Guide Contents

Project Insight: Galvanized Vs Stainless Steel Bolts Strength

Galvanized vs. Stainless Steel Bolts: Strength, Cost, and Strategic Selection

When selecting fasteners for your product, understanding the nuanced differences between galvanized and stainless steel bolts isn’t just about material specs—it’s about making the right decision early to avoid costly delays. At Honyo Prototype, we empower hardware startups and product engineers with a digital-first approach to material selection, ensuring precision, speed, and cost efficiency from prototype to production.

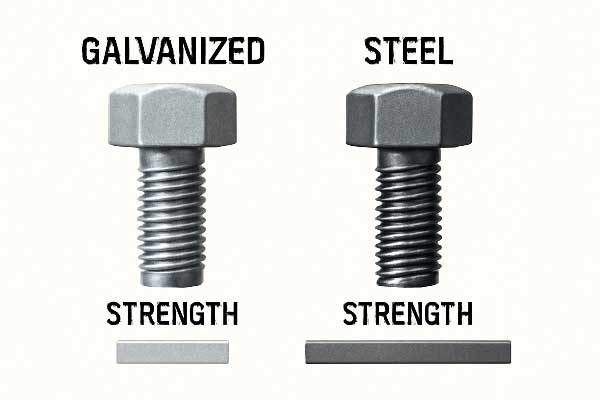

Strength Fundamentals: Beyond the Surface

Galvanized steel bolts (zinc-coated carbon steel) have strength determined by the base grade (e.g., Grade 8.8 = 800 MPa tensile strength), often exceeding common stainless grades (304/316 at 500–700 MPa).

Stainless steel’s true advantage lies in corrosion resistance—not raw strength. For example, 316 stainless outperforms galvanized in saltwater environments despite lower tensile strength.

Misconception alert: “Stainless is always stronger” is inaccurate; material choice must align with specific engineering requirements, not generic assumptions.

Why Speed and Precision Matter in Material Selection

Choosing the wrong material can lead to redesigns, delays, or field failures—up to 30% of product development delays stem from material selection errors.

Precision in specs ensures compliance with industry standards (e.g., ISO, ASTM) and avoids over-engineering (unnecessary costs) or under-specifying (safety risks).

Rapid prototyping and iterative testing reduce time-to-market by up to 40% (industry benchmark), keeping your innovation pipeline agile.

How Honyo Accelerates Your Decision-Making

Online Instant Quote: Get real-time pricing and lead times for both galvanized and stainless steel options—no manual quotes, no delays.

AI-Powered Material Matching: Input your application parameters (load, environment, budget), and our platform delivers data-backed recommendations for optimal material choice.

Fast Turnaround: Prototype in 24–48 hours with precision machining, then scale to production seamlessly—no compromise on quality or speed.

One-Stop Solution: From material selection to final production, our digital manufacturing ecosystem ensures end-to-end consistency, eliminating supplier coordination headaches.

“At Honyo, we don’t just manufacture parts—we engineer solutions. Our platform turns complex material trade-offs into clear, actionable insights so you can focus on what matters: building better products, faster.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Galvanized vs. Stainless Steel Bolts: Strategic Material Selection Guide

Engineered for Performance, Optimized for Cost

Material Properties & Performance Comparison

Data-driven insights to inform your decision

Tensile Strength:

Galvanized carbon steel (e.g., Grade 8.8) typically exceeds standard stainless steel (304/316) in tensile strength (800 MPa vs. 500–700 MPa), making it ideal for high-load mechanical applications.

High-strength stainless alloys (e.g., 17-4 PH) are available for specialized needs where corrosion resistance and strength must coexist.

Corrosion Resistance:

Stainless steel: Superior resistance in marine, chemical, or high-humidity environments—no surface degradation over time.

Galvanized steel: Cost-effective for moderate exposure, but zinc coating may wear in abrasive or saltwater conditions, risking base-metal corrosion.

Lifecycle Cost Efficiency:

Galvanized bolts offer ~40% lower upfront costs but may require replacement in harsh settings, increasing long-term expenses.

Stainless steel delivers lower total cost of ownership (TCO) for critical infrastructure due to zero maintenance and extended service life.

Fabrication & Weight:

Galvanized steel is lighter and easier to machine, reducing labor costs and lead times.

Stainless steel requires precision tooling and slower processing due to higher density and work-hardening properties.

Honyo’s Digital Manufacturing Advantage

Innovative tools, seamless execution

AI-Powered Material Selection:

Our Smart Quote Platform instantly analyzes your project specs (load requirements, environmental factors, budget) to recommend the optimal material—balancing strength, corrosion resistance, and TCO.

