Introduction: Navigating the Global Market for free cnc programming software

In an increasingly competitive global market, sourcing free CNC programming software can be a daunting challenge for businesses aiming to optimize their production processes without straining their budgets. As manufacturing landscapes evolve, the need for cost-effective solutions that enhance efficiency and precision has never been more critical. This comprehensive guide delves into the diverse types of free CNC programming software available, exploring their applications across various industries and machine types. From CAD and CAM tools to CNC control software, we cover essential features that cater to both beginners and seasoned professionals.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe—regions characterized by rapid industrial growth and unique market dynamics—making informed purchasing decisions is vital. This guide empowers you by providing insights into supplier vetting processes, highlighting key software functionalities, and offering cost considerations to help you navigate the complexities of software selection. By understanding the full spectrum of options available, you can effectively streamline your operations, reduce errors, and ultimately enhance your bottom line. Whether you’re looking to support a small workshop or a large-scale manufacturing facility, this resource is designed to facilitate your journey towards finding the right free CNC programming software tailored to your specific needs.

Understanding free cnc programming software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CAD Software | Allows design creation; outputs files like STL, DXF | Product design, prototyping | Pros: Free; versatile file formats. Cons: Steeper learning curve for complex software. |

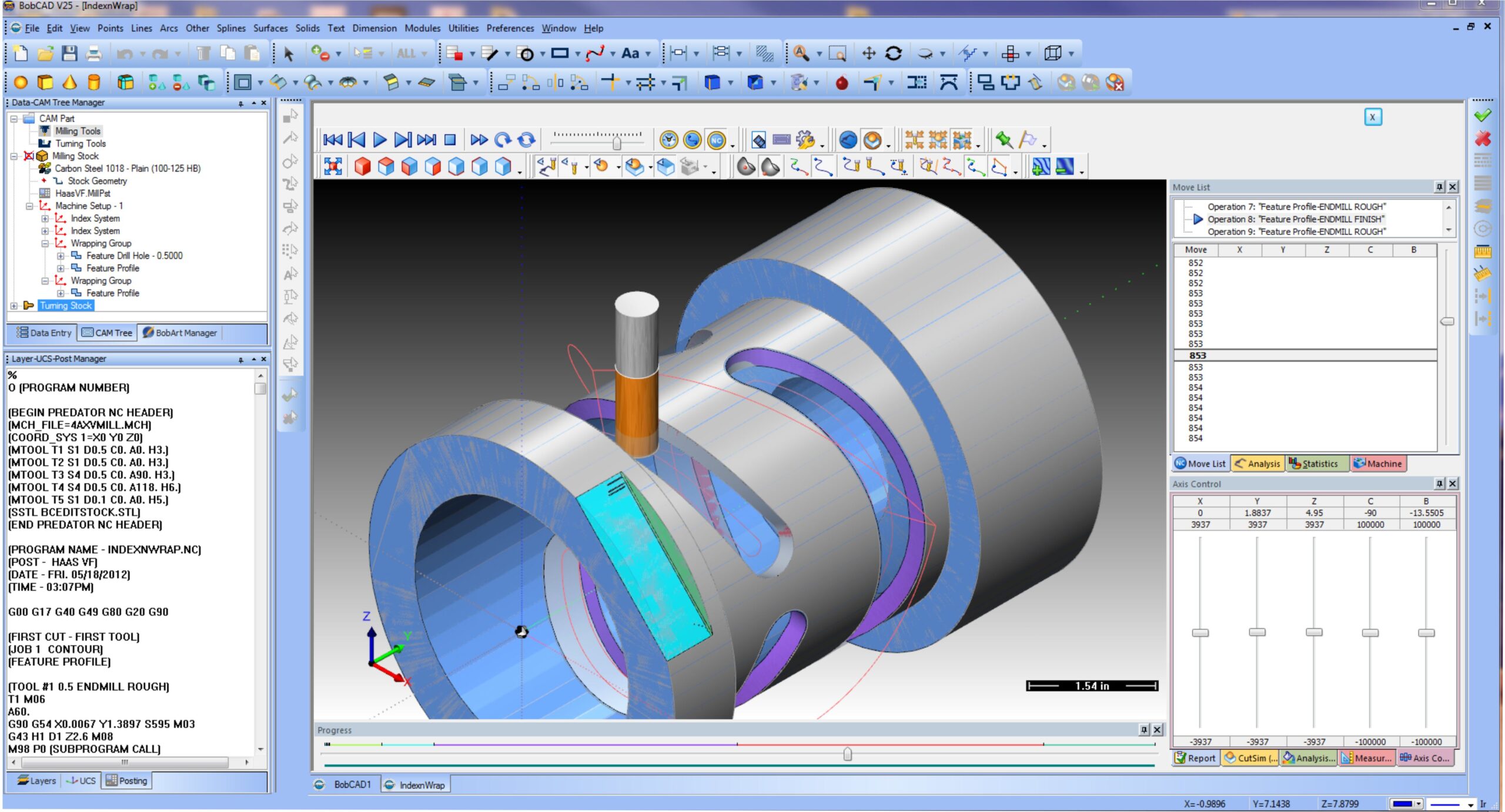

| CAM Software | Generates toolpaths from CAD designs; outputs G-code | Manufacturing, CNC machining | Pros: Essential for machine operation; some offer integrated CAD. Cons: Limited features in free versions. |

| Integrated CAD/CAM | Combines design and toolpath generation in one platform | Small businesses, hobbyists | Pros: Streamlined workflow; user-friendly. Cons: May lack advanced features of separate software. |

| CNC Control Software | Directly interfaces with CNC machines for operation | Industrial automation, machinery control | Pros: Critical for machine performance. Cons: Compatibility issues with different CNC models. |

| Simulation Software | Visualizes toolpaths and machining processes | Quality assurance, training | Pros: Reduces errors; enhances understanding. Cons: Often requires additional software for full functionality. |

What Are the Key Characteristics of CAD Software for CNC Programming?

