Introduction: Navigating the Global Market for g code programming basics

In today’s rapidly evolving manufacturing landscape, understanding the fundamentals of G-code programming basics is crucial for B2B buyers seeking to optimize their CNC machining processes. As companies in regions like Africa, South America, the Middle East, and Europe (including Nigeria and Vietnam) increasingly integrate advanced technologies, the challenge of sourcing reliable G-code programming solutions becomes paramount. This guide aims to demystify G-code, offering insights into its various types, applications, and best practices, enabling buyers to make informed decisions.

Navigating the complex world of G-code involves more than just understanding its syntax; it requires a strategic approach to supplier vetting, cost analysis, and the integration of G-code with existing manufacturing processes. This comprehensive resource covers essential topics, including the most common G-code commands, software options for programming, and tips for optimizing machine performance. By equipping buyers with actionable insights and a clear understanding of G-code programming, this guide empowers businesses to enhance their operational efficiency, reduce costs, and ultimately improve product quality.

Whether you are a small manufacturer in Nigeria or a large enterprise in Europe, our in-depth exploration of G-code programming basics will help you leverage this critical technology to stay competitive in a global market. Embrace the future of manufacturing by mastering G-code and unlocking new opportunities for growth and innovation.

Understanding g code programming basics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard G-code | Based on RS-274 and ISO-6983, widely accepted and used. | CNC machining, 3D printing | Pros: Universally applicable, extensive support. Cons: Variations may lead to compatibility issues. |

| Fanuc G-code | A specific implementation of G-code by Fanuc controllers. | Automotive, aerospace industries | Pros: Robust and reliable for complex tasks. Cons: Limited to Fanuc systems. |

| Heidenhain G-code | Proprietary language for Heidenhain CNC machines. | High-precision machining | Pros: Excellent for intricate designs. Cons: Requires specific training and software. |

| Conversational G-code | User-friendly, often generated through wizards or prompts. | Small-scale manufacturing | Pros: Easy for beginners, faster setup. Cons: Less flexibility for complex projects. |

| CAM-Generated G-code | Created through CAM software from CAD models. | Large-scale production | Pros: Efficient for mass production, high accuracy. Cons: Requires investment in software and training. |

What are the Characteristics of Standard G-code and its Suitability for B2B Buyers?

Standard G-code is the foundational programming language for CNC machines, adhering to international standards like RS-274 and ISO-6983. This version is characterized by its broad applicability across various CNC systems, making it a staple for manufacturers engaged in CNC machining and 3D printing. B2B buyers should consider the compatibility of their machinery with standard G-code, as it ensures a smooth workflow and minimizes training requirements for operators. However, variations in G-code dialects can sometimes lead to compatibility issues, necessitating careful evaluation before purchase.

How Does Fanuc G-code Stand Out for Specific Industries?

Fanuc G-code is a proprietary variant commonly used in Fanuc CNC machines, particularly in industries like automotive and aerospace where precision and reliability are paramount. This type of G-code is distinguished by its extensive command set and robust performance in complex machining tasks. B2B buyers in these sectors should weigh the benefits of Fanuc G-code’s reliability against its limitation to Fanuc systems, which may require additional investment in compatible machines or training for operators.

Why Choose Heidenhain G-code for High-Precision Applications?

Heidenhain G-code is tailored for high-precision CNC machines, making it ideal for industries that demand intricate designs, such as aerospace and medical device manufacturing. Its proprietary nature allows for advanced functionalities that enhance machining accuracy. For B2B buyers, investing in Heidenhain-compatible systems can lead to superior product quality, but it also necessitates specialized training and software, which can increase overall costs.

What are the Benefits and Limitations of Conversational G-code?

Conversational G-code is designed to simplify the programming process, often utilizing wizard-like interfaces that guide users through the setup. This makes it particularly attractive for small-scale manufacturers or those new to CNC machining. B2B buyers can benefit from its ease of use and quicker setup times, which can enhance productivity. However, its limitations in handling complex projects may lead buyers to consider more traditional G-code for advanced manufacturing needs.

How Does CAM-Generated G-code Enhance Production Efficiency?

CAM-generated G-code is produced by Computer-Aided Manufacturing software from CAD designs, streamlining the transition from design to production. This type is particularly useful for large-scale production environments where accuracy and efficiency are critical. B2B buyers should consider the initial investment in CAM software and training, as it can significantly improve production efficiency and reduce errors. However, the reliance on software may also pose challenges in cases of system failures or software updates.

Key Industrial Applications of g code programming basics

| Industry/Sector | Specific Application of g code programming basics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining for Precision Parts | Enhanced accuracy and reduced material waste | Availability of skilled CNC programmers and machines |

| Aerospace | Component Fabrication with 3D Printing | Streamlined production of complex geometries | Compliance with strict safety and quality standards |

| Automotive | Tooling and Mold Making | Faster turnaround times and improved design flexibility | Access to advanced CAM software for G-code generation |

| Electronics | PCB Manufacturing and Prototyping | Increased efficiency in circuit board production | Need for high-precision CNC machines |

| Metal Fabrication | Sheet Metal Cutting and Forming | Cost-effective mass production with minimal errors | Supply chain reliability for raw materials |

How is G-code Programming Applied in Manufacturing?

In the manufacturing sector, G-code programming is pivotal for CNC machining of precision parts. By providing detailed instructions on tool movement, G-code minimizes human error and maximizes efficiency. For international buyers, particularly in emerging markets like Nigeria or Vietnam, sourcing high-quality CNC machines and skilled programmers is essential to maintain production standards and optimize operational costs.

What Role Does G-code Play in Aerospace Component Fabrication?

