Introduction: Navigating the Global Market for free cad files for 3d printing

In today’s rapidly evolving landscape of additive manufacturing, sourcing free CAD files for 3D printing can be a daunting challenge for international B2B buyers. As companies from Africa, South America, the Middle East, and Europe seek to innovate and optimize production processes, the need for high-quality, accessible design files becomes increasingly critical. This comprehensive guide aims to demystify the global market for free CAD files, offering insights into the various types available, their applications across different industries, and strategies for vetting suppliers effectively.

Navigating this complex ecosystem requires a thorough understanding of not just the CAD files themselves, but also the associated costs, licensing issues, and potential use cases. By addressing these key aspects, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and strategic goals. Whether you are a manufacturer in Nigeria looking to streamline your prototyping process, or a design firm in Vietnam aiming to enhance your product offerings, understanding where to find and how to utilize free CAD files can significantly impact your bottom line.

Ultimately, this guide serves as a vital resource for businesses eager to leverage the advantages of 3D printing through effective sourcing of CAD files, enabling them to stay competitive in a global market that rewards innovation and efficiency.

Understanding free cad files for 3d printing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| STL Files | Standard format for 3D printing; widely supported | Prototyping, product development | Pros: Easy to find and use; Cons: Limited to geometry, no color or texture. |

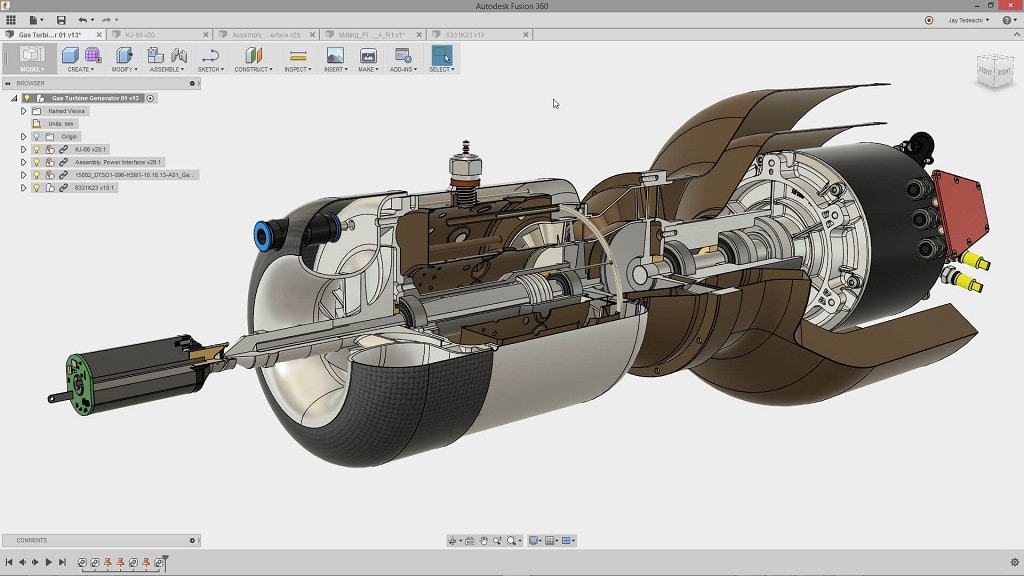

| CAD Models | Detailed design files created in CAD software | Engineering, manufacturing | Pros: High precision and detail; Cons: Requires CAD software for modifications. |

| 3D Printable Assemblies | Models designed for easy assembly without additional supports | Education, DIY projects | Pros: User-friendly; Cons: May require additional parts not included. |

| Parametric Models | Files that allow for variable dimensions and features | Custom manufacturing, design iterations | Pros: Highly customizable; Cons: Complexity in understanding parameters. |

| Multi-Material Designs | Models that incorporate multiple materials in one print | Specialized product development, art | Pros: Enhanced aesthetics and functionality; Cons: Requires advanced printers. |

What Are STL Files and Their Importance for B2B Buyers?

STL files are the most common file format used in 3D printing, consisting of a mesh of triangles that represent the surface geometry of a 3D object. They are universally compatible with nearly all 3D printers, making them a go-to choice for businesses looking to prototype or develop products quickly. However, their simplicity means they lack color, texture, and other details, which may limit their use in more complex projects. B2B buyers should consider the suitability of STL files for their specific applications, particularly if they prioritize speed and ease of use.

