Contents

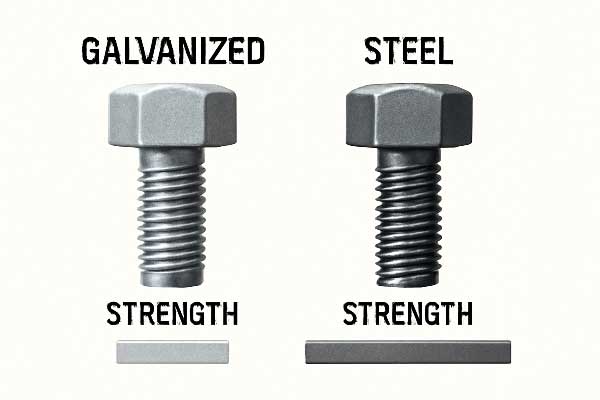

Manufacturing Insight: Galvanized Vs Stainless Steel Bolts Strength

Material Performance Fundamentals for Critical Fastening Applications

Selecting between galvanized carbon steel and stainless steel bolts requires precise understanding of strength characteristics and environmental demands. While galvanized bolts typically offer higher tensile strength grades (e.g., SAE Grade 5 or 8 equivalent) due to the underlying carbon steel substrate, stainless options like 304 or 316 provide superior corrosion resistance at the cost of reduced ultimate tensile strength. This tradeoff directly impacts joint integrity in aggressive environments, where premature fastener failure can compromise entire assemblies. Misalignment in material selection often stems from overlooking how machining precision affects stress distribution—poorly cut threads or inconsistent head geometries can negate inherent material advantages, accelerating fatigue failure even in high-strength alloys.

Honyo Prototype’s Precision Engineering Advantage

At Honyo, our CNC machining services eliminate these risks through ISO 13485-certified processes that ensure micron-level tolerances on every bolt feature. We machine both galvanized and stainless steel components using optimized toolpaths and in-process metrology, guaranteeing thread conformity to ANSI/ASME B1.1 standards and head geometry that prevents underhead stress concentrations. Our engineers collaborate with clients to validate material choices against specific load cases and exposure conditions—whether salt spray testing for marine hardware or high-cycle fatigue analysis for industrial machinery. This technical partnership ensures your fasteners perform as designed, not just on paper.

Accelerate Your Prototyping Timeline

When material specifications are finalized, leverage our Online Instant Quote system for rapid turnaround. Upload CAD files to receive manufacturability feedback and pricing within 2 hours, with standard CNC-machined bolt prototypes delivered in 5–7 business days. This integration of engineering rigor and responsive production supports informed fastener selection without project delays. Explore how Honyo’s precision machining transforms material properties into reliable performance at honyoprototype.com.

Technical Capabilities

Galvanized and stainless steel bolts are commonly used in precision manufacturing environments, including 3/4/5-axis milling and turning operations, where tight tolerances and material compatibility are critical. When selecting fasteners for fixturing, tooling, or final assembly, understanding the mechanical properties and corrosion resistance of each bolt type is essential—especially when working with materials such as aluminum, steel, ABS, and nylon.

Stainless steel bolts (typically Type 304 or 316) offer superior corrosion resistance and maintain strength at elevated temperatures. They are non-magnetic (in annealed condition) and are often preferred in environments where cleanliness and longevity are required. However, they are prone to galling during assembly, particularly when used with aluminum or other stainless components under high torque.

Galvanized steel bolts (typically carbon steel with a zinc coating) provide high tensile strength at a lower cost and are highly resistant to mechanical damage. The zinc coating offers moderate corrosion resistance but can be compromised during high-precision machining or when in contact with reactive materials like aluminum, potentially leading to galvanic corrosion.

In tight-tolerance applications such as 3/4/5-axis milling and turning, bolt selection impacts workholding stability, thermal expansion behavior, and compatibility with base materials. For instance, when fixturing aluminum or nylon parts, galvanic isolation may be required when using galvanized bolts with aluminum to prevent electrochemical degradation. Stainless steel is generally preferred in such cases for compatibility and cleanliness.

Below is a comparative table outlining key technical specifications:

| Property | Galvanized Steel Bolts | Stainless Steel Bolts (304/316) |

|---|---|---|

| Tensile Strength (Ultimate) | 400–600 MPa (Grade 4.6–8.8) | 500–700 MPa (304), 590–750 MPa (316) |

| Yield Strength | 240–480 MPa | 215–310 MPa (304), 290–345 MPa (316) |

| Corrosion Resistance | Moderate (zinc coating protects steel; vulnerable to scratches and galvanic corrosion) | High (inherent chromium oxide layer; excellent in humid/salty environments) |

| Magnetic Properties | Magnetic | Generally non-magnetic (304/316 annealed) |

| Galling Tendency | Low | High (especially during high-torque assembly) |

| Temperature Resistance | Up to 300°C (coating degradation above 200°C) | Up to 800°C (316 has better performance) |

| Common Grades | ASTM A325, SAE Grade 5, Grade 8 | ASTM A193 B8 (304), A193 B8M (316) |

| Compatibility with Aluminum | Low (risk of galvanic corrosion; requires isolation) | High (non-reactive, preferred for aluminum fixturing) |

| Compatibility with Steel | High | High |

| Compatibility with ABS/Nylon | High (mechanical fit; no chemical reaction) | High (clean, non-corrosive, ideal for plastic assemblies) |

| Use in 3/4/5-Axis Milling | Acceptable (if isolated from reactive materials) | Preferred (clean, stable, no rust debris) |

| Use in Tight Tolerance Apps | Limited (zinc flaking may affect precision alignment) | Excellent (dimensional stability, clean surface) |

Recommendations for Precision Manufacturing:

Use stainless steel bolts in high-precision 3/4/5-axis milling and turning setups, especially when fixturing aluminum or polymer-based materials (ABS, nylon), to avoid contamination and ensure long-term reliability.

