chemicals | Moderate gloss; less durable and prone to chipping | High corrosion resistance, matte finish with varying gloss levels |

| Cost | $15.99 to $17.77 per lb | Generally lower, around $8 to $15 per gallon | Higher initial costs; depends on material and thickness |

| Ease of Implementation | Requires specialized equipment and skilled applicators | Easier application; can be done in-house with spray guns | Specialized process; requires immersion in electrolytic solution |

| Maintenance | Low; typically requires only cleaning | Moderate; prone to wear and may require reapplication | Low; requires minimal upkeep, very durable |

| Best Use Case | Automotive parts, decorative items | General consumer products, furniture | Aerospace components, architectural applications |

What Are the Pros and Cons of Liquid Paint?

Liquid paint is a traditional method for surface finishing that offers a variety of finishes, including gloss and matte. One of its main advantages is cost-effectiveness; it is usually less expensive than powder coating and can be applied using standard spray equipment. However, the durability of liquid paint is a significant drawback. It is more susceptible to chipping, scratching, and fading over time, making it less ideal for high-wear applications. Liquid paint also often requires a longer curing time and may involve volatile organic compounds (VOCs) that raise environmental concerns.

How Does Anodizing Compare in Performance and Cost?

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, primarily aluminum. This method results in a hard, corrosion-resistant finish that can be dyed in various colors. Anodizing provides excellent protection against the elements, making it suitable for outdoor applications. However, the costs associated with anodizing can be higher, especially for thicker coatings, and the process requires specialized facilities. Anodizing also typically results in a matte finish, which may not meet the aesthetic requirements for all products.

How Can B2B Buyers Choose the Right Solution?

When selecting a surface finishing solution, B2B buyers should consider various factors, including the specific application, environmental conditions, and budget constraints. Gloss black chrome powder coat is ideal for applications requiring a high-gloss, durable finish, particularly in automotive or decorative contexts. In contrast, liquid paint may be the right choice for projects with lower durability requirements or tighter budgets. Anodizing should be considered for metal components that require exceptional corrosion resistance. Ultimately, the best choice will depend on balancing aesthetics, performance, cost, and the intended use of the finished product.

Essential Technical Properties and Trade Terminology for gloss black chrome powder coat

What Are the Essential Technical Properties of Gloss Black Chrome Powder Coat?

1. Material Composition

Gloss black chrome powder coats are primarily made from polyester resins, which provide a high-gloss finish and excellent durability. The composition can include additives that enhance properties like UV resistance, corrosion protection, and scratch resistance. Understanding the material composition is critical for B2B buyers as it influences the coating’s performance in various environments, impacting the longevity and maintenance costs of coated products.

2. Gloss Level

The gloss level of gloss black chrome powder coat typically measures above 85 gloss units, indicating a highly reflective surface. This property is essential for aesthetic applications where visual appeal is paramount, such as in automotive parts or consumer electronics. Buyers need to consider gloss levels to ensure they meet customer expectations for appearance and branding.

3. Coverage Rate

Coverage rate refers to the amount of surface area that can be coated with a specified weight of powder. For gloss black chrome, coverage can vary significantly based on application methods and substrate conditions. Buyers should assess the coverage rate to optimize material usage and reduce costs, particularly for large-scale projects.

4. Curing Temperature and Time

The curing temperature for gloss black chrome powder coat typically ranges from 180°C to 200°C, with a curing time of around 10 to 20 minutes. This specification is vital for manufacturers to ensure that the coating adheres properly and achieves the desired finish. Understanding the curing process can prevent production delays and quality issues, essential for maintaining competitive timelines in B2B transactions.

5. Chemical Resistance

Gloss black chrome powder coats generally exhibit good resistance to chemicals, including oils, solvents, and acids. This property is crucial for applications in industries like automotive and industrial manufacturing, where exposure to harsh substances is common. Buyers should prioritize coatings with high chemical resistance to minimize maintenance and replacement needs.

6. Weatherability

Weatherability refers to the coating’s ability to withstand environmental elements such as UV radiation, moisture, and temperature fluctuations. Gloss black chrome coatings with superior weatherability help prevent fading and degradation over time. For international buyers, especially in regions with extreme weather conditions, this property is essential to ensure long-lasting performance and reduce lifecycle costs.

