Introduction: Navigating the Global Market for furniture cnc router

In an increasingly competitive global market, sourcing a reliable furniture CNC router can present significant challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. The quest for high-quality machinery that not only enhances production efficiency but also meets diverse design requirements is paramount for businesses looking to thrive. This guide serves as an essential resource for international buyers seeking to navigate the complexities of the furniture CNC router landscape, offering insights into various types of routers, their applications in furniture making, and crucial factors for supplier vetting.

As you delve into this comprehensive guide, you will uncover actionable insights on selecting the right CNC router tailored to your specific needs—be it for custom cabinetry, intricate designs, or bulk production. We will explore the latest advancements in technology, the nuances of cost considerations, and the importance of reliable after-sales support. Additionally, this guide empowers B2B buyers with the knowledge needed to make informed purchasing decisions, ensuring that your investment in CNC technology translates into enhanced productivity and creative potential. Whether you’re a small artisan shop or a large-scale manufacturer, understanding the global market dynamics for furniture CNC routers will equip you with the tools to elevate your business in an ever-evolving industry.

Understanding furniture cnc router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Axis CNC Router | Standard configuration, capable of linear movements in three axes (X, Y, Z). | Basic furniture making, cabinetry, and signage. | Pros: Cost-effective, easy to use. Cons: Limited in complexity for intricate designs. |

| 4-Axis CNC Router | Adds a rotational axis, allowing for more complex shapes and engravings. | Custom furniture, artistic pieces, and detailed carvings. | Pros: Greater design flexibility, ideal for unique projects. Cons: Higher cost, requires advanced skill. |

| 5-Axis CNC Router | Can move along five different axes, enabling intricate designs and complex angles. | High-end furniture design, aerospace components, and specialized manufacturing. | Pros: Exceptional precision, capable of complex geometries. Cons: Expensive, requires specialized training. |

| Hybrid CNC Router | Combines CNC routing with laser cutting or engraving capabilities. | Multi-material furniture production and custom signage. | Pros: Versatile, can handle various materials. Cons: Maintenance can be complex, higher initial investment. |

| Benchtop CNC Router | Compact design suitable for small workshops, often portable. | Hobbyist furniture making, small-scale production. | Pros: Affordable, space-saving. Cons: Limited cutting area, less powerful than larger models. |

What Are the Characteristics of a 3-Axis CNC Router?

The 3-axis CNC router is the most common type found in furniture manufacturing. It operates along three linear axes, allowing for straightforward cutting, drilling, and engraving tasks. This router is particularly suitable for basic furniture pieces, cabinetry, and signage applications. B2B buyers should consider the machine’s ease of use and cost-effectiveness, making it an ideal choice for small to mid-sized operations looking to improve efficiency without a significant investment.

How Does a 4-Axis CNC Router Enhance Design Flexibility?

The 4-axis CNC router introduces a rotational axis, enabling the creation of more complex shapes and engravings. This router is particularly beneficial for custom furniture and artistic pieces that require intricate detailing. B2B buyers should evaluate their specific design needs, as this machine offers greater flexibility but comes with a higher price tag and necessitates advanced operational skills. It is an excellent choice for businesses focused on unique, high-value products.

What Advantages Does a 5-Axis CNC Router Provide for High-End Manufacturing?

The 5-axis CNC router allows for movement along five axes, making it ideal for high-end furniture design and specialized manufacturing applications. Its capability to handle complex geometries and angles provides unparalleled precision. B2B buyers interested in this technology should weigh the benefits of exceptional design capabilities against the higher costs and the requirement for specialized training. This router is best suited for businesses that prioritize quality and uniqueness in their offerings.

Why Choose a Hybrid CNC Router for Multi-Material Production?

Hybrid CNC routers combine traditional routing with laser cutting or engraving capabilities, making them versatile for various applications. They are particularly effective in multi-material furniture production and custom signage. B2B buyers should consider the advantages of versatility and the ability to work with different materials, but also be mindful of the complexities in maintenance and the higher initial investment. This type of router is ideal for businesses looking to expand their product offerings.

What Are the Benefits of Using a Benchtop CNC Router?

Benchtop CNC routers are compact and portable, making them suitable for small workshops or hobbyist settings. They offer an affordable entry point into CNC technology for businesses focused on small-scale production. However, buyers should be aware of the limited cutting area and power compared to larger models. This router is best for those who prioritize space and budget but may need to consider future growth and production needs.

Key Industrial Applications of furniture cnc router

| Industry/Sector | Specific Application of furniture cnc router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom Cabinetry Production | Enables rapid prototyping and mass production of unique designs. | Machine size, software compatibility, and material versatility. |

| Interior Design | Bespoke Furniture Creation | Facilitates the design of tailored pieces that meet client needs. | Precision capabilities, design software integration, and support. |

| Retail and Showrooms | Display Fixtures and Merchandising Solutions | Enhances visual appeal and maximizes space efficiency. | Customization options, lead time, and finishing capabilities. |

| Hospitality | Custom Furniture for Hotels and Restaurants | Improves guest experience with unique and functional designs. | Durability, compliance with safety standards, and bulk production. |

| Architectural Firms | Architectural Millwork and Custom Installations | Provides intricate designs that align with architectural visions. | Precision, material compatibility, and project scalability. |

How is Furniture CNC Router Used in Furniture Manufacturing?

