Contents

Manufacturing Insight: Fusion Edge 3D Printer

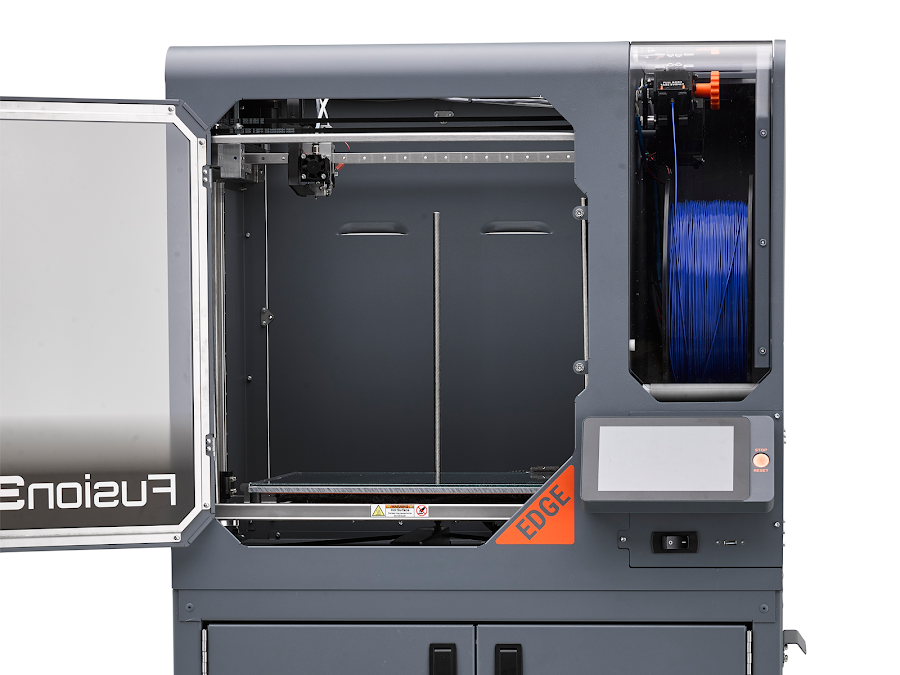

Honyo Prototype delivers industrial 3D printing solutions engineered for demanding manufacturing environments, where precision, repeatability, and throughput are non-negotiable. Our Fusion Edge 3D Printer platform represents the culmination of advanced engineering and rigorous process validation, designed specifically to bridge the gap between rapid prototyping and true production readiness. This industrial-grade system leverages high-temperature capabilities, robust material compatibility, and calibrated thermal management to produce end-use components and complex tooling with consistent mechanical properties and dimensional accuracy, directly supporting lean manufacturing workflows.

Beyond the hardware, Honyo Prototype provides a comprehensive industrial additive service ecosystem. We integrate the Fusion Edge platform with expert material science knowledge, stringent quality assurance protocols including in-process monitoring and post-build metrology, and scalable production planning. This ensures your parts meet exacting industry standards for aerospace, medical device manufacturing, and industrial equipment sectors. Eliminate procurement delays with our Online Instant Quote system, which provides transparent, real-time pricing and lead time estimates for qualified industrial projects within minutes, accelerating your path from CAD file to certified component. Experience how Honyo Prototype transforms additive potential into measurable production outcomes.

Technical Capabilities

Honyo Prototype – Technical Specifications Summary: Fusion Edge 3D Printer Platform

The Fusion Edge 3D printer is a high-performance, multi-process additive manufacturing platform engineered for industrial prototyping and end-use part production. It supports multiple advanced 3D printing technologies including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Each process is optimized for precision, repeatability, and material versatility across engineering-grade polymers and metals.

Below is a comparative technical specification table highlighting performance metrics and compatible materials for each supported process:

| Parameter | SLA (Stereolithography) | SLS (Selective Laser Sintering) | MJF (Multi Jet Fusion) | DMLS (Direct Metal Laser Sintering) |

|---|---|---|---|---|

| Technology Principle | UV laser cures photopolymer resin layer by layer | CO₂ laser sinters powdered polymer | Thermal fusing agent jetted and cured by infrared energy | High-power fiber laser melts metal powder |

| Layer Resolution | 25 – 100 µm | 80 – 120 µm | 80 – 100 µm | 20 – 50 µm |

| Build Volume (mm) | 145 x 145 x 185 | 250 x 250 x 300 | 380 x 284 x 380 | 250 x 250 x 300 |

| Dimensional Accuracy | ±0.1 mm (first 50 mm), ±0.05 mm/mm thereafter | ±0.3 mm | ±0.3 mm | ±0.1 mm |

| Surface Finish (Ra) | 0.8 – 1.6 µm (as printed) | 8 – 12 µm (as printed) | 4 – 8 µm (as printed) | 10 – 15 µm (as printed), polishable to <1 µm |

| Support Structures | Required (breakaway) | Self-supporting (powder bed) | Self-supporting (powder bed) | Required (metal supports) |

| Post-Processing | Wash, cure, support removal | Media blasting, depowdering | Media blasting, depowdering | Stress relieve, HIP, machining, polishing |

| Typical Applications | High-detail prototypes, molds, dental, jewelry | Functional prototypes, end-use parts | High-volume functional parts, housings | Aerospace, medical implants, tooling |