CAD (Computer-Aided Design) software is fundamental for creating detailed designs before they are translated into machine-readable code. It allows users to draw and model parts in 2D or 3D, with outputs in various formats like STL and DXF. For B2B buyers, the choice of CAD software can significantly impact the design process’s efficiency and precision. While many free options exist, the complexity and learning curve can vary, making it essential to consider the skill level of the users in the organization.

How Does CAM Software Enhance CNC Machining Efficiency?

CAM (Computer-Aided Manufacturing) software is crucial for converting CAD designs into toolpaths that CNC machines can follow. This software outputs G-code, which directs the machine’s movements and operations. For businesses focused on manufacturing, selecting effective CAM software can lead to improved machining accuracy and reduced production time. However, free versions may come with limitations, so buyers should evaluate their specific requirements against the software’s capabilities.

Why Choose Integrated CAD/CAM Solutions for Small Businesses?

Integrated CAD/CAM solutions combine the functionalities of both CAD and CAM software into a single platform, simplifying the workflow for users. These solutions are particularly beneficial for small businesses and hobbyists who may not require the advanced features of separate software packages. The ease of use and streamlined processes can enhance productivity, but potential buyers should assess whether these solutions meet their specific machining needs without sacrificing quality.

What Role Does CNC Control Software Play in CNC Operations?

CNC control software is vital for managing the actual operation of CNC machines. It translates G-code into machine movements and ensures that the CNC machine executes tasks correctly. For B2B buyers, the compatibility of the control software with their specific CNC equipment is a critical consideration. While some free options exist, the reliability and performance of these software solutions can significantly influence operational efficiency.

How Can Simulation Software Improve CNC Programming Outcomes?

Simulation software allows users to visualize and test toolpaths before actual machining begins, reducing the risk of errors and improving overall project outcomes. This type of software is particularly useful for quality assurance and training purposes. B2B buyers should consider the integration capabilities of simulation software with their existing CAD/CAM systems, as well as the potential for reducing costly mistakes during production runs.

Key Industrial Applications of free cnc programming software

| Industry/Sector | Specific Application of Free CNC Programming Software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision Component Manufacturing | Reduces production costs while maintaining high accuracy. | Compatibility with high-precision CNC machines. |

| Automotive | Prototyping and Tooling | Speeds up the design-to-production cycle, enhancing agility. | Availability of support for specific CNC machine types. |

| Furniture Design | Custom Furniture Fabrication | Enables unique designs and customization at lower costs. | User-friendly interface for designers with varying skills. |

| Electronics Manufacturing | PCB and Enclosure Fabrication | Streamlines the production process, reducing lead times. | Integration with existing CAD systems for seamless workflow. |

| Education & Training | CNC Machining Education Programs | Provides hands-on experience for students at no cost. | Accessibility of software for diverse educational institutions. |

How is Free CNC Programming Software Used in Aerospace Manufacturing?

In the aerospace industry, free CNC programming software is instrumental in the precision manufacturing of components. These software solutions help engineers and machinists convert complex designs into G-Code, enabling CNC machines to produce parts with tight tolerances. The challenge for international buyers, particularly in regions like the Middle East and Europe, is ensuring compatibility with high-precision CNC machinery. Additionally, businesses must consider software that can handle specialized materials used in aerospace applications.

What Role Does Free CNC Software Play in Automotive Prototyping?

Automotive companies leverage free CNC programming software for rapid prototyping and tooling, which accelerates the development process of new vehicles. By using these tools, manufacturers can quickly iterate designs and produce test components without significant investment in expensive software. For buyers in South America and Africa, the focus should be on software that integrates well with existing design systems and supports various CNC machine types, ensuring a smooth transition from design to production.

How Can Free CNC Software Benefit Furniture Design?

In the furniture design sector, free CNC programming software allows designers to create custom pieces tailored to client specifications. This flexibility enables small businesses to compete with larger manufacturers by offering unique designs at competitive prices. For buyers, especially in Europe and Africa, it is crucial to select software that is user-friendly, allowing designers of varying skill levels to easily navigate the design and machining process, thus enhancing productivity.

What Advantages Does Free CNC Software Provide in Electronics Manufacturing?

Electronics manufacturers utilize free CNC programming software for producing printed circuit boards (PCBs) and enclosures. These applications streamline the production process, reducing lead times and minimizing errors. International buyers should prioritize software that can integrate seamlessly with their existing CAD systems, ensuring that the transition from design to production is efficient and cost-effective. Additionally, support for various CNC machine types is essential for flexibility in production.

How is Free CNC Programming Software Used in Education and Training?

Free CNC programming software is invaluable in educational settings, providing students with hands-on experience in CNC machining without financial barriers. Educational institutions can implement these tools in their curricula, allowing students to learn essential skills in a cost-effective manner. For schools in regions like Africa and South America, it is important to choose software that is accessible and easy to learn, facilitating a smooth educational experience and preparing students for careers in manufacturing and engineering.