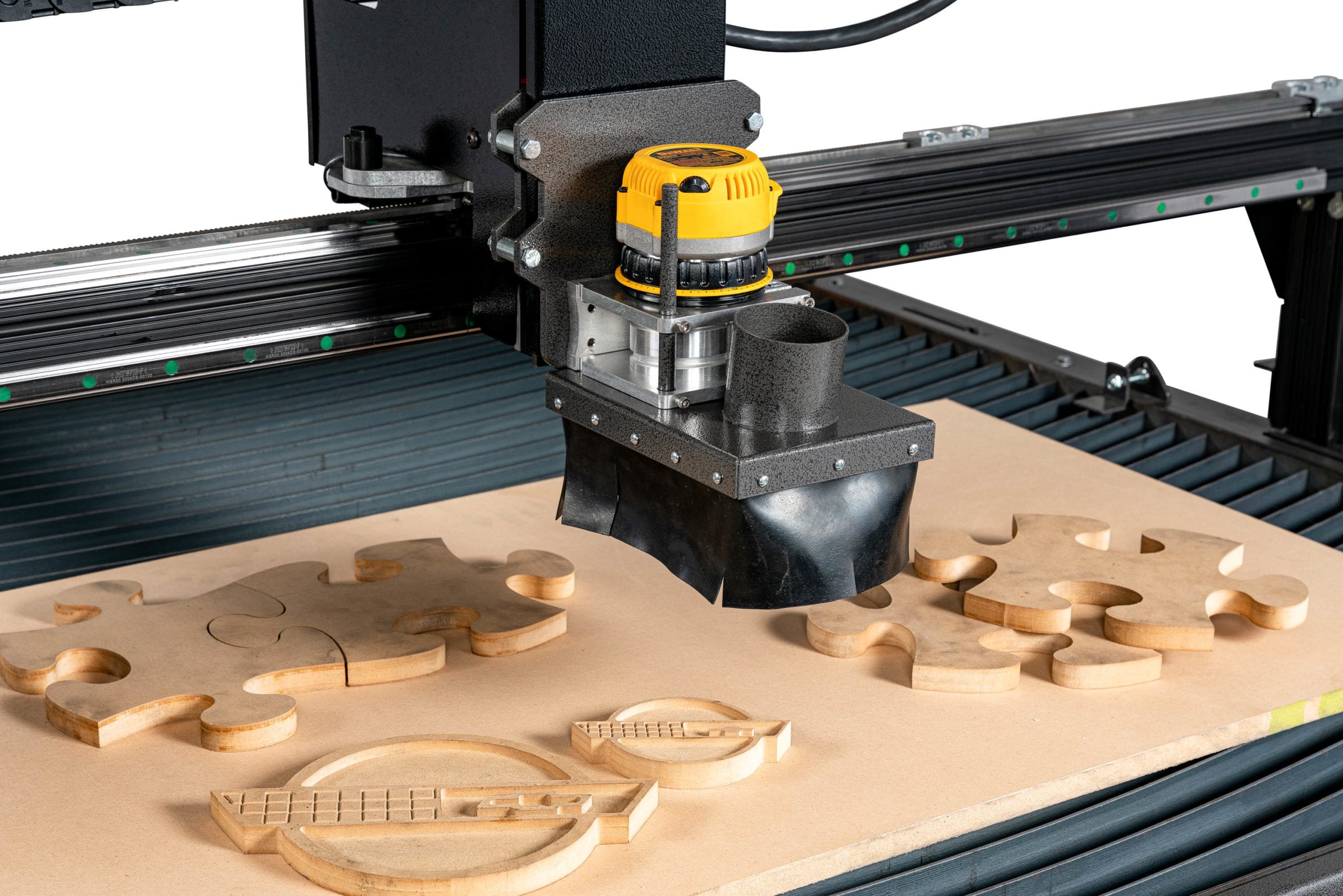

In furniture manufacturing, CNC routers are pivotal for producing custom cabinetry. These machines automate the cutting, drilling, and shaping of wood, enabling manufacturers to create intricate designs with high precision. By streamlining production processes, businesses can reduce labor costs and turnaround times, which is critical for fulfilling large orders. International buyers should consider the machine’s capability to handle diverse materials and the availability of technical support to ensure seamless integration into their existing workflows.

What Role Does Furniture CNC Router Play in Interior Design?

In the realm of interior design, furniture CNC routers are invaluable for crafting bespoke pieces tailored to specific client requirements. Designers leverage these machines to create unique furniture that enhances aesthetics and functionality within a space. The ability to produce customized items efficiently allows designers to offer a competitive edge in a saturated market. Buyers should focus on sourcing routers that offer flexibility in design options and compatibility with advanced design software to facilitate creative processes.

How Do Retail and Showrooms Benefit from Furniture CNC Routers?

Retailers and showrooms utilize CNC routers to produce eye-catching display fixtures that enhance product visibility and store layout efficiency. These machines allow for the creation of custom shelving, stands, and promotional displays that can significantly influence customer engagement and sales. For international buyers, it is essential to evaluate the machine’s capacity for custom designs, the speed of production, and the potential for cost-effective bulk manufacturing to meet seasonal demands.

Why is Custom Furniture Important for Hospitality?

The hospitality industry benefits from furniture CNC routers through the creation of custom furniture that enhances guest experiences in hotels and restaurants. These routers enable the production of unique, durable pieces that align with the branding and ambiance of each establishment. Buyers in this sector should prioritize machines that offer high durability, compliance with safety standards, and the ability to handle bulk production without compromising quality to maintain operational efficiency.

How Do Architectural Firms Leverage Furniture CNC Routers?

Architectural firms use furniture CNC routers for intricate millwork and custom installations that reflect their design vision. These machines facilitate the precise cutting and shaping of various materials, enabling architects to bring complex designs to life. When sourcing CNC routers, firms should consider the precision capabilities, compatibility with different materials, and the ability to scale production to accommodate various project sizes, ensuring they can meet client expectations effectively.