What Are Common Trade Terms Related to Gloss Black Chrome Powder Coat?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of powder coatings, buyers often seek OEM partners to ensure that their products meet specific quality and performance standards. Understanding OEM relationships can help buyers navigate sourcing and branding strategies.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For gloss black chrome powder coat, MOQs can vary based on the supplier and the specific product line. Buyers must consider MOQs to manage inventory effectively and avoid excess costs, particularly when testing new products or entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a document that potential buyers use to solicit price quotes from suppliers. In the context of gloss black chrome powder coat, submitting an RFQ allows buyers to compare pricing, lead times, and terms from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and risk management. Understanding Incoterms is crucial for B2B buyers engaging with suppliers across different countries, as they clarify cost responsibilities and can significantly impact the total landed cost of gloss black chrome powder coat products.

5. TDS (Technical Data Sheet)

A TDS provides detailed information about a product’s properties, application methods, and safety guidelines. For gloss black chrome powder coat, a TDS is essential for buyers to understand product specifications and compliance with industry standards, ensuring proper application and performance.

6. SDS (Safety Data Sheet)

An SDS contains critical information about the safety and handling of a product, including potential hazards and first-aid measures. For buyers of gloss black chrome powder coat, reviewing the SDS is vital for ensuring safe handling and compliance with local regulations, particularly in regions with stringent safety standards.

Understanding these technical properties and trade terminologies equips B2B buyers with the knowledge needed to make informed decisions in sourcing and utilizing gloss black chrome powder coat effectively.

Navigating Market Dynamics and Sourcing Trends in the gloss black chrome powder coat Sector

What Are the Current Market Dynamics and Key Trends in the Gloss Black Chrome Powder Coat Sector?

The global gloss black chrome powder coat market is experiencing robust growth, driven by increasing demand across various industries, including automotive, architectural design, and consumer goods. Notably, the automotive sector is a significant contributor, as manufacturers increasingly favor powder coatings for their durability, aesthetic appeal, and environmental advantages. Emerging technologies such as advanced powder application systems and automation in coating processes are enhancing efficiency and quality, making gloss black chrome a preferred choice for B2B buyers.

Furthermore, international buyers from regions like Africa, South America, the Middle East, and Europe are seeking suppliers who can offer customization options and high-quality finishes. The trend toward personalization in product design is pushing manufacturers to adopt unique color formulations, including gloss black chrome, to meet consumer preferences. Additionally, the rise of e-commerce platforms is facilitating direct sourcing, allowing businesses to connect with manufacturers and suppliers more efficiently than ever.

The market is also witnessing a shift towards hybrid powder coatings that combine gloss black chrome with other finishes, catering to diverse aesthetic requirements. As manufacturers strive to differentiate their products, the demand for innovative color solutions and finishes continues to rise, shaping the future of the powder coating industry.

How Is Sustainability and Ethical Sourcing Influencing the Gloss Black Chrome Powder Coat Market?

Sustainability is becoming a cornerstone of sourcing strategies in the gloss black chrome powder coat sector. B2B buyers are increasingly aware of the environmental impact of their supply chains, prompting a shift towards eco-friendly materials and processes. Powder coatings, including gloss black chrome, are inherently more sustainable than traditional liquid coatings due to their low volatile organic compound (VOC) emissions and ability to reduce waste during application.

Ethical sourcing practices are also gaining traction, with buyers prioritizing suppliers who demonstrate transparency in their production processes and adhere to international environmental standards. Certifications such as ISO 14001 and Greenguard are becoming essential for manufacturers seeking to establish credibility and attract environmentally-conscious clients.

Moreover, the focus on ethical sourcing extends to the materials used in powder coatings. B2B buyers are increasingly looking for suppliers who utilize recycled materials or sustainable raw inputs in their gloss black chrome formulations. This trend not only addresses environmental concerns but also enhances brand reputation, as companies that commit to sustainable practices are more likely to resonate with today’s consumers.

What Is the Brief Evolution of the Gloss Black Chrome Powder Coat?

The evolution of gloss black chrome powder coat has been marked by significant advancements in materials science and application technology. Initially developed in the late 20th century, powder coating emerged as a more durable and environmentally friendly alternative to traditional liquid coatings. The introduction of gloss black chrome formulations provided manufacturers with a unique aesthetic option that mimics the appearance of chrome while offering enhanced durability and resistance to corrosion.