In the aerospace industry, G-code programming is utilized for fabricating intricate components through CNC machining and 3D printing. This application allows for the production of lightweight yet strong parts, crucial for aircraft performance. Buyers must ensure compliance with rigorous aerospace regulations and quality control standards, making the sourcing of certified materials and technology a top priority.

How is G-code Transforming Automotive Tooling and Mold Making?

G-code programming significantly enhances tooling and mold-making processes in the automotive industry. By enabling precise and repeatable machining, manufacturers can produce molds that meet exact specifications, reducing lead times and costs. Buyers should focus on the compatibility of G-code with various CAM software to ensure seamless integration into existing workflows, especially in regions with rapidly evolving automotive markets.

Why is G-code Important for Electronics PCB Manufacturing?

In electronics, G-code is crucial for PCB manufacturing and prototyping, allowing for high-precision drilling and routing. This application not only speeds up production but also ensures that circuit boards meet stringent performance criteria. International buyers need to consider sourcing advanced CNC machines capable of handling intricate designs, as well as ensuring a reliable supply of electronic components to maintain production flow.

What Benefits Does G-code Offer in Metal Fabrication?

In the metal fabrication industry, G-code programming facilitates efficient sheet metal cutting and forming processes. By automating these tasks, businesses can achieve higher production rates and lower costs while minimizing material waste. For buyers, it is vital to assess the reliability of suppliers for raw materials, as well as the availability of skilled labor to operate CNC machinery effectively, particularly in regions where these resources may be limited.

3 Common User Pain Points for ‘g code programming basics’ & Their Solutions

Scenario 1: Navigating G-code Complexity for New CNC Programmers

The Problem: Many B2B buyers entering the CNC machining space, particularly in regions like Africa and South America, often face overwhelming complexity when first learning G-code programming. The intricacies of commands, syntax, and structure can lead to confusion, resulting in costly errors and inefficient production processes. This challenge is particularly pronounced for companies trying to integrate new employees into their operations, as those with limited programming backgrounds struggle to grasp the basics.

The Solution: To alleviate this pain point, businesses should invest in comprehensive training programs tailored to G-code fundamentals. This could involve a combination of online courses, hands-on workshops, and mentoring from experienced CNC programmers. For instance, providing access to user-friendly G-code simulators can help new programmers practice without the risk of damaging expensive machinery. Additionally, creating a repository of cheat sheets and quick reference guides can serve as valuable resources for quick troubleshooting and command recall. Companies should also encourage a culture of continuous learning, allowing employees to share insights and strategies that promote proficiency in G-code programming.

Scenario 2: Standardization Challenges Across Different CNC Machines

The Problem: Many organizations operate various CNC machines from different manufacturers, each potentially using distinct dialects of G-code. This discrepancy can lead to significant challenges in programming consistency and machine compatibility, ultimately resulting in delays and increased operational costs. For companies operating in diverse markets such as the Middle East and Europe, the variation in G-code standards can complicate cross-border operations and limit the scalability of production.

The Solution: To address this issue, B2B buyers should prioritize the adoption of G-code programming that adheres to widely accepted standards, such as ISO-6983 or RS-274. Conducting a thorough analysis of the machines in use and their specific G-code requirements can help identify commonalities and differences. Companies can then develop standardized templates or macros that facilitate smoother transitions between different machines. Additionally, investing in advanced CAM (Computer-Aided Manufacturing) software can automate the conversion of CAD files into compatible G-code for various machines, reducing manual programming errors. Lastly, establishing a cross-training program for staff on multiple G-code dialects can enhance workforce versatility and mitigate the risks associated with machine-specific programming.

Scenario 3: Debugging and Error Resolution in G-code Programming

The Problem: Debugging G-code can be a daunting task for manufacturers, particularly when errors arise during the machining process. Missteps such as incorrect coordinates or feed rates can lead to wasted materials, machine downtime, and compromised product quality. This challenge is often exacerbated in high-stakes environments where precision is critical, causing frustration among operators and management alike.

The Solution: Implementing a robust error-checking protocol is essential for mitigating these issues. Businesses should utilize G-code simulation software that allows programmers to visualize and test their code before sending it to the machine. This step can significantly reduce the likelihood of errors going unnoticed. Furthermore, creating a standardized checklist for G-code verification—covering aspects such as axis movements, tool changes, and feed rates—can help programmers systematically identify potential issues. Additionally, fostering an environment that encourages open communication about common mistakes and solutions can enhance team knowledge and reduce error rates over time. Regular workshops focused on troubleshooting techniques and best practices can further empower teams to tackle G-code programming challenges effectively.

Strategic Material Selection Guide for g code programming basics

What Are the Key Materials for G-Code Programming Basics?

When selecting materials for applications involving G-code programming, particularly in CNC machining and 3D printing, several factors come into play. Understanding the properties, advantages, disadvantages, and specific considerations for international buyers is crucial for successful implementation. Below, we analyze four common materials: Aluminum, Steel, PLA (Polylactic Acid), and Nylon.

How Does Aluminum Perform in G-Code Programming?

Aluminum is widely used in CNC machining due to its lightweight nature and excellent machinability. Key properties include a high strength-to-weight ratio and good corrosion resistance, making it suitable for various applications in automotive and aerospace industries.

Pros:

– Lightweight and strong, which enhances performance and reduces energy consumption.

– Excellent thermal conductivity, which is beneficial for heat dissipation in high-speed applications.

– Relatively low cost compared to other metals.

Cons:

– Prone to scratching and denting, which may affect the aesthetic finish.

– Requires specific tooling and machining techniques to avoid deformation.

For international buyers, particularly in regions like Africa and South America, compliance with ASTM standards for aluminum alloys is essential. Understanding local material availability and sourcing can also influence cost and lead times.

