Introduction: Navigating the Global Market for glass bead machine

In today’s competitive landscape, sourcing an efficient glass bead machine poses significant challenges for B2B buyers, particularly in rapidly evolving markets such as Africa, South America, the Middle East, and Europe, including industrial powerhouses like Brazil and Germany. Buyers face an overwhelming array of options, each with unique specifications, applications, and technological advancements. This comprehensive guide aims to navigate that complexity by detailing various types of glass bead machines, their applications across industries, and critical factors for supplier vetting.

Understanding how to evaluate machine features, operational efficiencies, and cost structures is paramount for informed purchasing decisions. Whether you’re in the automotive manufacturing sector looking for precision surface preparation or in the construction industry seeking effective cleaning solutions, this guide will provide vital insights. We delve into market trends, budget considerations, and the importance of reliable supplier relationships, ensuring you are equipped with the knowledge to make confident investments.

By empowering international B2B buyers with actionable intelligence about glass bead machines, this guide not only streamlines the purchasing process but also enhances operational capabilities. Together, let’s simplify your journey towards finding the perfect glass bead machine to meet your specific business needs.

Understanding glass bead machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bead Blasting Cabinet | Enclosed unit, various sizes, uses glass beads | Automotive, jewelry, industrial surface preparation | Pros: Efficient, minimizes media loss. Cons: Initial cost can be high. |

| Portable Glass Bead Blaster | Compact design, mobile, easy to set up | Small workshops, fieldwork, on-site applications | Pros: Versatile, easy transport. Cons: Limited capacity and power. |

| Bead Blasting Machine with Reclaimer | Integrated reclaimer system for media recycling | Heavy-duty applications, manufacturing | Pros: Cost-effective in the long run, cleaner process. Cons: Larger footprint. |

| Direct Pressure Blasters | Utilizes air pressure for high-speed blasting | Restoration, pool maintenance, surface finishing | Pros: High efficiency, effective for tough materials. Cons: Requires careful setup and monitoring. |

| Bench-Top Glass Beader | Compact, benchtop model with smaller work area | Jewelry making, small parts cleaning | Pros: Ideal for small items, space-efficient. Cons: Limited scale for larger pieces. |

What are the features and applications of Bead Blasting Cabinets?

Bead blasting cabinets are enclosed units that offer varying sizes to accommodate different levels of production. They use glass beads for abrasive blasting, making them ideal for applications in automotive restoration, jewelry finishing, and industrial surface preparation. When considering these machines, buyers should evaluate the initial investment against their efficiency and capacity. Although they may have a steep upfront cost, their efficiency can make them a worthwhile investment for high-volume operations.

How do Portable Glass Bead Blasters fit in B2B applications?

Portable glass bead blasters are designed for mobility and ease of use, making them advantageous for small workshops and on-site applications. Their compact size allows for versatility in various settings, including remote locations. However, while they are easy to transport, their capacity may be limited compared to larger models, which could restrict their utility for more substantial projects. Buyers should consider the trade-off between portability and capacity based on their specific operational needs.

What defines Bead Blasting Machines with Reclaimers?

These machines feature an integrated reclaimer system that allows for continuous recycling of the blasting media, thus enhancing productivity and reducing operational costs. Ideal for heavy-duty applications in manufacturing, the reclaimer ensures that broken beads and contaminants are filtered out efficiently. While the initial investment may be significant, the long-term media savings and cleaner operation make it appealing for businesses looking for sustainability. Buyers should consider the size and complexity of the unit, as they may require a larger designated workspace.

In what scenarios are Direct Pressure Blasters advantageous?

Direct pressure blasters use compressed air to propel abrasives at high speeds, making them effective for cleaning and surface finishing—a crucial factor in restoration projects or maintenance of pool tiles. They are known for their efficiency but require careful monitoring to maintain optimal performance levels. Businesses should consider the level of technical proficiency required for setup and operation. Despite the more complex operation, the results can justify the investment in terms of speed and effectiveness.

How do Bench-Top Glass Beaders serve niche B2B sectors?

Bench-top glass beaders are ideal for small-scale operations or workshops focusing on jewelry and delicate items. These compact machines occupy minimal space and provide an efficient means to clean small parts. However, their size may limit the types of projects that can be undertaken. Buyers interested in this type should assess the scale of their operations, ensuring it aligns with the capabilities of bench-top models. It’s an excellent option for specialized applications where space and precision are priorities.

Key Industrial Applications of glass bead machine

| Industry/Sector | Specific Application of glass bead machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Surface preparation for repainting | Ensures smooth finishes and paint adhesion, improving vehicle aesthetics and value. | Look for reliability, maintenance support, and customizable options for different vehicle components. |

| Aerospace Manufacturing | Cleaning components before assembly | Removes contaminants without damaging sensitive materials, increasing safety and performance. | Evaluate dust extraction capabilities and ensure compliance with aerospace regulations. |

| Metal Fabrication | Surface cleaning and texturing | Enhances surface quality for welding and painting; increases product lifespan. | Consider the machine’s media recovery system and its compatibility with various metals. |

| Jewelry Manufacturing | Surface polishing and engraving | Achieves a high-quality finish on intricate designs, appealing to luxury markets. | Focus on precision settings and the ability to handle diverse jewelry materials. |

| Construction and Restoration | Cleaning concrete and masonry surfaces | Prepares surfaces for sealing or painting, prolonging lifespan and reducing maintenance costs. | Ensure the machine can handle various abrasive materials and adapt to different project sizes. |

What are the Applications of Glass Bead Machines in Automotive Repair?

In the automotive repair industry, glass bead machines serve a crucial role in preparing surfaces for repainting. They are used to remove rust, old paint, and grime from vehicles without damaging underlying metal. This ensures a smooth surface ready for new finishes, enhancing both the visual appeal and resale value of the vehicle. Buyers in regions such as Brazil and Germany should look for machines that offer reliability and support, as well as options for customization to accommodate various types of vehicle components, from body panels to intricate parts.