3 Common User Pain Points for ‘free cnc programming software’ & Their Solutions

Scenario 1: Navigating the Learning Curve of Free CNC Programming Software

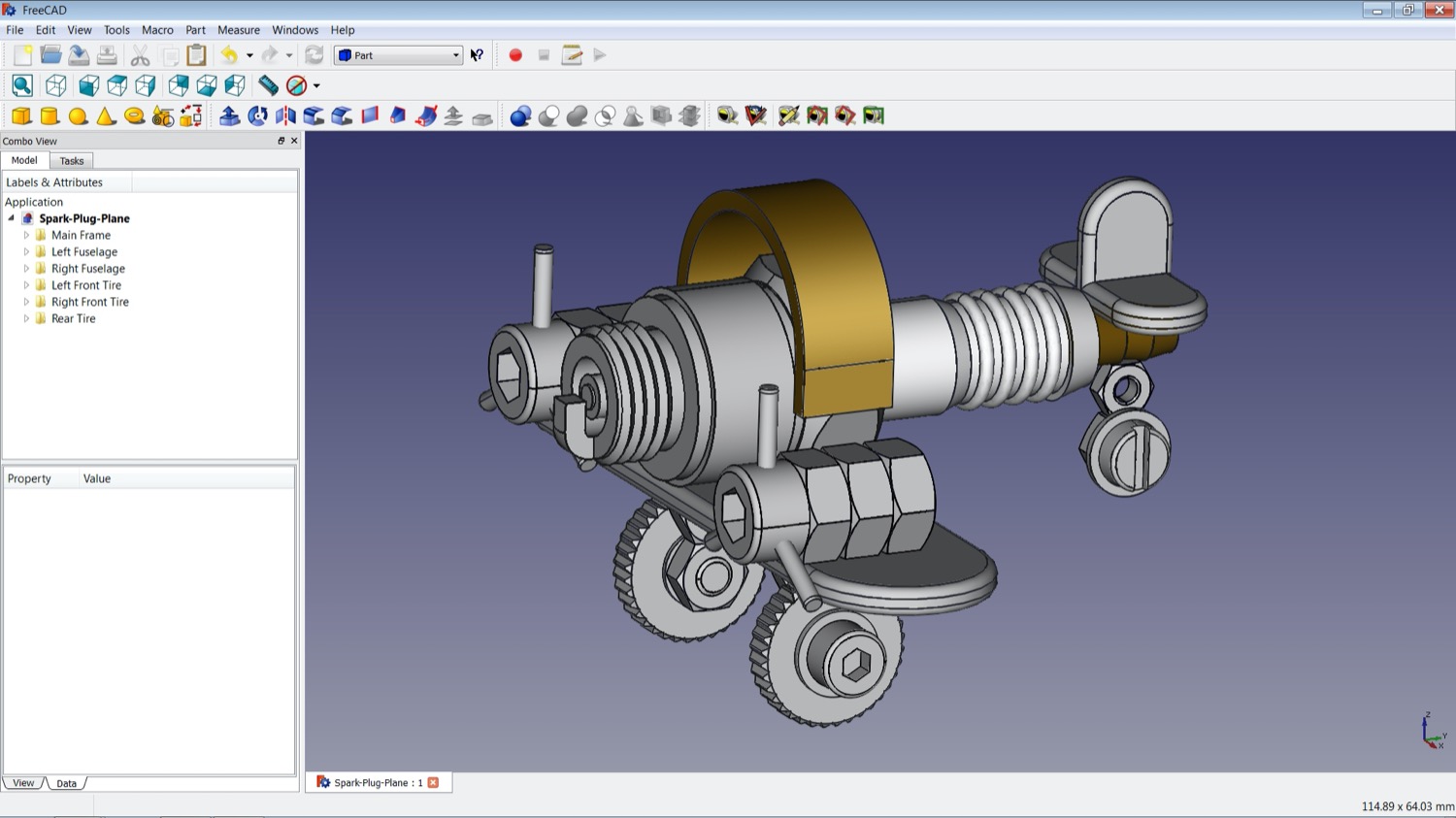

The Problem: Many B2B buyers, particularly those from regions with limited technical resources, struggle with the complexity of free CNC programming software. For instance, while platforms like FreeCAD and Carbide Create offer robust features, their steep learning curves can be overwhelming for teams without prior CNC experience. Users often find themselves frustrated, unable to complete projects efficiently or accurately due to inadequate training materials and limited user support. This can lead to wasted time and potential project delays, negatively impacting productivity and profitability.

The Solution: To mitigate this issue, businesses should invest in structured training sessions for their teams. This could involve sourcing online courses or engaging local CNC experts to provide hands-on workshops tailored to the specific software in use. Additionally, leveraging online communities and forums dedicated to CNC programming can provide users with invaluable insights and troubleshooting tips from experienced peers. Setting up a mentorship program within the company can also facilitate knowledge transfer and empower less experienced users to gain confidence in their abilities. Establishing a supportive learning environment will enhance overall competency and reduce dependency on external resources over time.

Scenario 2: Software Compatibility and Integration Challenges

The Problem: A common issue faced by B2B buyers is the lack of compatibility between free CNC programming software and existing hardware or other software tools. For example, companies may invest in a free CAM solution like Easel, only to discover that it doesn’t seamlessly integrate with their CNC machines or CAD software. This misalignment can lead to frustrating workarounds, increased downtime, and even the inability to complete projects, which can erode trust in the technology and stall production schedules.

The Solution: Before committing to any free CNC programming software, businesses should conduct a thorough compatibility assessment. This involves evaluating the specifications and requirements of both the software and the existing CNC equipment. Companies should also consider engaging with software vendors to inquire about integration capabilities and any available plugins or updates that could enhance compatibility. Additionally, maintaining an inventory of all software and hardware components can help streamline future upgrades or replacements. Seeking user reviews and case studies from similar industries can provide insights into successful integrations and help avoid potential pitfalls.

Scenario 3: Limited Features and Scalability Issues

The Problem: While free CNC programming software can be a great entry point, many users quickly find themselves limited by the basic features offered. For instance, small manufacturers might start with a free version of a CAD/CAM tool only to realize it lacks advanced functionalities like 3D modeling or complex toolpath strategies necessary for more intricate projects. This limitation can hinder growth and innovation, forcing companies to either compromise on quality or invest in costly upgrades to paid software, which can disrupt budgets and financial planning.

The Solution: To address this, businesses should carefully evaluate their long-term needs before selecting free CNC programming software. A pragmatic approach involves identifying essential features that align with current and future project requirements, and then prioritizing software that can grow with the company. Companies might also explore hybrid solutions that allow them to use free software for basic tasks while gradually transitioning to paid versions as their needs evolve. Establishing a clear roadmap for software utilization and growth can help manage expectations and ensure that the chosen software supports both immediate needs and future scalability. Regularly revisiting this roadmap will allow teams to adapt to technological advancements and changes in project scope effectively.

Strategic Material Selection Guide for free cnc programming software

What are the Key Properties of Common Materials for Free CNC Programming Software?

In the realm of CNC programming software, the selection of materials for the end products created using this software can significantly influence performance and usability. Below, we analyze four common materials that are often machined using CNC technology, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Metals Perform in CNC Machining?

Aluminum is a widely used material in CNC machining due to its favorable properties. It has a low density, excellent corrosion resistance, and good thermal conductivity. These properties make aluminum ideal for applications in automotive, aerospace, and consumer electronics.

- Pros: Aluminum is lightweight, easy to machine, and offers a good strength-to-weight ratio. It is also relatively inexpensive compared to other metals.

