Introduction: Navigating the Global Market for gdt basic dimension

In today’s competitive global marketplace, understanding the nuances of Geometric Dimensioning and Tolerancing (GD&T), particularly basic dimensions, is crucial for international B2B buyers. Sourcing high-quality components that adhere to precise specifications can be challenging, especially when navigating the complexities of basic dimensions. This guide offers a comprehensive overview of basic dimensions within the GD&T framework, detailing their types, applications, and the importance of accurate dimensioning for successful manufacturing processes.

Buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will find actionable insights to enhance their procurement strategies. This guide not only explains the theoretical aspects of basic dimensions but also delves into practical applications, supplier vetting processes, and cost considerations. By exploring these topics, international buyers will be empowered to make informed purchasing decisions that align with their specific operational needs and quality standards.

With the right knowledge at their fingertips, B2B buyers can confidently engage with suppliers, ensuring that their products meet the exacting standards required for success in a global economy. This resource is designed to demystify basic dimensions, equipping you with the tools necessary to optimize your sourcing strategies and enhance the overall quality of your manufacturing outputs.

Understanding gdt basic dimension Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic Dimension | Theoretically exact dimensions without tolerances. | Used in CAD models and manufacturing specifications. | Pros: Ensures precision; Cons: Requires geometric tolerances for practical application. |

| Reference Dimension | Dimensions for visualization only, indicated with parentheses. | Useful in design for clarity and communication. | Pros: Simplifies understanding; Cons: Not suitable for inspection. |

| Tolerance Dimension | Dimensions with specified tolerances, typically ± values. | Common in quality control and production settings. | Pros: Provides flexibility in manufacturing; Cons: May lead to ambiguity without GD&T. |

| Geometric Tolerance | Defines allowable variations for a feature’s size and location. | Critical in high-precision industries like aerospace and automotive. | Pros: Enhances quality assurance; Cons: Complexity in interpretation can lead to errors. |

| True Position | Indicates the exact location of a feature relative to datum references. | Essential in assemblies requiring precise fit. | Pros: Ensures proper alignment; Cons: Can complicate design if not well understood. |

What are Basic Dimensions and Their Characteristics?

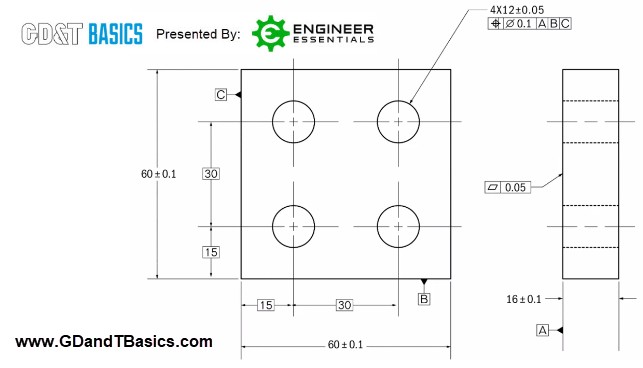

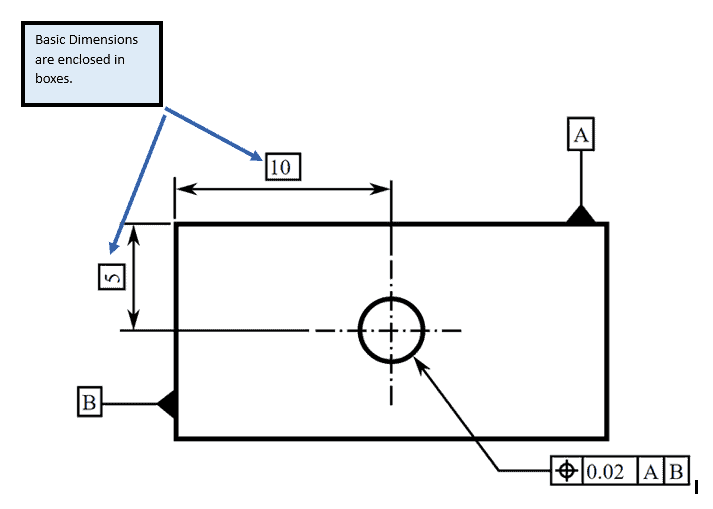

Basic dimensions are theoretically perfect measurements that define the ideal location, orientation, or profile of a feature without tolerances. They are critical in the design phase, particularly in CAD models where precision is paramount. For B2B buyers, understanding that basic dimensions represent the target to achieve during manufacturing can streamline communication with suppliers and ensure that the produced parts meet design intentions. However, it’s essential to note that basic dimensions must be paired with geometric tolerances to be practically applicable in manufacturing.

How Do Reference Dimensions Function in Design?

Reference dimensions serve as visual aids in technical drawings, helping stakeholders understand the overall design intent without being subject to inspection. These dimensions are enclosed in parentheses and are not measured during quality control processes. For businesses, using reference dimensions can enhance clarity in communication among design teams and manufacturers, reducing the risk of misinterpretation. However, their lack of enforceability means they should be used judiciously, ensuring that critical measurements are always backed by precise tolerances.

Why are Tolerance Dimensions Important?

Tolerance dimensions specify allowable variations, typically indicated with plus/minus values. They are crucial for quality control and production processes, ensuring that parts fit together correctly and function as intended. B2B buyers must consider the balance between tight tolerances, which may increase manufacturing costs, and the flexibility offered by wider tolerances, which can enhance production efficiency. Understanding how tolerance dimensions interact with basic dimensions can help businesses develop more effective inspection plans and quality assurance strategies.

