Introduction: Navigating the Global Market for glass filled nylon properties

In today’s competitive global market, sourcing materials like glass-filled nylon can pose significant challenges for international B2B buyers. As companies seek to enhance product performance while managing costs, understanding the properties of glass-filled nylon becomes crucial. This comprehensive guide delves into the essential aspects of glass-filled nylon properties, offering insights into its advantages, disadvantages, and applications across various industries. From construction to automotive, this material’s strength and heat resistance make it an ideal choice for demanding environments.

The guide will explore various types of glass-filled nylon, supplier vetting strategies, and cost considerations, equipping buyers from Africa, South America, the Middle East, and Europe—specifically in markets like Saudi Arabia and Germany—with the knowledge they need to make informed purchasing decisions. By highlighting critical factors such as mechanical properties, manufacturing processes, and potential challenges, this resource empowers businesses to navigate the complexities of sourcing glass-filled nylon. Ultimately, it aims to streamline the decision-making process, helping buyers select the right materials that align with their operational requirements and performance goals.

Understanding glass filled nylon properties Types and Variations

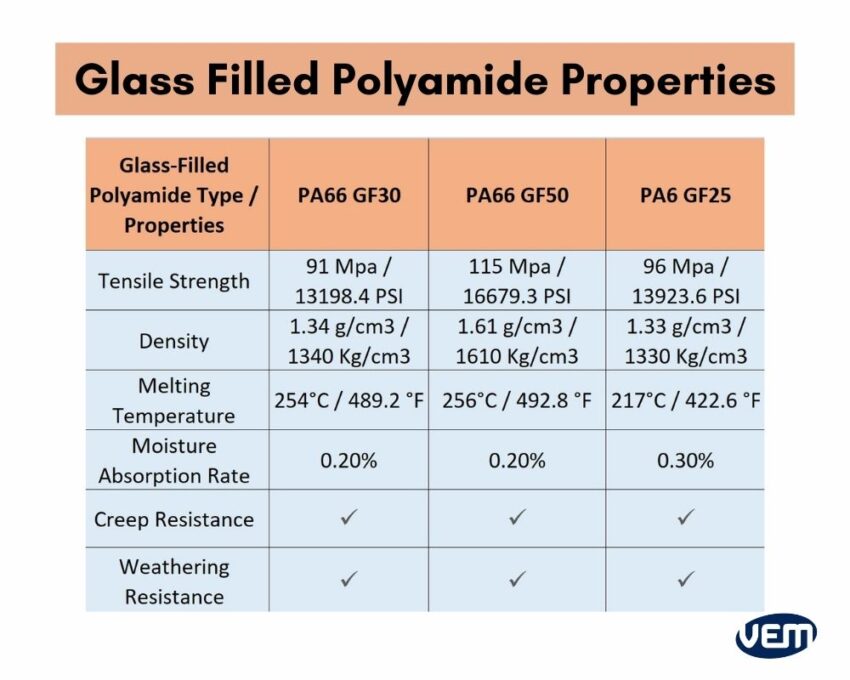

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nylon 6/6 30% Glass-Filled | High tensile strength, improved dimensional stability | Automotive parts, industrial machinery | Pros: Excellent strength, good heat resistance. Cons: More brittle, higher machining costs. |

| Nylon 6/6 40% Glass-Filled | Enhanced rigidity and wear resistance | Electrical housings, structural components | Pros: Superior stiffness, long-term durability. Cons: Increased weight, potential for warping. |

| Nylon 12 40% Glass-Filled | Lower density, excellent moisture resistance | Consumer products, sporting goods | Pros: Lightweight, good fatigue resistance. Cons: Limited chemical resistance to strong acids. |

| Nylon 66 20% Glass-Filled | Balanced properties for moderate loads | Fasteners, brackets, and clips | Pros: Good balance of cost and performance. Cons: Moderate heat resistance, less strength than higher glass content. |

| Nylon 6 13% Glass-Filled | Cost-effective option with decent performance | General-purpose applications, prototyping | Pros: Lower cost, improved mechanical properties. Cons: Not suitable for high-load applications. |

What Are the Characteristics of Nylon 6/6 30% Glass-Filled?

Nylon 6/6 with 30% glass-fill is renowned for its high tensile strength and improved dimensional stability, making it ideal for automotive parts and industrial machinery. This variation is particularly suited for applications that demand enhanced mechanical properties without excessive weight. Buyers should consider that while it offers excellent strength, its increased brittleness can lead to challenges in machining and assembly processes.

How Does Nylon 6/6 40% Glass-Filled Stand Out?

Nylon 6/6 with 40% glass-fill provides enhanced rigidity and wear resistance, which is critical for applications like electrical housings and structural components. This type excels in environments where parts are subject to high stress and temperature fluctuations. However, potential buyers must weigh the benefits of superior stiffness against its increased weight and susceptibility to warping during processing.

What Makes Nylon 12 40% Glass-Filled a Unique Choice?