- Cons: While durable, aluminum can be prone to scratching and denting. Additionally, its thermal expansion can lead to dimensional changes in high-temperature applications.

- Impact on Application: Aluminum is compatible with various CNC machining processes and can be used for intricate designs, making it suitable for a range of products.

- Considerations for International Buyers: Compliance with ASTM standards for aluminum alloys is crucial. In regions like the Middle East and Europe, buyers should ensure that the material meets local regulations for aerospace and automotive applications.

What Are the Benefits of Using Plastics in CNC Machining?

Acrylic is a popular plastic material used in CNC machining for its clarity and aesthetic appeal. It is often used in signage, displays, and protective barriers.

- Pros: Acrylic is lightweight, shatter-resistant, and easy to fabricate. It can be polished to achieve a high-gloss finish, enhancing its visual appeal.

- Cons: Acrylic is less durable than metals and can be susceptible to scratching and UV degradation over time.

- Impact on Application: Acrylic is ideal for applications where visibility and aesthetics are paramount, but it may not be suitable for high-stress environments.

- Considerations for International Buyers: Buyers should be aware of the specific grades of acrylic that comply with local standards, such as DIN for Germany or JIS for Japan, especially when used in public spaces.

How Does Wood Compare as a Material in CNC Applications?

Plywood is frequently used in CNC machining for furniture, cabinetry, and decorative items. Its layered structure provides strength and stability.

- Pros: Plywood is relatively inexpensive and easy to work with, making it suitable for a variety of applications. It also offers good resistance to warping.

- Cons: The quality of plywood can vary significantly based on the type of wood and adhesive used, impacting durability. It may also be less resistant to moisture compared to other materials.

- Impact on Application: Plywood can be machined into complex shapes, but its performance can be affected by environmental conditions, making it less suitable for outdoor applications without proper treatment.

- Considerations for International Buyers: Compliance with local standards for wood products, such as CARB in the U.S. or EN standards in Europe, is essential for ensuring product safety and sustainability.

What Are the Advantages of Using Composites in CNC Machining?

Carbon Fiber Reinforced Polymer (CFRP) is increasingly popular in high-performance applications such as aerospace and automotive due to its high strength-to-weight ratio.

- Pros: CFRP is extremely strong and lightweight, offering excellent fatigue resistance and dimensional stability.

- Cons: The cost of CFRP can be significantly higher than traditional materials. Additionally, machining CFRP requires specialized tools to prevent damage.

- Impact on Application: CFRP is ideal for applications where performance is critical, but its cost and machining complexity can limit its use in lower-budget projects.

- Considerations for International Buyers: Buyers should verify that CFRP materials meet international aerospace standards, such as those set by the FAA or EASA, especially in regions like Europe and the Middle East.

Summary Table of Material Selection for Free CNC Programming Software

| Material | Typical Use Case for free cnc programming software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, electronics | Lightweight and easy to machine | Prone to scratching and thermal expansion | Medium |

| Acrylic | Signage, displays | Shatter-resistant and visually appealing | Less durable, UV degradation | Low |

| Plywood | Furniture, cabinetry | Inexpensive and easy to work with | Quality variability, moisture sensitivity | Low |

| Carbon Fiber Reinforced Polymer | Aerospace, automotive applications | High strength-to-weight ratio | High cost, requires specialized machining | High |

This strategic material selection guide aims to provide B2B buyers with actionable insights to make informed decisions when utilizing free CNC programming software for their manufacturing needs.

In-depth Look: Manufacturing Processes and Quality Assurance for free cnc programming software

What Are the Key Manufacturing Processes for Free CNC Programming Software?

When it comes to the production of free CNC programming software, the manufacturing process primarily involves software development rather than traditional physical manufacturing. This process typically includes several key stages: material preparation (in this context, the development of software requirements), forming (coding and algorithm development), assembly (integration of various software components), and finishing (testing and deployment).

How Is Software Material Prepared for CNC Programming?

Material preparation in the context of CNC software involves gathering requirements and defining functionalities. This stage is crucial as it sets the foundation for the software’s capabilities. Developers conduct market research to identify user needs, followed by drafting software specifications that outline the features, usability, and compatibility with various CNC machines. This often involves collaboration with industry experts to ensure that the software meets the specific needs of different sectors, including woodworking, metalworking, and prototyping.

What Techniques Are Used in Forming CNC Programming Software?

Forming, or coding, is where the actual development of the software takes place. This involves utilizing programming languages such as C++, Python, or Java to create the software architecture. Key techniques in this stage include:

- Algorithm Development: Creating algorithms that convert design files into G-Code, the language understood by CNC machines. This is a critical function, as the accuracy of the G-Code directly impacts the quality of the machining process.

- User Interface (UI) Design: Developing an intuitive UI that allows users to easily navigate through the software. This is particularly important for free software targeted at beginners.

- Integration of Libraries and APIs: Leveraging existing libraries and APIs for functions like file import/export, machine control, and toolpath generation. This helps streamline the development process and enhance functionality.

How Is Software Assembled in CNC Programming Development?

The assembly phase involves integrating various components of the software. This may include:

- Combining CAD and CAM Functions: Many free CNC programming software solutions combine both CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) functionalities. This integration allows users to design their parts and create the necessary toolpaths in one platform.

- Testing Modules: Incorporating testing modules that simulate machine operations to ensure that the software generates correct and efficient G-Code before deployment.

What Finishing Processes Are Involved in CNC Programming Software Development?

Finishing in software development focuses on debugging, testing, and preparing the software for release. This includes:

- Quality Assurance Testing: Rigorous testing is conducted to identify bugs and ensure that the software performs as expected. This includes unit testing, integration testing, and user acceptance testing.

- Documentation and Support: Providing comprehensive documentation and user support to assist users in understanding the software and troubleshooting common issues.

What Quality Assurance Practices Are Essential for Free CNC Programming Software?

Quality assurance (QA) is a critical aspect of software development, particularly for free CNC programming software. Implementing robust QA practices ensures that the software is reliable and meets international standards.

How Do International Standards Like ISO 9001 Apply to CNC Software?

