Contents

Manufacturing Insight: Global Cnc Catalogue

Honyo Prototype Global CNC Catalogue Introduction

Honyo Prototype delivers precision CNC machining services engineered for global manufacturing excellence. As a trusted partner for aerospace, medical, automotive, and industrial innovators, we specialize in transforming complex designs into high-integrity components with unwavering accuracy and repeatability. Our global infrastructure integrates advanced multi-axis machining centers, rigorous quality control systems, and deep materials expertise to meet the most demanding technical specifications across international supply chains.

Our capabilities span CNC milling, turning, and multi-axis machining for prototypes through low-to-mid volume production. We process critical materials including titanium, Inconel, aluminum alloys, stainless steels, and engineering plastics, consistently achieving tight tolerances down to ±0.0002″ (5µm) with surface finishes as fine as Ra 0.8 µm. Every component undergoes stringent in-process and final inspection per AS9100, ISO 13485, and ISO 9001 standards, ensuring compliance with sector-specific regulatory requirements.

Key technical capabilities include

| Parameter | Specification |

|——————–|———————————————–|

| Materials | Titanium, Inconel, Aluminum, Stainless Steel, Plastics |

| Tolerances | ±0.0002″ (5µm) |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm |

| Max Work Envelope | 5-axis: 1000 x 600 x 500 mm |

| Certifications | AS9100, ISO 13485, ISO 9001 |

| Volume Range | 1-off Prototypes to 10,000+ units |

Accelerate your procurement timeline with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical and commercial assessment within hours—not days. Our system automatically analyzes manufacturability, material utilization, and geometric complexity, providing transparent pricing with zero obligation. This digital workflow eliminates traditional quoting bottlenecks while maintaining engineering-grade precision in cost estimation.

Leverage Honyo’s global CNC catalogue to access scalable, certified manufacturing solutions backed by real-time quoting intelligence. Partner with us to reduce time-to-market without compromising on the precision your critical applications demand.

Technical Capabilities

Honyo Prototype CNC Capabilities – Technical Specifications

The following table outlines the technical specifications for Honyo Prototype’s global CNC machining services, focusing on 3-axis, 4-axis, and 5-axis milling, precision turning, and tight tolerance capabilities across key engineering materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis CNC Milling, 4-Axis Indexed & Continuous Milling, 5-Axis Simultaneous Milling, CNC Turning (2-axis & multi-axis live tooling) |

| Positioning Accuracy | ±0.005 mm (X, Y, Z axes) |

| Repeatability | ±0.002 mm |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005″) standard; achievable down to ±0.005 mm (±0.0002″) with process control |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with polishing or fine toolpaths |

| Maximum Work Envelope (Milling) | 1200 mm × 800 mm × 600 mm (X×Y×Z) for 3/4/5-axis systems |

| Maximum Turning Diameter | 350 mm |

| Maximum Turning Length | 750 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Spindle Speed (Turning) | Up to 6,000 RPM (varies by material and bar stock size) |