Nylon 12 with 40% glass-fill is characterized by its lower density and excellent moisture resistance, making it suitable for consumer products and sporting goods. Its lightweight nature contributes to overall product efficiency, especially in applications where weight is a concern. Nevertheless, buyers should be cautious of its limited resistance to strong acids, which may affect its longevity in certain environments.

Why Choose Nylon 66 20% Glass-Filled for General Applications?

This variation offers a balanced performance profile, making it suitable for fasteners, brackets, and clips. The 20% glass-fill strikes a compromise between cost and performance, appealing to budget-conscious buyers. However, it has moderate heat resistance and does not provide the same level of strength as higher glass-filled variants, which may limit its use in high-load scenarios.

What Are the Benefits of Nylon 6 13% Glass-Filled for Prototyping?

Nylon 6 with 13% glass-fill is a cost-effective option that enhances mechanical properties for general-purpose applications and prototyping. This variation offers improved strength and stiffness compared to unfilled nylon while remaining budget-friendly. However, it is not ideal for high-load applications, and potential buyers should consider its limitations in demanding environments.

Key Industrial Applications of glass filled nylon properties

| Industry/Sector | Specific Application of glass filled nylon properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine components and housings | Enhanced durability and heat resistance | Ensure compatibility with specific automotive standards |

| Electronics | Insulating parts and housings | Improved dimensional stability and electrical insulation | Verify thermal and electrical properties for safety |

| Industrial Machinery | Gears and structural components | Increased wear resistance and load-bearing capacity | Assess machining requirements and tool compatibility |

| Aerospace | Structural components and fasteners | High strength-to-weight ratio and thermal stability | Evaluate regulatory compliance and material certifications |

| Consumer Products | Durable casings and housings | Enhanced aesthetic appeal and impact resistance | Focus on design specifications and customization options |

How is Glass-Filled Nylon Used in the Automotive Industry?

In the automotive sector, glass-filled nylon is utilized for manufacturing engine components and housings. Its superior heat resistance and enhanced durability address the challenges of high-temperature environments and mechanical stress. For international B2B buyers, particularly in regions like Saudi Arabia and Germany, sourcing requires an understanding of local automotive standards and material certifications to ensure compliance with safety regulations.

What Role Does Glass-Filled Nylon Play in Electronics?

Glass-filled nylon serves as an insulating material for electronic components, such as housings and connectors. Its excellent dimensional stability and electrical insulation properties are critical in preventing failures due to thermal fluctuations or moisture absorption. Buyers from Africa and South America should ensure that the sourced material meets specific thermal and electrical criteria to guarantee safety and performance in their applications.

How is Glass-Filled Nylon Beneficial in Industrial Machinery?

In industrial machinery, glass-filled nylon is commonly used for gears and structural components that face significant wear and tear. The material’s increased load-bearing capacity and wear resistance help extend the lifespan of machinery, reducing downtime and maintenance costs. Buyers in Europe and the Middle East should assess the machining requirements, as the abrasive nature of glass-filled nylon can lead to faster tool wear, necessitating careful selection of machining processes.

Why is Glass-Filled Nylon Important in Aerospace Applications?

The aerospace industry leverages glass-filled nylon for structural components and fasteners due to its high strength-to-weight ratio and thermal stability. These properties are vital for ensuring safety and performance in demanding flight conditions. International B2B buyers must consider regulatory compliance and material certifications, especially in regions with stringent aerospace standards, to ensure that sourced materials meet industry requirements.

How is Glass-Filled Nylon Used in Consumer Products?

In consumer products, glass-filled nylon is often employed in durable casings and housings, enhancing both aesthetic appeal and impact resistance. This material not only improves the longevity of products but also allows for innovative designs that meet consumer demands. Buyers should focus on design specifications and customization options to ensure that the sourced glass-filled nylon fits their unique product requirements, particularly in competitive markets across Africa and South America.

3 Common User Pain Points for ‘glass filled nylon properties’ & Their Solutions

Scenario 1: High Production Costs for Glass-Filled Nylon Components

The Problem: Many B2B buyers encounter significant challenges with the high costs associated with sourcing glass-filled nylon materials. This is particularly problematic for companies in price-sensitive markets, such as those in Africa or South America, where budget constraints are paramount. The added expense of glass fibers, combined with the complexities of CNC machining due to the material’s abrasiveness, can lead to inflated production costs, affecting overall project viability and competitiveness. Companies may also struggle to justify these costs to stakeholders, especially when lower-cost alternatives exist.

The Solution: To mitigate high production costs, it is essential to adopt a strategic approach to sourcing and utilizing glass-filled nylon. Start by conducting a thorough market analysis to identify suppliers that offer competitive pricing without compromising quality. Leveraging bulk purchasing agreements can also reduce costs significantly. Additionally, consider collaborating with suppliers who provide technical support in machining processes tailored for glass-filled nylon. For instance, using specialized cutting tools designed for abrasive materials can enhance machining efficiency, reduce tool wear, and ultimately lower production costs. Implementing a just-in-time inventory system can further alleviate financial pressure by minimizing the costs associated with holding excess stock.