How Do CAD Models Enhance Precision in B2B Applications?

CAD models are detailed representations created using specialized software, offering high precision and intricate details. They are ideal for engineering and manufacturing applications where accuracy is paramount, allowing businesses to create complex components. However, modifying CAD models typically requires access to CAD software and expertise, which may present a barrier for some companies. Buyers should assess their internal capabilities and whether they can leverage CAD models effectively in their workflows.

Why Choose 3D Printable Assemblies for Educational Purposes?

3D printable assemblies are designed for straightforward assembly, often requiring no additional supports. They are particularly beneficial in educational settings or DIY projects where users may not have extensive 3D printing experience. These models facilitate hands-on learning and engagement. However, while they are user-friendly, buyers should be aware that some assemblies may require additional parts that are not included, impacting overall project costs.

What Are the Advantages of Parametric Models in Custom Manufacturing?

Parametric models allow users to modify dimensions and features dynamically, making them invaluable in custom manufacturing and design iterations. This flexibility enables businesses to tailor products to specific requirements, enhancing their market responsiveness. However, the complexity of these models can be a hurdle, as understanding and manipulating parameters may require specialized knowledge. Buyers should evaluate their design teams’ capabilities before investing in parametric models.

How Do Multi-Material Designs Impact Product Development?

Multi-material designs allow for the incorporation of various materials in a single print, enhancing the functionality and aesthetics of the final product. This capability is particularly advantageous in specialized product development and artistic applications. However, to fully leverage these designs, businesses need advanced 3D printers capable of handling multiple materials, which can represent a significant investment. B2B buyers must weigh the benefits of enhanced product features against the costs of acquiring the necessary technology.

Key Industrial Applications of free cad files for 3d printing

| Industry/Sector | Specific Application of free cad files for 3d printing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Prototyping of custom parts | Reduces development time and costs for product iterations | Ensure files are compatible with specific 3D printers |

| Healthcare | Production of medical devices and prosthetics | Enhances patient care through tailored solutions | Verify compliance with medical standards and regulations |

| Automotive | Creation of tooling and fixtures | Increases efficiency in production processes | Assess material quality and durability of printed parts |

| Aerospace | Design of lightweight components | Lowers fuel consumption and improves performance | Consider certifications for aerospace-grade materials |

| Consumer Goods | Development of customized product designs | Enhances brand differentiation and customer satisfaction | Evaluate design complexity and post-processing requirements |

How Are Free CAD Files Used in Manufacturing Prototyping?

In the manufacturing sector, free CAD files for 3D printing are invaluable for rapid prototyping. Businesses can download and modify existing designs to create custom parts, significantly reducing the time and cost associated with traditional prototyping methods. This capability is especially beneficial for international buyers in regions like Africa and South America, where manufacturing costs can be high. Companies must ensure that the CAD files are compatible with their specific 3D printing technology to avoid production delays.

What Benefits Do Free CAD Files Offer in Healthcare Applications?

In healthcare, free CAD files facilitate the production of medical devices and prosthetics tailored to individual patient needs. This customization can lead to improved patient outcomes, as products can be designed to fit specific anatomical requirements. International buyers, particularly in developing markets, should focus on sourcing files that comply with local medical device regulations to ensure patient safety and product efficacy.

How Are Free CAD Files Transforming the Automotive Industry?

The automotive industry leverages free CAD files for creating tooling and fixtures that enhance production efficiency. By using 3D printing, manufacturers can quickly iterate on designs and produce lightweight components that contribute to improved vehicle performance and reduced fuel consumption. For automotive companies in Europe and the Middle East, it is crucial to assess the material quality and durability of 3D printed parts to meet industry standards.

Why Are Free CAD Files Important in Aerospace Design?

In aerospace, free CAD files are used to design lightweight components that contribute to fuel efficiency and overall performance. The ability to customize parts through 3D printing allows for innovative solutions that traditional manufacturing cannot achieve. International buyers must consider the certifications required for aerospace-grade materials when sourcing CAD files to ensure compliance with stringent industry regulations.

How Can Free CAD Files Enhance Consumer Goods Development?

The consumer goods sector benefits from free CAD files by enabling the development of customized product designs that enhance brand differentiation. Companies can quickly prototype and test new designs, leading to faster market entry and increased customer satisfaction. Businesses in regions like Nigeria and Vietnam should evaluate the complexity of designs and any post-processing requirements to streamline production and maintain quality standards.

