Contents

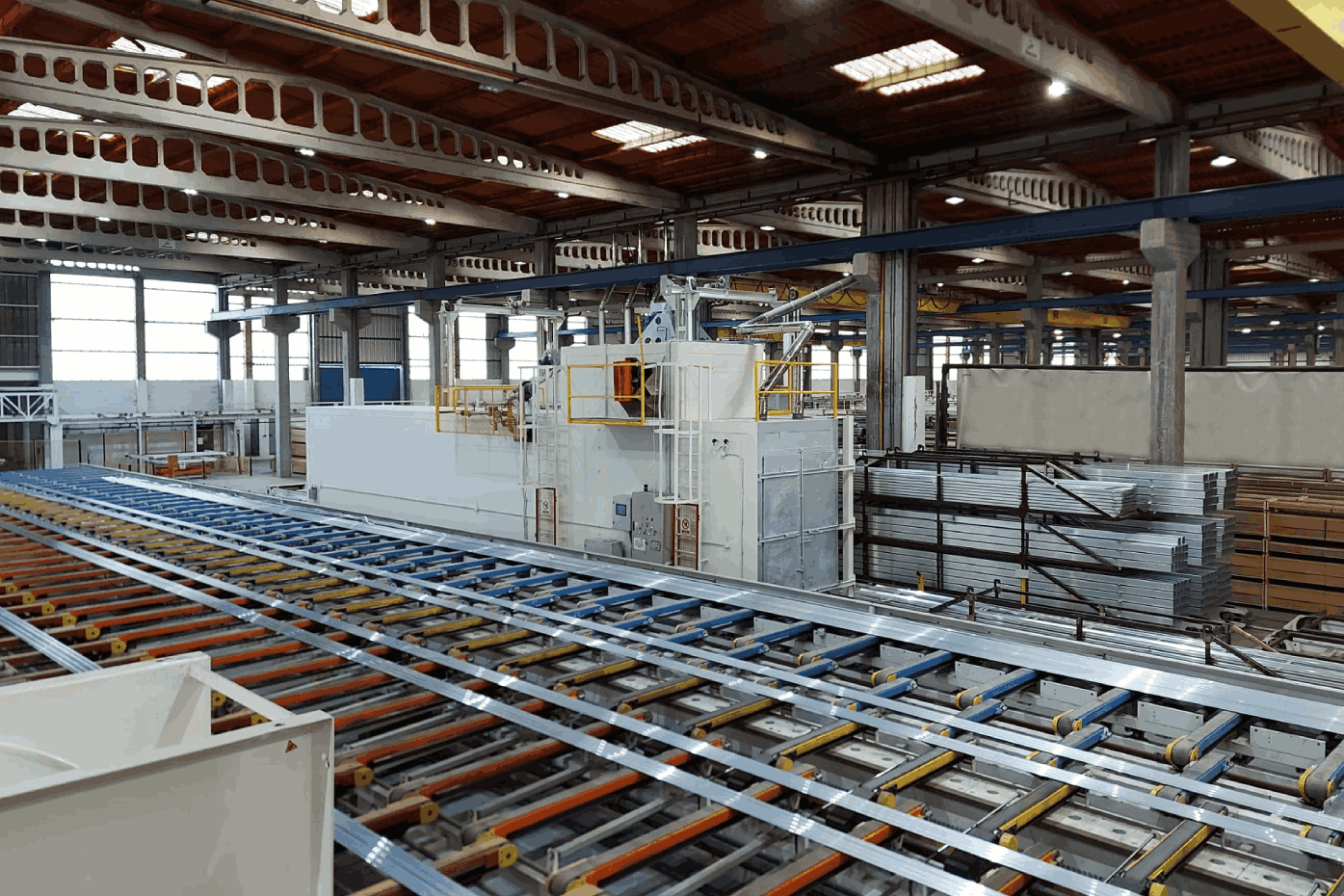

Manufacturing Insight: Ga Aluminum

Precision Aluminum Sheet Fabrication Through Advanced CNC Machining

Honyo Prototype delivers industry-leading CNC machining services for gauge aluminum components, serving aerospace, medical, and industrial clients requiring tight-tolerance, high-integrity parts. Our expertise spans aluminum alloys including 6061-T6, 5052-H32, and 7075-T6, processed via multi-axis milling and turning centers to achieve tolerances down to ±0.005mm. With decades of experience optimizing material utilization and minimizing waste in thin-gauge aluminum fabrication, we ensure structural integrity while meeting stringent industry specifications for corrosion resistance, weight reduction, and thermal performance.