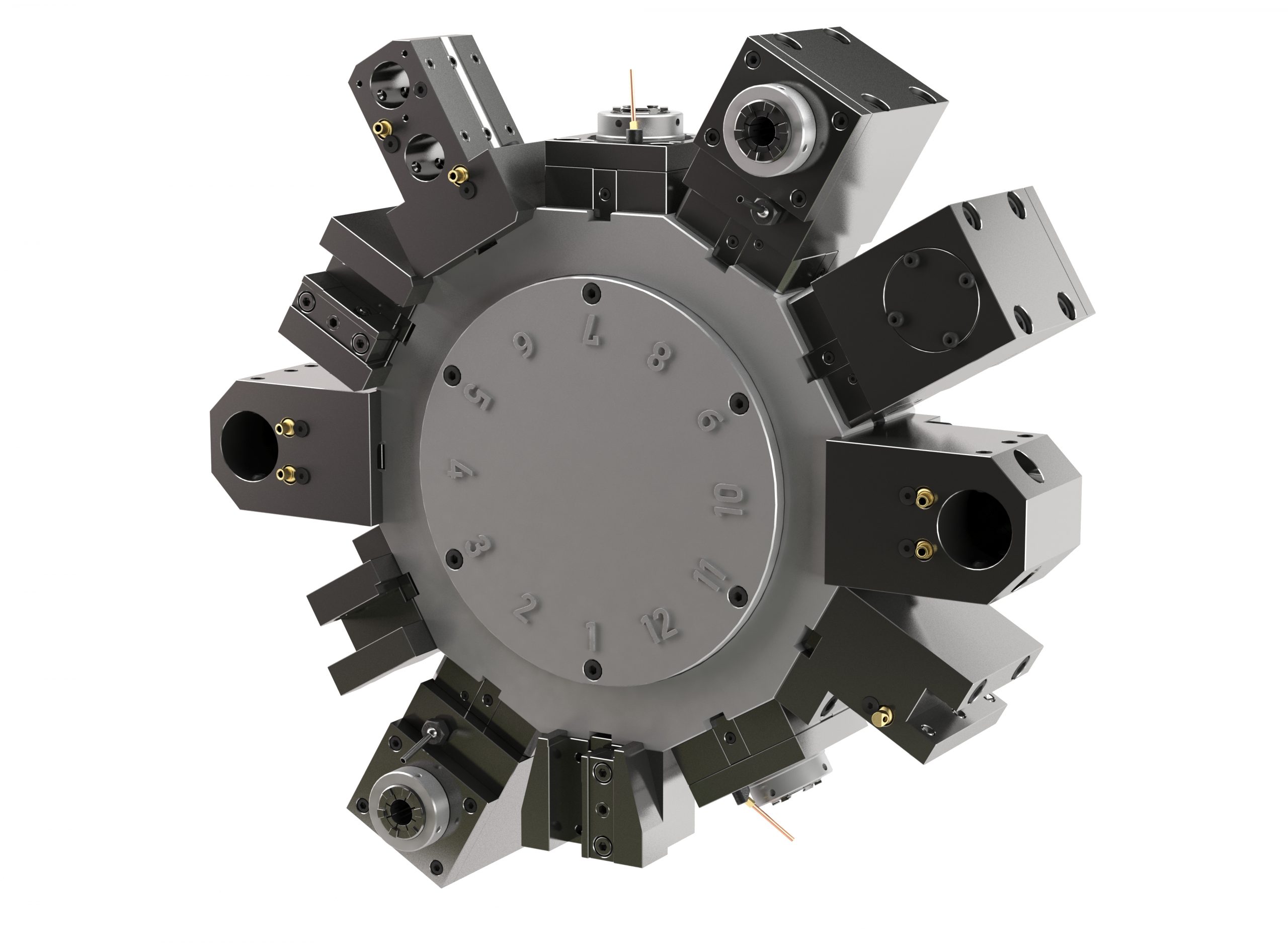

| Tool Changer Capacity | 24–40 tools (depending on machine model) |

| CNC Control Systems | Siemens 840D, Fanuc 31i, or Heidenhain iTNC 640 |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS (I400, Magnum 840), Nylon (6, 66, GF-reinforced) |

| Aluminum Machining | High-speed machining with optimized feeds and coolants; burr-free finishes achievable |

| Steel Machining | Carbide tooling with peck drilling and deep cavity strategies; hardened steel up to 55 HRC |

| ABS Machining | Low-heat cutting parameters; minimal tool buildup; ideal for prototypes and enclosures |

| Nylon Machining | Controlled feed rates to prevent deformation; use of sharp tools to avoid fraying |

| In-Process Metrology | On-machine probing for setup validation and feature verification |

| Post-Processing Options | Deburring, anodizing (Type II & III), passivation, bead blasting, custom coating |

All processes are supported by ISO 9001:2015-certified quality systems, with first-article inspection (FAI) and CMM reporting available upon request. Honyo Prototype maintains tight process control through statistical process monitoring (SPC) to ensure consistent part accuracy across production runs.