3 Common User Pain Points for ‘free cad files for 3d printing’ & Their Solutions

Scenario 1: Difficulty in Finding High-Quality Free CAD Files

The Problem: Many B2B buyers in industries such as manufacturing, prototyping, and product design face the challenge of sourcing high-quality, free CAD files for 3D printing. Often, the available files may not meet their specific requirements in terms of accuracy, compatibility, or material specifications. This can lead to wasted time and resources, as users may download multiple files only to find them unsuitable for their applications. Furthermore, with a plethora of platforms offering free files, identifying reliable sources becomes an overwhelming task.

The Solution: To effectively find high-quality free CAD files, B2B buyers should leverage established platforms such as GrabCAD, Cults3D, or 3D ContentCentral, which provide user-generated content and community ratings. Begin by utilizing advanced search filters to narrow down options based on specific criteria such as file format (e.g., STL, OBJ), complexity, and user reviews. Additionally, engaging with community forums or groups within these platforms can provide insights and recommendations from experienced users. When selecting a file, pay attention to the designer’s credibility and the feedback from other users to ensure you are obtaining a file that meets your standards.

Scenario 2: Compatibility Issues with 3D Printers

The Problem: Another common issue faced by B2B buyers is the compatibility of downloaded CAD files with their specific 3D printing technology. Many times, files are created without consideration for various printing methods, leading to potential failures in the printing process. Buyers may find that the downloaded files do not work with their printers, resulting in lost productivity and frustration, especially when deadlines are tight.

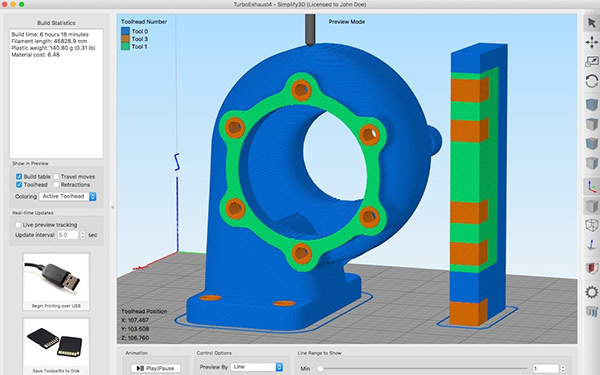

The Solution: To mitigate compatibility issues, B2B buyers should first assess the specifications of their 3D printers, including the supported file formats and material types. When searching for free CAD files, prioritize platforms that allow you to filter designs based on printer type or material compatibility. It may also be helpful to download files in universal formats like STL or OBJ, which are widely accepted across various printers. Before printing, conduct a thorough review of the file in a 3D modeling software to check for any potential discrepancies or necessary modifications. This proactive approach ensures a smoother transition from file to print, saving time and resources.

Scenario 3: Legal and Licensing Confusion

The Problem: B2B buyers often encounter confusion regarding the legal aspects of using free CAD files. Different platforms have varying licensing agreements, and users may inadvertently infringe on copyrights or violate terms of use, leading to potential legal repercussions. This uncertainty can deter companies from utilizing valuable resources or cause them to spend excessive time researching legalities rather than focusing on their projects.

The Solution: To navigate the legal landscape surrounding free CAD files, B2B buyers should familiarize themselves with common licensing terms such as Creative Commons or proprietary licenses. When downloading files, always check the licensing information provided on the platform, which typically outlines what is permissible, such as commercial use, modifications, or redistribution. It is advisable to maintain a record of where each file was sourced and its associated license to ensure compliance. For companies concerned about legal risks, considering a subscription to a reputable database of CAD files with clear licensing can provide peace of mind and access to a broader range of designs.

Strategic Material Selection Guide for free cad files for 3d printing

What Are the Key Properties of Common Materials Used in 3D Printing?

When selecting materials for 3D printing, particularly for free CAD files, understanding the properties of each material is crucial for ensuring product performance. Here, we analyze four common materials: PLA, ABS, PETG, and Nylon, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does PLA Perform in 3D Printing Applications?

Polylactic Acid (PLA) is one of the most widely used materials in 3D printing. It has a low melting temperature, typically around 180-220°C, which makes it easy to print. PLA is biodegradable and derived from renewable resources, making it an eco-friendly choice. Its rigidity and low warping characteristics contribute to its popularity.