Scenario 2: Difficulty in Achieving Desired Mechanical Properties

The Problem: B2B buyers often find it challenging to achieve the desired mechanical properties when working with glass-filled nylon in their applications. The variability in glass fiber content and the anisotropic nature of the material can lead to discrepancies in strength and stiffness, resulting in components that fail to meet specifications. This is particularly critical for industries such as automotive or aerospace, where material performance is non-negotiable, and even minor deviations can result in safety issues or costly recalls.

The Solution: To ensure consistency in mechanical properties, buyers should specify exact material grades and fiber content when placing orders. It’s advisable to collaborate closely with suppliers to understand the specific properties of the glass-filled nylon variants available. Conducting pre-production testing, such as tensile strength and impact resistance assessments, on sample components can help verify that the material meets application requirements before full-scale production. Additionally, adopting a robust quality assurance protocol that includes regular monitoring of material properties throughout the production process will help catch any deviations early, ensuring the final products maintain the necessary specifications for safety and performance.

Scenario 3: Challenges with Dimensional Stability in Humid Environments

The Problem: Humidity can significantly affect the dimensional stability of glass-filled nylon, leading to issues such as warping or shrinkage, especially in regions with high moisture levels, like the Middle East and parts of Europe. This poses a substantial risk for manufacturers who require precise tolerances in their components, as any dimensional variations can result in assembly difficulties or compromised functionality.

The Solution: To combat the effects of humidity on glass-filled nylon, it is crucial to implement effective moisture management strategies. Start by selecting glass-filled nylon grades that are specifically designed for high humidity environments, as some formulations offer enhanced moisture resistance. Additionally, consider incorporating moisture barriers or coatings for components that will be exposed to humid conditions. Prior to production, ensure that all materials are properly dried and conditioned to minimize moisture absorption. Finally, designing parts with appropriate tolerances that account for potential dimensional changes can help maintain functionality and reliability, even in challenging environments. Regular training for staff on best practices for handling and storing glass-filled nylon can further enhance material performance and longevity.

Strategic Material Selection Guide for glass filled nylon properties

What are the Key Properties of Glass-Filled Nylon?

Glass-filled nylon, a composite material created by blending nylon with glass fibers, is renowned for its enhanced mechanical properties. The typical formulations include variations like Nylon 6 and Nylon 66, with glass fiber content ranging from 10% to 40%. These materials exhibit superior tensile strength, improved rigidity, and enhanced thermal resistance, making them suitable for high-performance applications.

What are the Pros and Cons of Glass-Filled Nylon?

1. Glass-Filled Nylon 6 (30% GF)

- Key Properties: High tensile strength (up to 50 MPa), excellent wear resistance, and a maximum continuous use temperature of approximately 365°F (185°C).

- Pros: Offers a balance of strength and flexibility, making it suitable for a wide range of applications. Its thermal and dimensional stability enhances performance in fluctuating temperatures.

- Cons: Higher cost compared to unfilled nylon, and its brittleness can lead to failure under impact loads. The abrasive nature of glass fibers can lead to increased wear on machining tools.

- Impact on Application: Ideal for components exposed to mechanical stress, such as automotive parts and industrial machinery. However, care must be taken in humid environments due to its hygroscopic nature.

2. Glass-Filled Nylon 66 (40% GF)

- Key Properties: Exceptional rigidity, tensile strength exceeding 60 MPa, and a heat deflection temperature around 400°F (204°C).

- Pros: Superior dimensional stability and creep resistance make it ideal for precision applications. Its higher glass content enhances strength significantly.

- Cons: Increased weight compared to standard nylon and potential for warping during processing. The cost is also higher, which may impact budget-sensitive projects.

- Impact on Application: Suitable for high-load applications like structural components and brackets. Its performance in high-temperature environments makes it a preferred choice in the automotive and aerospace sectors.

3. Glass-Filled Nylon 12 (40% GF)

- Key Properties: Good chemical resistance, tensile strength around 50 MPa, and a heat deflection temperature of about 350°F (177°C).

- Pros: Offers excellent impact resistance and lower moisture absorption compared to other nylon variants, making it suitable for outdoor applications.

- Cons: While it has good chemical resistance, it is less effective against strong acids and bases. The manufacturing process can be complex due to its specific thermal properties.

- Impact on Application: Ideal for applications in the chemical processing industry where exposure to various media is a concern. Its lower moisture absorption makes it suitable for humid environments.

What Should International B2B Buyers Consider?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, compliance with local standards is crucial. Familiarity with ASTM, DIN, and JIS standards ensures that the selected materials meet regional safety and performance requirements. Additionally, understanding local market preferences can aid in selecting the right material for specific applications. For instance, buyers in Germany may prioritize stringent quality standards, while those in Saudi Arabia might focus on materials that withstand extreme temperatures.

