Contents

Manufacturing Insight: G-Code Cnc Machine

Precision CNC Machining Powered by Expert G-Code Execution

At Honyo Prototype, we transform complex engineering designs into high-integrity components through advanced CNC machining services anchored in meticulous G-code programming and optimization. Our engineering team leverages deep expertise in G-code generation to ensure every toolpath maximizes precision, surface finish, and material integrity across multi-axis milling, turning, and Swiss-type operations. Unlike standard machine shops, we treat G-code not merely as machine instructions but as a critical engineering layer—refining feeds, speeds, and clearance strategies to eliminate errors before metal is cut, directly impacting your part’s geometric tolerances and production efficiency.

This technical rigor enables us to consistently deliver prototypes and low-volume production parts within tight tolerances (±0.0002″ / ±0.005 mm) for aerospace, medical, and industrial clients, using premium alloys, plastics, and composites. We streamline your path from CAD model to certified component by integrating design-for-manufacturability (DFM) analysis early in the process, reducing costly iterations and accelerating time-to-market.

To simplify your sourcing workflow, Honyo provides an Online Instant Quote platform where you upload STEP or IGES files and receive detailed pricing, lead times, and material options within minutes—no manual submissions or delays. This transparency ensures you can evaluate manufacturability and costs at the earliest design stages, aligning engineering intent with production reality.

Partner with Honyo to leverage G-code mastery that turns design challenges into repeatable, high-precision outcomes. Begin your project with confidence using our instant quoting system at honyoprototype.com.

Technical Capabilities

Technical Specifications for G-Code CNC Machine – 3/4/5-Axis Milling and Turning with Tight Tolerance Capabilities

The following table outlines the key technical specifications for a high-precision G-code-controlled CNC machine platform capable of 3-axis, 4-axis, and 5-axis milling as well as CNC turning operations. This system is engineered for tight-tolerance production and prototyping across a range of engineering materials including aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Control System | G-code interpreter with support for ISO, EIA, and Heidenhain-compatible formats; integrated CAD/CAM post-processing compatibility |

| Machine Type | Multi-function CNC platform supporting 3-axis, 4-axis (rotary indexing), and 5-axis simultaneous milling with optional live tooling for turn-mill operations |

| Axis Configuration | X, Y, Z linear axes; optional A (rotary about X) and B (rotary about Y) axes for 5-axis continuous contouring |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-frequency spindle with through-coolant option) |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tolerance Capability | Capable of holding ±0.01 mm (±0.0004 in) on critical features; down to ±0.005 mm with precision finishing passes |

| Tool Changer | Automatic Tool Changer (ATC) with 12–30 tool capacity; tool length and diameter measurement via touch probe |

| Work Envelope (Max Travel) | X: 500 mm, Y: 400 mm, Z: 350 mm (custom builds available up to 1000 mm in X) |

| Rotary Axis (4th/5th Axis) | A-axis: ±180°; B-axis: ±120°; indexing accuracy ±5 arc seconds; continuous high-speed contouring |

| Spindle Power | 15 kW (20 hp) for milling; 7.5 kW (10 hp) for turning spindle (dual-spindle configuration available) |

| Maximum RPM (Turning) | 4,500 RPM (chuck diameter up to 250 mm) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) with mist collection and filtration |

| Materials Processed | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), Engineering Plastics (ABS, Nylon 6/66, PEEK, Delrin) |

| Surface Finish Capability | As low as Ra 0.4 µm (16 µin) with fine milling; Ra 0.8 µm typical for turned features |

| Fixturing Options | Modular vices, tombstones, vacuum tables, and custom soft jaws for complex geometries |

| Control Interface | Fanuc 31i-B5, Siemens 840D, or Heidenhain TNC7 (configurable) with 3D simulation and collision detection |

| Programming Input | G-code via USB, Ethernet, or direct CAD/CAM integration (Siemens NX, Mastercam, Fusion 360) |

| Environmental Requirements | Stable ambient temperature (18–22°C), humidity 40–60%, compressed air supply (6–7 bar, dry) |

This machine platform is designed for high-mix, low-volume production and precision prototyping, particularly in aerospace, medical, and industrial automation sectors where tight tolerances and material versatility are critical. The integration of multi-axis motion and high-resolution feedback systems ensures consistent part quality across aluminum and steel structural components as well as dimensionally stable plastic parts in ABS and nylon.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process: From CAD to Delivery

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining projects, ensuring precision, efficiency, and client transparency. Our proprietary process integrates automation with engineering expertise to minimize lead times while maintaining rigorous quality standards. Below is a detailed breakdown of each phase.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. Our system automatically validates file integrity, checks for unit consistency (metric/imperial), and identifies potential geometry errors. Non-native formats (e.g., STP) undergo neutral file conversion with tolerance verification to prevent data loss. This step ensures manufacturability begins with a technically sound digital foundation, reducing downstream revisions.

AI-Powered Quoting with Engineering Validation

Uploaded CAD data feeds into our AI quoting engine, which analyzes geometric complexity, material requirements, tolerances, and surface finishes. The AI generates a preliminary quote within 2 hours, factoring in machine time, material costs, and setup variables. Crucially, this output undergoes dual validation: first by the AI’s historical cost-database cross-referencing (trained on 50,000+ past CNC jobs), then by a senior manufacturing engineer who audits feasibility and cost drivers. Clients receive a transparent quote with clear rationale for pricing variables, including optional cost-saving suggestions.