Pros: PLA is known for its ease of use, low cost, and excellent surface finish. It is suitable for creating detailed prints and is compatible with a variety of printers.

Cons: However, PLA has lower heat resistance (up to 60°C) and is less durable than other materials, making it unsuitable for high-stress applications.

Impact on Application: PLA is ideal for prototypes, educational models, and decorative items. Its environmental benefits can appeal to businesses looking to enhance their sustainability profile.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially in regions with stringent sustainability standards. Buyers should also consider local availability and sourcing of PLA.

What Are the Advantages and Disadvantages of ABS?

Acrylonitrile Butadiene Styrene (ABS) is another popular material known for its strength and durability. It can withstand higher temperatures (up to 100°C) and is resistant to impact and chemicals.

Pros: ABS is favored for functional parts, automotive components, and toys due to its toughness and ability to be post-processed (e.g., sanding, painting).

Cons: The main drawbacks include its tendency to warp during printing and the release of fumes, which may require ventilation.

Impact on Application: ABS is suitable for applications requiring higher durability and heat resistance, making it a preferred choice in industries such as automotive and consumer goods.

Considerations for International Buyers: Buyers should be aware of compliance with safety standards, such as those from ASTM or ISO, especially in regions with strict manufacturing regulations.

Why Choose PETG for 3D Printing?

Polyethylene Terephthalate Glycol (PETG) combines the best features of PLA and ABS. It offers good strength, flexibility, and chemical resistance, making it an excellent choice for a variety of applications.

Pros: PETG is easy to print, has low warping, and is food-safe, making it suitable for both industrial and consumer applications.

Cons: However, it can be more expensive than PLA and may require specific printer settings to achieve optimal results.

Impact on Application: PETG is often used for packaging, medical devices, and mechanical parts, where durability and safety are paramount.

Considerations for International Buyers: Compliance with food safety regulations and material certifications is critical, especially in the food and medical sectors.

What Makes Nylon a Preferred Material in Certain Applications?

Nylon is known for its exceptional strength and flexibility, making it ideal for functional parts that require durability. It has a higher melting point (around 220-260°C) and is resistant to wear and chemicals.

Pros: Nylon’s toughness and ability to withstand stress make it suitable for mechanical applications, such as gears and fasteners.

Cons: The main challenges include its hygroscopic nature (absorbing moisture) and the need for a heated chamber to prevent warping during printing.

Impact on Application: Nylon is commonly used in industries such as aerospace and automotive, where high performance is essential.

Considerations for International Buyers: Buyers should ensure compliance with industry-specific standards, such as those from JIS or DIN, and consider the availability of moisture-resistant storage solutions.

Summary Table of Material Selection for 3D Printing

| Material | Typical Use Case for free cad files for 3d printing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototypes, educational models, decorative items | Eco-friendly, easy to print | Low heat resistance, less durable | Low |

| ABS | Functional parts, automotive components, toys | High durability, impact resistant | Tends to warp, fumes during printing | Medium |

| PETG | Packaging, medical devices, mechanical parts | Strong, flexible, food-safe | More expensive, requires specific settings | Medium |

| Nylon | Mechanical parts, gears, fasteners | Exceptional strength and flexibility | Hygroscopic, requires heated chamber | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of common 3D printing materials. Understanding these factors will help businesses make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for free cad files for 3d printing

What Are the Main Stages in the Manufacturing Process for Free CAD Files for 3D Printing?

The manufacturing process for free CAD files intended for 3D printing encompasses several critical stages that ensure the final product meets the required specifications and quality standards. These stages are material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step involves selecting the appropriate materials based on the intended application of the printed object. Common materials used in 3D printing include thermoplastics like PLA and ABS, resins for SLA printers, and metal powders for selective laser sintering (SLS). The material must be stored correctly to prevent contamination and degradation. Suppliers often provide Material Safety Data Sheets (MSDS) to ensure compliance with safety standards. -

Forming

Forming refers to the actual printing process where the CAD files are translated into physical objects. This stage utilizes various 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each method has its unique advantages and limitations, affecting factors such as print speed, detail resolution, and material compatibility. -

Assembly

While many 3D printed components are designed to be printed as a single unit, some applications may require post-processing assembly. This includes attaching multiple parts or integrating electronic components. Proper assembly techniques are crucial to ensure structural integrity and functionality. -

Finishing

The finishing stage enhances the aesthetic and functional properties of the printed object. This can involve sanding, painting, or applying protective coatings. Finishing processes can also include heat treatment to enhance strength or flexibility, depending on the material used.

