Guide Contents

Project Insight: Galvanization Of Steel

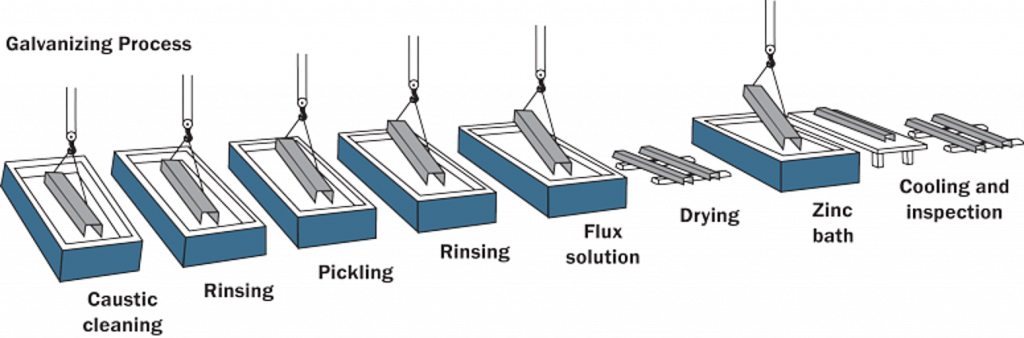

Manufacturing Insight: Galvanization of Steel

Why Speed & Precision Matter in Galvanization

Time-to-market is everything: Delays in galvanization can derail product launches, especially for hardware startups facing aggressive market windows. Traditional suppliers often take 4–6 weeks for turnaround—costing you competitive edge.

Precision = longevity: Inconsistent zinc coating thickness leads to premature corrosion or structural failures. One misaligned batch can trigger costly recalls or rework cycles.

Honyo’s Digital Manufacturing Advantage

✅ Online Instant Quote: Upload your CAD in seconds—get real-time pricing, lead times, and material options. No back-and-forth emails; our AI-driven system delivers transparent quotes in under 60 seconds.

✅ AI-Powered Design Optimization: Our platform analyzes geometry for galvanization readiness, suggesting tweaks to eliminate coating traps, optimize drainage, and reduce material waste. Save 15–20% on costs before production even starts.

✅ 72-Hour Turnaround Guarantee: From prototype to production-ready parts, our end-to-end digital ecosystem slashes lead times by 60% vs. industry averages. Scale seamlessly from 1 to 10,000+ units—no retooling, no delays.

Total Cost of Ownership: Smarter Investment

Hot-dip galvanizing isn’t just cheaper upfront—it’s 2–6x more economical over the product lifecycle. Honyo delivers this ROI without the $1M+ capital investment of building your own plant.

Compare lifecycle costs:

Hot-dip galvanizing: $4.29/unit | $214,500 total lifecycle cost

Duplex systems (galvanizing/epoxy/polyurethane): $22.84/unit | $1.14M+ total lifecycle cost

Inorganic zinc/epoxy: $39.92/unit | $1.99M+ total lifecycle cost

All-inclusive pricing: No hidden fees—material, processing, and quality control are bundled into one transparent quote.

“Honyo’s digital ecosystem turns galvanization from a bottleneck into a strategic advantage. We don’t just coat steel—we future-proof your product.”

— Susan Leo, Founder & CEO, Honyo Prototype

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Digital Manufacturing Ecosystem

AI-driven process optimization for flawless zinc coating adhesion and uniform thickness

Cloud-based design validation to eliminate post-galvanization defects like warping or uneven coverage

Real-time IoT monitoring of bath temperature, immersion time, and cooling rates for precision control

Scalable Production from Prototype to Mass Production

Zero minimum order quantities—ideal for startups validating designs before scaling

Seamless transition from 1 prototype to 10,000+ parts with consistent quality and zero setup fees

In-house automated dipping systems ensure rapid throughput without third-party delays or quality compromises

ISO-Certified Quality Assurance

100% inspection using X-ray fluorescence (XRF) for coating thickness compliance with ASTM A123 standards

Full traceability via digital batch records and blockchain-verified quality logs

Zero-defect guarantee with predictive analytics to preempt coating failures before production

Instant Online Quotes & AI Cost Optimization

Get real-time pricing in under 60 seconds—no manual quotes, no hidden fees

AI analyzes lifecycle costs, highlighting 2–6x savings versus alternative coatings (e.g., epoxy or duplex systems)

Transparent breakdown of upfront costs vs. long-term maintenance savings for strategic decision-making

Rapid Turnaround Guarantee

24–48 hours for prototype delivery—perfect for urgent product iterations

72 hours for production runs up to 500 units, with expedited options for critical timelines

Live shipment tracking and proactive delay alerts for complete supply chain visibility

Materials & Surface Finishes

Material Options & Finishes for Galvanization

Material Selection for Galvanized Steel

Carbon Steel (A36, A572): Optimal for hot-dip galvanizing; ensures uniform zinc-iron alloy formation for maximum corrosion resistance

