Contents

Manufacturing Insight: Gauge Table For Sheet Metal

Precision Sheet Metal Fabrication: Master Material Selection with Honyo’s Expertise

Selecting the correct sheet metal gauge is a critical engineering decision impacting structural integrity, manufacturability, cost, and final product performance. Missteps in gauge selection can lead to costly rework, material waste, or compromised part functionality. At Honyo Prototype, we understand that optimal material specification is foundational to successful sheet metal fabrication. Our comprehensive sheet metal fabrication services leverage deep technical expertise across a wide range of materials—including steel, aluminum, stainless steel, and specialty alloys—from ultra-thin 22 gauge to robust 10 gauge and beyond.

We provide detailed engineering support to ensure your design aligns with the precise mechanical and dimensional requirements of your application. This includes clear guidance on standard gauge thickness equivalents, material property considerations, and manufacturability analysis. To streamline your prototyping and low-volume production workflow, Honyo offers an Online Instant Quote platform. Upload your DXF, DWG, or STEP file directly to our system and receive a detailed, transparent cost estimate within hours—not days—factoring in exact material gauge, complexity, and finishing requirements.

Eliminate guesswork in material selection and accelerate your path from design to physical part. Partner with Honyo Prototype for fabrication precision rooted in engineering rigor and enabled by seamless digital quoting. Upload your design today and experience the efficiency of expert sheet metal manufacturing.

Technical Capabilities

Technical Specifications for Gauge Table for Sheet Metal Processing (Laser Cutting, Bending, Welding)