What Role Does Geometric Tolerance Play?

Geometric tolerance is essential for defining the permissible limits of variation in the size and location of features. This type of tolerance is particularly important in industries that demand high precision, such as aerospace and automotive manufacturing. For B2B buyers, investing in geometric tolerancing can lead to improved product quality and consistency. However, the complexity involved in understanding and applying these tolerances may require specialized training and expertise, which should be factored into purchasing decisions.

How Does True Position Ensure Accuracy?

True position is a specific application of geometric tolerancing that indicates the precise location of a feature concerning established datum references. It is vital for assemblies where components must align perfectly for proper function. B2B buyers should prioritize suppliers who understand and can implement true position specifications effectively, as this can significantly impact the performance and reliability of the final product. However, the complexity of true position requirements necessitates clear communication and thorough documentation to avoid costly errors during manufacturing.

Key Industrial Applications of gdt basic dimension

| Industry/Sector | Specific Application of gdt basic dimension | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision alignment of components in aircraft assembly | Enhances safety and reduces risk of component failure | Certification standards, material quality, and traceability |

| Automotive | Manufacturing of engine components with precise tolerances | Improves efficiency and performance of vehicles | Supplier reliability, quality control processes, and lead times |

| Electronics | Placement of connectors and circuit elements in PCB design | Ensures functionality and minimizes short-circuit risks | Compliance with international standards and testing capabilities |

| Industrial Machinery | Design and assembly of complex machinery parts | Increases operational efficiency and product reliability | Technical support, customization options, and post-sale services |

| Medical Devices | Precision in the production of surgical instruments and implants | Ensures patient safety and regulatory compliance | Regulatory certifications, biocompatibility, and supply chain integrity |

How is gdt basic dimension used in Aerospace Applications?

In the aerospace industry, gdt basic dimensions are crucial for the precise alignment of components during aircraft assembly. Basic dimensions define the exact theoretical locations for mounting brackets, fuselage sections, and other critical components, ensuring that they fit together perfectly. This precision is vital for safety and performance, as even minor misalignments can lead to catastrophic failures. International B2B buyers in this sector must consider certification standards and material quality, as these factors directly impact the safety and performance of aircraft.

What role does gdt basic dimension play in Automotive Manufacturing?

In automotive manufacturing, gdt basic dimensions are employed to ensure that engine components are manufactured within stringent tolerances. By defining the ideal positions for parts like pistons and crankshafts, manufacturers can enhance vehicle efficiency and performance. The application of basic dimensions helps mitigate issues such as vibration and wear, which are critical for long-term vehicle reliability. Buyers from regions like Brazil and Germany should focus on supplier reliability and quality control processes to ensure compliance with automotive standards.

How does gdt basic dimension contribute to Electronics Design?

In the electronics sector, gdt basic dimensions are essential for the accurate placement of connectors and circuit elements on printed circuit boards (PCBs). These dimensions define the perfect locations for components, minimizing the risk of short circuits and ensuring that devices function as intended. As electronic devices become increasingly compact and complex, the need for precision grows. Buyers must prioritize suppliers that comply with international standards and possess robust testing capabilities to mitigate risks associated with electronic failures.

Why is gdt basic dimension important in Industrial Machinery?

For industrial machinery, gdt basic dimensions facilitate the design and assembly of complex parts, such as gears and bearings. By establishing exact theoretical locations for these components, manufacturers can enhance operational efficiency and product reliability. This precision is particularly important in high-stakes environments where machinery downtime can lead to significant financial losses. Buyers should seek suppliers that offer technical support and customization options to meet specific machinery requirements.

How does gdt basic dimension ensure safety in Medical Devices?

In the medical device industry, gdt basic dimensions are critical for the production of surgical instruments and implants, where precision is paramount for patient safety. These dimensions help ensure that devices fit properly and function correctly, reducing the risk of complications during procedures. Compliance with regulatory standards is essential, making it crucial for buyers to evaluate suppliers based on their certifications, biocompatibility of materials, and the integrity of their supply chain.

3 Common User Pain Points for ‘gdt basic dimension’ & Their Solutions

Scenario 1: Confusion Over Basic vs. Tolerance Dimensions

The Problem: Many B2B buyers, particularly those new to Geometric Dimensioning and Tolerancing (GD&T), often confuse basic dimensions with tolerance dimensions. This confusion can lead to significant errors in product specifications, resulting in parts that do not meet the required design intent. For instance, a manufacturer in Brazil may specify a basic dimension incorrectly, thinking it allows for tolerances, leading to misalignment during assembly. Such misunderstandings can cause costly reworks, delays in production, and strained supplier relationships.

The Solution: To overcome this challenge, it is crucial for buyers to invest in comprehensive training on GD&T principles. This training should specifically address the distinctions between basic dimensions and tolerance dimensions. Encourage your team to utilize clear visual aids, such as annotated drawings, to illustrate these differences. Additionally, when reviewing product specifications, always verify that basic dimensions are clearly marked in boxes and that they do not include any tolerance values. Implementing a checklist during the specification review process can help ensure that all dimensions are correctly categorized before sending them to suppliers, minimizing the risk of errors.