3 Common User Pain Points for ‘furniture cnc router’ & Their Solutions

Scenario 1: Difficulty in Achieving Design Precision and Consistency

The Problem: Many furniture manufacturers struggle with achieving the level of precision and consistency required for high-quality products. Manual processes can lead to variations in dimensions and finishes, which not only impact the aesthetic appeal but can also result in costly errors and rework. B2B buyers often find that their current production methods cannot meet the increasing demand for customized designs, leading to delays and dissatisfied customers.

The Solution: Investing in a high-quality CNC router specifically designed for furniture production can drastically improve precision and consistency. For buyers, it’s essential to select a machine that features advanced algorithms for optimal cutting paths and settings. Additionally, integrating computer-aided design (CAD) software with the CNC router enables the creation of complex designs that can be executed flawlessly. When sourcing a CNC router, look for models that offer features such as automatic tool changers and programmable settings that can accommodate various materials and thicknesses. This way, manufacturers can streamline their production process, reduce human error, and ensure that every piece meets their exact specifications.

Scenario 2: High Production Costs and Inefficiencies

The Problem: As businesses expand, many B2B buyers face the challenge of rising production costs. The manual labor involved in furniture making is not only time-consuming but also expensive. These costs can eat into profit margins, especially when competing in global markets where price sensitivity is a significant factor. Manufacturers often find it challenging to keep up with orders while maintaining quality, leading to missed deadlines and customer dissatisfaction.

The Solution: To address high production costs, investing in a CNC router can be a game-changer. These machines automate various tasks such as cutting, drilling, and engraving, significantly reducing the amount of manual labor required. When selecting a CNC router, buyers should consider models that offer high-speed processing and multiple functionalities in a single machine. This reduces the need for multiple tools, thus lowering capital expenditure and operational costs. Furthermore, businesses should evaluate financing options that allow for flexible payment terms, making the investment more manageable. By streamlining production with a CNC router, companies can increase throughput while maintaining quality, effectively reducing overall costs and improving profitability.

Scenario 3: Limited Flexibility in Product Offerings

The Problem: In today’s competitive market, furniture manufacturers must adapt quickly to changing customer preferences and trends. However, many companies find their production capabilities limited by traditional woodworking methods, which restrict the variety of products they can offer. This lack of flexibility can hinder their ability to attract new customers and retain existing ones, as consumers increasingly seek unique, customized furniture options.

The Solution: A CNC router provides the versatility needed to expand product offerings without the typical constraints of manual woodworking. By utilizing CAD software, manufacturers can easily modify designs and create unique pieces tailored to specific customer requests. When sourcing a CNC router, buyers should look for machines with the capability to handle various materials, including wood, plastics, and composites, to cater to diverse market needs. Additionally, investing in training for staff on how to leverage the full capabilities of the CNC router can enhance creative outputs and production efficiency. By embracing this technology, manufacturers can position themselves as innovative leaders in the furniture industry, capable of delivering custom solutions that resonate with their target audience.

Strategic Material Selection Guide for furniture cnc router

What Are the Key Properties of Common Materials Used in Furniture CNC Routing?

When selecting materials for furniture CNC routing, it’s essential to understand the properties that influence product performance. Here, we analyze four common materials: hardwoods, MDF (Medium Density Fiberboard), plywood, and plastics, focusing on their suitability for various applications.

Hardwoods: The Classic Choice for Quality Furniture

Key Properties: Hardwoods, such as oak, maple, and cherry, are known for their strength, durability, and aesthetic appeal. They typically have high temperature and pressure ratings, making them suitable for furniture that endures regular use.

Pros & Cons: The primary advantage of hardwoods is their longevity and ability to withstand wear and tear. However, they can be expensive and require more complex manufacturing processes, including sanding and finishing. Additionally, variations in grain and color can make it challenging to achieve uniformity in large production runs.

Impact on Application: Hardwoods are ideal for high-end furniture pieces, offering a premium look and feel. They are compatible with various CNC routing techniques, allowing for intricate designs and customizations.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local sourcing to reduce costs and ensure compliance with sustainability standards. Familiarity with local species and their properties can also enhance product offerings.

MDF: The Cost-Effective Alternative

Key Properties: MDF is a composite material made from wood fibers, wax, and resin, providing a smooth surface ideal for CNC machining. It has a moderate temperature resistance and is less prone to warping compared to solid wood.

Pros & Cons: MDF is cost-effective and easy to work with, allowing for intricate designs without the risk of splintering. However, it is less durable than hardwoods and can be sensitive to moisture, which may limit its use in humid environments.

Impact on Application: MDF is suitable for painted furniture and intricate designs, making it popular for mass production. Its uniform density allows for consistent cutting and finishing.

Considerations for International Buyers: Compliance with environmental regulations regarding formaldehyde emissions is crucial, especially in Europe, where standards are stringent. Buyers should verify that MDF products meet relevant certifications.

Plywood: The Versatile Workhorse

Key Properties: Plywood consists of multiple layers of wood veneer glued together, offering strength and stability. It has good temperature and moisture resistance, making it suitable for various applications.

Pros & Cons: Plywood is durable and lightweight, making it easier to handle. Its layered structure provides resistance to warping and cracking. However, the quality can vary significantly based on the type of wood used and the manufacturing process.

Impact on Application: Plywood is versatile, suitable for furniture like cabinets and shelving. It can be easily CNC machined to create detailed designs, although the finish may require additional work.

Considerations for International Buyers: Buyers should be aware of the different grades of plywood and their intended uses. Ensuring compliance with international standards, such as BS 6566 in Europe, is essential for quality assurance.

