Contents

Manufacturing Insight: Gear Hobbing Services

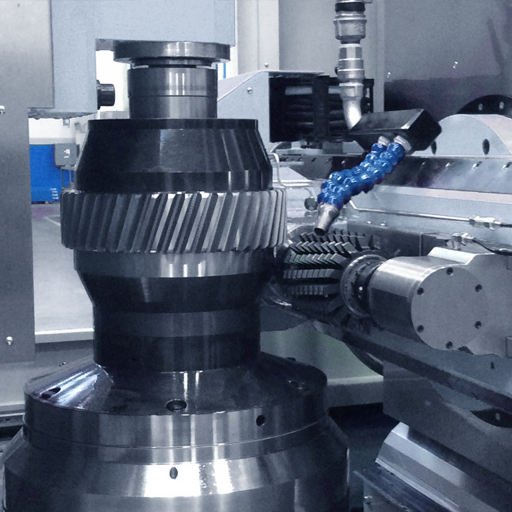

Precision Gear Hobbing Services Powered by Advanced CNC Machining

At Honyo Prototype, we deliver industry-leading gear hobbing services engineered for complex, high-precision applications across aerospace, automotive, and industrial machinery sectors. Our capabilities are anchored in state-of-the-art CNC machining infrastructure, featuring multi-axis hobbing centers with stringent thermal compensation and dynamic error correction systems. This foundation ensures repeatable accuracy to AGMA 10–12 quality standards, with tolerances held to ±0.002 mm on critical tooth profiles and concentricity.

We specialize in rapid prototyping and low-to-mid volume production of spur, helical, herringbone, and worm gears in materials ranging from 4140 steel and 17-4PH stainless to exotic alloys and engineered plastics. Every operation leverages our integrated CAD/CAM workflow, where gear geometry is validated through finite element analysis (FEA) prior to cutting, minimizing iteration cycles and material waste. Our process guarantees optimal surface finishes (Ra ≤ 0.8 μm) and precise lead/l involute characteristics critical for noise reduction and torque transmission efficiency.

Eliminate quoting delays with Honyo’s Online Instant Quote platform—engineered for manufacturing professionals. Upload your STEP or IGES file, specify material, quantity, and critical tolerances, and receive a detailed technical and commercial assessment in under 90 seconds. This seamless integration between design intent and production planning accelerates time-to-prototype by up to 70%, transforming your gear development from concept to certified hardware without operational bottlenecks. Partner with Honyo to convert precision requirements into realized performance.