How is Glass Bead Blasting Used in Aerospace Manufacturing?

Aerospace manufacturers utilize glass bead machines for the meticulous cleaning of components before assembly. The gentle yet effective nature of glass bead blasting removes surface contaminants, including oils and particulates, ensuring that sensitive materials are not damaged. This process enhances safety and performance in aerospace applications. International buyers must prioritize suppliers that comply with aerospace material standards and have robust dust extraction systems to maintain a clean working environment.

What Role Does Glass Bead Technology Play in Metal Fabrication?

Within metal fabrication, glass bead machines are employed for surface cleaning and texturing. By eliminating contaminants and preparing surfaces for welding or painting, these machines significantly improve the overall quality of metal outputs. Buyers should consider the effectiveness of the media recovery systems, which can both save costs and minimize waste. Compatibility with different metal types is also essential for optimizing operational efficiency in diverse production environments.

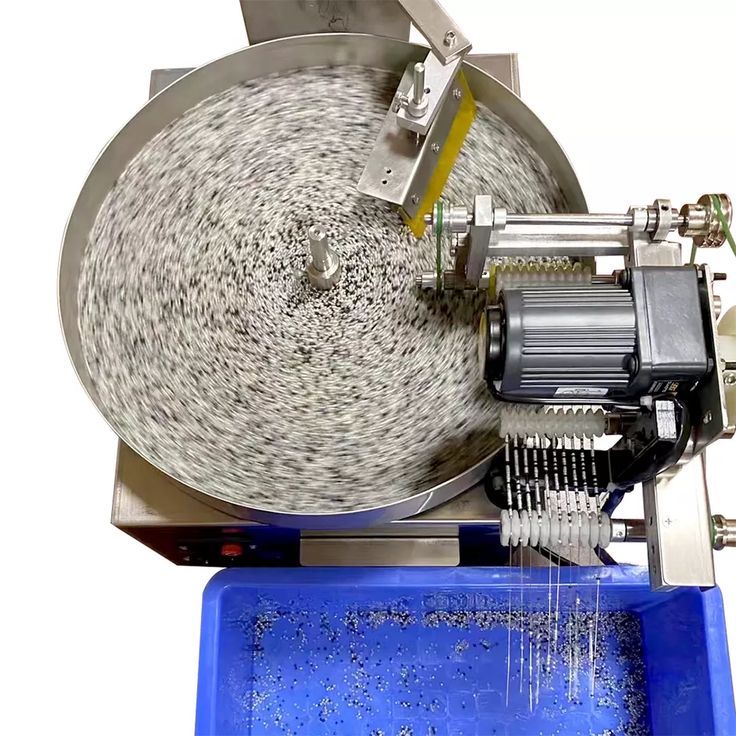

Why is Glass Bead Blasting Important for Jewelry Manufacturing?

In jewelry manufacturing, glass bead machines are used for polishing and finishing intricate designs. The precise cleaning afforded by these machines ensures that pieces achieve a high-quality finish, integral for attracting luxury buyers. For international B2B buyers, factors such as precision settings and the ability to manage a variety of materials—like gold, silver, and precious stones—are critical in choosing the right equipment for their operations.

What are the Benefits of Glass Bead Machines in Construction and Restoration?

In construction and restoration, glass bead blasting is utilized to prep concrete and masonry surfaces for sealing or painting. It effectively cleans surfaces while minimizing damage, resulting in enhanced durability and lower maintenance costs over time. Buyers in emerging markets should ensure that the machinery can facilitate the use of various abrasive materials and be adaptable for different site sizes, thus optimizing project productivity and cost-effectiveness.

3 Common User Pain Points for ‘glass bead machine’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Glass Bead Machine for Specific Applications

The Problem: Many B2B buyers face the challenge of selecting the right glass bead machine that meets their unique operational needs. With various models available, each tailored for different applications such as automotive refinishing, jewelry cleaning, or surface preparation, the decision-making process can be overwhelming. Buyers may struggle with understanding the technical specifications, such as the appropriate pressure settings, media type compatibility, or the machine’s handling capacity. This can lead to purchases that are either insufficient for heavy-duty tasks or unnecessary for lighter applications, resulting in financial waste.

The Solution: To effectively choose the best glass bead machine, buyers should conduct a thorough needs assessment prior to purchasing. Start by clearly defining the specific applications the machine will serve, factoring in the materials you’ll typically be working with. Next, consult manufacturer specifications and seek machines with adjustable pressure settings, as flexibility can help tailor operations to different tasks. Engaging in direct conversations with suppliers for expert recommendations can also provide insights into which models have proven effective for similar applications. Requesting product demonstrations or trial periods, if possible, can further ensure the machine’s suitability before making a financial commitment.

Scenario 2: High Operational Costs Due to Inefficient Media Usage

The Problem: B2B buyers often find that their operational costs for glass bead machines escalate quickly because of inefficient media usage. This could result from selecting inappropriate blasting media, inadequate machine maintenance, or poor operating practices. For example, not utilizing high-quality glass beads can lead to higher consumption rates, increased replacements, and additional downtime for machine cleaning or repairs. Consequently, businesses may experience diminished profitability and inefficient workflow.

The Solution: To mitigate operational costs, buyers should prioritize sourcing high-quality, reusable glass beads specifically designed for bead blasting applications. Establishing a reliable relationship with suppliers who can provide bulk purchasing options or wholesale rates can lead to significant savings. Additionally, implementing regular maintenance practices and routine inspections of the glass bead machine will ensure that it operates optimally and enhances media lifespan. Training operators on efficient blasting techniques and ensuring adherence to best practices can also prevent unnecessary waste. Comprehensive operator manuals and guidance from suppliers can support these training initiatives effectively.