| Compatible Materials | Standard, Engineering, Dental, Castable Resins | Nylon (PA11, PA12), TPU, GF-PA | Nylon (PA11, PA12), GF-PA, Antistatic PA | Aluminum (AlSi10Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel 718 |

| Material Examples | ABS-like, Rubber-like, Transparent resins | PA12 (Nylon 12), Glass-filled Nylon | Carbon-filled PA, Flame-retardant PA | Aluminum, Tool Steel, Cobalt Chrome |

| Lead Time (Typical) | 1–2 days | 2–3 days | 2–3 days | 5–7 days (including heat treatment) |

| Part Density | Near full (resin dependent) | >95% | >99% | >99.9% (fully dense) |

Material Notes:

Aluminum (AlSi10Mg): Used in DMLS for lightweight, high-strength components in aerospace and automotive sectors. Excellent thermal and corrosion resistance.

Steel (e.g., 17-4 PH, 316L): DMLS-processed stainless steels offering high strength, corrosion resistance, and suitability for medical and industrial applications.

ABS-like Resins (SLA): Simulate thermoplastic ABS in appearance and mechanical behavior; ideal for visual prototypes and fit testing.

Nylon (PA11, PA12): Available via SLS and MJF; offers excellent durability, chemical resistance, and flexibility. Widely used for functional parts such as enclosures, ducts, and mechanical assemblies.

The Fusion Edge platform integrates advanced motion control, inert gas environments (for metal processes), and real-time monitoring systems to ensure consistent part quality across all technologies. It is designed for seamless integration into industrial workflows, supporting automated data preparation, machine scheduling, and quality traceability.

From CAD to Part: The Process

Honyo Prototype employs a rigorously structured workflow for our Fusion Edge metal additive manufacturing service, designed to maximize precision, efficiency, and cost-effectiveness for industrial clients. The end-to-end process is engineered to minimize errors and accelerate time-to-part while maintaining aerospace-grade quality standards.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native CAD formats preferred) via our secure customer portal. Our system performs immediate automated validation checks for watertight geometry, minimum feature size compliance (≥0.4mm for standard builds), and orientation suitability. Unsupported formats undergo conversion with full topology verification before proceeding. File encryption and audit trails ensure IP protection per ISO 27001 protocols.

AI Quote Generation

Within 15 minutes, our proprietary AI quoting engine analyzes the validated geometry against real-time parameters including machine availability, material stock levels, and geometric complexity metrics. The system cross-references historical build data from 50,000+ production runs to predict support structure requirements, build time, and material consumption. Clients receive a dynamic quote showing cost breakdown by material, machine time, and post-processing, with options to adjust parameters like surface finish grade or heat treatment.

DFM Analysis

All projects undergo mandatory Design for Metal Additive Manufacturing review by our engineering team. This phase identifies critical manufacturability risks and optimization opportunities through dual-layer analysis:

| DFM Focus Area | Key Checks | Typical Resolution Time |

|---|---|---|

| Geometric Feasibility | Overhang angles (>45°), thin wall stability (<0.5mm), trapped powder zones | 4-8 hours |

| Thermal Stress Mitigation | Hotspot prediction, distortion risk zones, support density optimization | 8-12 hours |

| Cost Drivers | Support structure minimization, build orientation impact, nesting efficiency | 4-6 hours |

Engineers provide actionable recommendations via annotated 3D markups, with clients approving revisions within the portal. 92% of first-pass builds achieve zero critical DFM flags due to this proactive phase.

Production Execution

Approved designs move to our dedicated Fusion Edge production floor featuring EOS M400-4 quad-laser systems operating under argon atmosphere (O₂ < 25 ppm). Key production parameters include:

Layer thickness: 30μm (standard) or 20μm (high-resolution)

Build temperature: 150°C (Ti6Al4V) to 850°C (Inconel 718)

Laser power: 700W per emitter with real-time melt pool monitoring

All builds incorporate in-situ layer imaging and thermal camera tracking, with full traceability from powder lot to final part certification. Optional NDT (CT scanning, XRF) is available per AMS 4999.

Delivery and Certification

Post-processing occurs in our certified cleanroom (ISO Class 7) with options including:

HIP (1150°C/100MPa for critical aerospace parts)

Precision machining of critical interfaces

Shot peening for fatigue resistance improvement

Every shipment includes full material test reports (ASTM E8/E23), dimensional inspection data (per AS9102), and build parameter logs. Standard lead time is 7-10 business days from CAD approval, with expedited 72-hour options for urgent prototypes. Parts ship with serialized tracking and environmental control documentation meeting ITAR and REACH requirements.

Start Your Project

Discover the power of precision manufacturing with the Fusion Edge 3D Printer—engineered for high-performance prototyping and production-grade applications. Built with advanced fusion technology, it delivers exceptional accuracy, repeatability, and speed for demanding industrial environments.

Manufactured in our Shenzhen facility, the Fusion Edge combines cutting-edge innovation with rigorous quality control to meet the highest standards in additive manufacturing.

For sales inquiries or technical specifications, contact Susan Leo at [email protected]. Let’s advance your manufacturing capabilities—connect today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.