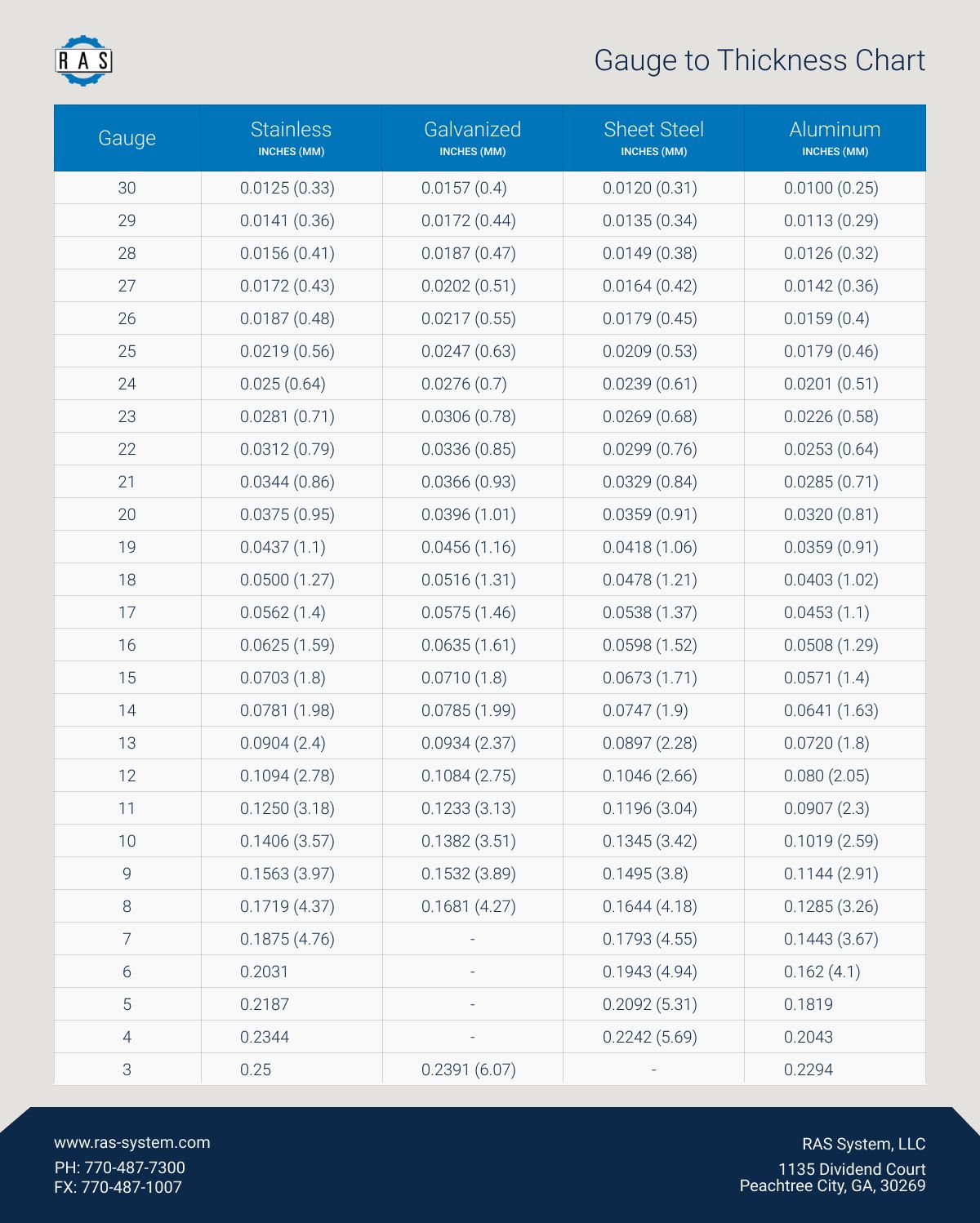

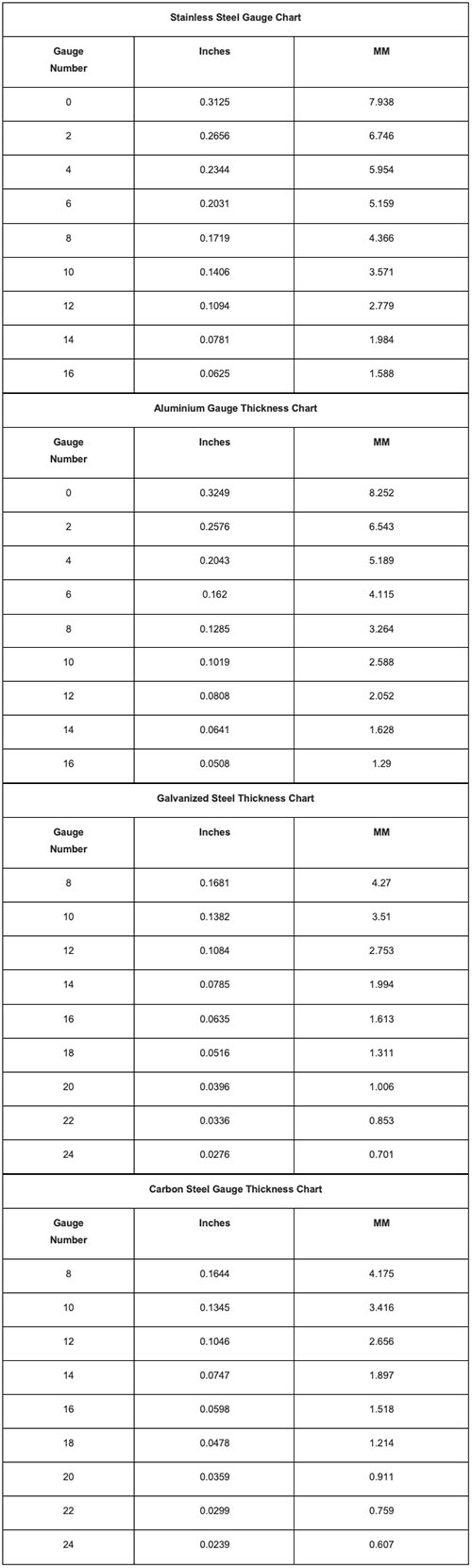

The following gauge table outlines standard sheet metal thicknesses used in laser cutting, bending, and welding operations. These values are critical for process parameter setup, tooling selection, and design for manufacturability. Materials include Aluminum, Steel (mild steel), ABS, and Nylon—commonly processed at Honyo Prototype for rapid prototyping and low-volume production.

| Material | Gauge (US Standard) | Thickness (inches) | Thickness (mm) | Laser Cutting Compatibility | Bending Minimum Radius (as multiple of thickness) | Welding Feasibility | Notes |

|---|---|---|---|---|---|---|---|

| Aluminum | 24 | 0.040 | 1.02 | Excellent | 1.5 × t | Yes (TIG/MIG) | Good for enclosures; reflective—requires adjusted laser settings |

| Aluminum | 20 | 0.050 | 1.27 | Excellent | 1.5 × t | Yes (TIG/MIG) | Common for brackets and chassis |

| Aluminum | 16 | 0.063 | 1.60 | Excellent | 1.5 × t | Yes (TIG/MIG) | Suitable for structural components |

| Aluminum | 14 | 0.080 | 2.03 | Very Good | 2.0 × t | Yes (TIG/MIG) | Increased reflectivity; may require assist gas optimization |

| Aluminum | 11 | 0.120 | 3.05 | Good | 2.5 × t | Yes (TIG/MIG) | Limited laser cutting on high-power systems only |

| Steel (Mild) | 24 | 0.040 | 1.02 | Excellent | 1.0 × t | Yes (MIG/Spot) | High precision cuts; minimal dross |

| Steel (Mild) | 20 | 0.050 | 1.27 | Excellent | 1.0 × t | Yes (MIG/Spot) | Most common for brackets and frames |

| Steel (Mild) | 16 | 0.063 | 1.60 | Excellent | 1.0 × t | Yes (MIG/Spot) | Ideal for welded assemblies |

| Steel (Mild) | 14 | 0.080 | 2.03 | Excellent | 1.5 × t | Yes (MIG/Spot) | Requires higher laser power; excellent edge quality |

| Steel (Mild) | 11 | 0.120 | 3.05 | Very Good | 2.0 × t | Yes (MIG/Spot) | Suitable for heavy-duty parts; piercing requires dwell time |

| ABS | — | 0.060 | 1.52 | Limited (CO₂ laser only) | Not applicable | No | Thermoplastic; prone to melting; not for structural use |

| ABS | — | 0.125 | 3.18 | Limited (CO₂ laser only) | Not applicable | No | Used for enclosures; requires ventilation due to fumes |

| Nylon | — | 0.060 | 1.52 | Poor (not recommended) | Not applicable | No | High reflectivity and melting risk; not suitable for laser cutting |

| Nylon | — | 0.125 | 3.18 | Poor (not recommended) | Not applicable | No | Better processed via machining; flammable under laser |