Plastics: The Modern Material

Key Properties: Plastics, including acrylic and PVC, are lightweight and resistant to moisture and chemicals. They can be easily molded and cut, making them suitable for innovative furniture designs.

Pros & Cons: The primary advantage of plastics is their versatility and low maintenance. However, they may lack the aesthetic appeal of natural materials and can be less durable under heavy use.

Impact on Application: Plastics are ideal for contemporary furniture designs and can be used for both structural and decorative elements. They are compatible with CNC routing, allowing for creative applications.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic materials and seek options that comply with recycling standards. Understanding local regulations regarding plastic use can also inform purchasing decisions.

Summary Table of Material Selection for Furniture CNC Routing

| Material | Typical Use Case for furniture cnc router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hardwoods | High-end furniture pieces | Durable and aesthetically appealing | Expensive and complex to manufacture | High |

| MDF | Mass-produced furniture | Cost-effective and easy to work with | Less durable and moisture-sensitive | Low |

| Plywood | Cabinets and shelving | Lightweight and resistant to warping | Quality can vary significantly | Medium |

| Plastics | Contemporary designs | Versatile and low maintenance | Lacks aesthetic appeal of natural materials | Medium |

This strategic material selection guide provides insights into the properties, advantages, and limitations of common materials used in furniture CNC routing, helping international B2B buyers make informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for furniture cnc router

What Are the Main Stages of the Manufacturing Process for Furniture CNC Routers?

The manufacturing process of furniture CNC routers involves several critical stages that ensure the machinery operates efficiently and meets high-quality standards. Understanding these stages is essential for B2B buyers looking to invest in reliable equipment.

Material Preparation: How Are Components Selected and Processed?

The first stage involves selecting the right materials, which typically include high-grade aluminum, steel, and various composite materials. These components are chosen for their durability and ability to withstand rigorous use. The materials undergo cutting, milling, or laser processing to create parts that fit together precisely. This step ensures that the structural integrity of the CNC router is maintained, allowing for consistent performance over time.

Forming: What Techniques Are Used to Shape the Router Components?

Forming is a crucial stage where the prepped materials are shaped into the required components. Techniques such as CNC machining, bending, and welding are commonly employed. CNC machining allows for high precision and repeatability, vital for creating parts that need to fit together seamlessly. Additionally, the use of laser cutting technology enhances the accuracy of intricate designs, which is particularly important for routers that may require complex shapes.

Assembly: How Are the Parts Integrated into a Complete Unit?

Once the individual components are formed, the next step is assembly. This process typically involves skilled technicians who follow detailed schematics to ensure that each part is correctly integrated. During assembly, quality checks are performed to ensure that all mechanical and electronic components function as intended. This stage often includes the installation of motors, control systems, and safety features, all of which contribute to the machine’s operational capabilities.

Finishing: What Processes Ensure the Router Is Ready for Market?

The finishing stage encompasses various processes designed to enhance the machine’s appearance and durability. This may include anodizing aluminum parts, applying protective coatings, and polishing surfaces. These finishing touches not only improve aesthetics but also provide resistance to wear and tear, thereby extending the lifespan of the equipment.

How Is Quality Assurance Implemented in the Manufacturing of Furniture CNC Routers?

Quality assurance (QA) is a critical aspect of manufacturing CNC routers, ensuring that the final product meets international and industry-specific standards. For B2B buyers, understanding these QA processes is essential for making informed purchasing decisions.

Which International Standards Are Relevant for Furniture CNC Routers?

Manufacturers of furniture CNC routers often adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that a manufacturer has established processes to consistently produce quality products. Additionally, CE marking is crucial for equipment sold in Europe, ensuring that it meets safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing stages, various tests and inspections are conducted to identify defects early in the production process.

- Final Quality Control (FQC): After assembly, the complete CNC router undergoes a thorough inspection to verify that it meets all design specifications and quality standards.

These checkpoints help mitigate defects and ensure that any issues are addressed before the product reaches the market.

What Common Testing Methods Are Used to Verify Quality?

Several testing methods are employed to ensure the quality and performance of furniture CNC routers. These may include:

- Functional Testing: Ensuring all components operate as intended under various conditions.

- Durability Testing: Subjecting the machine to stress tests to evaluate how it performs under extreme conditions.

- Safety Testing: Verifying that the router meets safety regulations, including electrical and mechanical safety standards.

By employing these testing methods, manufacturers can provide assurance of their products’ quality and reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some effective ways to do this:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers can request audits to evaluate the supplier’s manufacturing processes, quality management systems, and adherence to international standards. This can involve on-site visits or third-party assessments to ensure objectivity.

How Can Buyers Obtain and Review Quality Reports?

Buyers should request quality reports and certifications from suppliers. These documents provide insight into the manufacturing processes, testing results, and compliance with relevant standards. A thorough review of these reports can help buyers gauge the reliability and quality of the equipment.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection services can add another layer of assurance. These independent entities can conduct thorough inspections and testing of the CNC routers before shipment, ensuring they meet the specified standards. This is particularly important for international transactions, where buyers may not have the ability to inspect products on-site.

What Are the Specific Quality Control Nuances for International B2B Buyers?

When sourcing furniture CNC routers, international B2B buyers need to be aware of specific nuances in quality control:

- Cultural Differences: Understanding the cultural approach to quality and manufacturing standards in different regions can help buyers set realistic expectations.

- Regulatory Compliance: Different countries have varying regulations regarding machinery safety and environmental impact. Buyers should ensure that suppliers comply with local regulations in their intended markets.

- Communication: Clear communication regarding quality expectations and standards is essential. Language barriers or misunderstandings can lead to discrepancies in product quality.

