Contents

Manufacturing Insight: Free-Machining Steels

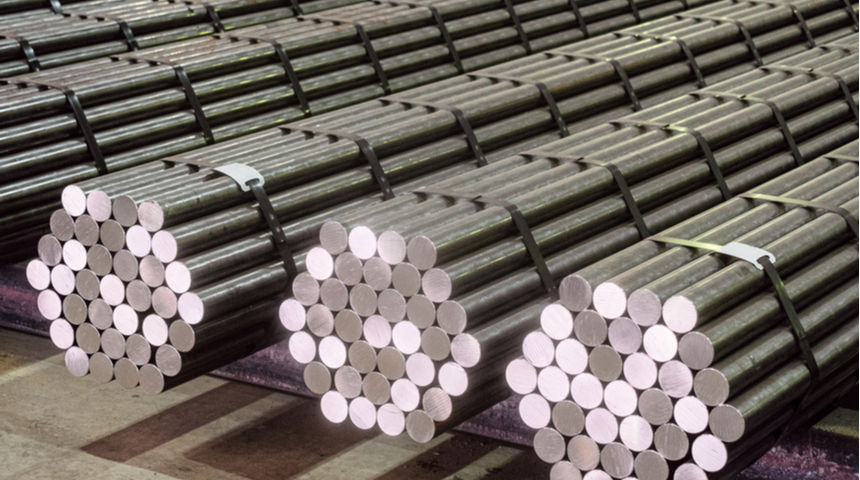

Free-machining steels such as 12L14, 1215, and 303 stainless represent a critical material solution for high-volume precision component manufacturing where efficiency and cost-effectiveness are paramount. These alloys incorporate controlled additions of elements like sulfur, lead, or selenium to significantly enhance machinability, promoting superior chip breakage, reduced tool wear, improved surface finishes, and extended tool life during CNC operations. This translates directly to faster cycle times, lower production costs, and higher throughput for complex turned or milled parts without sacrificing dimensional accuracy.

At Honyo Prototype, our advanced CNC machining capabilities are specifically optimized to leverage the advantages of free-machining steels. We utilize state-of-the-art multi-axis milling and turning centers, precision tooling strategies, and deep material science expertise to consistently achieve tight tolerances and exceptional part quality across diverse free-machining grades. Our engineering team understands the nuanced machining parameters required for each alloy, ensuring optimal feed rates, speeds, and coolant application to maximize productivity and minimize scrap for your production runs.

Accelerate your prototyping and low-to-mid volume production timelines with Honyo Prototype. Experience the efficiency of our specialized free-machining steel processing combined with rapid turnaround. Initiate your project immediately by utilizing our Online Instant Quote system, providing detailed RFQs and receiving validated pricing and lead times within hours, not days.

Technical Capabilities

Free-machining steels are engineered to enhance machinability, tool life, and surface finish in high-precision CNC operations such as 3-, 4-, and 5-axis milling and turning. These steels contain additives like sulfur, lead, or selenium that act as chip breakers and internal lubricants, reducing cutting forces and heat generation. This makes them ideal for tight-tolerance components requiring minimal post-processing.

While free-machining steels are optimized for steel-based applications, it is important to contrast their performance with other common prototyping and production materials such as aluminum, ABS, and nylon—especially in multi-axis machining environments where dimensional stability, thermal management, and tool wear are critical.

Below is a comparison of technical characteristics relevant to free-machining steels and alternative materials in precision CNC machining:

| Material | Typical Grade Examples | Machinability Rating (%) | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Max Achievable Tolerance (± mm) | Notes for 3/4/5-Axis Machining |

|---|---|---|---|---|---|---|---|

| Free-Machining Steel | AISI 12L14, AISI 1215, EN 32B | 70–85% (vs B1112 = 100%) | 540–680 | 160–220 | 45–52 | 0.012 | Excellent for tight-tolerance turned parts; produces small chips; limited weldability; high dimensional stability |

| Aluminum (Alloys) | 6061-T6, 7075-T6 | 90–100% | 310–570 | 95–150 | 150–200 | 0.010 | High MRR; excellent for complex 5-axis contours; low tool wear; requires proper chip evacuation |

| ABS (Thermoplastic) | ABS-M30, ABSplus | Not applicable (non-metal) | 35–45 | 80–100 (Shore D) | 0.15–0.25 | 0.050–0.100 | Low melting point; prone to burring; used in hybrid machining; minimal tool wear but sensitive to heat |

| Nylon (Polyamide) | Nylon 6, Glass-Filled Nylon | Not applicable | 70–85 (unfilled) | 85–110 | 0.25 | 0.050–0.125 | High moisture absorption; elastic recovery affects tolerances; requires sharp tools and stable fixturing |

Key Considerations for Free-Machining Steels in Precision Machining:

Chip Control: The sulfur and lead in steels like 12L14 promote discontinuous chip formation, critical for automated 4- and 5-axis operations where chip entanglement can damage tools or part surfaces.

Tool Life: Reduced friction and lower shear forces extend tool life compared to standard carbon steels, especially when using carbide or coated inserts.