Scenario 3: Insufficient Technical Support and After-Sales Service

The Problem: For many international B2B buyers, securing adequate technical support and after-sales service poses a significant challenge, particularly when purchasing specialized machinery like glass bead machines. Buyers may experience difficulties accessing replacement parts, troubleshooting technical issues, or receiving timely maintenance services, which can lead to prolonged downtime. This is particularly critical for buyers in remote or less accessible regions, where local support may be sparse.

The Solution: To ensure robust technical support, buyers should prioritize partnerships with manufacturers and suppliers who have a reputation for offering excellent after-sales services. Thoroughly researching the company’s commitment to post-purchase support, such as availability of manuals, response times for technical inquiries, or the ability to send technicians for on-site assistance, is key. Inquire about warranty options and service packages during the purchase negotiation to clarify what support will be available over time. Additionally, joining industry associations or online forums related to glass bead blasting can facilitate connections with other operators, providing shared solutions and advice on the efficient operation and maintenance of bead blasting tools. This community can serve as a supplementary resource for troubleshooting and best practices, reducing reliance on formal technical support lines.

Strategic Material Selection Guide for glass bead machine

When selecting materials for glass bead machines, several factors come into play that can significantly impact performance, longevity, and cost-effectiveness. Here, we analyze four common materials used in glass bead machines, highlighting their properties, advantages, disadvantages, and considerations pertinent to international B2B buyers in various regions.

What are the Key Properties of Carbon Steel for Glass Bead Machines?

Carbon Steel is a popular choice for the construction of glass bead machines due to its robust nature and relatively low cost. Key properties include high tensile strength, ability to withstand substantial impact, and good wear resistance. It typically has a temperature rating of around 500°F and shows decent corrosion resistance when properly coated.

- Pros: Carbon steel is cost-effective and offers excellent durability. It is also readily available and can be easily manufactured into complex shapes for various components of the glass bead machine.

- Cons: Without appropriate coatings, carbon steel is prone to rust, particularly in humid environments, which can be a concern in regions like the Middle East and parts of South America with high humidity levels.

- Impact on Application: Carbon steel’s inherent strength makes it suitable for heavy-duty blasting applications, where longevity and impact resistance are essential. However, its corrosion susceptibility necessitates considerations for protective coatings or corrosion inhibitors.

- International Buyer Considerations: Compliance with ASTM A569 standards for carbon steel may be necessary, especially for buyers in Europe (DIN/NF standards). Such standards ensure quality and durability, which can influence purchasing decisions significantly.

How Does Stainless Steel Compare in Glass Bead Machine Manufacturing?

Stainless Steel is another common choice due to its outstanding corrosion resistance. With properties like a temperature rating exceeding 1000°F and excellent mechanical strength, it is ideal for high-performance demanding applications.

- Pros: The most significant advantage of stainless steel is its resistance to corrosion and staining. This feature extends the life of glass bead machines, making it an excellent choice in applications prone to moisture.

- Cons: The primary drawback is the higher cost compared to carbon steel. Moreover, the manufacturing process is more complex, often requiring specialized tools and techniques.

- Impact on Application: Stainless steel ensures compatibility with a wide range of abrasive media without degradation, leading to consistent performance over time. This factor is especially important for industries relying on precise surface treatments.

- International Buyer Considerations: Buyers must recognize compliance with standards such as ASTM A240 and EN 1.4301, widely recognized across Europe and Asia. The investment in stainless steel is often justified in regions with stricter corrosion resistance requirements.

What are the Benefits of Using Aluminum in Glass Bead Machines?

Aluminum is favored for its lightweight properties and resistance to oxidation. With a lower temperature threshold (typically around 900°F) than steels, aluminum still offers decent strength.

- Pros: Its lightweight nature allows for easier handling and transportation, making it ideal for portable machines. Aluminum is also inherently resistant to corrosion, thus requiring less maintenance.

- Cons: One downside is that aluminum may not withstand higher pressures as effectively as steel, making it less suited for heavy-duty blasting operations. Additionally, it can be more expensive than carbon steel when considering the cost-to-strength ratio.

- Impact on Application: Aluminum works well with finer media types, providing smooth finishes, particularly in delicate applications. However, its limitations in high-pressure conditions mean its use may be restricted to specific industries, like jewelry or automotive detailing.

- International Buyer Considerations: Compliance with international aluminum standards (e.g., ASTM B221) can be critical, especially for buyers focused on high-quality manufacturing. Regions with increased scrutiny on product safety and environmental impact may prefer aluminum for its sustainability benefits.

How Does Composite Material Fit into Glass Bead Machine Design?

Composite Materials have recently gained traction due to their enhanced properties, combining the benefits of various materials into one.

- Pros: Composites are often engineered for specific applications, allowing for customized solutions that enhance performance characteristics such as impact resistance and weight reduction while being corrosion-resistant.

- Cons: However, composites can be substantially more expensive and require advanced manufacturing techniques, making them less accessible for some markets. The complexities can lead to longer lead times in production.

- Impact on Application: Composites can be tailored for optimal media compatibility across varying applications, making them versatile for different industries.

- International Buyer Considerations: Understanding the certification and compliance standards for composites (like ASTM D3039) is crucial for buyers across markets. Many international buyers from developing regions may face challenges in obtaining composite materials due to cost and availability.

Summary Table of Material Selection for Glass Bead Machines

| Material | Typical Use Case for glass bead machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty blasting applications | Cost-effective and durable | Prone to rust without proper coatings | Low |

| Stainless Steel | High-performance applications requiring corrosion resistance | Excellent longevity | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight portable machines and fine media applications | Lightweight and low maintenance | Limited high-pressure performance | Med |

| Composite | Customized solutions in specialized applications | Tailored properties for specific use | High cost and production complexity | High |

In conclusion, choosing the right material for glass bead machines requires careful consideration of the application, environmental factors, and compliance with international standards, ensuring optimal performance and longevity in various market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for glass bead machine

What Are the Key Stages in the Manufacturing Process of Glass Bead Machines?