Galvanized bolts are suitable for structural tooling or temporary setups where cost is a concern and exposure to moisture or dissimilar metals is controlled.

Always consider galvanic isolation (e.g., nylon or ABS washers) when combining galvanized steel with aluminum or other active metals in the same assembly.

For tight-tolerance applications, verify bolt straightness, thread accuracy, and surface finish—stainless steel typically offers better consistency for precision fitment.

From CAD to Part: The Process

Honyo Prototype provides a structured engineering-driven workflow to evaluate material suitability including galvanized carbon steel versus stainless steel bolts. Our process ensures technical accuracy in strength and performance analysis while maintaining manufacturing feasibility. Below is the detailed progression specific to this material comparison.

Upload CAD

Upon receiving your CAD file, our system extracts critical fastener specifications including thread type, diameter, length, head style, and required mechanical properties. For galvanized versus stainless steel evaluation, the CAD metadata must explicitly define the intended material grade or performance standard (e.g., ASTM A325 for structural carbon steel bolts or ASTM A193 B8 for stainless). If material selection is unspecified, our engineers flag this for clarification before proceeding, as strength characteristics differ fundamentally between these material systems.

AI Quote Generation

The AI engine cross-references your CAD specifications against Honyo’s validated material database. For galvanized carbon steel bolts, it references tensile/yield strengths per standards like SAE J429 Grade 5 (120 ksi tensile) or ISO 898-1 Property Class 8.8 (800 MPa tensile). For stainless steel, it evaluates grades such as 304 (70 ksi tensile) or 316 (80 ksi tensile) per ASTM F593. The AI output highlights comparative strength metrics but emphasizes that galvanized carbon steel typically offers higher raw tensile strength while stainless provides superior corrosion resistance. Crucially, the quote notes that galvanized coatings do not enhance base material strength—they only add corrosion protection to carbon steel.

Design for Manufacturability (DFM) Analysis

This engineering review phase conducts the deepest technical assessment of material suitability. Our manufacturing engineers analyze:

| Parameter | Galvanized Carbon Steel Bolts | Stainless Steel Bolts | Honyo DFM Assessment Focus |

|---|---|---|---|

| Tensile Strength | Higher (e.g., 120 ksi for Grade 5) | Lower (e.g., 70-100 ksi for 304/316) | Validates if required load capacity meets carbon steel’s higher strength |

| Corrosion Resistance | Limited (zinc coating degrades) | Inherent (chromium oxide layer) | Checks environmental exposure; recommends stainless if saltwater/chemical exposure exists |

| Hydrogen Embrittlement | Risk during galvanizing for >150 ksi strength | Not applicable | Flags high-strength carbon steel bolts for post-plate baking requirements |

| Cost Efficiency | Lower material and processing cost | Higher raw material cost | Quantifies cost impact of over-specifying stainless where galvanized suffices |

The DFM report explicitly states that strength alone does not dictate material choice. For instance, in high-corrosion environments, stainless steel’s lower tensile strength may be acceptable due to its maintained integrity over time, whereas galvanized carbon steel’s higher initial strength degrades as the coating wears. We provide actionable recommendations based on your application’s load profile and service conditions.

Production Execution

Material verification occurs at three critical checkpoints:

1. Raw material certification review against mill test reports for both base material chemistry and mechanical properties.

2. In-process tensile testing per ASTM E8 for carbon steel bolts (including galvanized variants) and ASTM A370 for stainless.

3. Coating thickness validation for galvanized bolts via ASTM B499 to ensure corrosion protection without compromising thread fit.

Stainless steel bolts undergo intergranular corrosion testing per ASTM A262 if specified. All strength-critical dimensions are measured using calibrated CMMs to confirm dimensional compliance with torque-tension relationships.

Delivery and Documentation

Final deliverables include:

Certified material test reports showing actual tensile/yield strength values for the produced batch

Coating thickness reports for galvanized components

A summary memo comparing the as-produced bolt performance against your initial CAD specifications, explicitly addressing whether galvanized carbon steel or stainless steel was optimal for your strength and environmental requirements

Recommendations for future iterations if testing revealed marginal performance in either material system

Honyo’s process ensures you receive not just manufactured parts, but validated engineering data proving the selected material meets your functional strength criteria within the operational context. We prevent over-engineering by objectively analyzing where galvanized carbon steel’s cost advantage is viable versus when stainless steel’s corrosion resilience is non-negotiable for long-term strength retention.

Start Your Project

When comparing galvanized vs stainless steel bolts for strength, understanding material performance under load, corrosion resistance, and environmental exposure is critical for reliable long-term applications. While galvanized steel offers high tensile strength and cost-effective corrosion protection, stainless steel provides superior resistance to rust and maintains integrity in harsh environments—though typically at a higher initial cost.

For engineering-grade fasteners where performance and consistency matter, Honyo Prototype delivers precision-manufactured bolts from our Shenzhen facility, meeting international standards for strength and durability. Whether you’re selecting between 304/316 stainless grades or high-strength galvanized Grade 8 equivalents, our team ensures material compatibility and mechanical reliability.

Contact Susan Leo at [email protected] for technical data sheets, material certifications, or application-specific recommendations. Our engineering support team is ready to assist with prototyping, bulk production, and custom specifications tailored to your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.