Engineering-Led DFM Analysis

Before production, all designs undergo mandatory Design for Manufacturing (DFM) review by Honyo’s CNC engineering team. This phase identifies and resolves manufacturability constraints, optimizing the part for CNC efficiency without compromising function. Key DFM checks include:

| DFM Focus Area | Purpose | Typical Resolution |

|---|---|---|

| Wall Thickness | Prevent chatter/vibration in thin features | Recommend minimum 0.8mm for aluminum, 1.2mm for steel |

| Internal Radii | Ensure tool access; avoid sharp corners | Suggest radius ≥ 1/3 tool diameter |

| Tolerance Stack-Ups | Flag unrealistically tight tolerances increasing cost | Propose GD&T adjustments per ISO 2768 medium class |

| Hole Depths | Verify drill rigidity for deep holes (>4x diameter) | Recommend step-drilling or alternative methods |

| Material Utilization | Optimize stock size to reduce waste | Adjust billet dimensions to minimize scrap |

Clients receive a formal DFM report within 24 hours, detailing actionable recommendations. We collaborate iteratively to finalize the design, ensuring optimal balance between performance and producibility.

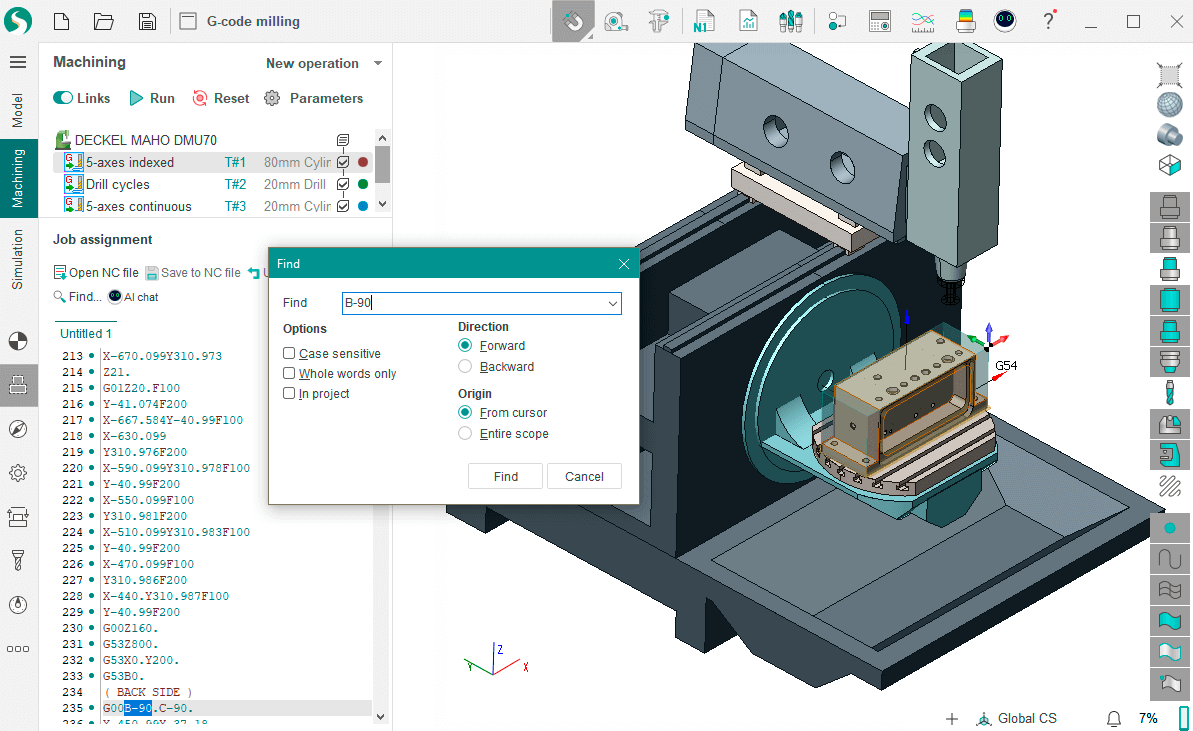

CNC Production with Verified G-Code

Approved designs enter production on our network of Haas, DMG MORI, and Makino CNC mills and lathes. Our process guarantees g-code integrity through:

CAM programming in Mastercam and Fusion 360, validated via Vericut simulation to eliminate collisions and optimize toolpaths.

On-machine probing for first-article alignment, ensuring <0.005mm positional accuracy.

In-process inspections at critical stages using calibrated CMMs and optical comparators.

Real-time monitoring of spindle load, vibration, and thermal drift to maintain dimensional stability. All g-code undergoes dry-run verification on the target machine before full production, with engineers onsite for complex multi-axis operations.

Quality-Controlled Delivery

Final parts undergo comprehensive inspection against AS9102 or client-specific FAIR documentation. This includes:

Full CMM reports for critical dimensions (certified to ISO 17025).

Surface roughness validation via profilometer (Ra values per print).

Material certification traceability (mill test reports included).

Packaged parts ship via DHL/FedEx with real-time tracking, accompanied by digital quality dossiers accessible through our portal. Standard lead time from DFM approval to delivery is 5–7 business days for 1–100 units, with expedited options available.

This integrated workflow—combining AI efficiency with human engineering oversight—ensures Honyo delivers CNC prototypes and low-volume production parts with 99.2% first-pass yield rate, adhering to ISO 9001:2015 standards. Clients retain full visibility through our portal at every phase, from CAD upload to certified delivery.

Start Your Project

Request a quote for precision G-code CNC machining services—contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures fast turnaround, tight tolerances, and high repeatability for prototyping and low-volume production.

All CNC programs are optimized using industry-standard G-code for accuracy and efficiency. Trust Honyo Prototype for reliable, in-house machining with real-time project updates and strict quality control.

Reach out today to discuss your next project or request a detailed capability overview.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.