The manufacturing of glass bead machines involves several critical stages, from initial material preparation to final assembly and finishing. Each stage is essential to ensure the machine’s performance and longevity, vital for industries such as automotive, aerospace, and jewelry.

Material Preparation

The first stage starts with the selection of high-quality raw materials, typically heavy-duty steel for the cabinet and durable components for internal parts. The steel should meet industry standards for strength and corrosion resistance. This ensures the finished product can withstand repeated use in demanding environments. Advanced techniques like laser cutting and CNC machining are often employed to ensure accuracy and repeatability in the part dimensions.

Forming and Fabrication

After preparation, the raw materials are formed into desired shapes using forming techniques such as bending, stamping, and welding. This stage often utilizes robotic welding to ensure consistent seam quality, minimizing human error. Such technology is critical in ensuring that the joints can handle the stress during operation without failure. The process may also include the application of protective coatings at this stage to further enhance durability.

Assembly

Once individual components are created, they are assembled into the final machine. A trained team follows detailed engineering guidelines to ensure everything fits securely and functions seamlessly. Assembly can involve both manual and automated processes, balancing productivity with precision. Specialists might perform post-assembly inspections to identify any potential operational issues early on.

Finishing Processes

Finishing touches such as powder coating or painting provide not only an aesthetic appeal but also add an additional layer of protection against chemical and physical wear. Quality checks in this stage confirm that the surface treatments meet standards for adhesion, thickness, and uniformity. A final thorough inspection is carried out to ensure that the finished machine meets all design specifications.

What Quality Control (QC) Measures Are Essential in Glass Bead Machine Production?

Quality control is a vital aspect of manufacturing glass bead machines, ensuring they meet both company standards and international regulations.

Relevant International Standards

Manufacturers typically adhere to international standards such as ISO 9001, which establishes criteria for a quality management system. Compliance with these standards guarantees that processes are controlled and that products are consistently high quality. Additional certifications, such as CE marking for products sold in Europe, or API specifications for machines intended for oil and gas applications, validate the manufacturer’s adherence to safety and quality standards.

Key QC Checkpoints

Quality assurance processes commonly include several checkpoints, notably Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC):

-

IQC: At the beginning of the production process, materials and components are tested for compliance with specifications. Rejecting subpar inputs avoids downstream production issues.

-

IPQC: During assembly, periodic inspections ensure each operational step meets quality standards. This may involve testing functional components or measurements of assembly tolerances.

-

FQC: Once production is complete, the final product undergoes rigorous testing to verify it functions as intended. This can include operational performance tests, pressure tests, and safety checks to evaluate the machine’s integrity.

How Can B2B Buyers Verify the Quality Assurance Practices of Suppliers?

Assessing manufacturing quality assurance practices before purchase is critical for international B2B buyers. Below are effective methods:

Conducting Supplier Audits

Buyers should conduct on-site audits to evaluate the manufacturer’s quality management systems. This helps verify compliance with standards and assess operational efficacy. Audits can be third-party or internal, but they should focus on reviewing documentation, production processes, and employee training programs.

Reviewing Quality Control Reports

Suppliers should provide comprehensive QC reports that outline all tests performed, results, and any corrective actions taken. Detailed records should illustrate the testing methodology, quality metrics, and incidences of failure to verify the supplier’s commitment to quality.

Relying on Third-Party Inspection Services

Third-party inspections offer an impartial assessment of the manufacturing processes and finished products. Independent organizations can conduct random checks during production runs, providing a layer of confidence regarding quality before shipment.

What Nuances Should International Buyers Consider Regarding Quality Certifications?

When sourcing glass bead machines internationally, buyers must be aware of the nuances involved in quality certifications and standards specific to different regions. For instance:

- In **Europe

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass bead machine’

This step-by-step sourcing guide is designed to assist B2B buyers in the procurement of glass bead machines. These machines are essential for surface preparation in various industries, including automotive, aerospace, and jewelry making. By following this checklist, buyers can ensure they make informed decisions leading to successful acquisitions.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before initiating the procurement process. Consider factors such as the size of the work area, type of materials you’ll be processing, and desired finishing quality. Detailed specifications will help streamline your search and ensure the machine meets your operational needs.

- Key Parameters: Size of the cabinet (e.g., 48in x 48in), type of abrasive media (glass beads vs. aluminum oxide), and operational speed (CFM).

- Application Needs: Consider the intended use, such as automotive paint removal or jewelry finishing, as this will influence your choice.

Step 2: Research Potential Suppliers

Conducting thorough research is integral to identifying reliable suppliers. Look for manufacturers with a good reputation and experience in the market. This step can prevent future operational headaches and ensure the reliability of the machinery.

- Supplier Evaluation: Visit company websites, read customer testimonials, and check for industry certifications.

- Local vs International: Evaluate suppliers from your region to minimize shipping costs and support local economies, but do not hesitate to consider international options for potentially better machinery.

Step 3: Verify Supplier Certifications

It’s essential to ensure that selected suppliers hold the relevant industry certifications. Certifications can serve as benchmarks for quality assurance and compliance with safety regulations, which are critical in sourcing glass bead machines.

- Quality Certifications: Look for ISO certifications or other relevant standards, which indicate a commitment to quality management.

- Compliance: Ensure that the products meet international safety standards, particularly with regard to handling equipment and dust extraction.

Step 4: Request Detailed Quotes

Requesting quotes from multiple suppliers will allow for better comparison. Be specific about your requirements so suppliers can provide accurate estimates, including cost and delivery timelines.