How Is Quality Assurance Implemented for Free CAD Files for 3D Printing?

Quality assurance (QA) is paramount in ensuring that the final products meet international standards and customer expectations. For B2B buyers, understanding the QA processes can significantly impact procurement decisions.

-

What International Standards Should Buyers Consider?

Key international standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards indicates a supplier’s commitment to quality and continuous improvement. Industry-specific certifications, such as CE marking for European markets or API standards for the oil and gas sector, may also be relevant depending on the application. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Ensuring that materials meet specified standards is crucial for maintaining overall product quality.

– In-Process Quality Control (IPQC): During the printing process, samples may be taken to verify that parameters such as temperature, speed, and layer adhesion are within acceptable limits.

– Final Quality Control (FQC): Once the printing is complete, a thorough inspection of the final product is conducted. This may include dimensional checks, surface finish evaluations, and functional testing. -

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to ensure product quality. Non-destructive testing (NDT) techniques, such as ultrasonic or X-ray inspection, can identify internal defects without damaging the product. Mechanical testing, including tensile and compression tests, evaluates the material’s strength and durability. Additionally, dimensional analysis ensures that the printed part meets the specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for mitigating risk.

-

What Role Do Audits and Reports Play in Quality Verification?

Conducting supplier audits provides insights into the operational processes and quality management systems in place. During an audit, buyers can assess compliance with relevant standards and the effectiveness of the QC checkpoints. Requesting detailed reports on past audits, quality metrics, and corrective actions taken can also offer a clearer picture of the supplier’s commitment to quality. -

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s capabilities. These inspections can validate the quality of materials and the printing process, ensuring that the products adhere to specified standards. This is particularly beneficial for international transactions, where buyers may not have the means to visit suppliers physically. -

What Are the Quality Control Nuances for International Buyers?

International buyers must consider potential challenges such as language barriers, cultural differences, and varying regulatory environments. It’s essential to establish clear communication channels and ensure that all quality expectations are documented in contracts. Buyers should also be aware of local regulations that may affect product compliance and safety standards.

Conclusion: Making Informed Decisions in the B2B 3D Printing Landscape

Understanding the manufacturing processes and quality assurance measures for free CAD files for 3D printing is vital for B2B buyers. By thoroughly evaluating suppliers based on their manufacturing capabilities, adherence to international standards, and robust quality control systems, businesses can make informed decisions that mitigate risk and ensure high-quality outcomes. As the 3D printing landscape continues to evolve, staying abreast of these processes will empower buyers to leverage this technology effectively for their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘free cad files for 3d printing’

Introduction

Navigating the world of 3D printing requires access to high-quality CAD files, especially for B2B buyers seeking efficient and cost-effective solutions. This guide serves as a practical checklist to help you source free CAD files for 3D printing, ensuring that you find reliable resources and avoid potential pitfalls in the procurement process.

Step 1: Identify Your Project Requirements

Clearly define the specifications and requirements of your project before sourcing CAD files. Consider factors such as the type of materials you will use, the scale of the project, and the intended application of the 3D-printed parts. This step ensures you filter out irrelevant designs and focus on files that meet your precise needs.

- Material Compatibility: Ensure the CAD files are compatible with your 3D printing technology (FDM, SLA, etc.).

- Complexity of Design: Assess whether the designs can be printed with the capabilities of your equipment.

Step 2: Research Reputable CAD File Sources

Explore well-established platforms that provide free CAD files, such as GrabCAD, Cults3D, and 3D ContentCentral. These platforms typically host a community of designers and engineers who share their files, ensuring a variety of options and quality standards.

- Community Feedback: Look for platforms with active user reviews and ratings to gauge the quality of the files.

- Diversity of Offerings: Ensure the platform offers a wide range of categories relevant to your industry.

Step 3: Check File Formats and Compatibility

Not all CAD files are created equal; they come in various formats like STL, OBJ, and 3MF. Confirm that the files you download are compatible with your 3D printing software and hardware.

- Software Requirements: Verify that your slicing software can handle the file format.

- Version Compatibility: Check if the files are compatible with the version of your 3D printer.