Scenario 2: Difficulty in Inspection and Reporting

The Problem: Another common pain point arises during the inspection process, where B2B buyers struggle to report actual measurements for basic dimensions. Since basic dimensions are theoretically perfect and do not include tolerances, inspectors may be uncertain about how to communicate this on inspection reports. For instance, a company in Germany might face challenges when conducting First Article Inspections (FAIs), leading to confusion among quality control teams and potentially impacting product acceptance.

The Solution: To streamline the inspection and reporting process, buyers should establish clear guidelines that differentiate between basic dimensions and geometric tolerances on inspection reports. Train inspectors to focus on reporting deviations related to geometric controls, such as position tolerances or size specifications, rather than trying to document basic dimensions. Implementing specialized software that auto-generates inspection reports based on GD&T principles can also facilitate accurate documentation. This approach not only simplifies reporting but also ensures compliance with quality standards, thereby enhancing overall operational efficiency.

Scenario 3: Inconsistent Application Across International Suppliers

The Problem: B2B buyers often face challenges when dealing with international suppliers, especially when it comes to the consistent application of GD&T principles, including basic dimensions. A buyer in South Africa may encounter a situation where a supplier in Asia uses different interpretations of basic dimensions, leading to discrepancies in product quality. This inconsistency can result in increased costs and extended lead times due to the need for rework or additional inspections.

The Solution: To mitigate this issue, it is essential to establish standardized GD&T practices across your supply chain. Start by developing a comprehensive GD&T manual that outlines your organization’s specific requirements for basic dimensions, including examples and acceptable practices. Host regular training sessions and workshops for both your internal teams and your suppliers to ensure everyone is aligned on these standards. Additionally, consider using collaborative tools that allow for real-time sharing of specifications and design documents, ensuring that all parties are working from the same set of guidelines. By fostering a culture of transparency and education, you can significantly reduce the risk of misunderstandings and improve the overall quality of your products.

Strategic Material Selection Guide for gdt basic dimension

What Are the Key Properties of Common Materials for GD&T Basic Dimensions?

When selecting materials for applications involving GD&T basic dimensions, it is crucial to consider properties that impact product performance, such as temperature and pressure ratings, as well as corrosion resistance. Here, we analyze four common materials—steel, aluminum, plastic, and titanium—highlighting their suitability for GD&T applications.

How Does Steel Perform in GD&T Applications?

Steel is renowned for its strength and durability, making it a popular choice in various industrial applications. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures (up to 600°C). However, steel is susceptible to corrosion unless treated or alloyed.

Pros: Steel’s durability and cost-effectiveness make it suitable for heavy-duty applications. It can be easily machined to achieve precise dimensions required in GD&T.

Cons: The main limitation is its weight and potential for rusting, which can be mitigated through coatings but adds to manufacturing complexity.

For international buyers, compliance with standards like ASTM A36 or DIN 17100 is essential. Regions such as Europe and the Middle East often favor high-grade steel to meet stringent quality requirements.

What Are the Advantages of Using Aluminum for GD&T Basic Dimensions?

Aluminum is lightweight and offers good corrosion resistance, making it ideal for applications where weight is a concern. Its thermal conductivity and ability to be anodized enhance its performance in various environments. Aluminum can handle moderate temperatures, typically up to 200°C.

Pros: The low density of aluminum allows for easier handling and transportation. It also offers good machinability, which is crucial for maintaining GD&T tolerances.

Cons: While aluminum is less expensive than titanium, it is not as strong as steel and can deform under high stress.

International buyers should consider compliance with standards like ASTM B221 and JIS H4000. In regions like South America, aluminum is favored for automotive and aerospace applications due to its lightweight properties.

How Do Plastics Compare in Terms of GD&T Basic Dimensions?

Plastics, particularly engineering plastics like polycarbonate and nylon, offer excellent corrosion resistance and are lightweight. They can operate effectively at moderate temperatures, typically up to 120°C, and are often used in applications requiring electrical insulation.

Pros: The cost of plastic materials is generally lower, and they can be produced in complex shapes through injection molding, allowing for intricate designs.

Cons: Plastics may not withstand high mechanical loads and can degrade under UV exposure, limiting their suitability for outdoor applications.

For international buyers, compliance with ISO standards is critical, especially in industries like consumer electronics and automotive. The preference for plastics varies by region, with Europe leading in sustainability initiatives that favor recyclable materials.

What Are the Benefits of Titanium in GD&T Applications?

Titanium is known for its exceptional strength-to-weight ratio and excellent corrosion resistance, making it suitable for high-performance applications. It can withstand extreme temperatures, often exceeding 600°C, and is biocompatible, which is essential in medical applications.

Pros: Titanium’s durability and resistance to fatigue make it ideal for aerospace and medical applications, where precision is critical.

Cons: The primary drawback is the high cost and complexity of machining titanium, which can lead to longer lead times in production.

International buyers need to be aware of compliance with standards like ASTM F136 and DIN 17813. In regions such as Germany, titanium is preferred for high-tech applications due to its performance characteristics.

Summary Table of Material Selection for GD&T Basic Dimensions

| Material | Typical Use Case for gdt basic dimension | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, automotive parts | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, automotive, lightweight structures | Lightweight and good machinability | Lower strength compared to steel | Medium |

| Plastic | Consumer electronics, automotive interiors | Cost-effective and complex shapes | Limited mechanical load capacity | Low |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | High cost and machining complexity | High |

This strategic material selection guide provides B2B buyers with insights into how different materials can impact the performance and compliance of GD&T basic dimensions, facilitating informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gdt basic dimension

What Are the Main Stages of Manufacturing Processes for GD&T Basic Dimensions?