Summary Table of Glass-Filled Nylon Properties

| Material | Typical Use Case for glass filled nylon properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass-Filled Nylon 6 (30% GF) | Automotive parts, industrial machinery | Balanced strength and flexibility | Higher cost, brittle under impact | Medium |

| Glass-Filled Nylon 66 (40% GF) | Structural components, brackets | Exceptional rigidity and creep resistance | Increased weight, potential for warping | High |

| Glass-Filled Nylon 12 (40% GF) | Chemical processing applications | Excellent impact resistance, low moisture absorption | Less effective against strong acids, complex manufacturing | Medium |

This guide provides actionable insights into the properties and applications of glass-filled nylon, enabling informed decision-making for B2B buyers across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for glass filled nylon properties

What Are the Main Stages of Manufacturing Glass-Filled Nylon?

The manufacturing of glass-filled nylon involves several critical stages, each designed to optimize the material properties and ensure the final product meets the required specifications for various applications. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in the manufacturing process is the preparation of the raw materials. Glass-filled nylon typically starts with base nylon resins, such as Nylon 6 or Nylon 6/6, which are then compounded with glass fibers. This blending process can involve several techniques, including:

- Dry Blending: In this method, glass fibers and nylon pellets are mixed together in a dry state, ensuring an even distribution of glass within the nylon matrix.

- Melt Compounding: This technique involves melting the nylon and then adding glass fibers during the molten state, which allows for better adhesion and distribution of the fibers within the polymer.

The ratio of glass fibers can vary, often ranging from 10% to 40% by weight, depending on the desired mechanical properties.

2. Forming

Once the material is prepared, the next step is forming the glass-filled nylon into the desired shape. There are several common techniques for forming:

- Injection Molding: This is the most widely used method for producing complex shapes. The compounded material is heated until it melts, then injected into molds where it cools and solidifies.

- Extrusion: In this process, the glass-filled nylon is forced through a die to create continuous shapes such as sheets, rods, or tubes. This method is ideal for producing parts with uniform cross-sections.

- 3D Printing: Advanced manufacturing techniques like selective laser sintering (SLS) and Multi Jet Fusion (MJF) have become popular for creating intricate designs and prototypes using glass-filled nylon.

Each forming technique has its own set of advantages, and the choice often depends on the end application and production volume.

3. Assembly

For products that require multiple components, assembly is the next step. Glass-filled nylon parts can be joined using various methods, including:

- Mechanical Fastening: This includes using screws, bolts, or rivets to connect parts, which is common in applications requiring disassembly.

- Adhesive Bonding: Suitable for applications where a permanent bond is needed, adhesives can provide a strong joining method without the need for additional hardware.

Proper assembly techniques are crucial to maintaining the integrity and performance of the final product.

4. Finishing

The final stage involves surface finishing to enhance the aesthetic and functional properties of glass-filled nylon products. Common finishing processes include:

- Machining: Post-processing through CNC machining can achieve precise tolerances and surface finishes.

- Coating: Applying paints or coatings can improve chemical resistance, reduce friction, or provide aesthetic appeal.

- Surface Treatment: Techniques like bead blasting or polishing can enhance surface characteristics, improving wear resistance or reducing roughness.

How Is Quality Assurance Implemented in Glass-Filled Nylon Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of glass-filled nylon to ensure that the products meet international standards and customer expectations. Here are the key components of QA:

Relevant International Standards for Quality Assurance

For B2B buyers, understanding the quality standards applicable to glass-filled nylon is essential. Some of the most relevant international standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards ensures that materials meet industry-specific requirements.

What Are the Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to maintain high standards:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before processing.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor parameters such as temperature, pressure, and material consistency.

- Final Quality Control (FQC): Once production is complete, final inspections and tests are conducted to verify that the finished product meets all specifications and quality standards.

What Testing Methods Are Commonly Used?

To ensure the performance and reliability of glass-filled nylon, various testing methods are employed, including:

- Mechanical Testing: Tensile strength, flexural strength, and impact resistance are commonly tested to assess the material’s performance under load.

- Thermal Testing: Heat deflection temperature and thermal conductivity tests help determine how the material will perform in high-temperature applications.

- Dimensional Testing: Ensuring that parts meet specified tolerances is critical, especially for applications requiring precision.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are several strategies:

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes, quality systems, and compliance with standards.

- Quality Reports: Requesting detailed quality reports, including test results and compliance certifications, can help assess a supplier’s reliability.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help in establishing better communication and expectations with suppliers.

- Regulatory Compliance: Each region may have different regulations concerning materials and manufacturing processes. Ensuring that suppliers comply with local regulations is crucial.

- Logistical Considerations: International shipping can introduce risks, such as damage during transit. Ensure that suppliers have robust packaging and handling procedures in place.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for glass-filled nylon products, ensuring high-quality materials that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass filled nylon properties’

In the competitive landscape of materials procurement, understanding the properties of glass-filled nylon is essential for making informed decisions. This guide provides a structured approach for B2B buyers seeking to source glass-filled nylon effectively, ensuring that you select the right material for your specific applications.

Step 1: Define Your Technical Specifications

Begin by outlining your project’s requirements regarding strength, rigidity, temperature tolerance, and environmental conditions. Glass-filled nylon comes in various compositions, typically ranging from 10% to 40% glass fiber content. Knowing your specific needs will help you communicate effectively with suppliers and ensure the right material is sourced.

