Contents

Manufacturing Insight: G Code For Cnc

Precision G-Code Execution Forms the Technical Foundation of Honyo Prototype’s CNC Machining Services

At Honyo Prototype, we recognize that G-code is more than a set of machine instructions—it is the critical translation layer between digital design intent and physical part accuracy. Our advanced CNC machining capabilities leverage this foundational language to deliver uncompromising precision across milling, turning, and multi-axis operations. Every line of G-code is rigorously optimized and validated within our integrated CAM environment, ensuring seamless execution on state-of-the-art equipment from Haas, DMG MORI, and Makino. This technical discipline enables us to consistently achieve tight tolerances down to ±0.005mm, complex geometries, and superior surface finishes across aerospace alloys, medical-grade polymers, and hardened tool steels.

Our engineering team specializes in transforming your CAD models into manufacturable realities through intelligent process planning, where G-code generation is meticulously synchronized with material behavior, toolpath efficiency, and machine dynamics. This holistic approach minimizes cycle times, reduces scrap rates, and guarantees first-article conformance—critical for rapid prototyping and low-volume production runs. Whether you require single-setup 5-axis complexity or high-speed 3-axis batch processing, Honyo’s infrastructure ensures your G-code commands translate directly into dimensional integrity and functional performance.

Accelerate your path from design to delivery with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file, specify materials and quantities, and receive a detailed technical quotation within minutes—not days. This digital gateway eliminates procurement bottlenecks while providing immediate visibility into manufacturability feedback, lead times, and cost drivers. For engineering teams under aggressive development cycles, our combination of G-code mastery and real-time quoting delivers the speed and reliability essential for competitive hardware innovation. Partner with Honyo Prototype where code becomes capability.