Over the years, improvements in the formulation of powder coatings have allowed for greater customization, including variations in gloss levels and finishes. The rise of advanced application techniques, such as electrostatic spraying, has further propelled the adoption of gloss black chrome in various industries. Today, this versatile coating is recognized not only for its striking visual appeal but also for its contribution to sustainability and efficiency in manufacturing processes, making it a key player in the modern coatings landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of gloss black chrome powder coat

-

1. How do I choose the right gloss black chrome powder coat for my application?

Choosing the right gloss black chrome powder coat involves understanding the specific requirements of your project. Consider factors such as the substrate material, desired finish quality, and environmental conditions the coated items will face. For optimal results, a high-gloss finish is recommended for surfaces that require a sleek appearance. Additionally, consult with suppliers to confirm compatibility with your application processes, and always conduct a test application to verify that the desired aesthetic and performance are achieved. -

2. What are the key benefits of using gloss black chrome powder coat over traditional liquid coatings?

Gloss black chrome powder coat offers several advantages over traditional liquid coatings, including superior durability, resistance to chipping and scratching, and lower environmental impact due to reduced volatile organic compounds (VOCs). The powder coating process also allows for a more uniform finish with better coverage, enhancing the aesthetic appeal of the final product. Furthermore, the application process is generally more efficient, leading to reduced production times and costs. -

3. What is the minimum order quantity (MOQ) for gloss black chrome powder coat?

Minimum order quantities for gloss black chrome powder coat can vary significantly among suppliers. Typically, MOQs may range from 10 to 100 pounds, depending on the manufacturer and the specific product line. It is advisable to directly contact potential suppliers to inquire about their MOQs, as some may be flexible, especially for established business relationships or larger orders. Always ensure that the MOQ aligns with your project needs to avoid excess inventory costs. -

4. How do I vet suppliers for gloss black chrome powder coat?

When vetting suppliers, consider factors such as their industry reputation, production capabilities, and compliance with international quality standards. Request references from other clients and review their product certifications, such as ISO or ASTM compliance. Additionally, assess their communication responsiveness and willingness to provide samples for testing. Conducting site visits, if feasible, can also help gauge their operational standards and quality control processes. -

5. What are the payment terms typically offered for gloss black chrome powder coat purchases?

Payment terms for gloss black chrome powder coat can vary widely depending on the supplier and the buyer’s creditworthiness. Common terms include net 30, net 60, or payment upon delivery. Some suppliers may also offer discounts for early payment or large orders. It’s essential to negotiate terms that suit your cash flow needs while ensuring the supplier is comfortable with the arrangement. Always clarify any potential fees for late payments or international transactions. -

6. What quality assurance measures should I expect from a supplier of gloss black chrome powder coat?

A reputable supplier should implement rigorous quality assurance measures throughout the production process. This includes raw material testing, in-process inspections, and final product evaluations to ensure adherence to specifications. Request documentation such as quality control reports and compliance certifications to verify their quality assurance practices. Additionally, inquire about their policies for addressing defects or issues post-delivery, ensuring you have recourse if the products do not meet your expectations. -

7. How can I ensure timely logistics and delivery for my gloss black chrome powder coat orders?

To ensure timely logistics and delivery, work closely with your supplier to establish a clear timeline and shipping expectations. Discuss shipping options, including air freight for urgent orders or sea freight for cost-effective solutions. It’s also beneficial to understand the customs regulations in your region to avoid delays. Regular communication with your supplier regarding order status can help preemptively address any potential logistical challenges, ensuring your project timelines are met. -

8. Can I customize gloss black chrome powder coat colors or finishes?

Yes, many suppliers offer customization options for gloss black chrome powder coat, including variations in color shades and finishes. If you have specific requirements, communicate them clearly to your supplier, as they may provide custom formulations or blends to achieve your desired outcome. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to align with your project schedules.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Gloss Black Chrome Powder Coat Manufacturers & Suppliers List

1. The Powder Coat Store – Black Powder Coating Paints

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: Black powder coating paints including flat, satin, high gloss, wrinkle and candy finishes. Products include: Sherwin Williams Mirror Gloss Black Powder Coating Paint (1 LB) – $8.99, Super Durable Gloss Wet Black Powder Coat Paint (1 LB) – $8.49, Wrinkle Black Powder Coating Paint (1 LB) – $7.49, Super Durable Flat Black Powder Coating Paint (1 LB) – $7.99, Satin Black Powder Coating Paint (1 LB) -…