Step 2: Research Material Properties

Familiarize yourself with the mechanical properties of glass-filled nylon, including tensile strength, wear resistance, and thermal stability. For instance, a 30% glass-filled nylon typically exhibits significantly enhanced strength and dimensional stability compared to unfilled nylon. Understanding these properties will guide you in selecting the appropriate grade for your application.

Step 3: Evaluate Potential Suppliers

Before finalizing any supplier, conduct thorough evaluations. Request detailed company profiles, product specifications, and customer references from businesses within your industry or region. Look for suppliers with proven experience in providing high-quality glass-filled nylon and those who can demonstrate compliance with international standards.

Step 4: Request Samples for Testing

Obtaining samples allows you to test the material in real-world applications before committing to larger orders. Conduct tests to evaluate the material’s performance under the specific conditions it will face, such as temperature fluctuations or mechanical loads. This step is crucial to ensure that the material meets your project’s demands.

Step 5: Verify Certifications and Compliance

Ensure that the glass-filled nylon you are considering complies with relevant industry standards and certifications. This may include ISO certifications, REACH compliance for chemical safety, or other regional regulations. Compliance not only assures quality but also mitigates risks associated with sourcing materials that do not meet necessary legal requirements.

Step 6: Discuss Pricing and Terms

Engage in discussions about pricing structures, minimum order quantities, and payment terms with your shortlisted suppliers. Be clear about your budget constraints and negotiate terms that align with your financial strategy. Understanding the total cost of ownership, including shipping and potential tariffs, is essential for accurate budgeting.

Step 7: Assess Logistics and Lead Times

Finally, evaluate the logistics involved in sourcing glass-filled nylon. Consider lead times for production, shipping options, and the supplier’s ability to meet your delivery schedules. Reliable logistics are vital to ensure that your supply chain remains uninterrupted and that your project timelines are adhered to.

By following these steps, you can confidently procure glass-filled nylon that meets your technical and business requirements, ultimately contributing to the success of your projects.

Comprehensive Cost and Pricing Analysis for glass filled nylon properties Sourcing

What Are the Key Cost Components in Sourcing Glass-Filled Nylon Properties?

When sourcing glass-filled nylon, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The price of glass-filled nylon varies depending on the percentage of glass fiber added, typically ranging from 10% to 40% by weight. Higher glass content often leads to increased material costs due to enhanced properties like strength and stiffness.

-

Labor: Labor costs can fluctuate based on the complexity of the manufacturing process. For instance, CNC machining of glass-filled nylon requires skilled labor due to the abrasive nature of the material, which can lead to higher operational costs.

-

Manufacturing Overhead: This includes expenses related to facility operation, equipment maintenance, and utilities. The production of glass-filled nylon is energy-intensive, and overhead can significantly impact overall pricing.

-

Tooling: Custom tooling for specific applications can increase initial costs. However, investing in durable tooling designed for glass-filled nylon can yield long-term savings by reducing wear and maintenance.

-

Quality Control (QC): Ensuring that glass-filled nylon meets specified standards may involve rigorous testing and inspection, contributing to additional costs. Certifications for quality assurance can also affect pricing.

-

Logistics: Transportation costs vary based on geographic location and the chosen shipping method. International buyers must account for customs duties and import taxes, which can add to the overall expense.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. This can vary widely depending on market conditions and the supplier’s positioning.

How Do Price Influencers Impact the Cost of Glass-Filled Nylon?

Several factors influence the pricing of glass-filled nylon properties, particularly for B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders usually result in lower unit prices. Buyers should assess their needs to negotiate favorable terms based on anticipated volume.

-

Specifications and Customization: Custom formulations or unique specifications may lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and relevant certifications can command premium pricing. Buyers should weigh the benefits of investing in certified materials against potential cost savings.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge more but can offer better service and consistency.

-

Incoterms: The agreed-upon Incoterms dictate the responsibilities of buyers and sellers in shipping. Understanding these terms can help buyers calculate total costs, including insurance and freight.

What Are Effective Negotiation Strategies for B2B Buyers?

To optimize costs when sourcing glass-filled nylon, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions around pricing, payment terms, and delivery schedules. Building strong relationships can also lead to better deals over time.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just purchase price but also long-term costs related to maintenance, durability, and performance. This holistic view can lead to more informed purchasing decisions.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that can affect pricing. Establishing relationships with local suppliers can also mitigate risks associated with international logistics.

Are There Important Considerations for International Buyers?

For international B2B buyers, particularly those in regions like Saudi Arabia and Germany, navigating the complexities of sourcing glass-filled nylon requires careful consideration:

-

Customs Regulations: Familiarize yourself with the import regulations in your country to avoid unexpected delays and additional costs.

-

Supplier Selection: Prioritize suppliers with international experience and the ability to handle logistics efficiently, as this can streamline the procurement process.

-

Market Trends: Stay informed about global market trends and pricing shifts, as these can impact sourcing strategies. Keeping abreast of technological advancements in material production can also provide insights into future pricing dynamics.