From CAD to Part: The Process

Honyo Prototype’s Global CNC Catalogue service delivers standardized, high-precision machined components through a streamlined digital workflow optimized for speed and manufacturability. This process is explicitly designed for parts conforming to our predefined catalogue geometries, materials, and tolerance standards, ensuring rapid turnaround without custom engineering overhead. The end-to-end sequence operates as follows:

Upload CAD

Clients initiate the process by uploading a native or neutral format CAD file (STEP, IGES, Parasolid) via our secure web portal. The system immediately validates the geometry against the catalogue’s strict dimensional constraints, material availability (e.g., 6061-T6 aluminum, 304 stainless steel, POM), and standard tolerance ranges (±0.05mm typical). Files failing validation receive instant feedback specifying non-compliant features, preventing downstream delays.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quoting system, which analyzes over 500,000 historical production datasets. The engine calculates precise costs and lead times within 90 seconds by assessing feature complexity, machine time estimates, material utilization, and real-time shop floor capacity. Quotes include granular cost breakdowns (material, machining, finishing) and are binding for catalogue-compliant designs, eliminating manual quotation bottlenecks.

Automated DFM Analysis

Every design undergoes mandatory AI-driven Design for Manufacturability (DFM) review against Honyo’s CNC-specific ruleset. The system flags non-optimal features such as inadequate tool access, thin walls below 0.8mm, or tolerances requiring secondary operations. Clients receive an interactive DFM report with specific recommendations—like adjusting hole depths or radii—to maintain catalogue pricing and lead times. Critical deviations trigger automatic engineering review; minor suggestions allow client approval with one click.

Production Execution

Approved orders move directly to production scheduling. Our MES system assigns jobs to networked CNC centers (3-axis vertical mills, turning centers) based on real-time machine availability and geographic proximity to the client. All catalogue parts use pre-verified toolpaths and fixturing, with in-process CMM verification at defined checkpoints. Material certifications and first-article inspection reports (FAIR) are generated automatically.

Global Logistics & Delivery

Completed parts undergo final dimensional validation against AS9102 standards before packaging. Honyo manages consolidated shipping via DHL/FedEx with regional hubs in Shenzhen, Stuttgart, and Chicago ensuring 72-hour delivery to major industrial zones. Clients track orders through a live dashboard showing production status, quality checkpoints, and customs documentation. All shipments include serialized traceability data linked to the original CAD file.

This integrated workflow achieves typical lead times of 5-7 days for standard catalogue components. Performance metrics are consistently maintained through our closed-loop system:

| Process Stage | Average Duration | Key Performance Indicator | Failure Rate |

|---|---|---|---|

| CAD Validation | < 2 minutes | 99.2% auto-approval rate | 0.8% |

| AI Quoting | 90 seconds | ±3% cost accuracy | 0.5% requote |

| DFM Review | < 4 hours | 87% auto-resolution rate | 13% engineering touch |

| Production | 3-5 days | 99.6% on-time completion | 0.4% scrap |

| Delivery | 2-3 days | 98.7% regional on-time | 1.3% logistics delay |

The Global CNC Catalogue eliminates traditional quotation and setup delays by enforcing design standardization while providing industrial-grade transparency from upload to delivery. Non-catalogue designs follow our separate rapid prototyping workflow with dedicated engineering support.

Start Your Project

Explore our global CNC catalogue to discover precision manufacturing solutions tailored to your prototyping and production needs.

Contact Susan Leo for detailed product specifications, pricing, and delivery options.

Email: [email protected]

Leverage our Shenzhen-based factory for fast turnaround, strict quality control, and scalable manufacturing capacity.

Let Honyo Prototype be your trusted partner in high-precision CNC machining.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.