Our end-to-end manufacturing workflow integrates precision CNC machining with secondary operations such as deburring, anodizing, and precision bending, all executed under ISO 9001-certified quality protocols. This holistic approach guarantees consistent repeatability for complex geometries—from intricate brackets to large-scale enclosures—while maintaining the inherent advantages of aluminum: lightweight strength, electrical conductivity, and sustainability.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed, no-obligation cost analysis and lead time estimate in under five minutes, complete with manufacturability feedback. This transparent, engineer-driven quoting system eliminates procurement delays without compromising technical rigor, enabling faster decision-making for your critical aluminum component projects.

Partner with Honyo Prototype to transform aluminum sheet designs into certified, production-ready parts with uncompromising precision and efficiency.

Technical Capabilities

Technical Specifications for GA Aluminum Machining – 3/4/5-Axis Milling and Turning with Tight Tolerance Focus

GA Aluminum refers to general-purpose aluminum alloys commonly used in precision CNC machining applications, particularly where complex geometries and tight tolerances are required. These alloys—typically from the 6000 series (e.g., 6061-T6)—are widely used in aerospace, automotive, and industrial prototyping due to their excellent machinability, strength-to-weight ratio, and dimensional stability.

The following table outlines the technical capabilities and material considerations for 3-axis, 4-axis, and 5-axis CNC milling and turning operations at Honyo Prototype, with an emphasis on tight tolerance machining.

| Parameter | Specification / Capability |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Mill-Turn) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerances down to ±0.001 mm (±0.00004″) achievable |

| Surface Finish (Milling) | Ra 0.8 µm (32 µin) standard; down to Ra 0.2 µm (8 µin) with polishing or fine finishing |

| Surface Finish (Turning) | Ra 0.4–1.6 µm (16–63 µin), depending on material and feature geometry |

| Max Work Envelope (Milling) | 5-axis: 1200 x 800 x 600 mm; 4/3-axis: up to 2000 x 1000 x 800 mm |

| Max Turning Diameter | 300 mm (standard); up to 500 mm with large-bore lathes |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed for aluminum and plastics) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) with laser calibration |

| Repeatability | ±0.001 mm (±0.00004″) |

| Primary Aluminum Alloy | 6061-T6, 7075-T6, 2024-T3, 5052; custom alloys on request |

| Other Materials Supported | Mild Steel (1018, 1045), Stainless Steel (303, 304, 316), ABS, Nylon (6 & 66), PEEK, PTFE |

| Coolant Use | High-pressure through-spindle coolant for aluminum; air cooling for plastics |

| Fixturing | Vacuum, mechanical, and custom soft jaws; tombstone setups for 4/5-axis batch production |

| Inspection Equipment | CMM, optical comparators, micrometers, bore gauges, surface profilometers |

| Lead Time (Prototype) | 3–7 days for machined aluminum parts; +2–3 days for steel or complex multi-axis setups |

Notes on Material Performance:

Aluminum (especially 6061-T6 and 7075-T6) is ideal for high-speed 5-axis milling due to its low cutting resistance and excellent thermal conductivity, enabling tight tolerance control and fast cycle times. Steel materials require lower speeds and rigid setups but are fully supported for hybrid or high-strength components. Engineering plastics like ABS and Nylon are machined with sharp tooling and reduced feed rates to prevent melting or deformation, particularly in thin-walled features.

All parts are inspected per ASME Y14.5 standards, with full first-article inspection reports (FAIR) available upon request.