Surface Finish: Free-machining steels typically yield Ra values below 0.8 µm (32 µin) in turning and milling, supporting tight-tolerance applications without grinding.

Dimensional Stability: These steels exhibit minimal warpage post-machining, essential for parts requiring ±0.012 mm tolerances and repeatable feature alignment in multi-axis setups.

While aluminum offers superior machinability and thermal performance, free-machining steels are preferred when higher strength, wear resistance, and structural rigidity are required in precision components such as bushings, shafts, and connectors. ABS and nylon, though easily machined, are generally reserved for non-structural or prototyping applications due to lower stiffness and thermal limitations.

For Honyo Prototype’s precision manufacturing workflows, free-machining steels provide a balanced solution for high-volume, tight-tolerance metal parts with excellent consistency across complex geometries.

From CAD to Part: The Process

Honyo Prototype Free-Machining Steel Manufacturing Process Overview

Honyo Prototype delivers precision components from free-machining steels such as 12L14, 1215, 303, and 416 through a rigorously defined workflow engineered for speed, cost efficiency, and material-specific optimization. This process leverages our AI-driven infrastructure and deep metallurgical expertise to address the unique characteristics of sulfur, lead, or selenium-enhanced alloys, which improve chip breakability and surface finish but require controlled machining parameters.

CAD Upload and Material Specification

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Crucially, the material selection must explicitly designate a free-machining steel grade. Our system validates geometric integrity and automatically flags potential conflicts with free-machining steel behaviors, such as excessive thin-wall sections prone to chatter or features requiring tight tolerances incompatible with inherent material variability. Failure to specify the correct grade triggers an immediate alert, preventing downstream quoting or DFM errors.

AI-Powered Quoting with Material Intelligence

Honyo’s proprietary AI engine processes the CAD geometry alongside the specified free-machining steel properties. The algorithm factors in grade-specific variables: lead content distribution effects on tool wear, sulfur-induced thermal sensitivity, and expected chip evacuation dynamics. This generates a granular cost and lead time estimate within 2 hours, differentiating free-machining steel economics from standard alloys through reduced cycle times and extended tool life. The quote explicitly itemizes savings derived from the material’s machinability index (e.g., 12L14 at 160% relative to 1212).

Material-Centric DFM Analysis

All free-machining steel projects undergo mandatory Design for Manufacturability review focused on metallurgical constraints. Our engineers evaluate:

| DFM Parameter | Free-Machining Steel Requirement | Risk Mitigation Action |

|---|---|---|

| Sulfur Distribution | Avoid features < 0.5mm thickness in high-sulfur zones | Recommend localized geometry thickening |

| Lead Content Zones | Isolate lead-rich areas from critical sealing surfaces | Suggest alternative sealing methods or plating |

| Chip Control | Minimize deep, narrow slots causing chip packing | Propose optimized toolpath sequencing or relief cuts |

| Surface Finish | Account for potential micro-inclusions affecting Ra | Adjust feed rates/tool selection in critical zones |

This phase identifies cost drivers unique to free-machining steels, such as the need for specialized coolant formulations to manage lead oxidation or the exclusion of certain finishing processes incompatible with sulfur stringers. Clients receive a formal DFM report with actionable recommendations prior to approval.

Precision Production with Alloy-Specific Protocols

Upon DFM sign-off, production executes under controlled parameters calibrated for the specific free-machining steel grade:

CNC machining employs reduced spindle speeds (15-20% below 1018 steel) but higher feed rates to leverage chip-breaking properties

Tooling utilizes sub-micron carbide grades with TiAlN coatings resistant to sulfur adhesion

In-process inspection includes real-time chip morphology monitoring to detect material inconsistencies

Post-machining, parts undergo ultrasonic cleaning with non-acidic solutions to prevent lead smearing

All free-machining steel lots are traceable to mill certificates, with critical dimensions verified against ASTM A576 or AMS 4800 standards as applicable.

Certified Delivery and Documentation

Final inspection confirms conformance to drawing tolerances and material specifications, with test reports including:

Dimensional verification per ASME Y14.5

Material certification traceability (heat number, mill test report)

Surface roughness validation against specified Ra/Rz values

Non-destructive testing results if required (e.g., MPI for critical threads)

Parts ship with protective packaging to prevent corrosion of sulfur-rich surfaces, accompanied by full documentation for audit compliance. Typical lead time from CAD upload to delivery for free-machining steel prototypes is 5-7 business days, reflecting the accelerated machining inherent to these alloys.

This integrated process ensures clients achieve optimal cost, speed, and quality outcomes by systematically addressing the metallurgical realities of free-machining steels at every stage, from digital submission to certified physical delivery.

Start Your Project

Looking for high-performance free-machining steels for your next precision component project? Honyo Prototype offers expert material selection and machining services from our state-of-the-art facility in Shenzhen.

Contact Susan Leo today to discuss your requirements and receive technical support tailored to your application.

Email: [email protected]

Leverage our manufacturing expertise to optimize machinability, reduce cycle times, and improve part consistency—request a quote or material consultation now.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.