ISO 9001 is an international standard that specifies requirements for a quality management system (QMS). For software development, adhering to ISO 9001 means:

- Process Orientation: Establishing clear processes for software development, including requirement gathering, coding, testing, and deployment.

- Continuous Improvement: Implementing feedback mechanisms to enhance software quality over time based on user experiences and technological advancements.

What Are the Key Quality Control Checkpoints in CNC Software Development?

Quality control (QC) checkpoints are vital for maintaining software integrity. Common QC checkpoints include:

- Incoming Quality Control (IQC): Evaluating the quality of third-party libraries and APIs used in the software to ensure they meet required standards.

- In-Process Quality Control (IPQC): Conducting regular code reviews and testing during the development process to catch errors early.

- Final Quality Control (FQC): Performing comprehensive testing and validation before the software is released to the public.

How Can B2B Buyers Verify the Quality Control of CNC Software Suppliers?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of CNC software suppliers is crucial. Here are actionable steps to ensure the reliability of the software:

What Audit Processes Should Be Conducted?

Conducting audits of potential suppliers can reveal their commitment to quality. This includes:

- Documentation Review: Requesting documentation of their QMS and any certifications (such as ISO 9001) that demonstrate adherence to quality standards.

- On-Site Audits: If feasible, performing on-site audits to observe the development processes and QA practices in action.

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspectors or consultants can provide an unbiased assessment of the software quality. These experts can evaluate the software against industry benchmarks and provide insights into its performance and reliability.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must consider specific quality control nuances when sourcing CNC programming software:

- Regulatory Compliance: Understanding the regulatory landscape in your region and ensuring that the software complies with local standards and requirements.

- Localization and Support: Evaluating whether the software supplier offers localized versions of their software and adequate support in your region’s language.

In summary, understanding the manufacturing processes and quality assurance practices for free CNC programming software is essential for B2B buyers. By focusing on reliable suppliers who adhere to international standards and implementing robust quality control measures, businesses can enhance their CNC machining capabilities and ensure the success of their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘free cnc programming software’

To assist international B2B buyers in effectively procuring free CNC programming software, this guide outlines a systematic checklist. By following these actionable steps, you can streamline your selection process, ensuring you choose the software that best meets your operational needs.

Step 1: Define Your Technical Specifications

Before exploring software options, clearly outline your technical requirements. Consider the types of CNC machines you will be using, the complexity of your projects, and the specific functionalities you need—such as CAD, CAM, or G-Code generation. This foundational step helps narrow down your choices and ensures compatibility with your existing systems.

Step 2: Research Available Free Software Options

Conduct thorough research on the available free CNC programming software. Look for reputable sources and software reviews that highlight the features and limitations of each program. Popular options include Carbide Create and Easel, which are particularly user-friendly for beginners. Understanding the landscape of free software will provide a solid foundation for your decision-making process.

Step 3: Evaluate Software Features and Usability

Assess the features of each software package against your defined specifications. Consider aspects such as:

– User Interface: Is it intuitive and easy to navigate?

– Functionality: Does it support both CAD and CAM processes?

– File Compatibility: Can it export files in the formats you require (e.g., STL, DXF)?

Evaluating these factors will help you identify software that can enhance your productivity and efficiency.

Step 4: Check Community Support and Resources

A strong user community can significantly impact your experience with any software. Look for platforms where users share tips, tutorials, and troubleshooting advice. Resources like forums, YouTube channels, and dedicated websites can be invaluable for learning and overcoming challenges. A vibrant community often indicates a widely adopted and reliable software solution.

Step 5: Test the Software Before Committing

Many free CNC programming software options allow for trial periods or have no-cost versions. Take advantage of these opportunities to test the software in real-world scenarios. Focus on how well it integrates with your workflow and whether it meets your expectations for performance and ease of use. This step is crucial to avoid potential disruptions in your operations.

Step 6: Evaluate Long-Term Viability and Updates

Consider the long-term support and viability of the software. Free software can sometimes be discontinued or lack regular updates, which can leave you vulnerable to security issues or compatibility problems in the future. Research the developer’s track record for updates and community engagement to ensure that you are choosing a sustainable option.

Step 7: Document Your Findings and Make an Informed Decision

Compile your research and testing results into a comprehensive document. This should include your evaluations of each software’s features, usability, community support, and long-term viability. Sharing this documentation with your team can facilitate discussion and ensure that all stakeholders are aligned before making a final decision.

By following this checklist, B2B buyers can systematically approach the procurement of free CNC programming software, ensuring that their chosen solution effectively supports their operational needs and enhances their machining capabilities.

Comprehensive Cost and Pricing Analysis for free cnc programming software Sourcing

What Are the Key Cost Components of Free CNC Programming Software?

When evaluating the cost structure for free CNC programming software, it’s essential to understand the underlying components that contribute to its value. Although the software itself may be free, associated costs can arise from various factors, including:

-

Materials: In the context of CNC programming, the materials refer primarily to the hardware on which the software will be utilized. High-quality CNC machines and components might require investment, which can impact the overall cost.

-

Labor: While the software is free, the cost of skilled labor to operate CNC machines remains a significant factor. Training personnel in using the software effectively can incur costs, especially if advanced capabilities are required.

-

Manufacturing Overhead: This includes expenses related to operating the CNC machines, such as electricity, maintenance, and facility costs. These are recurring costs that should be factored into the overall budget.

-

Tooling: Depending on the complexity of the projects, investing in specialized tools or attachments may be necessary. This will affect the total expenditure.

-

Quality Control (QC): Ensuring that the outputs from CNC machines meet quality standards may require additional resources for inspections and testing.

-

Logistics: If the software needs to be integrated with different machines across various locations, there may be logistical costs associated with installation and support.

-

Margin: For free software, the margin is less about the software price and more about the value it brings to the business. This could involve assessing how much time and cost savings the software can provide.

How Do Price Influencers Affect Free CNC Programming Software Selection?

Several factors can influence the effective costs associated with free CNC programming software, impacting B2B buyers’ decisions:

-

Volume/MOQ: The volume of software licenses required can influence negotiations. Some suppliers may offer additional features or support for bulk purchases.