2. Cool Tools – Ultra Black Chrome Powder Coat

Domain: cooltools.us

Registered: 2004 (21 years)

Introduction: This company, Cool Tools – Ultra Black Chrome Powder Coat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

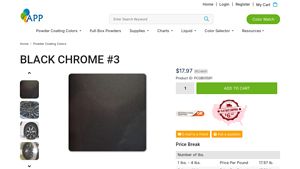

3. All Powder Paints – Black Chrome III

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Black Chrome III”, “Price”: “$17.97 (lb.)”, “Product ID”: “PCGB05591”, “Price Breaks”: [{“Weight Range”: “1 lbs. – 4 lbs.”, “Price Per Pound”: “$17.97 lb.”}, {“Weight Range”: “5 lbs. – 10 lbs.”, “Price Per Pound”: “$17.53 lb.”}, {“Weight Range”: “11 lbs. – 19 lbs.”, “Price Per Pound”: “$17.02 lb.”}, {“Weight Range”: “20 lbs. – 29 lbs.”, “Price Per Pound”: “$16.48 lb.”}, {“Weight …

4. Powder Buy The Pound – Bonded Black Chrome Powder Coating

Domain: powderbuythepound.com

Registered: 2006 (19 years)

Introduction: Bonded Black Chrome Powder Coating

5. Lexus LC 500 – Black Gloss Powder Coat Wheels

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Considering black gloss powder coat wheels for a Lexus LC 500. The user has already deleted all chrome from the car and is contemplating whether black wheels would be a good upgrade. They have examples of how the car would look before and after the change.

6. AT4 Forum – Gloss Black Exhaust Bezels

Domain: at4forum.com

Registered: 2020 (5 years)

Introduction: Chrome exhaust bezels, powder coated in gloss black finish. Originally chrome, they were modified for aesthetic purposes to match the truck’s look after removing badging and emblems. The product is suitable for GMC AT4 models, including Sierra 1500 and others. Users have shared experiences regarding installation, durability, and aesthetic appeal.

7. CalChrome – Fusion Powder Coating

Domain: calchrome.com

Registered: 1998 (27 years)

Introduction: Fusion Powder Coating offers 6500 color options for wheels, including the Ultimate Wet high gloss black, which is noted for being the deepest and most reflective in the industry. The process minimizes orange peel texture through proprietary Power-Pulse-technology. Pricing starts at $125 per wheel with a turnaround time of 2-5 business days. The service is available for various applications includi…

8. Akzo Nobel – Black Chrome High Gloss Powder Coating Paint

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Black Chrome High Gloss Powder Coating Paint”,”Weight”:”1LB”,”Type”:”Powder Coating”,”Brand”:”Akzo Nobel”,”Condition”:”New”,”Price”:”$21.99 or Best Offer”,”Shipping Cost”:”$9.00″,”Estimated Delivery”:”Sat, Jul 19 – Wed, Jul 23″,”Quantity Available”:”More than 10 available”,”Seller Feedback”:”99.5% positive feedback”,”Returns Accepted”:”Yes”,”Item Number”:”394325533412″}

Strategic Sourcing Conclusion and Outlook for gloss black chrome powder coat

In summary, strategic sourcing of gloss black chrome powder coat presents a valuable opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the unique properties of this high-gloss, durable coating can enhance product offerings across various industries, including automotive, architectural, and consumer goods. Buyers should focus on establishing reliable supplier relationships to ensure quality consistency and competitive pricing, while also considering the environmental impact and compliance with regional regulations.

The versatility of gloss black chrome powder coat allows for a wide range of applications, making it an essential component in achieving aesthetic and functional goals. As market demand continues to grow, it’s crucial for businesses to stay ahead of trends and invest in innovative solutions that meet evolving consumer preferences.

Looking forward, international buyers are encouraged to explore partnerships with reputable suppliers and leverage technology for streamlined procurement processes. By doing so, they can ensure access to high-quality products that not only enhance their brand image but also contribute to sustainable practices in manufacturing. Embrace the future of powder coating and position your business for success in a competitive landscape.