- Include Specifications: Share your defined specifications, such as machine size and desired features, to receive tailored quotes.

- Breakdown of Costs: Ask for detailed cost breakdowns, including shipping, training, setup, and after-sales support.

Step 5: Evaluate After-Sales Support and Warranty

Assessing after-sales support can save you from future complications. Ensure that suppliers provide robust customer service, including maintenance services and access to spare parts.

- Warranty Terms: Consider suppliers that offer comprehensive warranties, which can protect your investment.

- Technical Support: Verify the availability of technical assistance or training for operating the machine, particularly for users unfamiliar with bead blasting technology.

Step 6: Assess Delivery Timeline and Payment Terms

Understanding the expected delivery timeline is essential to avoid disruptions in your operations. Alongside this, ensure that payment terms are agreeable to your budget and cash flow.

- Delivery Commitment: Clarify the time from ordering to delivery and set expectations regarding any delays.

- Flexible Payment Options: Look for suppliers offering flexible payment terms to assist with budgeting and financial planning.

Step 7: Read Customer Reviews and Case Studies

Gaining insights into other customers’ experiences can significantly influence your decision. Pay attention to case studies and reviews that highlight the performance and reliability of the glass bead machines.

- Industry-Specific Experiences: Seek out feedback from buyers within your industry to understand how well the machine performs in similar applications.

- Longevity and Performance: Look for insights related to the machine’s durability and effectiveness over time, which can guide your investment choice.

By following this practical sourcing checklist, B2B buyers can make well-informed decisions when procuring glass bead machines, ultimately ensuring long-term operational success and efficiency.

Comprehensive Cost and Pricing Analysis for glass bead machine Sourcing

What Are the Key Cost Components in Sourcing Glass Bead Machines?

When evaluating the cost structure for sourcing glass bead machines, understanding the essential components is crucial for B2B buyers. Key cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The main materials include robust steel for the cabinet, specialized glass beads for blasting, and electronic components for operational controls. The choice between standard and premium materials can significantly affect costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in machine assembly, testing, and quality assurance. Training and specialized skills required can contribute to elevated labor costs.

-

Manufacturing Overhead: Factors such as utility costs, facility maintenance, and equipment maintenance form the overhead. These fixed and variable costs can vary widely based on the manufacturer’s location and operational efficiency.

-

Tooling: This involves the cost associated with creating molds or specialized tools needed for precision in manufacturing. Tooling costs can represent a significant upfront investment, particularly for customized machines.

-

Quality Control: QC processes ensure that machines meet safety and performance standards. Rigorous testing and certification requirements can escalate costs, particularly if compliance with international standards is necessary.

-

Logistics: Transportation, warehousing, and customs fees significantly impact total costs, especially for international buyers. Factors such as the distance from the manufacturing facility to the buyer’s location and customs regulations play a vital role.

-

Margin: Manufacturer’s markup varies, influenced by brand reputation, demand, and supply chain efficiencies. Higher-quality brands typically command higher margins.

How Do Volume and Customization Influence Pricing for Glass Bead Machines?

Volume and customization are critical factors in determining the pricing of glass bead machines.

-

Volume or Minimum Order Quantity (MOQ): Larger orders often attract significant discounts, making a compelling business case for bulk purchases. Manufacturers are more inclined to offer favorable pricing in exchange for large commitments.

-

Specifications and Customization: Customized machines tailored for specific applications or requirements may incur additional costs due to unique design elements or materials. Specifications, including the size of the dust collection system and the type of abrasive media compatibility, can also affect pricing.

What Pricing Influencers Should International B2B Buyers Consider?

When sourcing glass bead machines, particularly from diverse regions such as Africa, South America, Europe, and the Middle East, several influencers affect pricing:

-

Quality Certifications: Different manufacturers may offer various quality certifications, which can impact costs. Machines certified to international standards may be priced higher but offer better reliability and operational efficiency.

-

Supplier Factors: The reputation and reliability of the supplier can influence prices. Established suppliers may charge a premium based on brand recognition but could offer better after-sales support.

-

Incoterms: Understanding Incoterms is critical for cost management. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) shift the financial responsibility during transport. Buyers should assess which options provide the best total cost benefits.

What Are the Best Negotiation Strategies for B2B Buyers Sourcing Glass Bead Machines?

To navigate potential negotiations effectively, consider the following strategies:

-

Establish Clear Requirements: Define your technical requirements and budgets upfront to ensure that negotiations remain focused and productive.

-

Leverage Competitive Quotes: Use multiple quotes from different suppliers to foster a competitive environment. This practice can lead to more favorable pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Assess not just the initial purchase price but the ongoing operational costs, including maintenance and potential repairs, which impact the total cost of ownership.

-

Timing and Market Understanding: Be aware of market trends and factors influencing the manufacturing landscape, such as raw material costs and demand shifts, to better position yourself during negotiations.

What Pricing Nuances Should B2B Buyers Be Aware of When Sourcing Internationally?

Keep in mind that prices may vary considerably between regional suppliers, influenced by currency exchange rates, local economic conditions, and tariffs. Building relationships with suppliers, transparently discussing pricing, and thoroughly understanding all variables can lead to successful sourcing and enhanced profitability.

Disclaimer: Pricing indicated in this guide is for illustrative purposes and may vary based on market conditions, supplier terms, and product specifications. Always ensure to verify current prices directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing glass bead machine With Other Solutions

Understanding Alternatives to Glass Bead Machines in Surface Treatment

When evaluating options for surface treatment and cleaning, businesses may consider various technologies beyond glass bead machines. These alternatives can provide unique advantages depending on specific project needs, operational budgets, and desired outcomes.