Step 4: Evaluate Design Quality and Usability

Before downloading, assess the quality of the CAD files. Look for designs that have been tested and proven effective by other users. Quality files will often come with detailed descriptions and assembly instructions.

- User Reviews: Pay attention to user comments regarding printability and ease of assembly.

- Visual Inspection: If possible, preview the designs to evaluate their complexity and structural integrity.

Step 5: Verify Licensing and Usage Rights

Ensure that the CAD files you intend to use are licensed for your specific needs. Some files may have restrictions on commercial use, while others may allow modifications.

- Commercial Licensing: If you plan to use the designs for commercial purposes, ensure they come with the appropriate licensing.

- Attribution Requirements: Be aware of any attribution requirements if you intend to share or modify the files.

Step 6: Download and Test Print

Once you have selected suitable CAD files, download them and conduct test prints to evaluate their performance. Testing ensures that the designs meet your quality standards and are suitable for your final applications.

- Prototype Testing: Create prototypes to identify any issues before full-scale production.

- Adjustments: Be prepared to make adjustments to the designs based on the results of your test prints.

Step 7: Establish a Review Process

Implement a systematic review process for future CAD file downloads. This will help maintain quality control and ensure that all files align with your operational standards.

- Documentation: Keep a record of sources, licensing, and quality evaluations for future reference.

- Continuous Improvement: Regularly review and update your sourcing criteria as new technologies and materials emerge in the 3D printing landscape.

By following these steps, B2B buyers can streamline their sourcing process for free CAD files and enhance their 3D printing projects.

Comprehensive Cost and Pricing Analysis for free cad files for 3d printing Sourcing

What Are the Key Cost Components for Free CAD Files for 3D Printing?

When sourcing free CAD files for 3D printing, understanding the underlying cost structure is crucial for effective budgeting and decision-making. The cost components can be segmented into several categories:

-

Materials: While CAD files themselves are free, the materials required for 3D printing, such as plastics or metals, can vary significantly in price. For instance, filament costs fluctuate based on type (PLA, ABS, PETG) and quality.

-

Labor: Even with free CAD files, labor costs for preparing, printing, and finishing the models can accumulate. Skilled labor may be needed for complex designs or post-processing, impacting overall expenses.

-

Manufacturing Overhead: This includes costs associated with running 3D printers, such as electricity, maintenance, and equipment depreciation. These costs can add up over time, especially for businesses operating multiple machines.

-

Tooling: Although not directly related to CAD files, tooling costs may arise if specialized attachments or modifications are needed for specific prints. This is particularly relevant for industrial applications requiring precision.

-

Quality Control (QC): Ensuring the integrity and accuracy of printed models may necessitate investment in QC processes, especially for applications requiring compliance with industry standards.

-

Logistics: Shipping costs for materials or finished products, including customs duties for international transactions, should also be factored into the total expenditure.

-

Margin: Suppliers often build a margin into their pricing to cover the aforementioned costs and ensure profitability. This margin can vary widely based on the supplier’s market strategy and competitive landscape.

How Do Pricing Influencers Affect the Cost of Free CAD Files?

Several factors can influence the pricing of services and materials associated with free CAD files:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders typically lower the per-unit cost, making it essential for buyers to consider their production needs.

-

Specifications and Customization: Unique designs or modifications can lead to higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: The choice of materials can significantly impact overall costs. Higher quality or specialty materials may increase expenses but can also enhance product performance.

-

Quality and Certifications: Products requiring specific industry certifications will often incur additional costs. Buyers should inquire about certifications to avoid unexpected expenses.

-

Supplier Factors: The reliability and reputation of a supplier can influence pricing. Established suppliers may charge a premium for their services, while emerging suppliers might offer competitive rates.

-

Incoterms: Understanding Incoterms is vital for international transactions. Different terms can affect shipping costs and responsibilities, influencing the total cost of ownership.

What Buyer Tips Can Help in Sourcing Free CAD Files for 3D Printing?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiate Pricing: Engage suppliers in discussions regarding pricing. Many are open to negotiation, especially for larger orders or long-term contracts.

-

Assess Total Cost of Ownership: Look beyond the initial costs of CAD files and materials. Consider long-term expenses, including maintenance and operational costs, to make informed decisions.