Understanding the manufacturing processes associated with GD&T (Geometric Dimensioning and Tolerancing) basic dimensions is essential for B2B buyers who seek precision and quality in their products. The manufacturing process typically consists of four main stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the basic dimensions of a part are achieved with high accuracy.

How Does Material Preparation Affect Basic Dimensions?

Material preparation involves selecting the right raw materials and preparing them for the manufacturing process. This may include cutting, machining, or treating materials to meet specific requirements. The choice of material can significantly affect the final dimensions of the product. For example, metals and plastics may behave differently under stress, which can lead to dimensional changes during the forming process.

Investing in high-quality materials and precise preparation techniques ensures that the manufacturing process can achieve the theoretically exact dimensions specified in the design. This is particularly crucial for international buyers who may have varying standards for material quality.

What Techniques Are Used in the Forming Stage to Achieve Basic Dimensions?

The forming stage encompasses various techniques, such as machining, casting, and molding. Machining, which includes processes like turning, milling, and grinding, is particularly effective for achieving the exact dimensions required by GD&T standards.

Advanced CNC (Computer Numerical Control) machines are commonly used in this stage to provide the precision needed for basic dimensions. These machines can execute intricate designs with minimal human intervention, thus reducing the risk of errors. Furthermore, employing techniques like laser cutting or water jet cutting can also enhance precision, ensuring that basic dimensions remain intact.

How Does Assembly Impact the Accuracy of Basic Dimensions?

The assembly stage is where individual components are brought together to form the final product. This stage often involves using jigs and fixtures designed to hold parts in their correct positions, ensuring that the assembly aligns with the specified basic dimensions.

Proper training for assembly personnel is crucial, as even minor deviations during assembly can lead to significant errors in the final product. Moreover, using assembly techniques that minimize the risk of misalignment, such as self-locating features or fasteners, can help maintain the integrity of basic dimensions.

What Finishing Techniques Are Important for Maintaining Basic Dimensions?

Finishing processes, such as polishing, coating, or surface treatment, are essential for enhancing the appearance and durability of the final product. These processes can also affect dimensional accuracy. For instance, excessive polishing can remove material and alter dimensions, while coatings may add a layer that could affect tolerances.

To maintain basic dimensions, it is crucial to establish clear guidelines for finishing processes. B2B buyers should communicate their requirements to suppliers, ensuring that any finishing techniques employed do not compromise the integrity of the basic dimensions.

How is Quality Assurance Integrated into Manufacturing for GD&T Basic Dimensions?

Quality assurance (QA) is vital in ensuring that products meet the specified basic dimensions and adhere to international standards. For B2B buyers, understanding the QA process is essential for verifying supplier capabilities and ensuring product quality.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 establish guidelines for quality management systems that manufacturers must adhere to. Compliance with these standards ensures that the manufacturing processes are consistently effective in producing high-quality products.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil and gas products further validate the quality and reliability of a supplier’s offerings. Buyers should ensure that their suppliers are compliant with the relevant standards applicable to their industry.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are essential for ensuring that products meet the required specifications throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Regular inspections are conducted during the manufacturing process to catch any deviations early.

- Final Quality Control (FQC): A comprehensive inspection is performed on the finished product to verify that all dimensions, including basic dimensions, are within acceptable tolerances.

Implementing these checkpoints helps identify issues at various stages, thereby reducing the risk of non-conformance in the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. This can be achieved through:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their quality management systems and manufacturing practices. Buyers should assess the supplier’s adherence to international standards and their ability to maintain basic dimensions.

-

Inspection Reports: Requesting detailed inspection reports can help buyers understand how suppliers monitor and control quality. These reports should include information on the inspection methods used, the results obtained, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services adds an extra layer of assurance. These organizations can provide unbiased evaluations of a supplier’s compliance with quality standards and the accuracy of basic dimensions.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, navigating the nuances of QC and certification can be complex. Different regions may have varying regulations and standards, which can affect product compliance. It is crucial for buyers to:

-

Understand Local Regulations: Buyers should familiarize themselves with the regulations in their target markets, as compliance may vary significantly from one region to another.

-

Communicate Clearly with Suppliers: Open dialogue about quality expectations and certification requirements can help prevent misunderstandings and ensure alignment on product specifications.

-

Consider Cultural Differences: Different countries may have varying approaches to quality assurance and manufacturing practices. Acknowledging these differences can facilitate better relationships and more effective collaborations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices associated with GD&T basic dimensions is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with implementing robust quality control measures, buyers can ensure they receive products that meet their exact specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gdt basic dimension’

The following practical sourcing guide serves as a checklist for B2B buyers looking to procure components related to Geometric Dimensioning and Tolerancing (GD&T), particularly focusing on basic dimensions. This guide will help ensure that your procurement process is thorough, efficient, and aligned with industry standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Basic dimensions serve as the theoretical ideal for the location and orientation of features; thus, understanding your specific needs will help in communicating effectively with suppliers. Consider factors such as the size, shape, and tolerance requirements that relate to the basic dimensions.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suppliers who specialize in GD&T and have a solid reputation in the industry. Look for suppliers that have experience in your specific sector and can demonstrate expertise in handling basic dimensions. Utilize online directories, trade shows, and industry publications to gather a list of potential candidates.