Comparison of Glass Bead Machines with Alternative Solutions

| Comparison Aspect | Glass Bead Machine | Soda Blasting | Dry Ice Blasting |

|---|---|---|---|

| Performance | Highly effective for smoothing and polishing surfaces. | Suitable for gentle cleaning without surface damage. | Excellent for tough debris removal without residual waste. |

| Cost | Mid-range investment; machines like the BB-4000 LED start around $10,399. | Generally lower initial costs for equipment. | Higher upfront costs; machines can be expensive. |

| Ease of Implementation | Requires trained personnel but is relatively straightforward. | Simple setup and can be conducted with minimal training. | Requires specialized operators familiar with the technology. |

| Maintenance | Regular maintenance; media circulation needs consistent checking. | Low maintenance required; typically just replenishing soda media. | Maintenance dependent on equipment type, but can be costly. |

| Best Use Case | Ideal for automotive, aerospace, and jewelry industries needing surface smoothing. | Effective for softer materials and delicate cleaning (e.g., historical restoration). | Perfect for sensitive cleaning, like electronics or intricate machinery. |

In-Depth Look at Soda Blasting

Soda blasting serves as an eco-friendly alternative that uses sodium bicarbonate as the abrasive medium. Its gentle nature makes it ideal for delicate materials and surfaces, such as historical artifacts or automotive parts without degrading the substrate. While the initial investment in soda blasting equipment can be lower, the ongoing costs may include purchasing soda media, which must be replenished frequently. The process is quick and straightforward, requiring minimal setup, making it attractive for smaller operations or projects.

Detailed Exploration of Dry Ice Blasting

Dry ice blasting utilizes solid carbon dioxide pellets to clean surfaces without the use of solvents or abrasives. This method excels in removing paint, grease, and other contaminants from sensitive equipment in industries such as food processing and electronics, where moisture from traditional methods may cause damage. However, it comes with a higher initial investment and may require trained personnel to operate effectively. Its ability to minimize waste by evaporating upon impact adds to its appeal, especially for environmentally-conscious businesses.

Conclusion: How to Choose the Right Surface Treatment Solution

Selecting the appropriate surface treatment technology involves understanding the specific needs of your projects and operational constraints. For those looking for a robust solution for smoothing and polishing a variety of surfaces, glass bead machines offer efficient performance despite higher maintenance requirements. Alternatively, soda blasting could be advantageous for operations focused on delicate cleaning and lower initial costs. Meanwhile, dry ice blasting presents a high-end solution suited for sensitive applications where cleanliness and zero moisture are critical. Consider your use case, budget, and maintenance capabilities to identify the best solution for your business needs.

Essential Technical Properties and Trade Terminology for glass bead machine

What are the Essential Technical Properties of a Glass Bead Machine?

Understanding the technical properties of a glass bead machine is crucial for making informed purchasing decisions. Here are some key specifications that should be considered:

-

Material Grade

– The material composition of the machine is vital for durability and performance. High-grade steel and powder coating are common features that enhance resistance to wear and corrosion. This is particularly important for buyers in industries such as automotive and jewelry, where consistent quality and longevity are essential. -

Work Area Dimensions

– The work area dimensions vary significantly between models, influencing the size of components that can be effectively cleaned or treated. For example, larger work areas can accommodate bigger parts but may require more floor space. Buyers should evaluate their operational needs against the machine’s dimensions to ensure compatibility. -

Blast Pressure

– Measured in PSI (pounds per square inch), blast pressure determines the effectiveness of the cleaning process. Higher pressure can remove tougher contaminants but may also risk damaging softer substrates. Buyers should consider the types of materials they will be working with to choose the right pressure settings. -

Abrasive Media Recirculation System

– A well-designed abrasive media recirculation system enhances efficiency by filtering and reusing blasting media, such as glass beads. This reduces costs and increases productivity, making it an attractive feature for businesses looking to maximize value over time. -

Vacuum System

– A powerful vacuum system is essential for maintaining a clean work environment and ensuring the effective reuse of abrasive materials. It reduces downtime and operational costs by decreasing the need for repetitive media replacement. -

Control Systems

– User-friendly control systems, such as foot pedals or digital interfaces, enhance operational efficiency. These controls allow for precise adjustments during the blasting process, minimizing user error and streamlining workflow.

What are the Common Trade Terms Related to Glass Bead Machines?

Familiarity with industry jargon can significantly streamline the purchasing process. Here are some common trade terms associated with glass bead machines:

-

OEM (Original Equipment Manufacturer)

– This refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess product reliability and performance history. -

MOQ (Minimum Order Quantity)

– MOQ specifies the least number of units a supplier is willing to sell. This is particularly critical for B2B buyers who may need to balance inventory levels with budget constraints. Larger MOQs can offer better pricing but require careful financial planning. -

RFQ (Request for Quotation)

– An RFQ is a formal request for suppliers to provide prices for specific products or services. This process helps buyers gather competitive pricing and services before making purchases and can be critical for international transactions where exchange rates may impact overall costs. -

Incoterms (International Commercial Terms)

– These are standardized trade terms used in international transactions to define responsibilities regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers navigate cross-border trade more effectively, minimizing misunderstandings between buyers and suppliers. -

Cycle Time

– Cycle time is the total time required to complete a blasting job, including setup, operation, and cleaning. Reducing cycle time can significantly improve production efficiency, making it a vital metric for buyers seeking to enhance operational workflows. -

CE and ISO Certifications

– CE marking indicates conformity with health, safety, and environmental protection standards in Europe, while ISO certifications reflect international standards for quality management systems. Checking for these certifications can provide reassurance of product quality and compliance with global standards.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their overall efficiency in using glass bead machines.

Navigating Market Dynamics and Sourcing Trends in the glass bead machine Sector

Market Overview & Key Trends: What Should International B2B Buyers Consider in the Glass Bead Machine Sector?

The glass bead machine sector is experiencing robust growth driven by several key global factors. Firstly, advancements in technological innovation, such as the integration of automation and IoT capabilities, are enhancing the efficiency of bead blasting processes. International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking equipment that offers precision, reduced operational costs, and improved productivity.