-

Evaluate Pricing Nuances: Be aware of regional pricing differences. Factors such as local demand, shipping routes, and tariffs can lead to significant cost variations.

-

Leverage Technology: Use advanced software solutions that can streamline the design and printing process, potentially lowering labor and material costs.

-

Research Suppliers Thoroughly: Investigate potential suppliers to understand their pricing models and service offerings. This can lead to better deals and higher-quality outputs.

Disclaimer

The prices and cost structures mentioned above are indicative and can vary based on numerous factors including location, market conditions, and specific project requirements. Always conduct thorough market research and supplier evaluations to ensure the best pricing for your needs.

Alternatives Analysis: Comparing free cad files for 3d printing With Other Solutions

Introduction

In the dynamic landscape of 3D printing, businesses often seek the most effective solutions to streamline their production processes. While free CAD files for 3D printing provide an accessible entry point, alternative methods and technologies may better serve specific needs. This analysis compares free CAD files with viable alternatives, helping B2B buyers make informed decisions tailored to their operational requirements.

| Comparison Aspect | Free CAD Files For 3D Printing | Online Custom Design Services | CAD Software Licenses |

|---|---|---|---|

| Performance | Varies based on model quality | High, tailored to specifications | High, dependent on user skill |

| Cost | Free | Typically subscription-based or per project | High upfront cost, ongoing maintenance fees |

| Ease of Implementation | User-friendly, but requires some design knowledge | Minimal design knowledge required | Steep learning curve, requires training |

| Maintenance | Low, dependent on file updates | Medium, based on service provider | High, requires regular updates and support |

| Best Use Case | Prototyping and hobby projects | Custom projects needing specific design | Industrial-grade projects and complex designs |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Online Custom Design Services?

Online custom design services offer tailored solutions for businesses that require specific design features. These platforms allow users to submit project specifications and receive professional-grade designs in return. The primary advantage is the high performance and quality of the final product, as experts handle the design process. However, the cost can be a drawback, as these services typically operate on a subscription basis or charge per project, which may not be feasible for smaller businesses or one-time projects.

How Do CAD Software Licenses Compare to Free CAD Files?

CAD software licenses represent a more traditional approach to 3D design, providing powerful tools for creating intricate models. These applications are ideal for industrial-grade projects and complex designs, offering high performance and versatility. However, the associated costs can be significant, both in terms of initial investment and ongoing maintenance. Additionally, the steep learning curve can be a barrier for teams without dedicated design expertise, making this option less accessible for all businesses.

Conclusion

When selecting the right solution for 3D printing, B2B buyers should carefully evaluate their specific needs, budget, and expertise. Free CAD files for 3D printing serve as an excellent entry point for prototyping and smaller projects, while online custom design services offer tailored solutions for more complex requirements. Conversely, CAD software licenses are best suited for organizations with the resources to invest in training and maintenance for high-quality, industrial-grade outputs. By understanding these alternatives, businesses can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for free cad files for 3d printing

What Are the Key Technical Properties of Free CAD Files for 3D Printing?

In the realm of 3D printing, particularly for B2B applications, understanding the technical properties of CAD files is crucial for ensuring compatibility and quality in the final products. Here are some essential specifications to consider:

-

File Format

Common formats include STL, OBJ, and 3MF. Each format has unique characteristics affecting data fidelity and compatibility with various 3D printers. For instance, STL is widely used for its simplicity, while 3MF supports richer data like color and material information. Selecting the right format is essential for successful printing and may influence production timelines. -

Material Compatibility

Different 3D printing technologies utilize various materials (e.g., PLA, ABS, nylon). The CAD file must specify the material intended for printing to avoid issues during production. Understanding material properties, such as strength and flexibility, is vital for applications ranging from prototyping to end-use products. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. A tighter tolerance ensures precision but may increase production costs and time. B2B buyers must balance the need for accuracy with budget constraints, making it important to specify tolerances in the CAD file. -

Layer Height

This parameter determines the thickness of each layer in the printing process. A smaller layer height can enhance detail and surface finish but may lead to longer print times. For B2B applications where aesthetics and functionality matter, understanding the implications of layer height is crucial. -

Resolution

Resolution defines the quality of the 3D model in terms of detail and clarity. Higher resolution files produce finer details but require more processing power and time to print. B2B buyers should assess the required resolution based on the final use of the printed part. -

Assembly Instructions

For complex models, including assembly instructions within the CAD file can facilitate easier post-print assembly. Clear guidelines help reduce errors and streamline the assembly process, which is particularly beneficial for B2B operations where efficiency is key.