By paying attention to these nuances, buyers can better navigate the complexities of international sourcing and ensure they receive high-quality CNC routers that meet their specific needs.

Conclusion

The manufacturing processes and quality assurance practices for furniture CNC routers are complex but crucial for ensuring reliable performance and longevity. B2B buyers must thoroughly understand these aspects to make informed purchasing decisions, ensuring they invest in equipment that meets their operational needs and quality expectations. By leveraging proper audits, quality reports, and third-party inspections, buyers can confidently navigate the international market and select suppliers that uphold the highest standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘furniture cnc router’

Introduction

When sourcing a furniture CNC router, B2B buyers must navigate a landscape rich with options and technologies. This guide offers a step-by-step checklist to streamline your procurement process, ensuring you select the right machine that meets your operational needs while enhancing production efficiency.

Step 1: Define Your Technical Specifications

Before beginning your search, outline the specific features and capabilities required for your furniture production. Consider factors such as the size of the workpieces, materials to be processed, and the complexity of designs. A clear understanding of your needs will help narrow down options and prevent costly mistakes later.

- Machine Size: Determine the maximum dimensions of the pieces you plan to create.

- Material Compatibility: Ensure the CNC router can handle various materials, including wood, MDF, and laminates.

Step 2: Research Available CNC Router Models

Investigate the different models available on the market that fit your defined specifications. Look for reputable brands known for quality and reliability in CNC machinery. This step is crucial as it sets the foundation for your purchasing decision.

- Brand Reputation: Focus on manufacturers with a history of customer satisfaction and industry recognition.

- Model Features: Compare features like spindle power, speed, and precision to identify the best fit.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence ensures that you are engaging with reliable partners who can support your needs.

- Supplier Background: Look for suppliers with extensive experience in the CNC market.

- Customer Testimonials: Read reviews and case studies to understand other buyers’ experiences.

Step 4: Verify Certifications and Compliance

Ensure that the CNC router and the supplier adhere to relevant industry standards and certifications. This guarantees that the equipment meets safety and performance benchmarks essential for your operations.

- ISO Certification: Look for ISO certifications that indicate quality management.

- Safety Standards: Confirm compliance with local and international safety regulations.

Step 5: Assess After-Sales Support and Training

Evaluate the after-sales support and training offered by the supplier. A good support system can significantly enhance your operational efficiency and minimize downtime.

- Technical Support: Ensure the availability of knowledgeable support staff for troubleshooting.

- Training Programs: Check if the supplier provides training for your team to maximize the machine’s capabilities.

Step 6: Consider Financing and Warranty Options

Explore financing options and warranty terms available from suppliers. Understanding these aspects can help you manage your budget while ensuring you have protection for your investment.

- Financing Plans: Look for flexible financing options that suit your cash flow.

- Warranty Coverage: Ensure the warranty covers essential parts and provides a reasonable duration.

Step 7: Request Quotes and Negotiate Terms

Finally, solicit detailed quotes from shortlisted suppliers and be prepared to negotiate terms. This step allows you to compare pricing and features comprehensively, ensuring you receive the best value for your investment.

- Detailed Quotes: Ask for itemized quotes that include all costs, including shipping and installation.

- Negotiation: Don’t hesitate to negotiate terms, as many suppliers are willing to adjust pricing or offer additional services.

By following this structured checklist, you can confidently navigate the procurement process for a furniture CNC router, setting your business up for success in a competitive marketplace.

Comprehensive Cost and Pricing Analysis for furniture cnc router Sourcing

What Are the Key Cost Components for Sourcing Furniture CNC Routers?

When sourcing furniture CNC routers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: This encompasses the cost of raw materials, such as metals for machine frames and components, as well as electronic parts. The quality and type of materials can significantly affect the price. For instance, routers designed for high-precision tasks may require superior materials, thus increasing costs.

-

Labor: Labor costs vary by region and are influenced by local wage standards and the skill level required for assembly and maintenance. In regions with higher labor costs, such as Europe, the overall price may reflect these expenses.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, rent, and administrative expenses. Efficient production methods can help mitigate these costs, allowing suppliers to offer competitive pricing.

-

Tooling: Tooling costs involve the design and production of custom parts needed for specific CNC router functions. These costs can escalate if the machinery requires specialized tooling for intricate designs.

-

Quality Control (QC): Ensuring the equipment meets industry standards involves additional costs. A robust QC process can add to the overall price but is essential for maintaining reliability and performance.

-

Logistics: Shipping costs play a significant role, particularly for international buyers. Factors such as distance, shipping method, and handling can influence logistics expenses, which must be factored into the total cost.

-

Margin: Suppliers will add a profit margin to cover their business expenses and ensure profitability. Understanding typical margins in the CNC router market can assist buyers in identifying reasonable pricing.

How Do Price Influencers Impact the Cost of Furniture CNC Routers?

Several factors can influence the price of furniture CNC routers, making it essential for buyers to be aware of these variables when negotiating.

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQs) that can impact pricing structures, making it beneficial for businesses looking to scale.

-

Specifications and Customization: Custom features and specifications can increase costs. While unique designs may enhance product offerings, they require additional resources and time, leading to higher prices.

-

Materials Quality and Certifications: Higher-quality materials and relevant industry certifications can add to the cost but may result in better performance and durability, reducing long-term maintenance costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge more, but their machines might offer better longevity and support.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect overall pricing. Different terms dictate responsibilities for shipping, insurance, and tariffs, which can substantially impact the final cost of the machinery.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing CNC Routers?

For international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency and negotiation power.