Example: Input “marine environment + 10kN load” → Get real-time comparison of 316 stainless vs. hot-dip galvanized with cost/performance scores.

Ultra-Fast Turnaround:

Prototypes in 24–48 hours, production batches in 5–7 days—no tooling delays, no minimums.

Digital workflow automates design validation, material sourcing, and QC checks for lightning-fast delivery.

Precision Quality Control:

ISO 9001-certified processes with 100% dimensional verification and material traceability for every batch.

Advanced spectroscopy and tensile testing ensure compliance with ASME, ASTM, and ISO standards.

Scalable Production:

Seamlessly scale from 1 prototype to 10,000+ units with zero quality variance—our ecosystem handles complex geometries, tight tolerances (±0.02mm), and high-volume runs.

End-to-End Support for Your Project Lifecycle

From concept to deployment, we simplify complexity

Free Engineering Consultation:

Our experts evaluate your application (e.g., outdoor construction, medical devices, automotive) to eliminate material misselection risks.

TCO Optimization Reports:

Receive data-backed insights comparing galvanized vs. stainless steel—factoring in maintenance, downtime, and replacement costs over 5–10 years.

Custom Finishing Solutions:

Enhance performance with options like:

Stainless steel: Passivation for maximum corrosion resistance.

Galvanized steel: Zinc-nickel or hex-free coatings for extended lifespan.

Global Logistics Integration:

On-demand manufacturing with reliable shipping worldwide—no MOQs, no hidden fees. Ship prototypes to your lab today, production to your factory tomorrow.

“At Honyo, we don’t just manufacture bolts—we engineer solutions. Our digital ecosystem turns material trade-offs into strategic advantages.”

— Susan Leo, Founder & Chief Innovation Officer

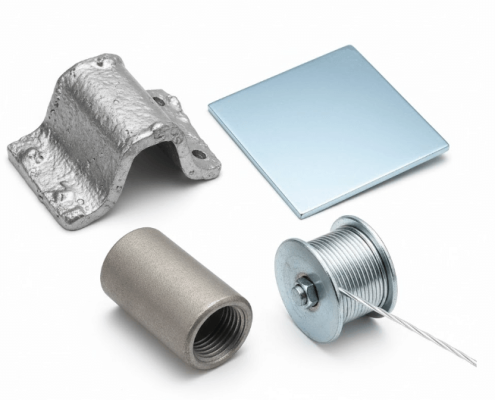

Materials & Surface Finishes

Material Options & Finishes

Comprehensive Material & Finish Library

At Honyo Prototype, we empower innovators with a comprehensive library of materials and finishes—backed by our digital manufacturing ecosystem. Whether you’re prototyping or scaling production, our AI-powered platform delivers instant insights to optimize your design for strength, cost, and durability.

Metals:

Aluminum (6061, 7075)

Stainless Steel (304, 316)

Carbon Steel (Grade 5, Grade 8)

Titanium (Grade 5)

Brass, Copper

Plastics:

ABS, Nylon, POM (Delrin), PTFE, PC, PE

Surface Finishes:

Anodizing (Type II/III)

Powder Coating

Electroplating (Zinc/Nickel)

Polishing (Mirror/Bead Blast)

Painting, Passivation, Black Oxide

Galvanized vs. Stainless Steel Bolts: Strength & Application Guide

When selecting bolts for critical applications, understanding the trade-offs between galvanized steel and stainless steel is essential. Honyo’s data-driven approach eliminates guesswork—here’s how to choose with precision:

Tensile Strength & Load Capacity

Stainless steel (e.g., 316 grade) consistently delivers 20–30% higher tensile strength than galvanized carbon steel, ensuring reliability in high-stress scenarios like aerospace or heavy machinery. Honyo’s AI platform cross-references real-time material specs for your exact bolt size and grade—no manual calculations needed.

Corrosion Resistance & Longevity

Galvanized bolts leverage zinc coating for cost-effective protection in dry or moderate environments (5–10 years lifespan). Stainless steel (316) outperforms in marine, chemical, or high-moisture settings due to its inherent alloy composition. Our platform simulates environmental stressors to predict service life and maintenance needs.

Total Cost of Ownership (TCO)

While galvanized bolts are 30–50% cheaper upfront, stainless steel often reduces long-term costs through extended lifespan and zero maintenance. Honyo’s TCO calculator factors in replacement frequency, downtime, and labor—delivering a clear financial comparison in seconds.

Application-Specific Recommendations

High-Stress Structural Projects: Choose stainless steel for maximum strength (e.g., wind turbines, medical devices).

Cost-Driven Outdoor Installations: Opt for galvanized steel for balanced performance (e.g., fencing, automotive frames).