From CAD to Part: The Process

Honyo Prototype’s manufacturing process for General Aluminum alloys (typically 6061-T6 or 7075-T6, referenced as “GA Aluminum” in our system) follows a rigorously defined digital workflow designed for speed, accuracy, and manufacturability. This integrated sequence ensures seamless transition from design intent to certified physical part while minimizing errors and delays. Below is the precise technical execution of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SolidWorks formats preferred) via our secure customer portal. Our system immediately performs automated geometry validation checks, including watertightness verification, unit consistency audits, and feature recognition specific to aluminum machining constraints. Non-native formats like STL undergo tessellation error analysis with a default tolerance of ±0.025mm. Any detected anomalies trigger an instant notification to the client with specific error coordinates, preventing downstream rework. File acceptance occurs within 15 minutes for validated submissions.

AI-Powered Quoting Engine with Engineering Oversight

Upon CAD validation, proprietary AI algorithms analyze the model against Honyo’s live production database of 2.1 million+ aluminum machining records. The system evaluates material utilization efficiency, toolpath complexity, feature accessibility, and historical machine performance data to generate a preliminary quote within 90 seconds. Crucially, this AI output undergoes mandatory review by a senior manufacturing engineer specializing in aluminum alloys. The engineer validates AI assumptions regarding chip load parameters, coolant requirements for aluminum’s thermal conductivity, and potential vibration risks in thin-wall features. Final quotes include explicit notes on any DFM-recommended adjustments, with typical turnaround under 2 business hours.

Engineering-Driven DFM Analysis

Our DFM stage is not automated suggestion software but a collaborative engineering dialogue. A dedicated manufacturing engineer conducts a full technical review focusing on aluminum-specific challenges:

Assessment of minimum wall thickness against 6061-T6’s 0.8mm practical limit for vibration control

Verification of hole depth-to-diameter ratios to prevent chip packing (max 10:1 without peck drilling)

Thermal deformation analysis for features requiring tight tolerances (<±0.05mm)

Surface finish feasibility evaluation based on grain structure requirements

The engineer provides a formal DFM report with actionable recommendations, such as suggesting chamfers instead of sharp corners to reduce micro-cracking during anodization. Client approval of DFM inputs is required before production release, ensuring design integrity is maintained.

Precision Production Execution

Approved jobs move to our dedicated aluminum production cell featuring 32 CNC machining centers (DMG MORI and Makino) with optimized parameters for aluminum alloys. Key production protocols include:

Tooling: Carbide end mills with ZrN coating and 45° helix angles to evacuate soft aluminum chips

Coolant: High-pressure through-spindle delivery (70 bar) with biodegradable emulsion to prevent smearing

Fixturing: Vacuum tables or custom soft jaws to avoid marring anodized surfaces

In-process inspection: On-machine probing for critical features after roughing and before finishing

All operations adhere to AS9100-certified procedures with real-time SPC monitoring of critical dimensions.

Certified Delivery and Documentation

Completed parts undergo first-article inspection per AS9102 standards, including CMM verification of all critical features and surface roughness testing (Ra values documented per client specs). Each shipment includes:

Material test report (MTR) from the certified aluminum supplier

Dimensional conformance certificate with actual vs. nominal values

Anodization verification report (if applicable)

Traceability logs linking the part to specific machine, operator, and tooling batches

Standard delivery for GA aluminum prototypes is 5-7 business days from DFM approval, with expedited options available. All parts ship in anti-static, humidity-controlled packaging with corner protection to prevent transit damage to soft aluminum edges.

Typical Timeline Breakdown for GA Aluminum Projects

| Process Stage | Duration | Key Dependencies |

|—————|———-|——————|

| CAD Upload to Validation | <15 min | File format compliance |

| AI Quote to Engineering Approval | 2 business hours | Client DFM feedback cycle |

| DFM Finalization | 1 business day | Complexity of required design iterations |

| Production | 3-5 business days | Quantity (1-10 parts standard) |

| Inspection & Shipping | 1 business day | Certification documentation requirements |

This integrated workflow leverages digital efficiency while maintaining essential human engineering oversight at critical decision points, ensuring GA aluminum parts meet both functional requirements and stringent industry standards for aerospace, medical, and industrial applications.

Start Your Project

Looking for high-quality GA aluminum components? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and dedicated facility in Shenzhen, Honyo Prototype delivers precision-engineered solutions tailored to your specifications. Trust our expertise in GA aluminum fabrication for superior performance and reliability. Reach out today to request a quote or schedule a consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.