What Are the Benefits of Using Steel in G-Code Programming?

Steel, particularly stainless steel, is another common material used in CNC machining. It offers high tensile strength and durability, making it ideal for heavy-duty applications.

Pros:

– Exceptional strength and toughness, suitable for high-stress applications.

– Corrosion-resistant varieties (like stainless steel) are available, enhancing longevity.

– Readily available and widely used, ensuring compatibility with various machining processes.

Cons:

– Heavier than aluminum, which may not be suitable for all applications.

– Higher machining complexity and costs due to the need for specialized tools.

For buyers in Europe and the Middle East, familiarity with DIN standards for steel grades is crucial. Additionally, understanding the local market for steel can help in negotiating costs effectively.

Why Choose PLA for G-Code Programming in 3D Printing?

PLA is a popular thermoplastic used in 3D printing, particularly for prototyping and low-stress applications. It is biodegradable and derived from renewable resources, making it an environmentally friendly option.

Pros:

– Easy to print with and requires lower temperatures than other materials, reducing energy consumption.

– Available in various colors and finishes, enhancing aesthetic appeal.

– Cost-effective for prototyping and small-scale production.

Cons:

– Not suitable for high-temperature applications, as it can deform under heat.

– Lower mechanical strength compared to other plastics and metals.

International buyers, especially in developing regions, may find PLA appealing due to its low cost and ease of use. However, they should consider local regulations regarding biodegradable materials and their disposal.

What Are the Key Considerations for Using Nylon in G-Code Programming?

Nylon is a versatile material known for its toughness and flexibility, making it suitable for functional parts in various industries, including automotive and consumer goods.

Pros:

– High impact resistance and durability, suitable for functional components.

– Good chemical resistance, allowing compatibility with various media.

– Can be easily dyed, offering customization options.

Cons:

– More expensive than other plastics, which could affect budget constraints.

– Requires careful handling during machining due to its tendency to absorb moisture.

For B2B buyers in regions like Africa and Vietnam, understanding JIS standards for nylon products can facilitate compliance and quality assurance. Additionally, considering the local availability of nylon can impact sourcing strategies.

Summary Table of Material Selection for G-Code Programming Basics

| Material | Typical Use Case for g code programming basics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | CNC machining for lightweight components | High strength-to-weight ratio | Prone to scratching | Medium |

| Steel | Heavy-duty applications in CNC machining | Exceptional strength | Higher machining complexity | Medium to High |

| PLA | 3D printing for prototypes | Easy to print and cost-effective | Not heat-resistant | Low |

| Nylon | Functional parts in various industries | High impact resistance | More expensive than other plastics | Medium to High |

By understanding these materials and their properties, international B2B buyers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for g code programming basics

What Are the Key Stages in the Manufacturing Process for G-Code Programming?

Understanding the manufacturing process is crucial for B2B buyers seeking to optimize their operations. The manufacturing process for G-code programming typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage requires specific techniques to ensure efficiency and quality.

How Does Material Preparation Impact G-Code Programming?

Material preparation is the first step in the manufacturing process. It involves selecting the right materials based on the specifications of the G-code program. This may include metals, plastics, or composites, which must be cut to size and treated to meet the required tolerances. Techniques such as laser cutting, water jet cutting, or CNC routing can be employed to achieve precise dimensions.

For B2B buyers, it is essential to collaborate with suppliers who have robust material handling procedures. This ensures that materials are free from defects and suitable for further processing. Additionally, understanding the material properties can help in selecting the appropriate G-code commands for effective machining.

What Techniques Are Used During the Forming Stage?

The forming stage is where the actual machining occurs. G-code programming instructs CNC machines on how to shape the material, typically involving processes such as milling, turning, and drilling. Each of these processes has its own set of G-code commands that dictate the machine’s movements and operations.

Common techniques include:

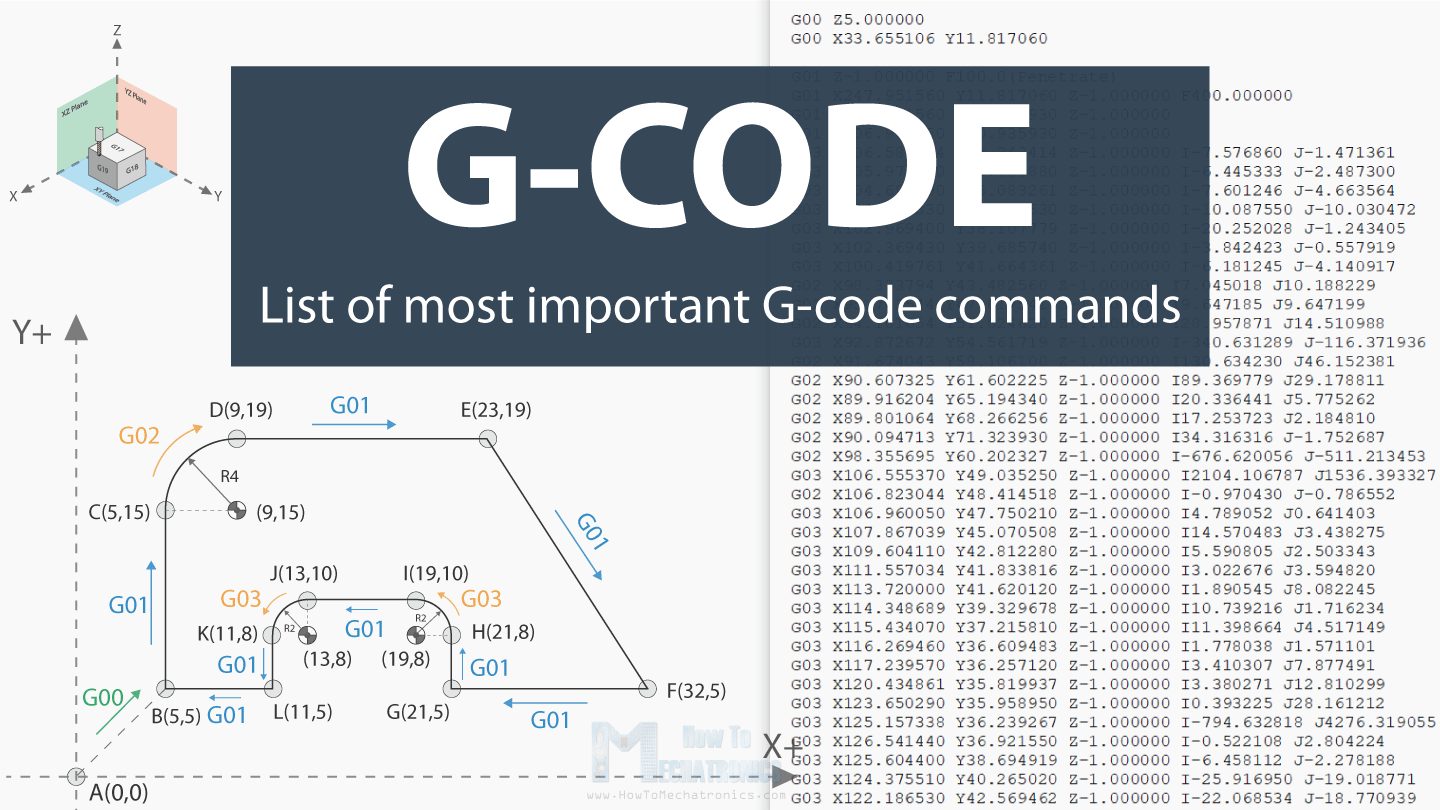

- CNC Milling: This involves rotating cutting tools to remove material from a workpiece. G-code commands like G01 and G02 are frequently used for linear and circular interpolation, respectively.

- Turning: Involves rotating the workpiece while a stationary cutting tool removes material. G-code commands for this process may differ slightly depending on the machine’s configuration.

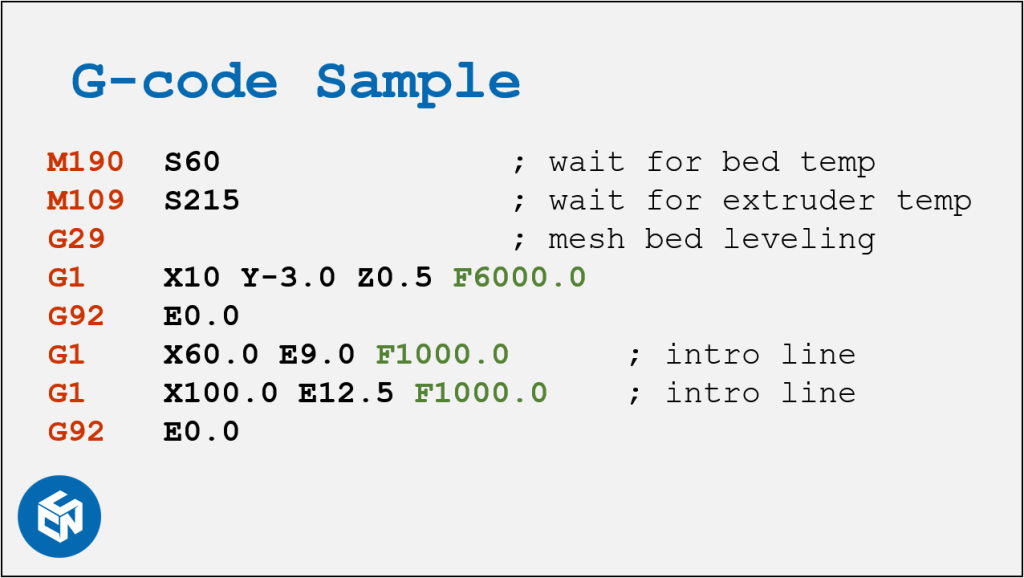

- 3D Printing: For additive manufacturing, G-code commands dictate the layer-by-layer deposition of material. Each layer is built according to the specified geometry in the G-code file.

B2B buyers should ensure that their suppliers utilize advanced CNC machinery capable of executing complex G-code programs efficiently, which is critical for maintaining competitive production rates.

How Does Assembly Fit into the G-Code Programming Process?

Assembly is the stage where individual components manufactured through G-code programming are brought together to create a finished product. While G-code primarily focuses on the machining aspects, it is essential for buyers to consider how assembly processes can be optimized.

Techniques such as automated assembly and the use of jigs can enhance precision and reduce labor costs. B2B buyers should inquire about the assembly capabilities of their suppliers and whether they employ automated systems that can integrate with CNC processes.

What Finishing Techniques Are Commonly Used After G-Code Programming?

Finishing is the final stage in the manufacturing process and involves refining the surface of the machined parts. Techniques such as sanding, polishing, anodizing, and coating are commonly applied to enhance appearance and performance. The choice of finishing technique can significantly impact the final product’s quality and durability.

B2B buyers must verify that their suppliers have the necessary equipment and expertise in finishing processes that align with their product requirements. This ensures that the finished components meet industry standards and customer expectations.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is critical in ensuring that the G-code programming and subsequent manufacturing processes yield high-quality products. International standards such as ISO 9001 set the benchmark for quality management systems across various industries. Compliance with these standards demonstrates a commitment to quality and continuous improvement.

How Do Industry-Specific Certifications Affect Quality Assurance?