Moreover, emerging B2B trends highlight a rising demand for customizations that cater to specific industry needs, whether it be in automotive, aerospace, or electronics. The shift toward eco-friendly practices is also reshaping supplier relationships; companies that can demonstrate sustainability in their production processes are more attractive to global buyers. For instance, the ability to use recyclable materials is becoming a significant selling point.

Market dynamics are influenced by a growing preference for integrated solutions. Suppliers who provide comprehensive packages—including maintenance, training, and technical support—are increasingly favored. As the market expands, buyers should also be aware of regional considerations, such as import regulations and tariffs, that could affect their cost structures and sourcing strategies. The burgeoning e-commerce platforms enhance the sourcing process, providing easy access to global suppliers, thereby broadening the landscape for international purchases.

Sustainability & Ethical Sourcing: How Do They Affect Your Purchase Decisions in Glass Bead Machines?

Sustainability and ethical sourcing are increasingly pivotal in the procurement strategies of international B2B buyers. The environmental impact of glass bead blasting operations—including energy consumption and waste generation—places pressure on manufacturers to adopt greener practices. Organizations are now prioritizing suppliers who employ sustainable materials and methods for producing glass beads.

Ethical supply chains are essential, especially in an age illuminated by corporate social responsibility (CSR). Buyers should consider suppliers who adhere to fair labor practices and transparency in their sourcing strategies. Certifications such as ISO 14001 for environmental management or adherence to specific ethical manufacturing codes can be significant indicators of a supplier’s commitment to sustainability.

Investing in machinery that features energy-efficient designs and reductions in harmful emissions can yield long-term savings and improve operational sustainability. Furthermore, many suppliers now offer ‘green’ glass bead products made from recycled materials, which not only meet performance requirements but also resonate with corporate sustainability goals. By prioritizing ethical sourcing and sustainability in their procurement decisions, B2B buyers can foster a positive brand image while contributing to global environmental efforts.

Brief Evolution/History: How Has the Glass Bead Machine Industry Developed Over Time?

The glass bead machine industry has evolved considerably since its inception, with technological advancements fundamentally transforming its landscape. The concept of using glass beads for abrasive blasting can be traced back to the late 19th century, where its application began primarily in the cleaning and finishing of metals. Over the decades, innovations such as high-efficiency reclaimer systems and automated controls have emerged, enhancing the efficacy of glass bead blasting.

As the demand for surface preparation has grown, so too has the variety of applications—from automotive refinishing to intricate restoration projects across various sectors. Today, high-tech features such as integrated dust collection systems and remote monitoring capabilities have become commonplace, reflecting the industry’s commitment to improving productivity while adhering to stringent environmental regulations.

This ongoing evolution illustrates a clear trajectory towards enhanced efficiency and sophistication in glass bead machines, aligning with the broader trends of Industry 4.0 that emphasize automation, sustainability, and precision. As the global market continues to expand, these historical advancements lay a foundation for future innovations that will further support the burgeoning requirements of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of glass bead machine

-

How do I troubleshoot common issues with glass bead machines?

To troubleshoot common issues with glass bead machines, first, verify that the machine is properly supplied with compressed air and that all fittings and hoses are secure. Check for blockages in the media flow system, including the media hopper, that could affect performance. Regularly inspect the internal components for wear, especially the nozzle and reclaimer systems, as abrasives can cause wear over time. If the machine isn’t functioning as expected, consult the manufacturer’s manual for specific diagnostics or reach out to customer support for assistance. -

What is the best glass bead machine for small to medium businesses?

For small to medium businesses, models like the BB-4100LED or SL-46 stand out due to their balance of efficiency and cost. They offer adequate work areas and features such as efficient reclaim systems and user-friendly controls, making them ideal for general bead blasting purposes. When selecting a machine, consider factors like the work material, size of operation, and the required throughput. Additionally, ensure the chosen machine can easily accommodate your specific glass beading projects. -

What customization options are available with glass bead machines?

Customization options for glass bead machines can vary significantly by supplier. Many manufacturers allow modifications to the cabinet size, media delivery mechanisms, and control systems to fit specific operational needs. Additionally, you might find options for additional features like enhanced lighting, filtration systems, or specialty media hoppers. When discussing customization with suppliers, outline your workflow requirements clearly, so they can propose the best solutions for your business’s needs. -

What is the typical minimum order quantity (MOQ) for glass bead machines?

The typical minimum order quantity (MOQ) for glass bead machines can vary widely between suppliers. While some manufacturers will sell single units, others may impose an MOQ of 3-5 units or more, especially for custom machines. Always inquire directly with the supplier about their MOQ policies, as they can also depend on your geographical location or the complexity of the customization required. Establishing a clear understanding of MOQ can help facilitate negotiation and better planning for inventory. -

How should I vet suppliers for glass bead machines?

When vetting suppliers for glass bead machines, first assess their reputation by reviewing customer testimonials and case studies. Check their certifications and compliance with international standards, which can assure quality and safety. It’s also advisable to request samples or demonstrations of the machines to validate performance claims. Establish open communication regarding their after-sales support, warranty policies, and technical assistance. Engaging in trade shows or industry expos can also provide valuable insights into reputable suppliers. -

What payment terms are typically offered for glass bead machine purchases?

Payment terms for glass bead machines generally range from 30% upfront, with the remainder due on delivery, to full pre-payment, particularly for international orders. Some manufacturers may offer financing options or payment plans based on the purchase size. Always clarify terms before finalizing the order, and ensure that the methods of payment accepted align with your organization’s capabilities, as options often include bank transfer, credit card, and sometimes third-party financing solutions. -

What quality assurance measures should I look for in glass bead machines?