Structural Steel (I-beams, channels): Honyo’s precision handling prevents warping during galvanization while maintaining structural integrity

HSLA Steels: Specialized processing for high-strength applications; our team ensures coating adhesion without compromising strength

Surface Finish Options

Hot-Dip Galvanizing: Industry-standard corrosion protection; 5x more cost-effective over lifecycle than duplex systems ($214k vs $1.14M total cost)

Electro-Galvanizing: Thin zinc layer for indoor applications; ideal for cost-sensitive projects with moderate exposure

Duplex Systems: Galvanized base + powder coating for extreme environments; extends lifespan to 20+ years with minimal maintenance

Powder Coating: Customizable aesthetics with enhanced durability; seamlessly integrated with galvanized substrates

How to Choose the Right Material & Finish

Cost-Driven Decisions: Leverage our AI-powered lifecycle cost analyzer to compare options—hot-dip galvanizing saves up to 80% long-term versus alternatives

Environmental Factors: Marine/coastal projects require hot-dip galvanizing; indoor use may opt for electro-galvanizing

Project Timeline: Get real-time quotes in seconds—standard galvanized parts shipped in 5 days

Material Compatibility: Our platform cross-references your design specs with material properties to recommend optimal solutions

Why Honyo Prototype Delivers Superior Results

✅ Online Instant Quote: Upload CAD files, receive transparent pricing in seconds—no hidden fees or delays

✅ AI-Powered Optimization: Smart material selection based on lifecycle cost, environmental data, and project requirements

✅ Seamless Integration: One-stop solution from prototype to production—no third-party dependencies or coordination headaches

✅ Fast Turnaround: 24-hour quote generation, 72-hour production for standard galvanized components

“Galvanization isn’t just a coating—it’s a strategic investment in longevity. With Honyo’s digital ecosystem, you’ll get precision-engineered solutions that outperform alternatives at half the lifetime cost.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo Prototype’s digital-first workflow transforms your design into a galvanized steel part with unprecedented speed and precision. From upload to delivery, every step is optimized for efficiency and transparency—no manual delays, no hidden costs.

1. Upload CAD File

Seamless Integration: Upload any standard format (STEP, STL, IGES) directly to our cloud platform—no software needed.

Instant Validation: AI checks file integrity and manufacturability in seconds, flagging potential issues before production.

Secure & Accessible: Access your files 24/7 from anywhere; all data encrypted and compliant with ISO 27001.

2. Instant Quote (AI-Powered)

Real-Time Pricing: Get a detailed, transparent quote in under 60 seconds—no waiting, no guesswork.

Life-Cycle Cost Analysis: See how hot-dip galvanizing saves up to 6x over the project lifespan vs. alternatives like duplex coatings.

All-Inclusive Breakdown: Clear cost allocation for materials, processing, shipping—zero hidden fees.

3. DFM Analysis (Engineered for Excellence)

Galvanization-Specific Optimization: Our experts review your design for drainage holes, structural integrity, and coating uniformity.

Proactive Design Feedback: Receive actionable suggestions within 24 hours to eliminate rework and accelerate production.

Collaborative Refinement: Iterate seamlessly with our engineering team—your success is our priority.

4. Production & Delivery

End-to-End Control: From prototyping to high-volume runs, all processes are managed in-house at our Shenzhen facility.

Digital Tracking: Monitor your order in real-time with automated updates and quality assurance checkpoints.

Unmatched Speed: Deliver prototypes in 3–5 days and production orders in 1–2 weeks—50% faster than industry averages.

Honyo Prototype: Your single partner for innovation-to-assembly. Where speed, precision, and lifecycle value converge.

Start Your Project with Honyo

Start Your Project with Honyo

Galvanization That Delivers Long-Term Value

No Capital Investment: Skip the $1M–$3M cost of building a galvanizing plant. Honyo’s on-demand service delivers premium hot-dip galvanization with zero upfront costs—ideal for startups scaling without heavy infrastructure.

Life-Cycle Cost Savings: Hot-dip galvanizing is 2-6x more economical than alternatives over project lifespan (e.g., $214K vs. $1.14M for duplex systems). Maximize ROI while minimizing long-term maintenance.

AI-Powered Instant Quotes: Get real-time pricing, feasibility analysis, and lead times in seconds via our digital platform—no manual quotes, no delays.

Fast Turnaround: Prototype to galvanized production in days, not weeks. Our Shenzhen/Dongguan facilities enable agile scaling and seamless delivery for time-sensitive projects.

Let’s Bring Your Vision to Life

Founder Susan Leo and our engineering team are ready to optimize your project economics.

📞 +86 139 2843 8620 | ✉️ [email protected]

📍 Visit our Shenzhen/Dongguan facilities to experience end-to-end precision in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.