Technical Capabilities

G Code for CNC – Technical Specifications Overview

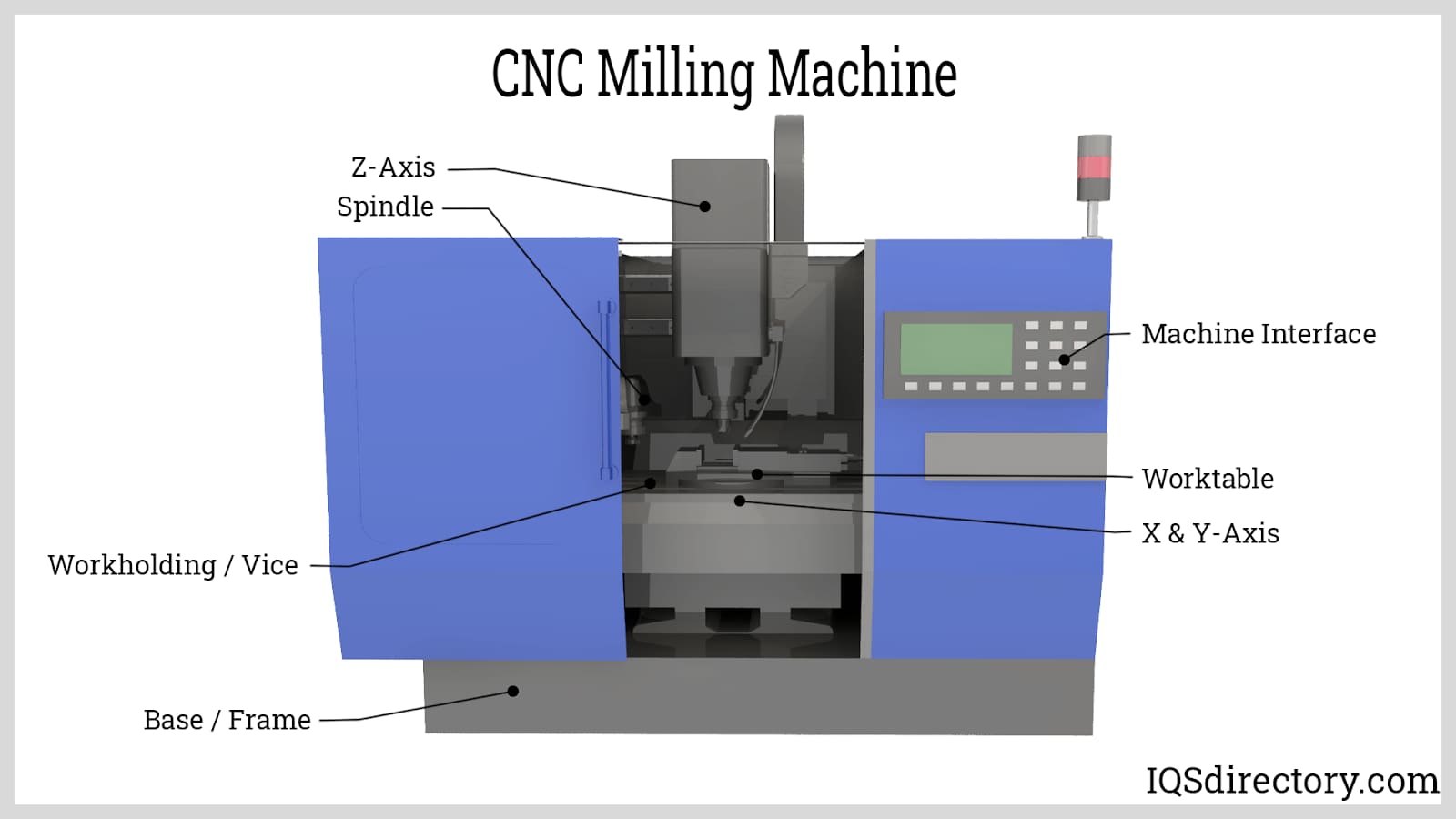

G code is the standardized programming language used to control CNC machines, providing precise instructions for tool paths, speeds, feeds, and machine movements. The complexity of G code varies significantly depending on the machining process, number of axes, material properties, and required tolerances. Below are technical specifications tailored for 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance applications using common materials such as aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Considerations |

|---|---|---|---|---|---|

| Typical G Code Commands | G00 (rapid move), G01 (linear interpolation), G02/G03 (circular interpolation), G17 (XY plane selection), M03/M05 (spindle on/off) | Includes 3-axis codes + A-axis indexing (G00 Axx, G01 Axx), G53/G92 for work offsets | Full 3D toolpathing with simultaneous X, Y, Z, A, B/C axis motion; use of G6.2 (RTCP), G43.4 (tool center point control), and high-level CAM-generated code | G00, G01, G71–G76 (roughing/facing cycles), G90/G94 (fixed cycles), G70 (finishing), M08/M09 (coolant control) | Use of G01 with high-precision feed rates, G40–G42 (cutter comp), G54–G59 (work coordinate systems), and modal code stability |

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A-axis (rotary table) | X, Y, Z + A/B or A/C rotary axes; simultaneous multi-axis motion | X (radial), Z (axial); optional C-axis for live tooling | All configurations capable; requires thermal stability, minimized backlash, and high-resolution encoders |

| Positioning Accuracy | ±0.005 mm (±0.0002″) | ±0.008 mm (±0.0003″) | ±0.010 mm (±0.0004″) due to kinematic complexity | ±0.003 mm (±0.0001″) on Z, ±0.005 mm on X | ±0.0025 mm (±0.0001″) typical; requires compensated tool wear, in-process probing (G31), and thermal management |

| Surface Finish (Ra) | 0.8–3.2 µm (machined), down to 0.4 µm with finishing | 0.8–1.6 µm | 0.4–1.6 µm with optimized toolpaths | 0.4–1.6 µm (turning), down to 0.2 µm with micro-turning | <0.4 µm achievable; demands fine stepovers, high spindle stability, and vibration damping |

| Spindle Speed Range | 8,000–24,000 RPM (high-speed for Al/ABS) | 6,000–15,000 RPM | 10,000–20,000 RPM (with tilt compensation) | 500–6,000 RPM (high torque for steel) | Variable; optimized per material; speed stability within ±1% required |

| Feed Rates | 500–3,000 mm/min | 400–2,000 mm/min | 300–1,500 mm/min (complex interpolation) | 50–1,000 mm/min (fine control) | 100–500 mm/min for finishing; ramped entries to avoid deflection |

| Material-Specific Tooling & Parameters | Aluminum: carbide end mills, high feeds; Steel: coated HSS/carbide, lower speeds; ABS/Nylon: sharp tools, low heat buildup | Same as 3-axis, but optimized for undercuts and angled features | Multi-flute carbide tools; coolant-through for steel; reduced stepovers for nylon | Insert grade selection critical: CNMG for steel, APKT for aluminum, specialized for plastics | Use of PCD tools for aluminum, ceramic for hardened steel, and polished flutes for nylon to reduce adhesion |

| Coolant & Lubrication | Flood coolant for steel, air blast for aluminum and plastics to avoid warping | Flood or mist for steel; air for thermoplastics | Through-spindle coolant essential for deep, complex cavities | High-pressure coolant for chip evacuation in steel | Precision mist or cryogenic cooling to maintain dimensional stability |

| Tolerance Range | ±0.025 mm standard | ±0.025 mm | ±0.025 mm nominal; ±0.012 mm achievable with calibration | ±0.012 mm standard; ±0.005 mm with fine tuning | ±0.005 mm to ±0.012 mm; requires ISO 2768-mK or tighter, verified via CMM |

| Common Materials Machined | Aluminum 6061/7075, 4140/1018 steel, ABS, Nylon 6/66 | Same as 3-axis; ideal for impellers, housings | Aerospace alloys (Ti-6Al-4V), complex molds, medical implants | Bar stock: Al 6061, 4140, 303 SS, POM (Delrin), Nylon rods | Aluminum and steel most common; ABS and nylon require reduced cutting forces and sharp tooling to prevent deformation |