-

Specifications/Customization: While many free options exist, customization may come at a cost. Buyers should assess whether they need tailored features that could drive up expenses.

-

Materials and Quality Certifications: The quality of the CNC machine and the software’s compatibility with various materials can also affect pricing. Software that supports higher-quality machining processes may yield better returns.

-

Supplier Factors: Reliability, support, and reputation of the software supplier are crucial. Suppliers offering robust after-sales support may justify higher costs through improved operational efficiencies.

-

Incoterms: Understanding the terms of sale, including delivery and liability, is vital for international buyers. This can impact the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Free CNC Programming Software?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable strategies to optimize costs:

-

Negotiation: Even when dealing with free software, negotiating for support or additional features can provide significant value. Don’t hesitate to explore options that may enhance your operational capabilities.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the immediate savings from using free software but also the long-term costs associated with maintenance, updates, and potential training.

-

Understand Pricing Nuances for International Markets: Be aware that software costs can vary significantly by region. Some suppliers may offer localized versions or support that can enhance usability and efficiency.

-

Seek Community Support: Many free software solutions have user communities. Engaging with these can provide insights into best practices and troubleshooting without incurring additional costs.

-

Monitor Updates and Features: Free software may evolve over time, offering new features or capabilities. Stay informed to leverage these updates effectively.

Disclaimer on Indicative Prices

While many CNC programming software options are available for free, associated costs can vary widely based on the factors discussed above. It’s crucial for buyers to perform thorough due diligence, considering both direct and indirect costs when making decisions.

Alternatives Analysis: Comparing free cnc programming software With Other Solutions

Introduction: Exploring Alternatives to Free CNC Programming Software

In the landscape of CNC programming, free software solutions provide accessible entry points for businesses looking to optimize their machining processes. However, the effectiveness of these tools may vary based on specific project requirements and operational contexts. This section explores alternative solutions to free CNC programming software, allowing B2B buyers to make informed decisions based on their unique needs.

Comparison Table

| Comparison Aspect | Free CNC Programming Software | Paid CAD/CAM Software | Open-Source CNC Solutions |

|---|---|---|---|

| Performance | Good for basic tasks; may lag with complex projects | High performance; optimized for various machine types | Generally high performance; community-driven improvements |

| Cost | Free | $200 – $5,000+ (one-time or subscription) | Free, with optional paid support |

| Ease of Implementation | User-friendly for basic use; may require learning curve for advanced features | Moderate; often requires training | Varies by software; may need technical knowledge |

| Maintenance | Limited support; community forums available | Full customer support included | Community-driven; support varies |

| Best Use Case | Hobbyists, small-scale projects | Professional machining, complex designs | Custom applications, experimental projects |

Detailed Breakdown of Alternatives

1. Paid CAD/CAM Software

Paid CAD/CAM software options, such as Alibre Atom or Fusion 360, offer robust features that cater to professional machinists and larger enterprises. These programs provide advanced functionalities, including better toolpath optimization, support for complex geometries, and integration with various CNC machines. However, the significant cost associated with these solutions can be a barrier for small businesses or hobbyists. Furthermore, while the learning curve is moderate, the investment in training may be necessary to leverage their full capabilities effectively.

2. Open-Source CNC Solutions

Open-source CNC software presents a viable alternative for businesses seeking customization and flexibility without the financial burden of commercial products. Programs like LinuxCNC or GRBL provide comprehensive control over CNC machinery, allowing for tailored solutions to specific machining needs. The pros of open-source software include a strong community for support and continuous updates. However, these tools may require a higher level of technical expertise to implement and maintain, making them less suitable for users without programming knowledge or those seeking a quick setup.

Conclusion: How to Choose the Right CNC Programming Solution

Selecting the right CNC programming solution involves assessing your specific operational needs, budget constraints, and the complexity of your projects. For businesses just starting out or with limited resources, free CNC programming software can be a practical entry point. However, for those requiring advanced features or dealing with intricate designs, investing in paid software or exploring open-source options may yield better long-term results. Evaluating these alternatives will empower B2B buyers to make strategic decisions that align with their machining goals and operational capabilities.

Essential Technical Properties and Trade Terminology for free cnc programming software

When considering free CNC programming software, it’s essential to understand the technical properties and terminology that influence decision-making in a B2B context. This knowledge not only helps in selecting the right software but also aids in enhancing operational efficiency and cost-effectiveness.

What are the Key Technical Properties of Free CNC Programming Software?

-

Compatibility with CAD/CAM Systems

Compatibility refers to the software’s ability to seamlessly integrate with various Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. This is crucial for businesses as it determines how easily design files can be converted into machine-readable formats, affecting workflow efficiency. For example, software like Carbide Create supports various file formats such as SVG and DXF, allowing users to import designs easily and reduce conversion errors. -

User Interface and Ease of Use

A user-friendly interface is vital, especially for teams with varying levels of technical expertise. Software that is intuitive minimizes training time and accelerates the production process. For instance, Easel’s straightforward design and integrated toolpath generation make it particularly appealing for beginners and hobbyists, fostering faster adoption and reducing operational disruptions. -

Toolpath Generation Capabilities

This property describes the software’s ability to create optimized toolpaths for CNC machines. Effective toolpath generation enhances machining accuracy and efficiency, directly impacting production costs and material usage. Advanced software may offer customizable toolpath strategies, such as pocketing or contouring, which can lead to significant time savings in the machining process. -

G-Code Generation

G-Code is the language used to control CNC machines, dictating their movements. The ability of free CNC software to generate accurate G-Code is essential for ensuring that machines operate correctly and efficiently. Software like Carbide Create simplifies this process, allowing users to produce G-Code without needing in-depth programming knowledge, which is especially beneficial for small businesses or startups. -

Support and Community Resources

Access to support and community resources can significantly enhance the user experience. Software that provides forums, tutorials, and customer support can help users troubleshoot issues quickly, minimizing downtime. This is particularly important for B2B buyers who rely on consistent machine operation to meet production deadlines.

What are Common Trade Terms in CNC Software Procurement?