In addition to general QA standards, industry-specific certifications such as CE marking for European markets or API certification for oil and gas can be pivotal for certain sectors. These certifications often require rigorous testing and documentation, ensuring that products meet regulatory and safety standards.

B2B buyers should prioritize suppliers who hold relevant certifications, as this can mitigate risks associated with non-compliance and enhance product reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early and reduce waste.

- Final Quality Control (FQC): A comprehensive review of the finished product before it is shipped to customers.

By implementing these QC checkpoints, B2B buyers can ensure that their suppliers maintain consistent quality throughout the production cycle.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are utilized in the manufacturing industry to verify the quality of G-code programmed parts:

- Dimensional Inspection: Using tools like calipers and coordinate measuring machines (CMM) to ensure components meet specified dimensions.

- Functional Testing: Assessing the performance of the finished product under operational conditions.

- Material Testing: Conducting tests such as tensile strength or hardness to verify material properties.

B2B buyers should ask suppliers about their testing protocols and the equipment they use to ensure comprehensive quality evaluations.

How Can B2B Buyers Verify Supplier Quality Control Effectiveness?

To ensure that suppliers adhere to high-quality standards, B2B buyers can take several proactive steps:

- Conduct Audits: Regular audits of supplier facilities can provide insight into their manufacturing processes and quality control practices.

- Request Quality Reports: Suppliers should be able to provide detailed reports on their QC processes, including inspection results and compliance with standards.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s quality control measures and product reliability.

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and regulations, which can affect the selection of suppliers. Buyers must be aware of:

- Local Regulations: Ensure that suppliers comply with local laws and standards in the target market.

- Cultural Differences: Recognize that quality expectations and manufacturing practices may vary across regions, necessitating clear communication.

- Documentation Requirements: Be prepared to manage extensive documentation, especially when importing products that must meet specific certifications.

By being diligent in these areas, B2B buyers can effectively navigate the complexities of international sourcing and ensure the quality of products manufactured through G-code programming.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘g code programming basics’

Introduction

Navigating the procurement of G-code programming basics is essential for B2B buyers looking to enhance their manufacturing capabilities. This guide serves as a practical checklist to help you evaluate your needs, identify potential suppliers, and ensure that you receive high-quality G-code programming solutions tailored to your specific requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specific G-code requirements for your CNC machines or 3D printers. This includes understanding the types of materials you will be working with, the complexity of the parts you intend to manufacture, and the precision needed in your operations. Defining these specifications upfront helps streamline the procurement process and ensures that suppliers can meet your exact needs.

Step 2: Research Industry Standards and G-code Variants

Familiarize yourself with the various G-code standards relevant to your industry, such as ISO-6983 or RS-274, and their specific applications. Different CNC machines may use proprietary G-code dialects, so understanding these distinctions will aid in selecting compatible programming solutions. This knowledge will also help you communicate effectively with suppliers about your requirements.

Step 3: Evaluate Potential Suppliers

Before making any commitments, conduct thorough evaluations of potential suppliers. Request detailed company profiles, including case studies and references from similar industries or regions. Look for suppliers who demonstrate a proven track record in G-code programming and can provide examples of successful projects.

- Checklist for Evaluation:

- Confirm their experience with your specific CNC machines.

- Assess their ability to provide ongoing support and updates.

Step 4: Verify Supplier Certifications and Quality Assurance

Ensure that your selected suppliers possess the necessary certifications that validate their expertise in G-code programming. Certifications can indicate adherence to industry standards and best practices, which is crucial for maintaining quality control in your manufacturing processes.

- Key Certifications to Look For:

- ISO 9001 for quality management systems.

- Relevant industry-specific certifications.

Step 5: Request Samples or Prototypes

Before finalizing your order, ask suppliers to provide samples or prototypes of their G-code programming outputs. This hands-on evaluation allows you to assess the quality, precision, and suitability of the programming for your specific applications. It also provides an opportunity to identify any potential issues early in the process.

Step 6: Assess Technical Support and Training Options

Inquire about the technical support and training services offered by your suppliers. A reliable supplier should provide comprehensive training on G-code programming and troubleshooting, ensuring that your team can efficiently operate and maintain the CNC machinery.

- Considerations for Support:

- Availability of online resources, manuals, and customer service.

- Options for on-site training and ongoing technical assistance.

Step 7: Negotiate Terms and Finalize Contracts

Once you have selected a supplier that meets your criteria, engage in negotiations to finalize terms and conditions. Focus on aspects such as pricing, delivery timelines, warranty provisions, and payment terms. A well-defined contract will protect your interests and ensure a smooth procurement process.

By following this checklist, B2B buyers can effectively navigate the complexities of procuring G-code programming basics, ensuring that they make informed decisions that align with their operational needs and goals.

Comprehensive Cost and Pricing Analysis for g code programming basics Sourcing

What Are the Key Cost Components in G-Code Programming Basics Sourcing?

When sourcing G-code programming services, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: While G-code itself is a digital product, the costs associated with its application involve the materials used in CNC machining or 3D printing. This could range from metals, plastics, and composites, which vary significantly in price depending on quality and sourcing locations.

-

Labor: Skilled labor is essential for effective G-code programming. This includes CNC programmers and machine operators who understand G-code intricacies. Labor costs can vary widely based on geographic location, skill level, and the complexity of the programming required.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and equipment depreciation. Efficient operations can significantly reduce overhead costs, influencing the overall pricing of G-code programming services.

-

Tooling: The tools required for CNC machining and 3D printing can be significant cost factors. The choice of tooling affects both the quality of the output and the efficiency of the production process, impacting the final pricing of G-code services.

-

Quality Control (QC): Ensuring that the G-code produced meets quality standards involves additional costs. This includes inspection processes, testing of machined parts, and adherence to certifications, which can vary based on industry requirements.