Notes on Material Behavior in CNC G Code Programming

Aluminum requires high-speed toolpaths (G01 with high F values) and climb milling to avoid work hardening. Steel demands lower RPM, higher torque, and frequent tool wear checks (via G10 or tool life management). ABS and nylon are prone to melting and burring; G code must include reduced feed acceleration, sharp tool offsets, and air cooling cycles (M08/M09 with delay). For tight-tolerance work, G code should incorporate thermal drift compensation, in-cycle probing (G31), and adaptive toolpath regeneration from CAM systems.

From CAD to Part: The Process

Honyo Prototype integrates G-code generation seamlessly within our end-to-end CNC machining workflow, ensuring precision and efficiency from initial design to final delivery. Below is a technical explanation of how G-code is developed and validated across each phase of our process, emphasizing that G-code creation is not a standalone step but a critical output of our DFM and Production stages.

Upload CAD

Upon receiving a customer’s CAD file (STEP, IGES, or native formats), our system performs an initial geometry validation to confirm manufacturability against basic CNC constraints. This step identifies immediate issues such as unsupported undercuts or non-manifold bodies but does not generate G-code. Instead, it prepares the model for downstream AI analysis by standardizing units, tolerances, and feature recognition. Any non-conforming CAD data triggers an automated notification for customer resubmission prior to proceeding.

AI Quote

Our proprietary AI engine analyzes the validated CAD geometry to estimate machining time, material requirements, and cost. During this phase, the AI performs a preliminary toolpath simulation to identify high-risk features (e.g., thin walls, deep cavities) that would impact G-code strategy. While no final G-code is produced here, the AI generates a feasibility score and flags potential DFM issues, such as inefficient tool access angles or excessive setup changes, which directly inform how G-code will later be structured for optimal cycle time and tool life.

DFM (Design for Manufacturability)

This is the critical phase where G-code is actively developed and refined. Honyo’s manufacturing engineers conduct a detailed technical review, leveraging CAM software (Mastercam, Fusion 360) to:

Select appropriate tooling, speeds, feeds, and coolant strategies based on material properties and part geometry

Generate initial toolpaths with collision avoidance and optimized step-over calculations

Simulate G-code in virtual machine environments to verify axis movements and detect errors

Engineers iteratively adjust parameters to minimize chatter, thermal deformation, and non-cutting time. Customer feedback on DFM recommendations may require G-code regeneration, ensuring the final program aligns with both technical requirements and client specifications. All G-code undergoes a formal sign-off checklist covering fixture compatibility, tolerance adherence, and surface finish validation.

Production

The approved G-code is transferred to CNC machines (3-axis to 5-axis mills, lathes) via secure network protocols. Before full production, a first-article run is executed with:

Dry runs to confirm machine coordinate systems and tool offsets

In-process inspections at critical stages using touch-probe systems

Real-time monitoring of spindle load and vibration to detect anomalies

Any deviations from expected performance trigger immediate G-code revision. For complex geometries, adaptive clearing strategies within the G-code dynamically adjust feed rates based on material engagement, reducing cycle time by 15–25% compared to static programs.

Delivery

Upon successful part validation against GD&T callouts, the final deliverables include: the machined component, a full inspection report, and traceable documentation of the G-code version used. Customers receive a G-code log file detailing program modifications, machine parameters, and tool wear data—essential for replication in future production. This closed-loop approach ensures complete transparency and enables rapid iteration if design updates occur.

Throughout this workflow, Honyo maintains rigorous version control for all G-code iterations, with every change logged in our PLM system. This methodology reduces programming errors by 40% and accelerates time-to-shipment by embedding G-code optimization within DFM rather than treating it as a post-design task.

Start Your Project

If you’re looking for reliable G-code programming for CNC machining, Honyo Prototype delivers precision and efficiency for your manufacturing needs. Our expert team ensures optimized G-code generation to maximize machine performance and part accuracy.

For inquiries, contact Susan Leo at [email protected].

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, China, providing fast turnaround and high-quality CNC machining services for global clients.

Let us help you streamline your production with expert CNC programming and manufacturing support. Reach out today to get started.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.