Quality assurance measures are critical when purchasing glass bead machines. Look for machines backed by international quality certifications such as ISO 9001, which indicates adherence to quality management practices. Ensure that the manufacturer conducts regular inspections and testing during production. You may also request information on any warranties offered; a longer warranty typically indicates greater confidence in product reliability. Understanding the manufacturer’s maintenance recommendations can help in ensuring ongoing operational efficiency. -

What logistical considerations should I keep in mind when purchasing glass bead machines internationally?

When purchasing glass bead machines internationally, consider shipping logistics including costs, timelines, and customs procedures. Factor in import duties and taxes, which can significantly influence the overall cost. Research reliable shipping methods that align with the urgency of your project timeline. Additionally, ensure that the supplier provides clear packaging and handling instructions to avoid damage during transit. Having a local agent or representative can facilitate smoother communication with customs and support after-sales service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Glass Bead Machine Manufacturers & Suppliers List

1. Stuller – Expedite 14K Gold Commodity Bands

Domain: stuller.com

Registered: 1996 (29 years)

Introduction: Need this product now? Expedite it. Only 3 items per request. Unavailable for sizing, engraving, and other customization services. Commodity bands in 14K gold only. $25.00 fee per request.

2. AXE – SL-46 Glass Bead Cabinet

Domain: axeequipment.com

Registered: 1997 (28 years)

Introduction: Model: AXE SL-46 Glass Bead Cabinet

Key Features:

– 450 CFM reclaimer acts as a cyclonic separator

– Heavy duty removable work screen with 90 degree braces for heavy parts

– Foot pedal operated air control system

– Aluminum pistol grip media gun for precise cleaning

– Built-in air nozzle for finishing details

– 45 degree brake inside the cabinet to keep media contained

– Inside dimensions: 24″ x 4…

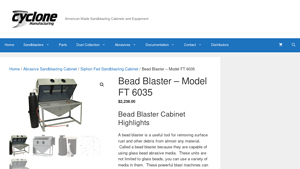

3. Cyclone Blasters – Bead Blaster Model FT 6035

Domain: cycloneblasters.com

Registered: 2004 (21 years)

Introduction: {“name”:”Bead Blaster – Model FT 6035″,”price”:”$2,238.00″,”made_in”:”USA”,”dimensions”:”large interior for almost any size parts”,”construction”:”fully welded 16 gauge steel, angle iron legs”,”features”:[“fully assembled, no assembly required”,”90 CFM sandblast dust collector to improve visibility”,”foot pedal operated sandblast gun with tungsten carbide nozzle”,”full top opening system with side…

4. Sandblast Equipment – Bead Blasters

Domain: sandblastequipment.com

Registered: 2000 (25 years)

Introduction: Bead blasters utilize high pressured streams of spherical abrasives to clean or resurface parts in industrial, commercial, and domestic settings. They are equipped with an abrasive media hopper that contains blasting beads made from materials like glass, ceramic, plastic, or metallic components (aluminum oxide, silicon carbide). These machines operate with an air compressor that creates a vacuum t…

5. Canadian Hobby Metalworkers – Recycled Glass Beads

Domain: canadianhobbymetalworkers.com

Registered: 2015 (10 years)

Introduction: 50 lb bags of recycled glass in stock, fine grade, used for glass bead blasting, effective for cleaning aircraft parts, leaves a satin surface finish on steel and aluminum, suitable for low pressure applications, glass beads last longer than crushed glass, keeps pressure at or under 70 psi for best results, used in sandblast cabinets and siphon setups.

6. Easel – Glass Bead Blasting

Domain: forum.easel.com

Registered: 1997 (28 years)

Introduction: This company, Easel – Glass Bead Blasting, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Raptor Blaster – High-Quality Abrasive Blasting Cabinets

Domain: raptorblaster.com

Registered: 2015 (10 years)

Introduction: Raptor Blaster offers a range of high-quality abrasive blasting cabinets made in the USA, including the following models: RB4226 (small to medium objects, 12 gauge steel body, laser cut and hand-welded), RB4836 (medium to large objects, 100 CFM can style dust collector), RB5446 (large industrial cabinet, sturdy 100 CFM BP style dust collector), RB4836S (heavy-duty slurry wet blast cabinet, 12 gaug…

8. Blasting Cabinet – Unused $35 Buy

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Blasting cabinet, purchased for $35, never used.

Strategic Sourcing Conclusion and Outlook for glass bead machine

What Are the Key Takeaways for Effective Sourcing of Glass Bead Machines?

As the manufacturing landscape becomes increasingly competitive, effective strategic sourcing of glass bead machines is paramount for international B2B buyers. Investing in advanced bead blasting technology not only enhances operational efficiency but also extends the life of equipment by providing superior surface cleaning, essential for industries ranging from automotive to jewelry and beyond. Key factors for consideration include machine durability, ease of maintenance, and the availability of parts, which can significantly impact long-term profitability.

Why Is Strategic Sourcing Vital for Global Buyers?

Strategic sourcing enables companies to optimize their suppliers, manage costs, and ensure access to the latest innovations in bead blasting equipment. Engaging with reputable manufacturers and understanding regional market dynamics—whether in Africa, South America, the Middle East, or Europe—can lead to significant cost savings, improved quality control, and better sustainability practices. In addition, building robust supplier relationships allows for greater flexibility in meeting evolving production needs.

How Can International Buyers Position Themselves for Future Success?

As we look ahead, global demand for glass bead machines will likely expand with the growth of manufacturing sectors in emerging economies. By aligning with reliable suppliers who offer customization and support, businesses can ensure they remain competitive in the market. We encourage buyers to take proactive steps—explore diverse sourcing options, evaluate machinery based on specific operational needs, and stay informed on technological advancements. The opportunity to elevate your sourcing strategy is within reach; seize it to position your company for success in the rapidly evolving landscape of bead blasting technology.