-

Logistics: For international buyers, logistics costs must be factored in. This includes shipping, handling, customs duties, and any associated fees, which can vary significantly depending on the origin and destination of the materials or services.

-

Margin: Suppliers will add a margin to cover their risks and ensure profitability. This margin can fluctuate based on competition, demand, and the perceived value of the service.

How Do Price Influencers Affect G-Code Programming Costs?

Several factors influence pricing in G-code programming:

-

Volume/MOQ: Larger orders may lead to economies of scale, reducing per-unit costs. Minimum order quantities (MOQ) often apply, and negotiating these can benefit buyers looking to reduce expenses.

-

Specifications and Customization: Custom G-code programming tailored to specific machine types or production processes can incur additional costs. Clearly defining specifications upfront can help manage costs effectively.

-

Materials and Quality Certifications: The choice of materials not only impacts the price but also the quality of the final product. Suppliers with quality certifications may charge a premium, reflecting their commitment to high standards.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their track record and reliability, while newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding international shipping terms is essential for calculating the total landed cost. Incoterms dictate who bears responsibility for shipping costs and risks, impacting the overall price.

What Are the Best Buyer Tips for Cost-Efficiency in G-Code Programming?

To ensure cost-efficiency when sourcing G-code programming services, consider the following tips:

-

Negotiate Terms: Always negotiate payment terms, including bulk discounts and payment schedules, to improve cash flow and reduce upfront costs.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial price but the long-term costs associated with the G-code programming, including maintenance, operational efficiency, and potential rework costs.

-

Understand Pricing Nuances for International Buyers: Be aware of regional pricing variations, customs duties, and logistics challenges that could affect overall costs. Building relationships with local suppliers in Africa, South America, the Middle East, and Europe can yield better pricing and terms.

-

Leverage Technology: Utilize CNC programming software that integrates G-code generation and editing to minimize labor costs and improve efficiency. This can also lead to a reduction in material waste and machine setup times.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in G-code programming basics is essential for B2B buyers. By analyzing these factors and employing strategic sourcing tactics, businesses can achieve significant cost savings while ensuring high-quality outputs. Always keep in mind that indicative prices can fluctuate based on market conditions and specific project requirements.

Alternatives Analysis: Comparing g code programming basics With Other Solutions

Introduction to Alternative Solutions for G-Code Programming

When it comes to CNC machining and additive manufacturing, G-code programming serves as a foundational language. However, it is essential for B2B buyers to explore alternative solutions that may better suit their specific operational needs. Various programming methods and software solutions exist, each with distinct advantages and drawbacks, offering potential enhancements in performance, cost-effectiveness, and ease of use.

Comparison of G-Code Programming Basics with Alternative Solutions

| Comparison Aspect | G-Code Programming Basics | CAM Software | Conversational Programming Software |

|---|---|---|---|

| Performance | High precision; widely used | Excellent for complex designs; automates toolpath generation | Good for simple tasks; quick setup |

| Cost | Low (text-based) | Moderate to high (software licenses) | Low to moderate (often bundled with machines) |

| Ease of Implementation | Moderate (requires coding skills) | Requires initial learning; integrates with CAD | User-friendly; minimal coding knowledge needed |

| Maintenance | Low (text file edits) | Moderate (software updates) | Low (minimal ongoing maintenance) |

| Best Use Case | General CNC and 3D printing | Complex, high-volume production | Small-scale or one-off projects |

Detailed Breakdown of Alternatives

CAM Software

Computer-Aided Manufacturing (CAM) software is designed to streamline the CNC programming process by converting CAD models into G-code. This method is highly effective for complex and intricate designs, as it automates the generation of tool paths. While CAM software can be costly due to licensing fees, it significantly reduces the time and labor involved in programming, making it ideal for manufacturers focused on high-volume production. However, the learning curve may be steep for users unfamiliar with CAD software.

Conversational Programming Software

Conversational programming software simplifies CNC programming by allowing users to input commands through a series of guided prompts instead of writing code manually. This approach is particularly beneficial for small-scale operations or one-off projects where speed and ease of use are paramount. While it is generally user-friendly, this software may lack the depth of control that experienced programmers find in traditional G-code programming. Consequently, it may not be suitable for complex tasks that require nuanced programming techniques.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate programming solution involves assessing the specific requirements of your CNC operations. For B2B buyers, understanding the trade-offs between G-code programming basics, CAM software, and conversational programming software is crucial. Consider factors such as production volume, complexity of designs, and available budget. By aligning these considerations with the strengths of each method, businesses can optimize their manufacturing processes and achieve greater efficiency and precision in their operations.

Essential Technical Properties and Trade Terminology for g code programming basics

What Are the Key Technical Properties of G-code Programming?

Understanding the essential technical properties of G-code programming is vital for businesses engaged in CNC machining or additive manufacturing. Here are some critical specifications that should be considered:

-

Precision and Tolerance

– Precision refers to how closely the manufactured part aligns with the desired specifications. Tolerance defines the acceptable range of variation in a dimension. In B2B contexts, tighter tolerances often translate to higher production costs. Understanding precision and tolerance is crucial for buyers to ensure that parts meet functional requirements without incurring unnecessary expenses. -

Material Compatibility

– Different materials require specific G-code commands to achieve optimal machining results. For instance, metals may need slower feed rates compared to plastics. Buyers must be aware of material compatibility to select the right machinery and programming methods, ensuring efficiency and minimizing waste. -

Feed Rate

– The feed rate specifies the speed at which the tool moves through the material. It affects both the quality of the finished product and the overall efficiency of the machining process. In a B2B setting, understanding how to adjust the feed rate can lead to cost savings and improved productivity, making it a crucial factor in CNC programming. -

Axis Configuration

– CNC machines can have different axis configurations (e.g., 3-axis, 5-axis). The complexity of the G-code increases with the number of axes. Businesses must consider their machining needs when choosing a machine, as more axes allow for more complex geometries but may also increase programming time and costs. -

G-code Standards

– Various G-code standards exist (e.g., Fanuc, Haas), each with unique commands and structures. Familiarity with these standards is essential for ensuring compatibility between machines and software. For B2B buyers, understanding these standards can streamline the procurement process and ensure that machinery can effectively communicate with existing systems.