Disclaimer on Pricing Information

Prices for glass-filled nylon properties can vary significantly based on the factors outlined above. It is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure they are making the most cost-effective purchasing decisions.

Alternatives Analysis: Comparing glass filled nylon properties With Other Solutions

Understanding Alternatives to Glass-Filled Nylon Properties

When selecting materials for engineering applications, understanding the alternatives to glass-filled nylon can be crucial for making informed decisions. Glass-filled nylon is known for its enhanced strength, rigidity, and thermal resistance, but there are other materials that might also meet specific project requirements. This comparison will evaluate glass-filled nylon against two prominent alternatives: carbon fiber reinforced polymer (CFRP) and polycarbonate.

Comparison Table

| Comparison Aspect | Glass-Filled Nylon Properties | Carbon Fiber Reinforced Polymer (CFRP) | Polycarbonate |

|---|---|---|---|

| Performance | High strength, rigidity, and temperature resistance | Exceptional strength-to-weight ratio, excellent fatigue resistance | Good impact resistance, less rigid than CFRP |

| Cost | Moderate to high | High | Moderate |

| Ease of Implementation | Moderate complexity in machining | Requires specialized manufacturing processes | Easy to mold and machine |

| Maintenance | Low maintenance, but can wear tools faster | Low maintenance, resistant to corrosion | Requires UV protection for longevity |

| Best Use Case | Mechanical parts, automotive applications | Aerospace, high-performance sports equipment | Transparent components, safety glasses, consumer products |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Carbon Fiber Reinforced Polymer (CFRP)?

CFRP stands out for its exceptional strength-to-weight ratio, making it an ideal choice for applications where weight savings are crucial, such as in aerospace and high-performance sports equipment. Its fatigue resistance also contributes to long-term durability. However, CFRP is significantly more expensive than glass-filled nylon, which can deter budget-conscious projects. Additionally, the manufacturing processes for CFRP can be complex and require specialized equipment, which may not be readily available in all regions.

How Does Polycarbonate Compare to Glass-Filled Nylon?

Polycarbonate is known for its excellent impact resistance and transparency, making it suitable for applications like safety glasses and protective shields. It is easier to mold and machine compared to glass-filled nylon, which can lead to quicker production times and lower labor costs. However, polycarbonate does not offer the same level of rigidity and thermal resistance, which may limit its use in high-stress applications. Furthermore, polycarbonate can degrade under UV exposure, necessitating additional coatings or treatments to prolong its lifespan.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between glass-filled nylon, CFRP, and polycarbonate, B2B buyers should consider several factors including the specific performance requirements of their application, budget constraints, and the manufacturing capabilities available to them. For applications requiring high strength and rigidity, glass-filled nylon may be the best fit, particularly in mechanical components. However, if weight is a critical factor, CFRP could provide superior performance despite its higher cost. Conversely, for applications needing good impact resistance and ease of processing, polycarbonate may be the more appropriate choice. Ultimately, the decision should align with the technical specifications and economic considerations of the project at hand.

Essential Technical Properties and Trade Terminology for glass filled nylon properties

What Are the Key Technical Properties of Glass-Filled Nylon?

When considering glass-filled nylon for industrial applications, understanding its essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that buyers should be aware of:

-

Material Grade

Material grade indicates the specific formulation of glass-filled nylon, such as Nylon 6 or Nylon 66, often denoted by the percentage of glass fiber content (e.g., 30% GF). This specification impacts the mechanical performance, thermal stability, and cost. Selecting the appropriate grade is vital for ensuring that the material meets the performance requirements of specific applications, such as automotive or aerospace. -

Tensile Strength

Tensile strength measures a material’s ability to withstand tension without breaking, typically expressed in megapascals (MPa) or pounds per square inch (psi). Glass-filled nylon generally exhibits significantly higher tensile strength compared to unfilled nylon, making it suitable for high-load applications. B2B buyers need to consider tensile strength to ensure that the material can handle the stresses it will encounter in real-world conditions. -

Heat Deflection Temperature (HDT)

This property indicates the maximum temperature at which a material can maintain its shape under a specified load. Glass-filled nylon has a higher HDT than standard nylon, making it ideal for applications exposed to heat. Understanding HDT helps manufacturers select materials that will not deform during operation, thereby ensuring product reliability and safety. -

Dimensional Stability

Dimensional stability refers to a material’s ability to maintain its shape and size when exposed to varying environmental conditions such as temperature and humidity. Glass-filled nylon offers improved dimensional stability compared to unfilled nylon, which is crucial for precision applications. Buyers should prioritize this property to avoid issues related to warping or shrinkage, especially in critical components. -

Creep Resistance

Creep resistance measures a material’s ability to resist deformation under sustained load over time. Glass-filled nylon typically has lower creep rates, making it suitable for applications involving prolonged stress. This characteristic is particularly important for components in high-temperature environments where deformation could lead to failure.

What Are Common Trade Terms Related to Glass-Filled Nylon?