Step 3: Evaluate Supplier Certifications and Standards

Verify that potential suppliers adhere to recognized quality standards and certifications relevant to GD&T. Certifications such as ISO 9001 or specific GD&T training qualifications can indicate a supplier’s commitment to quality and precision. Ensure they have documented processes for quality control that include the handling of basic dimensions.

Step 4: Request Detailed Proposals

Once you have narrowed down your list of suppliers, request detailed proposals that outline their capabilities regarding basic dimensions. The proposals should include information on their manufacturing processes, inspection methods, and any relevant case studies. Look for clarity in how they plan to meet your specifications and tolerances.

Step 5: Conduct Supplier Audits or Visits

If possible, conduct audits or site visits to assess the supplier’s facilities and processes firsthand. This step is vital to understanding their operational capabilities and the technology they employ. Pay attention to how they manage GD&T and basic dimensions in practice, as this will provide insights into their reliability.

Step 6: Assess Communication and Support

Evaluate the supplier’s communication practices and customer support. Effective communication is crucial when discussing technical specifications and addressing any potential issues. Ensure that the supplier has a dedicated support team that can assist you throughout the procurement process and after-sales.

Step 7: Finalize Contracts with Clear Terms

Once you’ve selected a supplier, draft contracts that clearly outline all terms related to the supply of components with basic dimensions. Ensure that the contract includes detailed specifications, delivery schedules, and quality assurance measures. This clarity will help mitigate risks and establish a solid foundation for your partnership.

By following these steps, B2B buyers can effectively navigate the procurement of components related to GD&T basic dimensions, ensuring that their sourcing decisions are informed, strategic, and aligned with best practices.

Comprehensive Cost and Pricing Analysis for gdt basic dimension Sourcing

What Are the Key Cost Components in Sourcing GD&T Basic Dimensions?

When sourcing GD&T basic dimensions, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

Materials represent the foundational cost, influenced by the type of raw materials required to produce the components. For example, high-grade metals or specialized plastics often come at a premium, impacting the overall cost.

Labor costs depend on the complexity of the manufacturing process. Regions with higher labor costs, such as Western Europe, may lead to increased pricing compared to regions like South America or parts of Africa, where labor might be more affordable.

Manufacturing overhead encompasses indirect costs like utilities, rent, and administrative expenses. This can vary significantly based on the supplier’s location and operational efficiency.

Tooling costs can be substantial, particularly for customized parts requiring specific molds or machinery. Buyers should consider these costs when evaluating suppliers, as they can affect the total price.

Quality Control (QC) is essential in ensuring that products meet the required specifications. The costs associated with QC can vary based on the complexity and the certifications required, such as ISO or other industry standards.

Logistics plays a vital role in the total cost, especially for international buyers. Shipping costs, customs duties, and insurance can add considerable expenses, depending on the Incoterms agreed upon in the contract.

Finally, the margin represents the supplier’s profit. This can be influenced by the supplier’s positioning in the market, their brand reputation, and the perceived value of their services.

How Do Price Influencers Affect GD&T Basic Dimension Sourcing?

Several factors influence the pricing of GD&T basic dimension components. Understanding these price influencers is vital for buyers aiming to optimize their sourcing strategy.

Volume and Minimum Order Quantity (MOQ) are significant. Suppliers often offer better pricing for larger orders, allowing buyers to reduce per-unit costs. However, this requires careful forecasting of demand to avoid overstocking.

Specifications and Customization also play a crucial role. Highly customized parts may incur additional costs due to the need for specialized tooling or processes. Clear communication of specifications can help manage expectations and costs.

Material selection is another critical influencer. Opting for standard materials can lead to cost savings, while unique or high-performance materials may increase the overall price.

Quality and Certifications are essential for ensuring compliance with industry standards. Suppliers with recognized certifications may charge a premium, but this can provide assurance of quality and reliability.

Supplier factors, including reputation and experience, can also impact pricing. Established suppliers may command higher prices due to their track record, but they often provide superior quality and service.

Incoterms determine the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers avoid unexpected costs related to shipping and customs.

What Are the Best Buyer Tips for Sourcing GD&T Basic Dimensions?

When navigating the sourcing landscape for GD&T basic dimensions, buyers should employ strategic approaches to enhance cost-efficiency and value.

Negotiation is vital. Engaging in open discussions with suppliers about pricing, volume discounts, and payment terms can lead to favorable agreements. Demonstrating knowledge of market rates can strengthen your position.

Cost-efficiency should be a priority. Evaluating the Total Cost of Ownership (TCO) rather than just the initial purchase price provides a more comprehensive understanding of long-term costs. This includes logistics, maintenance, and potential rework.

Pricing nuances for international buyers must be considered. Currency fluctuations, tariffs, and local market conditions can significantly affect pricing. Buyers from Africa, South America, the Middle East, and Europe should stay informed about these factors to make informed purchasing decisions.

Lastly, it’s essential to keep in mind that prices can vary widely based on the aforementioned factors, and indicative pricing should be approached with caution. Engaging with multiple suppliers and conducting thorough market research can provide a clearer picture of what to expect in terms of costs and pricing.