Technical Capabilities

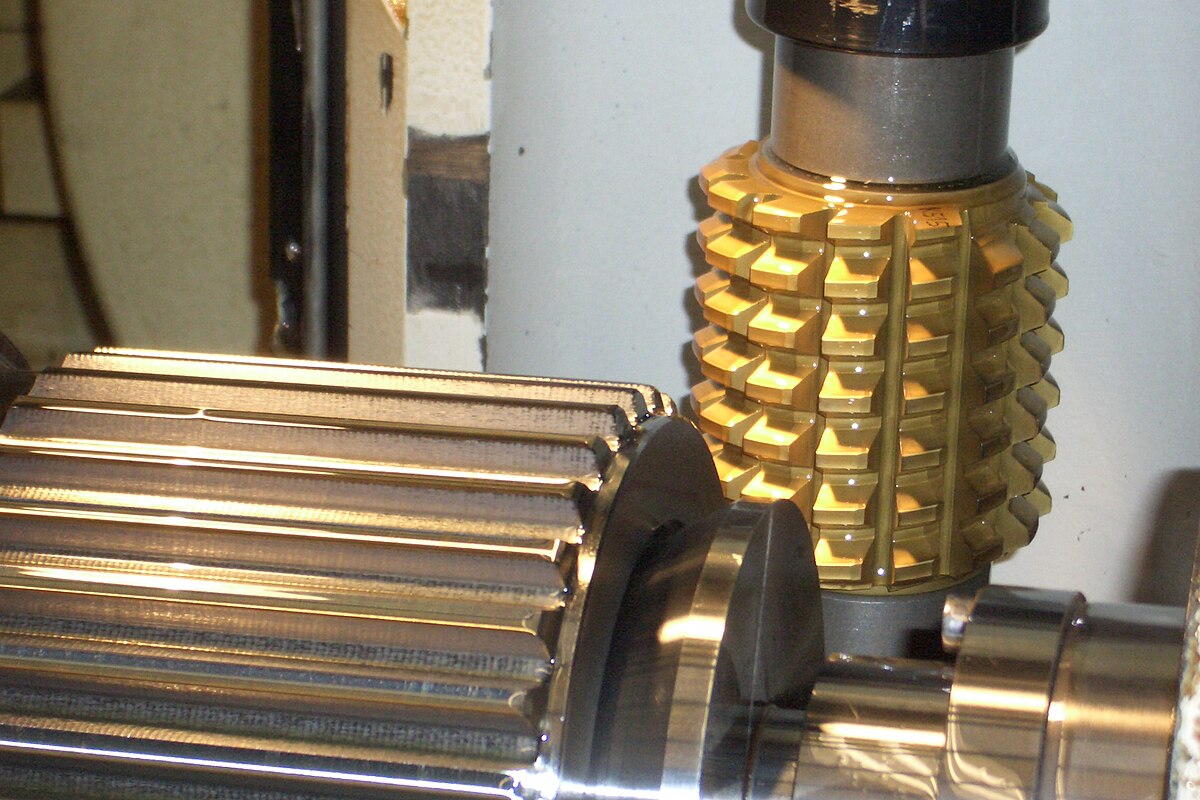

Gear hobbing services at Honyo Prototype are precision manufacturing solutions designed to produce high-quality gears with tight tolerances, utilizing advanced 3, 4, and 5-axis CNC milling and turning capabilities. These services are optimized for complex gear geometries and high repeatability, supporting a variety of engineering-grade materials including aluminum, steel, ABS, and nylon. The integration of multi-axis machining enables efficient hobbing of spur, helical, bevel, and worm gears with superior surface finishes and dimensional accuracy.

Key technical specifications are outlined in the table below:

| Parameter | Specification |

|---|---|

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning; gear hobbing operations |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on part geometry and material) |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm (achievable with post-processing as needed) |

| Minimum Gear Module | 0.3 mod (metric) / 80 DP (diametral pitch) |

| Maximum Gear Diameter | Up to 500 mm (20 inches) |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6 & 66) |

| Lead Time | 7–15 business days (varies by complexity and volume) |

| Quality Standards | ISO 1328-1 (Cylindrical Gears), ISO 21771 (Gear Accuracy) |

| Additional Finishes | Anodizing (Aluminum), Passivation (Stainless Steel), Shot Peening, Coating |

These gear hobbing services are ideal for applications in aerospace, automation, robotics, and industrial machinery where precision motion control and durability are critical. Honyo Prototype ensures tight tolerance consistency across both prototype and low-volume production runs, with full in-process inspection using CMM and optical comparators.

From CAD to Part: The Process

Honyo Prototype delivers precision gear hobbing services through a streamlined digital workflow designed for engineering accuracy and manufacturing efficiency. Our process begins with secure CAD file upload via the Honyo Portal, where clients submit 3D models in STEP, IGES, or native formats. The system performs immediate geometric validation, flagging potential issues like non-manufacturable fillets or unsupported geometries before proceeding.

The uploaded design triggers our AI-powered quoting engine, which analyzes over 200 manufacturing parameters including material density, tooth module, pressure angle, helix angle, and required AGMA quality class. This engine cross-references real-time data on material costs, machine availability, and tooling requirements to generate a technically validated quote within 90 minutes, significantly reducing traditional estimation latency.

Following quote acceptance, the design enters our dedicated Gear DFM phase. Senior gear engineers conduct a comprehensive manufacturability review focusing on hobbing-specific considerations: tooth profile optimization to prevent undercutting, blank diameter validation against hob cutter limitations, helix angle feasibility for existing machine capabilities, and surface finish requirements versus achievable Ra values. We provide actionable recommendations such as modifying root fillet radii or suggesting alternative materials to improve grindability while maintaining functional performance.

Production occurs in our climate-controlled gear manufacturing cell using state-of-the-art CNC hobbing machines with 0.002mm positional accuracy. Key process controls include:

In-process laser scanning for tooth profile verification after roughing

Thermal compensation systems maintaining ±1°C ambient control

ISO 1328-1:2013 compliant inspection using Zeiss CMMs

Batch traceability with material certificates and process logs

Final delivery incorporates rigorous quality documentation packaged with the physical gears. Each shipment includes AGMA 2015-1-A01 inspection reports, CMM point cloud data, and surface roughness certifications. Logistics utilize shock-sensor equipped packaging with real-time GPS tracking, with standard lead times varying by complexity as shown below.

Typical Lead Time Structure for Precision Gears

| Module Range | AGMA Class | Standard Lead Time | Rush Option |

|————–|————|——————-|————|

| 0.5 – 2.0 mm | 10 – 12 | 12 business days | 7 days |

| 2.1 – 5.0 mm | 8 – 10 | 15 business days | 9 days |

| 5.1+ mm | 6 – 8 | 18 business days | 11 days |

This integrated workflow ensures dimensional accuracy to ±0.005mm on critical pitch diameters while maintaining strict adherence to ISO 1328 gear quality standards. Our closed-loop system captures process data from each run to continuously refine our AI quoting algorithms and optimize machine parameters for subsequent orders.

Start Your Project

For precision gear hobbing services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for prototype and production runs. Reach out today to discuss your gear machining requirements and leverage our expertise in high-accuracy hobbing for spur, helical, and specialty gears.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.