Familiarity with industry jargon is essential for B2B buyers to navigate purchasing processes effectively. Here are some common terms associated with glass-filled nylon:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable suppliers of glass-filled nylon components that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell in a single order. This term is crucial for budgeting and inventory management, as suppliers may impose MOQs that affect purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. Including detailed specifications in an RFQ for glass-filled nylon can lead to more accurate quotes and better negotiation outcomes. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers navigate shipping, insurance, and customs duties associated with importing glass-filled nylon products. -

Thermoplastic

A thermoplastic is a type of polymer that becomes pliable when heated and hardens upon cooling. This characteristic allows glass-filled nylon to be molded into various shapes, making it versatile for different applications. -

Composite Material

Composite materials consist of two or more constituent materials with significantly different physical or chemical properties. Glass-filled nylon is a composite that combines nylon with glass fibers, enhancing its mechanical properties. Recognizing this term aids buyers in understanding the benefits of using glass-filled nylon over standard nylon.

Understanding these properties and terms will empower international B2B buyers to make well-informed decisions when sourcing glass-filled nylon for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the glass filled nylon properties Sector

What Are the Key Market Drivers for Glass-Filled Nylon Properties?

The glass-filled nylon market is experiencing robust growth, driven by increasing demand across various industries, including automotive, aerospace, and consumer goods. Key factors propelling this trend include the material’s superior mechanical properties, such as enhanced strength, rigidity, and thermal resistance. As industries strive for lightweight yet durable materials, glass-filled nylon has emerged as a preferred choice for components subjected to high stress and wear.

Emerging technologies such as additive manufacturing (3D printing) are reshaping sourcing trends in the glass-filled nylon sector. This technology allows for rapid prototyping and the creation of complex geometries that traditional manufacturing methods cannot achieve. Consequently, international B2B buyers from regions like Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany) are increasingly exploring partnerships with suppliers who can offer advanced materials tailored to specific applications.

In addition, the growing emphasis on customization and just-in-time manufacturing is driving a shift towards local sourcing. Companies are looking for suppliers that can provide flexible production capabilities and shorter lead times, facilitating quicker responses to market demands. This trend underscores the importance of strategic supplier relationships, especially for international buyers navigating diverse regulatory environments and market dynamics.

How Is Sustainability Influencing Sourcing Trends in Glass-Filled Nylon?

Sustainability is becoming a critical factor in the sourcing of glass-filled nylon properties. As environmental concerns rise, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes the use of recycled materials in glass-filled nylon production, which not only reduces waste but also lessens the carbon footprint associated with sourcing raw materials.

Furthermore, ethical supply chains are gaining prominence. Buyers are now scrutinizing their suppliers’ sourcing practices to ensure compliance with environmental regulations and social responsibility standards. This trend is particularly relevant in regions like Europe, where stringent regulations are in place to promote sustainability.

Certificates such as ISO 14001 for environmental management systems and other “green” certifications serve as indicators of a supplier’s commitment to sustainable practices. Buyers are encouraged to seek out manufacturers that provide transparency in their sourcing and production processes, ensuring that their glass-filled nylon products meet both performance and ethical standards.

What Is the Evolution of Glass-Filled Nylon and Its Significance for B2B Buyers?

The evolution of glass-filled nylon can be traced back to the mid-20th century when nylon was first developed as a synthetic polymer. Initially utilized in textiles, its application soon expanded into engineering materials due to its favorable mechanical properties. The introduction of glass fibers to nylon marked a significant advancement, enhancing its strength and thermal stability, making it suitable for more demanding applications.

Today, glass-filled nylon is not only recognized for its superior performance in high-stress environments but also for its versatility across various manufacturing processes, including injection molding and 3D printing. This evolution is significant for B2B buyers as it opens up a broader range of applications, from automotive components to industrial machinery parts, allowing companies to leverage the material’s properties to meet specific performance requirements.

Understanding the history and development of glass-filled nylon equips buyers with the knowledge necessary to make informed decisions about material selection and supplier partnerships, ensuring they choose products that align with both their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of glass filled nylon properties

-

How do I choose the right glass-filled nylon for my application?

Selecting the appropriate glass-filled nylon involves assessing your specific application requirements, such as mechanical properties, thermal resistance, and environmental conditions. Consider factors like tensile strength, stiffness, and the percentage of glass fiber content, which typically ranges from 10% to 40%. Additionally, evaluate the processing methods you will use, such as CNC machining or injection molding, as this may influence your choice. Collaborating with suppliers who can provide samples and technical data sheets can help you make an informed decision tailored to your needs. -

What are the typical applications of glass-filled nylon in industry?

Glass-filled nylon is widely used across various industries due to its enhanced strength and rigidity. Common applications include automotive components, electrical housings, industrial machinery parts, and structural components in aerospace. Its excellent wear resistance makes it suitable for high-load applications and environments with temperature fluctuations. Understanding the specific demands of your project can help identify if glass-filled nylon is the right material choice for durability and performance. -

What are the main advantages of using glass-filled nylon over standard nylon?

The primary advantages of glass-filled nylon include significantly improved tensile strength, stiffness, and thermal resistance. The addition of glass fibers enhances dimensional stability and wear resistance, making it ideal for high-performance applications. It also exhibits lower thermal expansion rates and better creep resistance compared to standard nylon. However, it’s essential to consider the trade-offs, such as increased brittleness and potential for higher costs, when making your selection. -

What should I consider when vetting suppliers for glass-filled nylon?