Alternatives Analysis: Comparing gdt basic dimension With Other Solutions

Introduction to Alternatives in GD&T Solutions

When exploring solutions for precise dimensioning and tolerancing, particularly in the context of Geometric Dimensioning and Tolerancing (GD&T), it is essential to consider various methodologies that can achieve similar objectives. While the GD&T basic dimension is widely recognized for its ability to define theoretically exact locations and features without tolerances, other alternatives may offer distinct advantages or cater to specific industry needs. This analysis compares the GD&T basic dimension against two viable alternatives: Coordinate Measuring Machines (CMM) and Traditional Tolerance Stack-Up Analysis.

Comparison Table

| Comparison Aspect | GDT Basic Dimension | Coordinate Measuring Machines (CMM) | Traditional Tolerance Stack-Up Analysis |

|---|---|---|---|

| Performance | High precision for ideal targets | Very high precision and accuracy | Variable; depends on calculations |

| Cost | Low implementation cost | High initial investment and upkeep | Low to moderate, depending on complexity |

| Ease of Implementation | Requires training in GD&T | Requires skilled operators and software | Relatively straightforward |

| Maintenance | Minimal once implemented | High; requires regular calibration | Low; mainly documentation |

| Best Use Case | CAD modeling and design validation | Quality control and inspection | Early design phase and assembly planning |

Detailed Breakdown of Alternatives

Coordinate Measuring Machines (CMM)

CMMs are advanced tools used for measuring the physical geometrical characteristics of an object. They utilize a probe, which touches the object’s surface, and can collect data points in three-dimensional space. The primary advantage of CMMs is their high precision and ability to measure complex geometries. However, they come with a significant cost, both in terms of initial investment and ongoing maintenance. Additionally, operating a CMM requires skilled technicians, which can add to operational complexities. CMMs are best suited for quality control environments where exact measurements are critical.

Traditional Tolerance Stack-Up Analysis

This method involves calculating the cumulative effect of tolerances in an assembly to ensure that parts will fit together properly. It is a relatively straightforward approach that can be employed during the design phase, allowing engineers to foresee potential issues before production begins. While it is cost-effective and easy to implement, the accuracy of this analysis heavily relies on the quality of initial data and assumptions. This method is best utilized in environments where components are assembled in large quantities and where minor deviations can lead to significant issues.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate dimensioning and tolerancing method depends on various factors, including the specific application, budget constraints, and the level of precision required. The GD&T basic dimension is ideal for environments focused on design accuracy and CAD modeling, while CMMs offer unmatched precision for physical inspections. On the other hand, traditional tolerance stack-up analysis is beneficial during the early design stages. B2B buyers should evaluate their unique operational requirements, budget, and the skill set of their workforce to determine which solution aligns best with their goals and processes. By carefully considering these factors, businesses can enhance their manufacturing efficiency and product quality.

Essential Technical Properties and Trade Terminology for gdt basic dimension

What Are the Key Technical Properties of GD&T Basic Dimensions?

When dealing with GD&T (Geometric Dimensioning and Tolerancing), understanding the essential technical properties of basic dimensions is critical for effective communication and quality assurance in manufacturing. Here are the key specifications that every B2B buyer should be familiar with:

1. Theoretically Exact Dimensions (TEDs)

Basic dimensions are also referred to as Theoretically Exact Dimensions (TEDs). They denote the ideal size and location of a feature without any associated tolerances. This is crucial for ensuring precise alignment in assembly and manufacturing processes. Understanding TEDs enables buyers to communicate clearly with suppliers about the expected quality standards and eliminates ambiguity in specifications.

2. Geometric Tolerances

While basic dimensions themselves do not include tolerances, they are often paired with geometric tolerances, which define the permissible variation in the location, orientation, and size of features. For instance, a geometric tolerance might specify that a hole should be within a cylindrical tolerance zone of a certain diameter. This relationship is essential for maintaining product integrity and ensuring that parts fit together correctly, which is particularly important in industries such as aerospace and automotive.

3. Datum Features

Datum features are reference points or surfaces on a part used to establish a coordinate system for measurement. Basic dimensions must relate back to these datum features, ensuring that all measurements are taken from a common point. This is vital for maintaining consistency across different parts and assemblies, particularly in large-scale manufacturing operations.

4. Chain Dimensioning

This term refers to a method of dimensioning where dimensions are sequentially linked together, often using basic dimensions. In chain dimensioning, basic dimensions are crucial as they provide a clear path for measuring the position and size of features without accumulating tolerances. This approach helps in reducing measurement errors and ensures that the final product meets design specifications.

5. Inspection Reporting

In GD&T, basic dimensions are not recorded on inspection reports since they are theoretically perfect. Instead, actual measurements are compared against geometric tolerances. Understanding this distinction helps B2B buyers ensure that their quality control processes accurately reflect the specifications laid out in design documents.

What Are Common Trade Terms Associated with GD&T Basic Dimensions?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are several essential trade terms relevant to GD&T basic dimensions:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of GD&T, understanding OEM requirements is vital for ensuring that parts meet the specific tolerances and dimensions required for integration into larger systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Buyers need to understand MOQs when negotiating contracts, especially when sourcing precision components governed by GD&T standards, as smaller orders may not be feasible for suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods or services. In the context of GD&T, a well-defined RFQ that specifies basic dimensions and tolerances helps ensure accurate quotes and minimizes the risk of miscommunication.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B buyers engaged in cross-border transactions, particularly when specifying delivery terms related to GD&T components.