-

Negotiation: Engage in discussions about pricing, especially concerning bulk purchases or long-term contracts. Suppliers may offer flexible pricing structures to secure larger orders.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term operational costs. Consider maintenance, spare parts, and potential downtime when assessing the overall investment.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that may apply in your region. These factors can significantly alter the final cost and should be factored into budgeting.

-

Research and Comparison: Conduct thorough market research and compare offerings from multiple suppliers. This helps in identifying competitive pricing and understanding the features that deliver the best value.

Disclaimer on Indicative Prices

Prices for furniture CNC routers can vary widely based on the above factors. Buyers should always request detailed quotes and consider the total cost implications before making a purchasing decision.

Alternatives Analysis: Comparing furniture cnc router With Other Solutions

Introduction: Exploring Alternatives to Furniture CNC Routers

In the dynamic landscape of furniture manufacturing, businesses are constantly seeking innovative solutions to enhance productivity and creativity. While furniture CNC routers have become a popular choice for automating the design and production process, several alternative methods and technologies can also achieve similar goals. Understanding these alternatives allows B2B buyers to make informed decisions that align with their specific operational needs and budget constraints.

Comparison Table

| Comparison Aspect | Furniture CNC Router | Laser Cutting Machine | Manual Woodworking Tools |

|---|---|---|---|

| Performance | High precision and speed for complex designs | Excellent for intricate cuts and engravings | Variable, heavily reliant on the skill of the craftsman |

| Cost | Moderate to high initial investment, with ongoing software costs | High initial investment, lower operational costs | Low initial investment, but potentially high labor costs |

| Ease of Implementation | Requires CAD software and training | User-friendly with minimal training required | Simple to use but labor-intensive |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance, but lens replacement is necessary | Minimal maintenance, but requires skilled labor for repairs |

| Best Use Case | Mass production and custom designs | Decorative elements and detailed patterns | Artisan and bespoke pieces where craftsmanship is key |

Detailed Breakdown of Alternatives

Laser Cutting Machine

Laser cutting machines provide an alternative that excels in producing intricate designs with high precision. They are particularly effective for decorative elements, such as engravings and detailed cuts. While the initial investment can be high, operational costs are generally lower compared to CNC routers since they do not require extensive software for operation. The ease of implementation is another advantage, as these machines are often more user-friendly and require less specialized training. However, their limitations include a smaller range of materials compared to CNC routers and a tendency to be less effective for thicker materials.

Manual Woodworking Tools

For businesses focused on artisanal craftsmanship, manual woodworking tools present a viable alternative. These tools allow craftsmen to create bespoke pieces that emphasize skill and creativity. The initial investment in manual tools is relatively low, making them accessible for small operations or startups. However, the performance is highly variable and depends significantly on the skill of the operator. While maintenance is minimal, the labor costs can be high due to the time-consuming nature of manual work. This method is best suited for businesses that prioritize craftsmanship over mass production and are willing to invest in skilled labor.

Conclusion: Choosing the Right Solution for Your Furniture Manufacturing Needs

When considering the right manufacturing solution, B2B buyers should carefully assess their specific needs, budget, and production goals. Furniture CNC routers offer unparalleled precision and efficiency for businesses looking to scale production, while laser cutting machines provide an excellent alternative for intricate designs at a potentially lower operational cost. On the other hand, manual woodworking tools cater to those who value artisanal craftsmanship, albeit with higher labor intensity. By evaluating these options against their operational requirements, businesses can make informed decisions that enhance their competitive edge in the furniture market.

Essential Technical Properties and Trade Terminology for furniture cnc router

What Are the Key Technical Properties of a Furniture CNC Router?

When selecting a CNC router for furniture making, understanding specific technical properties is crucial for optimizing production and ensuring quality. Here are some critical specifications that B2B buyers should consider:

1. Material Grade

The material grade of the CNC router components, including the frame, bed, and spindle, significantly impacts durability and performance. High-grade materials like aluminum or steel resist wear and tear, ensuring longevity. In a B2B context, investing in routers made from superior materials can reduce maintenance costs and downtime, leading to higher productivity.

2. Tolerance

Tolerance refers to the allowable deviation from a specified measurement, which is vital in furniture making for achieving precise cuts and fittings. A CNC router with a tolerance of ±0.01 mm is preferred for high-quality furniture production. In B2B operations, maintaining tight tolerances can enhance the quality of finished products, ensuring that parts fit together seamlessly and meet client specifications.

3. Spindle Power

Spindle power, typically measured in horsepower (HP), determines the router’s ability to handle various materials, from softwoods to hardwoods and composites. A router with higher spindle power can manage more demanding tasks, such as deep cuts or engraving. For businesses, selecting the right spindle power is essential for ensuring that the machine can handle the intended workload without compromising quality.

4. Working Area

The working area defines the maximum dimensions of the material that the CNC router can process. For furniture makers, a larger working area allows for the fabrication of bigger pieces, such as tables or cabinets, without requiring multiple setups. B2B buyers must assess their production needs to choose a machine with an adequate working area that aligns with their product offerings.

5. Cutting Speed

Cutting speed, measured in inches per minute (IPM), affects how quickly the machine can complete tasks. A higher cutting speed can significantly increase production efficiency, which is crucial for businesses looking to meet demand and reduce lead times. However, it’s essential to balance speed with quality to prevent issues like chipping or burning.

6. Software Compatibility

Compatibility with advanced design software (CAD/CAM) is vital for seamless operation. The ability to integrate with software allows for easier design modifications and automation of the cutting process. For B2B buyers, ensuring that the CNC router can work with existing software solutions can streamline operations and reduce training time for staff.

What Are Common Trade Terms Related to Furniture CNC Routers?