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help businesses identify software that is specifically designed for their machines, ensuring compatibility and optimal performance. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. While this term is more common in product procurement, it can also apply to software licenses, especially for companies looking to scale operations. Knowing the MOQ can help businesses plan their budget and purchase decisions effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on providing specific goods or services. For CNC software, issuing an RFQ can help companies compare different software solutions based on features, pricing, and support, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help businesses navigate logistics and shipping for software licenses, especially when dealing with international suppliers. -

SLA (Service Level Agreement)

An SLA is a contract that outlines the expected level of service between a service provider and a customer. For software, this might include uptime guarantees, support response times, and maintenance schedules. Having a clear SLA ensures businesses can hold software providers accountable for their services. -

Version Control

This term refers to the management of changes to software over time. Effective version control ensures that users can track updates and maintain compatibility with older project files, which is essential for businesses that rely on ongoing projects and iterative design processes.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions about free CNC programming software, leading to enhanced operational efficiency and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the free cnc programming software Sector

What Are the Current Market Dynamics and Key Trends in Free CNC Programming Software?

The landscape of free CNC programming software is rapidly evolving, influenced by several global drivers that cater to the needs of international B2B buyers. A significant trend is the increasing demand for cost-effective solutions in regions such as Africa, South America, the Middle East, and Europe. As many businesses in these areas seek to optimize production without incurring high software costs, free CNC software presents an attractive alternative. The proliferation of open-source platforms has empowered manufacturers to leverage robust software without the financial burden typically associated with licensed products.

Moreover, technological advancements are reshaping the software capabilities available to users. The integration of user-friendly interfaces, intuitive design tools, and comprehensive functionalities—such as CAD and CAM capabilities in a single platform—enhances accessibility for beginners and experts alike. This trend is particularly relevant for emerging markets, where the workforce may require simplified solutions to quickly adopt CNC technologies.

Additionally, the rise of cloud-based solutions is becoming increasingly prominent. These platforms facilitate collaboration and real-time updates, crucial for teams distributed across different geographical locations. For B2B buyers, understanding these dynamics is essential to effectively navigate the software landscape and capitalize on the benefits offered by free CNC programming solutions.

How Can Sustainability and Ethical Sourcing Impact the Free CNC Programming Software Sector?

Sustainability and ethical sourcing are becoming critical considerations in the B2B landscape, including the free CNC programming software sector. As businesses globally strive to reduce their environmental impact, the software they choose can play a role in promoting sustainable practices. For instance, free CNC software can enable companies to optimize their machining processes, leading to reduced waste and energy consumption. By employing efficient toolpath strategies and minimizing machine downtime, organizations can achieve both cost savings and environmental benefits.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly seeking vendors that prioritize transparency and sustainability in their operations. This trend extends to software solutions, where companies are encouraged to ensure that their software development processes adhere to ethical standards, such as fair labor practices and responsible sourcing of materials. Certifications and green labels can serve as indicators of a software provider’s commitment to sustainability, thus influencing purchasing decisions among conscientious buyers.

As organizations across various sectors prioritize sustainability, free CNC programming software offers an opportunity to align operational practices with broader environmental goals, making it a strategic choice for forward-thinking B2B buyers.

What Is the Brief Evolution and History of Free CNC Programming Software?

The evolution of free CNC programming software reflects the broader technological advancements in manufacturing and design. Initially, CNC programming relied heavily on expensive, proprietary software that limited access for smaller companies and emerging markets. However, the rise of open-source initiatives and the democratization of technology in the late 20th century paved the way for free software solutions.

In the early 2000s, as 3D printing gained traction, the demand for accessible CAD and CAM software surged, leading to the development of various free tools designed to cater to both hobbyists and professionals. This transition was further accelerated by community-driven platforms that fostered collaboration and innovation, enabling users to share knowledge and improve software capabilities collectively.

Today, the landscape is characterized by a diverse array of free CNC programming tools that cater to varying skill levels and applications. This evolution has not only made CNC technology more accessible but has also empowered a new generation of manufacturers to harness the power of CNC machining without the significant overhead costs previously associated with proprietary software. For B2B buyers, understanding this evolution is crucial to making informed decisions that align with their operational needs and budget constraints.

Frequently Asked Questions (FAQs) for B2B Buyers of free cnc programming software

-

How do I choose the right free CNC programming software for my business needs?

Selecting the appropriate free CNC programming software involves assessing your specific operational requirements. Consider the types of CNC machines you are using, the complexity of the designs you need to create, and whether you require both CAD and CAM functionalities. Evaluate user reviews and community support, especially from similar industries. Ensure compatibility with your existing systems and check for additional features like G-code generation and toolpath customization. Testing a few options through demos or trials can help you make an informed decision. -

What is the best free CNC programming software for beginners?

For beginners, Carbide Create and Easel are among the best free CNC programming software options. Carbide Create offers a user-friendly interface with basic CAD/CAM functionalities, making it easy for newcomers to transition from design to machining. Easel provides an integrated web-based platform combining CAD and CAM, which simplifies the workflow. Both options have supportive communities and resources that can help beginners get accustomed to CNC programming without feeling overwhelmed. -

Are there any limitations with free CNC programming software?

Yes, free CNC programming software often comes with limitations compared to paid alternatives. These may include restricted functionalities, limited customer support, or fewer advanced features like 3D modeling or complex toolpath strategies. Additionally, some free software may have compatibility issues with specific CNC machines or file formats. It’s crucial to assess whether the limitations align with your production needs, especially if your projects require high precision or complexity. -

What are the common payment terms for purchasing CNC software upgrades?

While many free CNC programming software options are available, should you decide to upgrade to a paid version, payment terms can vary by supplier. Common terms include one-time payments, monthly subscriptions, or annual licenses. Always review the payment structure, including any hidden fees for additional features or updates. Additionally, check for refund policies or guarantees, as this can provide security in your investment. -

How do I vet suppliers of CNC programming software?

To vet suppliers of CNC programming software, start by researching their reputation within the industry. Look for customer reviews, testimonials, and case studies that demonstrate their software’s effectiveness. Ensure they have a solid support system in place, including technical assistance and user forums. Additionally, confirm that the software complies with industry standards and regulations relevant to your region, particularly if you’re in Africa, South America, or the Middle East. -

What customization options should I look for in free CNC programming software?