What Are Common Trade Terms in G-code Programming?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms related to G-code programming:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that manufactures products or components that are sold by another company under its brand. Understanding the role of OEMs is essential for buyers looking to source reliable machinery or components, as it can affect pricing, quality, and service support. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for businesses that need to manage inventory costs and ensure they are not overcommitting financially. Being aware of MOQ can help buyers negotiate better terms and optimize their purchasing strategy. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This term is crucial for B2B buyers to understand, as it facilitates the procurement process and helps ensure competitive pricing. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowledge of Incoterms is vital for B2B transactions, especially for companies operating in multiple countries, as it can significantly impact the total cost of goods. -

CAM (Computer-Aided Manufacturing)

– CAM refers to software that automates the manufacturing process by generating G-code from CAD (Computer-Aided Design) models. Understanding CAM can help businesses optimize their production workflows and reduce lead times, making it a critical aspect of modern manufacturing.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of G-code programming, leading to better decision-making and more efficient procurement processes.

Navigating Market Dynamics and Sourcing Trends in the g code programming basics Sector

What Are the Current Market Dynamics Influencing G-Code Programming Basics?

The global market for G-code programming is being driven by advancements in automation and the increased adoption of CNC (Computer Numerical Control) technology across various industries, including manufacturing, aerospace, and automotive. As businesses seek to enhance production efficiency, the demand for skilled CNC programmers who understand G-code is on the rise. Emerging technologies such as Artificial Intelligence (AI) and Machine Learning (ML) are also influencing how G-code is generated and optimized, enabling more precise and efficient machining processes.

International B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, should be aware of the growing trend towards integrating G-code programming with CAD/CAM software. This integration simplifies the transition from design to production, allowing companies to streamline operations. Additionally, the trend of digitalization in manufacturing is paving the way for cloud-based solutions that facilitate remote programming and monitoring of CNC machines, thus enhancing collaboration and reducing downtime.

Moreover, the sourcing of G-code programming services is evolving. Buyers are increasingly looking for suppliers who offer comprehensive training programs, ensuring their teams are well-versed in the latest G-code standards and practices. This reflects a shift towards building long-term partnerships with suppliers who can provide ongoing support and innovation in programming solutions.

How Are Sustainability and Ethical Sourcing Impacting the G-Code Programming Sector?

Sustainability has become a critical consideration for international buyers in the G-code programming sector. The environmental impact of CNC machining, particularly regarding waste generation and energy consumption, is prompting companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems.

Ethical sourcing is also gaining traction as businesses recognize the importance of maintaining transparent supply chains. Companies are now expected to not only evaluate the technical capabilities of their suppliers but also their ethical practices, including labor standards and sourcing of materials. Buyers should seek partnerships with suppliers who utilize environmentally friendly materials and processes, thereby contributing to a more sustainable manufacturing ecosystem.

Furthermore, the incorporation of “green” certifications into G-code programming services is becoming more prevalent. Suppliers who can provide evidence of their sustainable practices, such as the use of recycled materials in tooling and reduced energy consumption in machining processes, will likely gain a competitive edge in the market.

What Is the Brief Evolution of G-Code in the B2B Landscape?

G-code has evolved significantly since its inception in the mid-20th century. Originally developed as a simple programming language for controlling CNC machines, it has undergone several revisions to accommodate the growing complexity of modern manufacturing processes. Early versions of G-code were limited in functionality, but as CNC technology advanced, so too did the programming language, integrating features that support intricate machining operations.

In recent years, the shift towards automation and the integration of software solutions have further transformed G-code programming. The emergence of CAM (Computer-Aided Manufacturing) software has streamlined the process of generating G-code from CAD designs, enabling manufacturers to produce parts with greater accuracy and efficiency. This evolution reflects a broader trend in the B2B landscape, where technological advancements are driving the need for skilled programmers who can adapt to new tools and methodologies in G-code programming.

As the G-code programming sector continues to evolve, international buyers must stay informed about these changes to leverage the latest advancements and maintain a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of g code programming basics

-

How do I solve issues with G-code compatibility across different CNC machines?

To resolve compatibility issues with G-code across various CNC machines, first, familiarize yourself with the specific G-code dialect used by each machine. Different manufacturers may implement variations of G-code, such as Fanuc or Haas. Ensure that your G-code is compliant with the machine’s standards by consulting the machine’s manual or manufacturer resources. Additionally, using CAM software can help generate machine-specific G-code, minimizing errors. Testing the G-code on a simulation software can also help identify potential issues before actual machine operation. -

What is the best method for learning G-code programming for CNC machines?

The best method for learning G-code programming involves a combination of theoretical knowledge and practical application. Start with comprehensive online courses or tutorials that cover the fundamentals of G-code and CNC operations. Hands-on experience is crucial; therefore, utilize simulation software to practice writing and modifying G-code. Joining forums or community groups related to CNC programming can provide support and additional resources. Finally, consider mentorship or training sessions with experienced CNC programmers to gain insights and tips that enhance your learning process. -

What are the key factors to consider when vetting G-code programming suppliers?