Understanding industry jargon is essential for effective communication and negotiation in B2B environments. Here are several key terms relevant to CNC routers:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC routers, buyers may deal with OEMs when sourcing machines or components. Recognizing OEM relationships can help buyers assess quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In furniture CNC router transactions, understanding the MOQ can help buyers plan their inventory and budget effectively. Knowing MOQ can also facilitate negotiations for bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers in the furniture industry, issuing an RFQ can help compare offers from different suppliers, ensuring they receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers when negotiating shipping, delivery, and risk management associated with importing CNC routers.

5. Lead Time

Lead time is the time taken from placing an order to receiving the product. For furniture manufacturers relying on CNC routers, understanding lead times is crucial for planning production schedules and meeting customer deadlines.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when investing in furniture CNC routers, optimizing their operations and enhancing their product offerings.

Navigating Market Dynamics and Sourcing Trends in the furniture cnc router Sector

What Are the Key Trends Driving the Furniture CNC Router Market?

The furniture CNC router market is experiencing significant growth driven by several global trends. Digital transformation is at the forefront, with manufacturers increasingly adopting advanced technologies such as CAD/CAM software and automated machinery to enhance production efficiency. This shift allows for rapid prototyping and customization, catering to the evolving demands of consumers who seek unique and personalized furniture designs.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note the rise of eco-friendly practices in furniture production. Manufacturers are increasingly focusing on sustainability, sourcing materials responsibly, and minimizing waste. The demand for versatile machines capable of working with a variety of materials, including wood, plastics, and composites, is also on the rise. This versatility enables businesses to meet diverse customer needs, from bespoke pieces to mass production.

Emerging markets are witnessing increased investments in manufacturing capabilities, driven by a growing middle class and urbanization. As a result, there is a surge in demand for affordable, high-quality furniture. B2B buyers must stay informed about regional sourcing trends and local supplier capabilities to navigate this dynamic landscape effectively. Collaborations with technology providers can also enhance operational efficiencies and product offerings, making it crucial for buyers to assess potential partnerships strategically.

How Are Sustainability and Ethical Sourcing Shaping the Furniture CNC Router Sector?

Sustainability and ethical sourcing are increasingly vital considerations in the furniture CNC router sector. The environmental impact of furniture production is under scrutiny, prompting manufacturers to adopt more sustainable practices. This includes utilizing renewable resources, reducing carbon footprints, and minimizing waste through efficient production processes.

For B2B buyers, understanding the significance of ethical supply chains is paramount. This involves sourcing materials from suppliers who adhere to sustainable practices and possess relevant certifications, such as FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative). These certifications not only ensure responsible sourcing but also enhance a company’s reputation among environmentally conscious consumers.

In addition, innovations in eco-friendly materials, such as recycled composites and low-VOC finishes, are gaining traction. Buyers should actively seek out CNC routers that can work with these sustainable materials, allowing them to meet the growing consumer demand for green products. By prioritizing sustainability and ethical sourcing, B2B buyers can not only fulfill regulatory requirements but also differentiate themselves in a competitive market.

How Has the Furniture CNC Router Market Evolved Over Time?

The evolution of the furniture CNC router market has been marked by significant technological advancements. Initially, furniture making relied heavily on manual processes, which were time-consuming and limited in design capabilities. The introduction of CNC technology revolutionized the industry by automating cutting, engraving, and shaping processes, significantly reducing production time and increasing precision.

Over the years, CNC routers have become more sophisticated, incorporating features such as multi-axis capabilities, automatic tool changers, and advanced software integration. These advancements have enabled furniture makers to produce complex designs and custom pieces with ease, catering to a broader range of consumer preferences.

As the market continues to evolve, the focus is shifting towards greater efficiency, versatility, and sustainability. B2B buyers must remain vigilant to these changes, ensuring that they invest in the latest technologies and practices that align with market demands and consumer expectations. Embracing this evolution will empower businesses to thrive in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of furniture cnc router

-

How do I choose the right CNC router for furniture making?

Selecting the right CNC router depends on your specific production needs. Consider factors such as the size of the machine, the types of materials you’ll be working with, and your desired production capacity. If you’re a small business focusing on bespoke pieces, a compact machine may suffice. Conversely, larger operations should invest in industrial-grade routers capable of handling bulk production. Research various models, read user reviews, and consult with suppliers to ensure you select a machine that aligns with your craftsmanship goals. -

What types of furniture can I create with a CNC router?

CNC routers are versatile and can be used to create a wide range of furniture items. From intricate cabinetry and bespoke dining tables to simple shelves and decorative pieces, the possibilities are vast. Your creativity and the machine’s capabilities determine what you can produce. Additionally, with the right software and attachments, you can incorporate detailed engravings, unique shapes, and customized designs, allowing you to stand out in the competitive furniture market. -

What are the key features to look for in a CNC router for furniture production?

When sourcing a CNC router, prioritize features such as precision, speed, and versatility. Look for machines with advanced software integration, automatic tool changers, and the ability to handle various materials like wood, MDF, and plastics. Additionally, consider the machine’s size and whether it can accommodate your workspace. Reliability and support from the manufacturer, including warranty and technical assistance, are also critical to ensure uninterrupted production. -

What is the typical minimum order quantity (MOQ) for CNC routers?

Minimum order quantities for CNC routers can vary significantly by manufacturer and model. Some suppliers may allow single-unit purchases, while others may require a MOQ of several machines, particularly for bulk orders or customized models. It’s essential to communicate your needs clearly with suppliers and inquire about their specific MOQ policies. This information will help you budget accordingly and determine if a supplier aligns with your production scale. -

How can I ensure quality assurance when purchasing a CNC router?