5. FAI (First Article Inspection)

FAI is a process used to ensure that the manufacturing process is capable of producing parts that meet specified requirements. In GD&T, conducting an FAI is crucial to verify that basic dimensions and geometric tolerances are adhered to before full-scale production begins.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the complexities of GD&T with greater confidence, ensuring that their specifications are met and that their products maintain the highest quality standards.

Navigating Market Dynamics and Sourcing Trends in the gdt basic dimension Sector

What Are the Current Market Dynamics in the GD&T Basic Dimension Sector?

The global market for GD&T (Geometric Dimensioning and Tolerancing) is evolving rapidly, driven by increased automation and precision in manufacturing processes. As industries across Africa, South America, the Middle East, and Europe push for higher quality standards, the demand for basic dimensions—characterized by their theoretically exact values—has surged. This trend is supported by advancements in CAD (Computer-Aided Design) technologies and the integration of AI in manufacturing, allowing for better accuracy and efficiency in production processes.

One key trend is the growing emphasis on digital transformation within supply chains, which facilitates real-time data sharing and enhances collaboration among stakeholders. International buyers are increasingly seeking suppliers who can provide comprehensive GD&T documentation, ensuring that basic dimensions are accurately represented and adhered to in production. Additionally, the adoption of Industry 4.0 principles is driving the need for sophisticated measurement systems that can handle complex GD&T specifications, further influencing sourcing decisions.

Another notable dynamic is the rise of global sourcing networks. As companies expand their reach, they are looking to source components from diverse geographical locations, including emerging markets in Africa and South America. This diversification not only mitigates risks but also leverages cost advantages, making it imperative for buyers to understand local standards and practices regarding GD&T.

How Is Sustainability and Ethical Sourcing Impacting the GD&T Basic Dimension Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the GD&T basic dimension sector. As environmental regulations tighten globally, businesses are increasingly held accountable for their sourcing practices and the ecological impact of their supply chains. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and minimizing waste during production.

The importance of ethical supply chains cannot be overstated. International buyers are actively seeking partners who adhere to ethical sourcing standards, which include fair labor practices and responsible resource management. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ credentials are becoming essential benchmarks in supplier selection. This shift not only aligns with corporate social responsibility goals but also resonates with consumers who prefer brands with sustainable practices.

In the context of GD&T, incorporating sustainable materials can enhance the overall quality and compliance of products. Buyers should look for suppliers who utilize ‘green’ certifications or materials that meet strict environmental standards. By doing so, businesses can ensure that their products not only meet the necessary technical specifications but also contribute positively to the environment.

How Has the GD&T Basic Dimension Sector Evolved Over Time?

The evolution of the GD&T basic dimension sector can be traced back to the need for precise manufacturing and quality control in engineering. Initially, traditional dimensioning methods were often insufficient for complex geometries, leading to inconsistencies and quality issues. The introduction of GD&T in the late 20th century revolutionized how dimensions were specified, providing a standardized framework that allowed for greater accuracy and flexibility.

With the rise of CAD technology, the application of basic dimensions has become more widespread, enabling engineers to define the perfect geometric relationships between features without the constraints of traditional tolerance limits. This evolution has facilitated a more precise manufacturing process, leading to improved product quality and reduced waste. As industries continue to embrace advanced technologies, the role of basic dimensions in ensuring compliance with global standards will remain pivotal in the years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of gdt basic dimension

-

How do I solve discrepancies in basic dimensions when inspecting parts?

To address discrepancies in basic dimensions during inspections, ensure that you are aligning your measurements with the geometric tolerances specified on the technical drawings. Basic dimensions represent theoretically perfect locations, so any deviation should be assessed against the geometric tolerances, not the basic dimensions themselves. Utilize precise measuring tools and methods to confirm that the actual features fall within the defined tolerance zones. If discrepancies persist, review the manufacturing processes and quality controls to identify potential areas for improvement. -

What is the best approach for sourcing gdt basic dimensions from international suppliers?

When sourcing gdt basic dimensions from international suppliers, prioritize vendors with proven expertise in Geometric Dimensioning and Tolerancing (GD&T). Look for suppliers who can provide detailed technical documentation, including drawings that clearly indicate basic dimensions and associated tolerances. It’s beneficial to conduct supplier audits to assess their capabilities and quality management systems. Additionally, consider suppliers with experience in your specific industry to ensure they understand your unique requirements and can deliver consistent results. -

What should I consider when vetting suppliers for gdt basic dimensions?

When vetting suppliers for gdt basic dimensions, evaluate their experience and certifications in GD&T practices. Request samples of their previous work, particularly focusing on projects that utilized basic dimensions. Assess their quality assurance processes, including inspection methodologies and tools used to verify compliance with GD&T standards. It’s also crucial to check customer references and reviews to gain insights into their reliability and delivery performance, ensuring they can meet your business’s quality and timeline expectations. -

How can I customize gdt basic dimensions for my specific projects?

Customizing gdt basic dimensions for your projects involves clear communication of your requirements to the supplier. Provide detailed specifications, including the intended application and any unique tolerances needed. Collaborate closely with your design and engineering teams to create a comprehensive set of drawings that reflect the exact basic dimensions required. Ensure that your supplier understands these specifications and is capable of adapting their processes to meet your customized needs while maintaining quality and consistency. -

What are the minimum order quantities (MOQs) for gdt basic dimensions?