When vetting suppliers for G-code programming, assess their technical expertise in CNC programming and experience with your specific machine types. Request samples of their previous work to evaluate their programming quality and accuracy. It’s also essential to check customer testimonials and references. Ensure they have a clear understanding of industry standards and regulations, especially concerning quality assurance. Lastly, consider their ability to provide ongoing support and training, which can be crucial for long-term partnerships. -

How can I customize G-code programming to meet specific production requirements?

Customizing G-code programming involves adjusting parameters to fit your specific production needs. Start by defining the desired part specifications and machining processes. Then, modify the G-code commands to reflect the necessary movements, speeds, and toolpath adjustments. Utilize CAM software to help visualize and refine the toolpaths before finalizing the G-code. Collaborating with your programming supplier can also facilitate customization, ensuring they understand your requirements and can implement them effectively. -

What minimum order quantities (MOQs) should I expect from G-code programming service providers?

Minimum order quantities (MOQs) for G-code programming services can vary significantly based on the supplier’s business model and the complexity of the project. For small-scale projects, some suppliers may offer flexible MOQs or even accept single-piece orders, especially for prototypes. However, larger projects may have higher MOQs to justify the programming time and resources. Always discuss your specific needs with potential suppliers to negotiate terms that align with your production requirements and budget constraints. -

What payment terms are typically offered by G-code programming suppliers?

Payment terms for G-code programming services can range from upfront payments to post-delivery payments, depending on the supplier’s policies and the project scope. Common arrangements include a 50% deposit before work begins, with the remaining balance due upon completion. Some suppliers may offer discounts for early payments or bulk orders. It’s essential to clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that provide protection against fraud. -

How can I ensure quality assurance (QA) in G-code programming?

To ensure quality assurance in G-code programming, establish clear specifications and standards before the project begins. Implement a rigorous review process where the G-code is checked for accuracy and compliance with your requirements. Utilizing simulation software can help identify potential issues before actual machining. Additionally, consider setting up a feedback loop where operators can report any problems encountered during production, allowing for continuous improvement in programming quality. -

What logistical considerations should I keep in mind when sourcing G-code programming services internationally?

When sourcing G-code programming services internationally, consider the logistical implications such as shipping times, customs regulations, and potential tariffs that may affect overall costs. Ensure that your supplier has experience with international shipping and understands the required documentation for cross-border transactions. Communication is vital; choose suppliers who are responsive and can provide updates throughout the process. Lastly, factor in time zones and language barriers that may impact coordination and project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 G Code Programming Basics Manufacturers & Suppliers List

1. HowToMechatronics – Understanding G-Code for CNC and 3D Printing

Domain: howtomechatronics.com

Registered: 2015 (10 years)

Introduction: G-code is a programming language for CNC machines and 3D printers, used to instruct machines on movement, speed, and path. Key commands include: G00 (Rapid Positioning), G01 (Linear Interpolation), G02 (Circular Interpolation Clockwise), G03 (Circular Interpolation Counterclockwise), G20/G21 (Units Selection), G17/G18/G19 (G-code Plane Selection), G28 (Return Home), G90/G91 (Positioning). G-code c…

2. GCodeTutor – CNC Programming Courses

Domain: gcodetutor.com

Registered: 2018 (7 years)

Introduction: CNC G Codes – Learn how to program CNC machines with G-Code. Courses offered include: Professional G-Code Foundation, GCode Course, CNC Lathe Programming, CNC Mill Programming, CNC Macro Programming, CAD/CAM Fusion 360 for CNC Mills, Fusion 360 for CNC Lathes, Machine Shop Maths, Speeds and Feeds mini-course, Metrology – GD&T measuring equipment, Machine Shop Safety, Hobbyist CNC router programmin…

3. Reddit – CNC Resources

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. The Hobbyist’s Guide to CNC by Dennis Grant

2. Peter Smid’s book on CNC programming (specific edition not mentioned, but noted as a good resource)

3. Machinery’s Handbook (considered a comprehensive reference for machining and mechanical engineering)

4. YouTube Channels:

– Fusion 360 School

– Claas Kuhnen

– Clough42

– Andrew Klein

– Jeremy Fielding

– NYC CNC (focus on machinin…

4. Practical Machinist – G-Code Learning Resources

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: The discussion revolves around learning manual G-coding for CNC machining, with a focus on writing simple G-code programs such as machine warm-up routines. Participants suggest various resources for learning, including YouTube videos and machine manuals, particularly for HAAS machines. A specific recommendation is made for the “CNC Programming Handbook” by Peter Smid, which is widely used in educa…

5. All3DP – G-Code Tutorial

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: This company, All3DP – G-Code Tutorial, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for g code programming basics

How Can Understanding G-code Programming Drive Your Business Forward?

In conclusion, mastering G-code programming is essential for international B2B buyers engaged in CNC machining and additive manufacturing. Understanding the core commands—such as G00 for rapid positioning, G01 for linear interpolation, and G02 for circular interpolation—empowers businesses to optimize production processes and enhance precision in manufacturing. By strategically sourcing G-code programming expertise and resources, companies can streamline operations, reduce costs, and improve product quality, ultimately leading to a competitive advantage in the global market.

The value of strategic sourcing extends beyond mere cost savings; it includes the ability to tap into specialized knowledge, innovative technologies, and robust support systems that can drive efficiency and productivity. For businesses in regions like Africa, South America, the Middle East, and Europe, leveraging local expertise while staying abreast of global trends can unlock new opportunities for growth.

As you consider your next steps, prioritize partnerships with suppliers and experts who can provide the necessary training and tools to elevate your G-code programming capabilities. By doing so, you position your organization to meet the evolving demands of the manufacturing landscape and to seize the opportunities that lie ahead.