To ensure quality assurance, start by researching reputable manufacturers with a proven track record in the industry. Request samples of their work, check client testimonials, and inquire about their quality control processes. Additionally, ask about warranties and service agreements, as these can indicate the manufacturer’s confidence in their product. It’s also beneficial to visit the supplier’s facility if possible, allowing you to assess their operations firsthand. -

What payment terms should I expect when buying a CNC router internationally?

Payment terms can vary widely among suppliers, especially in international transactions. Common arrangements include upfront payments, deposits, or letters of credit. Always clarify payment conditions before finalizing a purchase, including currency, payment methods (e.g., bank transfer, PayPal), and any applicable taxes or tariffs. Establishing clear terms can help prevent misunderstandings and ensure smooth transactions, especially when dealing with international suppliers. -

How do I vet suppliers for CNC routers in international markets?

When vetting suppliers, start by checking their business credentials and industry reputation. Look for certifications, such as ISO standards, and read reviews from other buyers. Utilize platforms like Alibaba or industry-specific forums for insights on supplier reliability. Request references and conduct background checks to verify their history and quality of service. Engaging in direct communication can also help assess their responsiveness and professionalism. -

What logistical considerations should I be aware of when importing a CNC router?

Importing a CNC router requires careful planning around logistics, including shipping methods, customs clearance, and delivery times. Research the most efficient shipping routes and consider using freight forwarders experienced in handling machinery. Be aware of customs duties and ensure all necessary documentation, such as invoices and certificates of origin, is in order. Additionally, factor in potential delays in shipping, especially when sourcing from international suppliers, to avoid disruptions in your production schedule.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Furniture Cnc Router Manufacturers & Suppliers List

1. Inventables – X-Carve Pro CNC

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: CNC Router Furniture – Inventables, Inc. offers an all-in-one platform for furniture manufacturing, integrating digital design with CNC machine capabilities. The X-Carve Pro CNC acts as a reliable partner in the shop, allowing artisans to focus on detailed work while automating the cutting process. Key features include: 1. Tools for creating stunning and functional furniture designs. 2. Algorithms…

2. ShopSabre – CNC Routers

Domain: shopsabre.com

Registered: 2002 (23 years)

Introduction: CNC Routers: Elevate your craft with precision, versatility, and quality.

– IS-A Series CNC Router: Industrial and commercial use, auto unload, high efficiency nested based sheet processing, starting at $99,995.00.

– IS-M Series CNC Router: Fastest and most accurate CNC control, industrial and commercial use, dedicated high production, high accuracy, starting at $57,995.00.

– Industrial Seri…

3. CNC Machines – Recommendations for Furniture Making

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC machine for furniture making with a working area of 4’x8′. Budget range of ~$5,000-$10,000. Recommendations include hobbyist CNCs like Shapeoko XL or XXL, and brands like Blue Elephant for a more professional setup. Considerations include the difference between CNC routers and mills, learning curve, and potential import tariffs on Chinese equipment.

4. STYLECNC – S4 Nesting CNC Wood Cutting Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Nesting CNC Wood Cutting Machine for Custom Furniture Maker – STYLECNC

– Brand: STYLECNC

– Model: S4

– Table Size: 4′ x 8′ (48″ x 96″, 1300mm x 2500mm)

– Price: $19,800 – Standard Edition / $23,800 – Pro Edition

– Stock: 360 Units in Stock Available for Sale Every Month

– Compliance: Meeting CE Standards in Terms of Quality & Safety

– Warranty: One-Year Limited Warranty for Entire Machine (Extende…

5. FORSUN CNC – 5+4 Boring Spindle ATC Wood Furniture Nesting CNC Router Machine

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: Product Name: 5+4 Boring Spindle ATC Wood Furniture Nesting CNC Router Machine

Brand: FORSUN CNC

Model: FS1330ATC

Price: $4500.00 / Set

Price Range: $4500.00 to $50000.00 / Set based on configuration

Payment Terms: T/T, Visa, Mastercard, American Express, Discover cards

Warranty: 2 Years

Supply Ability: 30 Sets / Month

Key Features:

– 5+4 vertical type boring head for custom cabinet doors, wooden …

6. CNC Furniture Designs – Key Products

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: CNC furniture designs, download link by licence type, 168 Pins, 10 years old, by Algirdas Sabaliauskas, Mykolas Svirskis, Sarune, Ponoko Studio, Lo, Bloesem, CLICdiner chair, ARPA Circa Double Seater – Rawstudio, CLICDINER chair delta bamboo, CLICbar table trespa, Green Design juniper, Circa Chair – Rawstudio, CLIClounge trespa, Green Design, CLICROCKER bamboo, CLIC childrens chair, Finish It Your…

Strategic Sourcing Conclusion and Outlook for furniture cnc router

In the rapidly evolving landscape of furniture manufacturing, strategic sourcing of CNC routers has become paramount for businesses aiming to enhance productivity, precision, and creativity. The integration of advanced CNC technology not only streamlines production processes but also allows for the creation of unique, customized furniture designs that cater to diverse markets. By investing in reliable machines and complementary tools, companies can significantly reduce labor costs while maintaining high craftsmanship standards.

Furthermore, the versatility of CNC routers enables manufacturers to work with various materials, accommodating both traditional and contemporary styles. This adaptability is especially valuable for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where market demands are diverse and ever-changing.

As the furniture industry continues to embrace automation, now is the ideal time for businesses to evaluate their sourcing strategies. By selecting the right CNC equipment, companies can position themselves for growth, enhance their competitive edge, and meet the increasing demand for high-quality, custom-made furniture. Take the next step in your furniture manufacturing journey by exploring innovative CNC solutions tailored to your unique needs.