When vetting suppliers, prioritize their experience in the industry and their ability to provide high-quality materials that meet your specifications. Request technical certifications, quality assurance processes, and product samples to evaluate material performance. Additionally, assess their logistical capabilities, such as delivery times and shipping options to your region, and inquire about their customer service responsiveness. A supplier with a strong reputation and a commitment to quality can be invaluable for your sourcing needs. -

What is the minimum order quantity (MOQ) for glass-filled nylon?

Minimum order quantities for glass-filled nylon can vary significantly between suppliers, typically ranging from a few kilograms to several tons, depending on the type and grade of material. Discuss your specific requirements with potential suppliers to determine their flexibility regarding MOQs. Some suppliers may offer lower MOQs for custom or prototype orders, allowing you to test materials before committing to larger quantities. -

What are common payment terms for international purchases of glass-filled nylon?

Payment terms can vary by supplier and region but often include options such as advance payment, letter of credit, or payment upon delivery. It’s essential to clarify these terms upfront to avoid misunderstandings. Many suppliers may also offer payment plans for larger orders. Ensure that the payment terms are mutually agreeable and provide sufficient protection for both parties involved in the transaction. -

How do I ensure quality assurance for glass-filled nylon products?

To ensure quality assurance, work with suppliers who have established quality control processes, such as ISO certification or other industry-specific standards. Request documentation for material testing, including tensile strength, dimensional stability, and thermal resistance results. Regular audits and inspections of the manufacturing processes can also help maintain quality. Building a strong relationship with your supplier and communicating your quality requirements will contribute to better outcomes. -

What logistics considerations should I keep in mind when sourcing glass-filled nylon internationally?

When sourcing glass-filled nylon internationally, consider factors such as shipping methods, lead times, and import/export regulations. Evaluate the supplier’s logistics capabilities to ensure timely delivery and compliance with your country’s customs requirements. Additionally, factor in costs related to shipping, tariffs, and taxes when calculating total expenses. Clear communication regarding logistics between you and the supplier can help prevent delays and ensure a smooth procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Glass Filled Nylon Properties Manufacturers & Suppliers List

1. Ensinger Plastics – Glass Filled Polyamides

Domain: ensingerplastics.com

Registered: 2015 (10 years)

Introduction: Glass filled polyamides (GF) are high-performance engineering thermoplastics known for their very high rigidity, mechanical strength, hardness, toughness, and creep strength. They exhibit high dimensional stability, good fatigue strength, and high mechanical damping properties, making them suitable for parts under high static loads in elevated temperatures. The specific product, PA 66 GF30, is a 3…

2. MatWeb – Material Property Database

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: This company, MatWeb – Material Property Database, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Ensinger – 30% Glass Filled Nylon 6/6

Domain: ensinger-pc.com

Registered: 2015 (10 years)

Introduction: This company, Ensinger – 30% Glass Filled Nylon 6/6, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Wayken – Glass-Filled Nylon (PA GF)

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Glass-Filled Nylon (PA GF) is a nylon-based compound infused with glass fibers, enhancing its material properties such as high strength, rigidity, and thermal stability. Key properties include:

– High Tensile Strength: Up to 200 MPa depending on grade.

– Low Thermal Expansion: Resists thermal deformation, suitable for high-temperature applications.

– Improved Thermal Stability: Maintains strength …

5. Forge Labs – Glass Filled Nylon PA12

Domain: forgelabs.com

Registered: 2018 (7 years)

Introduction: Glass Filled Nylon PA12, also known as PA 3200 GF, is a polyamide material reinforced with glass fibers to enhance mechanical properties. It is used in selective laser sintering (SLS) 3D printing. Key features include:

– Average Lead Time: 3-5 Business Days

– Machines Used: EOS P110 Velocis, EOS P396

– High tensile strength and rigidity, suitable for functional prototypes and end-use parts.

– Exce…

Strategic Sourcing Conclusion and Outlook for glass filled nylon properties

In conclusion, the strategic sourcing of glass-filled nylon presents a compelling opportunity for B2B buyers across diverse global markets, particularly in Africa, South America, the Middle East, and Europe. By leveraging the enhanced mechanical properties of glass-filled nylon—such as superior tensile strength, rigidity, and thermal resistance—businesses can significantly improve the performance and durability of their products.

However, it is essential to weigh these advantages against potential drawbacks, including increased costs and brittleness. Strategic sourcing not only involves selecting the right materials but also understanding their applications and implications in various manufacturing processes, such as CNC machining and injection molding.

As industries continue to evolve, the demand for high-performance materials like glass-filled nylon is expected to rise. Therefore, now is the time for international buyers to evaluate their material needs, consider partnerships with reputable suppliers, and invest in glass-filled nylon solutions that meet their specific requirements. By doing so, they will position themselves to capitalize on future innovations and market demands, ensuring sustained growth and competitive advantage.