Notes:

t = material thickness

Laser cutting parameters assume fiber laser (for metals) and CO₂ laser (for plastics)

Bending guidelines assume air bending on CNC press brakes with appropriate tooling

ABS and Nylon are included for reference but are not typically processed alongside metals in structural applications

Welding is not applicable for thermoplastics; joining typically involves adhesives or mechanical fasteners

This gauge table supports process planning and material selection across Honyo Prototype’s manufacturing workflows.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Gauge Table Integration Process

Honyo Prototype’s end-to-end workflow for sheet metal fabrication leverages a proprietary gauge table to ensure precision from design to delivery. This table—embedded within our digital infrastructure—maps material thickness (gauge) to critical manufacturing parameters, including bend radii, laser cutting tolerances, and forming allowances. Below is the technical execution of this process:

Upload CAD

Upon receiving a customer’s CAD file (STEP, DWG, or native formats), our system auto-detects sheet metal components and extracts material specifications, including gauge or thickness. The gauge table cross-references the declared material type (e.g., 304 stainless steel, 5052 aluminum) against Honyo’s validated thickness-to-gauge conversion standards (per ASTM/EN/DIN). If gauge is specified without explicit thickness, the table converts it to millimeters for downstream process calibration. Undeclared materials trigger an automated query to the client before progression.

AI Quote

Our AI quoting engine ingests the CAD-derived gauge data and applies the gauge table’s tolerance rules. For instance, 16-gauge (1.51 mm) cold-rolled steel incurs different laser kerf allowances (±0.1 mm) versus 22-gauge (0.76 mm) aluminum (±0.08 mm). The AI calculates secondary effects: thinner gauges (<1.0 mm) automatically add handling surcharges due to warpage risks, while thicker gauges (>3.0 mm) adjust cutting speed multipliers. Real-time cost modeling factors in gauge-dependent scrap rates, tool wear, and press brake tonnage requirements, generating a technically validated quote within 2 hours.

DFM (Design for Manufacturability)

During DFM analysis, the gauge table drives automated rule checks. Critical validations include:

Minimum bend radius verification (e.g., 20-gauge steel requires ≥0.8 mm radius)

Hole-to-edge distance compliance (e.g., 18-gauge = 1.2× material thickness)

Flat pattern nesting efficiency based on gauge-specific kerf loss

Forming springback compensation curves unique to each gauge-material pair

Non-compliant features (e.g., a 0.5 mm tab on 14-gauge steel) trigger engineering change proposals with annotated 3D markups. All DFM feedback explicitly references gauge table metrics to justify recommendations.

Production

The approved gauge parameters synchronize directly to production systems:

Laser cutters receive kerf compensation values tied to gauge (e.g., 0.05 mm wider cut for 12-gauge vs. 18-gauge)

CNC press brakes apply gauge-specific bend deduction charts and tonnage limits

In-process inspection uses gauge-calibrated CMM probes (e.g., 0.025 mm tolerance for ≤1.0 mm gauges)

Material traceability logs gauge, batch number, and certified mill test reports. Any deviation from the table’s thickness tolerance bands (e.g., +0.05/-0.10 mm for 16-gauge CR steel) halts production for client consultation.

Delivery

Final quality documentation includes a gauge validation report showing:

Measured thickness at 5+ points per part (vs. nominal gauge)

Bend angle deviations correlated to gauge-induced springback

Surface finish verification (e.g., Ra limits for <1.5 mm gauges)

Parts are packaged with gauge-appropriate protection: interleaved sheets for gauges ≤18, rigid framing for ≥10-gauge, and humidity control for corrosion-prone thin gauges. Shipment includes digital as-built data with gauge-specific dimensional analytics for the client’s records.

This closed-loop gauge integration eliminates manual interpretation errors, reduces DFM iterations by 65%, and ensures first-article compliance with ISO 2768-mK tolerances across all sheet metal projects.

Start Your Project

Looking for a precision gauge table for sheet metal applications? Ensure accurate measurements and consistent quality in your prototyping and production processes with our high-precision gauge tables, manufactured to meet strict industry standards.

All products are made in our Shenzhen factory, where advanced manufacturing techniques combine with rigorous quality control. For more information or to request a quote, contact Susan Leo at [email protected]. Let Honyo Prototype be your trusted partner for reliable, high-quality sheet metal solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.