When evaluating free CNC programming software, consider the level of customization it offers. Look for features that allow you to modify toolpaths, create custom templates, and integrate your specific machining processes. The ability to import various file formats and adapt settings for different CNC machines is also essential. Customization can significantly enhance your productivity and ensure the software meets your unique production requirements. -

What quality assurance practices should I implement when using free CNC programming software?

Implementing quality assurance (QA) practices is crucial when using free CNC programming software. Regularly test the software with sample projects to ensure it generates accurate G-code and toolpaths. Establish a protocol for reviewing and validating machine outputs against design specifications. Additionally, keep your software updated to benefit from any improvements or bug fixes. Document any issues encountered and solutions found to enhance your team’s overall learning and efficiency. -

What logistics considerations should I keep in mind when sourcing CNC software?

When sourcing CNC programming software, consider the logistics of installation and integration into your existing systems. Assess the software’s compatibility with your hardware and network infrastructure, especially if you operate in diverse regions like Europe or the Middle East. Consider the download size and whether you require internet access for installation and updates. Finally, evaluate the support provided for installation and any potential training needed for your team to effectively use the software.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Free Cnc Programming Software Manufacturers & Suppliers List

1. Carbide 3D – Free CNC Software Options

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Free CNC Software options available for CAD, CAM, and CNC control software. Key software includes: 1. FreeCAD – Free 3D CAD parametric program, outputs STL, STEP, SVG, DXF, runs on Mac, Windows, Linux. 2. Solvespace – Free 3D CAD program, exports STL, STEP, runs on Mac, Windows, Linux. 3. Inkscape – Free 2D design software, exports SVG, DXF, runs on Mac, Windows, Linux. 4. Carbide Create – 2D CAM …

2. StyleCNC – CNC Programming Software

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: CNC Programming Software for Beginners and Professionals includes a list of popular free and paid CNC programming software suitable for both novices and experts. Key software options highlighted are: 1. Carbide Create – a free CAD/CAM program for beginners with customizable toolpaths and user-friendly 2D sketching tools. 2. Easel by Inventables – a web-based CNC solution combining CAM and CAD, fea…

3. Minimillr – Easel & Kiri:Moto

Domain: minimillr.com

Registered: 2021 (4 years)

Introduction: 1. Easel: Browser-based CAD/CAM tool, 2D/2.5D only, limited free version, supports SVG import/export, auto-tabs, custom feeds/speeds, compatible with Minimillr machines.

2. Kiri:Moto: Browser-based CAM tool for CNC milling, 3D printing, and laser cutting, imports 3D STL files, features ‘image to heightmap’ for 3D relief work.

3. Fusion 360: Free for hobby users, complex with a steep learning curve…

4. Autodesk – Free CAM Software and Tools

Domain: autodesk.com

Registered: 1989 (36 years)

Introduction: Free CAM software options for CNC machining and 3D printing; includes Fusion for personal use (cloud-based, free CAM and CAD 3D modeling tool for hobbyists); free access for students and educators through Autodesk Education plan; 30-day free trials for professional CAM software like Fusion with PowerMill and FeatureCAM; advanced CAM functionality for 2.5- to 5-axis milling, turning, and mill-turn …

5. Easel – All-in-One CNC Software Solution

Domain: easel.com

Registered: 1997 (28 years)

Introduction: Easel is an all-in-one CNC software solution designed for design and CNC machining. Key features include:

1. **Design Tools**: Create stunning designs with artisan-crafted tools. Access a design library with over 3 million designs and a customizable font library with 300+ fonts.

2. **Carving Capabilities**: Import STL files for 3D carving, achieve perfect cuts with advanced toolpaths including V-…

6. OpenBuilds – CONTROL and CAM Software

Domain: software.openbuilds.com

Registered: 2012 (13 years)

Introduction: OpenBuilds CONTROL and OpenBuilds CAM are free software applications for controlling CNC, Laser, Plasma, or Dragknife machines. OpenBuilds CONTROL is a desktop application available for Windows 10/11, Mac, and Linux, allowing users to interface with machines, run GCODE jobs, set zero coordinates, perform probing operations, calibrate machines, and load machine profiles. OpenBuilds CAM is a web-bas…

7. CNC Cookbook – Best Free CAM Software

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Best Free CAM Software + CAD & CNC 2024 Update

– Recommended Free CNC Software: CAM Software, CNC Control Software, CAD Software, Feeds and Speeds Calculator, CNC Simulator Free

– Top Recommendations: Fusion 360, Carbide Create, GRBL, G-Wizard Feeds and Speeds Calculator, G-Wizard Editor and Simulator

– G-Wizard Calculator: Free trial available, many features remain free after trial, includes vari…

8. RCKeith – Free CNC Software

Domain: rckeith.co.uk

Registered: 2009 (16 years)

Introduction: Free CNC software for 3 and 4-axis machines includes options like OpenBuilds Control, SenderIO, UGS (Universal Gcode Sender), CNCjs, Mach3, and LinuxCNC. The software is suitable for hobbyists looking to cut foam wings, fuselages, or parts on CNC routers. Paid software examples include Mach3 ($175), Mach4 ($200), DevWing Foam 2 (€125), and DevFus Foam (€95). Benefits of using free software include…

Strategic Sourcing Conclusion and Outlook for free cnc programming software

As businesses worldwide increasingly embrace CNC technology, the significance of strategic sourcing for free CNC programming software cannot be overstated. By leveraging these cost-effective tools, companies can streamline their operations, reduce overhead costs, and enhance productivity without compromising on quality. Key options such as Carbide Create and Easel offer intuitive interfaces that cater to both novices and seasoned professionals, ensuring accessibility across various skill levels.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, sourcing the right software solutions can facilitate faster project turnaround times and improve machining accuracy. The diverse landscape of free CNC programming software presents a valuable opportunity for businesses to innovate and compete in an ever-evolving market.

As you explore these resources, consider integrating them into your CNC operations to maximize efficiency and drive growth. The future of CNC programming is not only about the machines but also about the software that powers them. Embrace these advancements and position your business for success in the global marketplace.