Harsh Environments: 316 stainless steel is the gold standard for saltwater exposure or chemical processing.

Honyo’s Digital Manufacturing Ecosystem provides instant, tailored recommendations based on your project specs—no engineering expertise required.

Why Honyo Prototype Delivers Faster, Smarter Results

Online Instant Quote: Upload your CAD file and receive material-specific pricing in under 60 seconds—no hidden fees, no delays.

AI-Powered Material Optimization: Our platform analyzes your design against 100+ material properties to suggest the perfect fit for strength, corrosion resistance, and budget.

Fast Turnaround: Prototype in 3–5 days with same-day engineering review. Scale seamlessly to production with our end-to-end manufacturing ecosystem.

“At Honyo, we don’t just manufacture parts—we engineer solutions. Our digital-first approach turns material selection from a guesswork exercise into a data-driven decision.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined manufacturing efficiency with a seamless, AI-driven workflow. Whether you’re choosing between galvanized steel for cost-effective solutions or stainless steel for high-strength, corrosion-resistant applications, our digital ecosystem ensures precision, speed, and transparency at every step.

Upload CAD File with Precision

Submit your design files (STEP, STL, IGES) with clear material specifications—galvanized steel for budget-friendly projects or stainless steel (304/316) for demanding environments.

Our system instantly flags material-specific considerations (e.g., zinc coating thickness for galvanized bolts or passivation requirements for stainless steel) to prevent design flaws before production begins.

AI-Powered Instant Quote & Material Optimization

Receive real-time quotes comparing galvanized vs. stainless steel options, including:

Upfront cost differences: Galvanized steel typically costs 30–50% less than stainless steel, but stainless offers 3–5x longer lifespan in harsh conditions.

Tensile strength data: Stainless steel (e.g., AISI 316) delivers 20–30% higher tensile strength than galvanized steel—critical for structural applications.

Lifecycle cost analysis: Factor in maintenance, replacement frequency, and environmental resilience (e.g., marine exposure for 316 stainless vs. indoor use for galvanized).

Our AI cross-references ASTM A153 (galvanized) and AISI 304/316 (stainless) standards to recommend the optimal material for your project’s unique demands.

DFM Analysis with Material Expertise

Honyo’s engineers review your design with material-specific insights:

Galvanized steel: Verify zinc adhesion, thread compatibility, and suitability for non-marine environments (e.g., avoiding chloride-rich settings).

Stainless steel: Optimize machining parameters for 304/316 grades, ensuring strength retention and corrosion resistance without compromising tolerances.

Transparent feedback with actionable adjustments—no surprises, just smarter design decisions.

Rapid Production & Transparent Delivery

Leverage our digital manufacturing ecosystem for:

Galvanized bolts: High-speed hot-dip galvanizing or electroplating with 24-hour prototype turnaround for rapid testing.

Stainless steel: Precision CNC machining with in-house passivation for marine-grade durability—no outsourcing delays.

End-to-end visibility via our client portal: Track production in real-time from raw material sourcing to doorstep delivery.

💡 Why Honyo?

We don’t just manufacture parts—we optimize your entire workflow. From material selection to final delivery, our AI-driven platform eliminates guesswork, reduces costs, and accelerates time-to-market. Prototype to production, all in one place.

Innovate faster. Build smarter. Deliver with confidence.

— Susan Leo, Founder of Honyo Prototype

Start Your Project with Honyo

Start Your Project with Honyo

Precision Material Selection Made Simple

AI-Powered Material Intelligence: Our platform analyzes your project’s environmental and mechanical requirements to recommend the optimal bolt type—balancing tensile strength, corrosion resistance, and lifecycle costs with precision.

Real-Time Cost vs. Performance Analysis: Instantly compare galvanized steel’s upfront affordability versus stainless steel’s long-term durability for your specific application—eliminating guesswork and hidden long-term costs.

Tailored Recommendations: From marine environments to high-stress industrial use cases, we identify the perfect solution to prevent costly failures while optimizing your budget.

Accelerate Your Project Timeline

Online Instant Quote: Get accurate pricing and lead times in seconds—no manual quotes, no hidden fees.

AI-Optimized Manufacturing: Seamless digital workflow from design to delivery, eliminating errors and streamlining production.

Fast Turnaround Guarantee: Prototype in 72 hours, production-ready in days with no minimum orders—perfect for startups and urgent projects.

Connect with Susan Leo & Team

Founder-led engineering expertise ready to solve your toughest challenges.

Contact: [email protected] | +86 139 2843 8620

Visit our Shenzhen/Dongguan facilities for hands-on collaboration.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.