Minimum order quantities (MOQs) for gdt basic dimensions can vary significantly among suppliers, depending on their production capabilities and the complexity of the parts required. It’s important to discuss MOQs upfront during negotiations, as some suppliers may be flexible, especially for custom projects or first-time orders. If your project requires low quantities, seek out suppliers who specialize in small batch production or those who offer a range of MOQs to accommodate various project sizes without compromising quality. -

What payment terms should I expect when sourcing gdt basic dimensions internationally?

Payment terms for sourcing gdt basic dimensions internationally often depend on the supplier’s policies and the nature of the transaction. Common terms include upfront deposits (usually 30-50%), with the balance due upon delivery or before shipment. Letter of Credit (LC) is also a popular option for international transactions, providing security for both parties. Always clarify payment terms in your contract to avoid misunderstandings and ensure that they align with your cash flow requirements. -

How do I ensure quality assurance for gdt basic dimensions?

To ensure quality assurance for gdt basic dimensions, implement a robust quality management system that includes regular inspections and compliance checks. Request detailed inspection reports from your supplier, including measurements against the specified basic dimensions and geometric tolerances. Additionally, consider third-party quality inspections, especially for critical components. Establishing clear quality metrics and maintaining open communication with your supplier can help address any issues proactively and ensure consistent product quality. -

What logistics considerations should I keep in mind when ordering gdt basic dimensions?

When ordering gdt basic dimensions, logistics considerations include shipping methods, lead times, and customs regulations. Choose a shipping method that balances cost and delivery speed, especially if the parts are critical to your production schedule. Be aware of any import duties and customs requirements in your country to avoid delays at the border. Additionally, maintain a buffer stock for essential components to mitigate risks associated with shipping delays or unforeseen disruptions in the supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Gdt Basic Dimension Manufacturers & Suppliers List

1. GD&T Basics – Understanding Basic Dimensions

Domain: gdandtbasics.com

Registered: 2014 (11 years)

Introduction: Basic Dimensions are theoretically exact dimensions defining the ideal exact point in space where something needs to be. They are placed in boxes and do not have a tolerance following them. Basic Dimensions are used within the GD&T framework to control the location or geometry of features, often in conjunction with geometric tolerances. They serve as the perfect target for manufacturing, with tole…

2. CNC Cookbook – Essential Guide to Basic Dimensions

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Basic dimensions are essential for applying GD&T to a part, providing precise control over size, shape, and position. They are theoretically exact values that define the form, size, orientation, or position of a part or feature without associated tolerances. Basic dimensions are indicated on drawings by enclosing them in a box, distinguishing them from traditional dimensions. They serve as the fou…

3. Reddit – Reference vs. Basic Dimensions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Reference dimensions are non-toleranced dimensions used for reference purposes only, indicated in parentheses, and do not define part acceptance criteria. Basic dimensions are critical for defining a part, must have associated tolerances, and represent theoretically perfect distances. Both dimensions are untoleranced, but basic dimensions are essential for part definition, while reference dimensio…

4. Tec-Ease – GD&T Training Solutions

Domain: tec-ease.com

Registered: 1997 (28 years)

Introduction: Tec-Ease, Inc. provides comprehensive GD&T training and coaching for engineers, designers, and inspectors. They offer various training options including On-Site Courses, Public Seminars, Webinars, and Computer Based Training. Their software packages support training and continued education in the industrial manufacturing field. The GD&T courses are designed to engage participants and make learning…

5. FiveFlute – GD&T Basics Guide

Domain: fiveflute.com

Registered: 2019 (6 years)

Introduction: GD&T Basics – A Comprehensive Introduction to Geometric Dimensioning and Tolerancing; A beginner’s guide to GD&T and its application on engineering drawings; Covers: What is GD&T, Getting started with datums, Tolerance zones and feature symbols, Basic dimensions, Building feature control frames, Introduction to material condition modifiers, Inspection; GD&T is a system for defining and communicati…

6. Eng-Tips – Basic Dimensions Explained

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: This company, Eng-Tips – Basic Dimensions Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Elsmar – Theoretical Dimensions Guide

Domain: elsmar.com

Registered: 2002 (23 years)

Introduction: Basic dimensions are theoretical dimensions used to specify the exact location of a feature of size, exact profile, and location of datum targets. They do not have tolerances by themselves and are treated as reference dimensions unless linked with GD&T. The ASME Y14.5.1M 1994 standard provides guidelines on basic dimensions, but the interpretation can vary among companies. Training in GD&T is reco…

Strategic Sourcing Conclusion and Outlook for gdt basic dimension

As we conclude our exploration of GD&T’s basic dimensions, it is crucial to recognize their role in enhancing precision and efficiency in manufacturing processes. Basic dimensions serve as the foundation for establishing theoretically perfect locations, sizes, and orientations of features, eliminating ambiguity in engineering drawings. This clarity not only facilitates better communication among international suppliers and manufacturers but also enhances quality control, reducing the risk of costly errors.

Strategic sourcing becomes imperative in this context, allowing businesses to identify and engage suppliers who are adept in GD&T principles. By focusing on suppliers that understand the nuances of basic dimensions and geometric tolerancing, companies can ensure that products meet stringent quality standards while optimizing costs.

Looking ahead, international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—should prioritize partnerships with suppliers who are committed to implementing advanced GD&T practices. This proactive approach will not only bolster product quality but also enhance competitive advantage in the global marketplace. Embrace the power of strategic sourcing today to unlock the potential of GD&T in your operations.