What Are Common Trade Terms Related to Free CAD Files for 3D Printing?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms relevant to free CAD files and 3D printing:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of CAD files, OEM specifications can dictate the standards required for compatibility and performance in specific applications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory and budget effectively, especially when acquiring 3D printed components or prototypes. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specified products or services. B2B buyers should prepare detailed RFQs that include technical specifications of CAD files to ensure accurate and competitive pricing. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms is crucial for B2B transactions, as they clarify costs, risks, and delivery timelines associated with the procurement of CAD files and 3D printed products. -

Post-Processing

This term refers to any additional steps taken after 3D printing, such as sanding, painting, or assembly. Understanding post-processing requirements is important for buyers to ensure that the final product meets quality and functional standards. -

Prototyping

Prototyping is the process of creating a preliminary model of a product to test concepts and functionality. In B2B environments, rapid prototyping using CAD files can significantly speed up the product development cycle, allowing businesses to bring innovations to market more quickly.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing free CAD files for 3D printing, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the free cad files for 3d printing Sector

What Are the Current Trends Shaping the Free CAD Files for 3D Printing Market?

The market for free CAD files for 3D printing is witnessing significant transformation, driven by technological advancements and changing buyer preferences. Globally, the demand for rapid prototyping, customization, and the ability to innovate at lower costs is propelling the adoption of 3D printing technologies. Key trends include the rise of open-source platforms like GrabCAD and Cults3D, which facilitate access to a broad range of CAD models. These platforms not only support individual designers but also empower businesses to source models efficiently, reducing time-to-market.

Additionally, the integration of AI and machine learning in design processes is enabling more sophisticated and user-friendly tools for generating CAD files. For international B2B buyers, especially from regions like Africa and South America, this represents an opportunity to leverage cost-effective solutions that enhance production capabilities. Furthermore, the trend toward collaboration among designers and manufacturers is fostering a more interconnected ecosystem, where businesses can share resources and expertise to optimize their supply chains.

How Are Sustainability and Ethical Sourcing Impacting the Free CAD Files for 3D Printing Sector?

Sustainability is becoming a critical consideration in the sourcing of free CAD files for 3D printing. As environmental concerns rise globally, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste. The incorporation of ‘green’ certifications in the supply chain can enhance a company’s reputation and appeal to environmentally-conscious consumers.

Moreover, ethical sourcing practices are gaining traction. Buyers are now looking for suppliers who ensure fair labor practices and transparency in their operations. This shift towards ethical supply chains not only supports social responsibility but also aligns with the growing consumer demand for sustainable products. For B2B buyers, adopting these practices can not only mitigate risks associated with supply chain disruptions but also create a competitive advantage in markets that favor environmentally responsible companies.

How Has the Free CAD Files for 3D Printing Sector Evolved Over Time?

The evolution of free CAD files for 3D printing reflects broader technological advancements and changing market needs. Initially, CAD files were predominantly proprietary, limiting access to designs and stifling innovation. However, the rise of open-source communities and platforms has democratized access to design resources, enabling users to share and modify files easily. This shift has fostered a culture of collaboration among designers, engineers, and manufacturers, accelerating the pace of innovation in the sector.

As 3D printing technology has matured, the quality and complexity of available CAD files have significantly improved. Today’s files cater to a diverse range of applications, from industrial manufacturing to consumer products. The focus has expanded beyond mere accessibility to include considerations for design optimization, functionality, and sustainability, making the market more attractive for international B2B buyers looking to enhance their production capabilities.

This evolution not only illustrates the adaptability of the 3D printing industry but also highlights the importance of staying abreast of these changes to leverage new opportunities for growth and efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of free cad files for 3d printing

-

How can I find reliable sources for free CAD files for 3D printing?

To find reliable sources for free CAD files, consider established platforms like GrabCAD, Cults3D, and 3D ContentCentral. These sites host a variety of user-generated files, ensuring a broad selection. It’s essential to check user reviews and ratings to gauge the quality of the files. Additionally, joining professional forums and communities focused on 3D printing can provide insights into trustworthy sources and recommendations from experienced users. -

What types of CAD file formats are commonly available for 3D printing?

The most common CAD file formats for 3D printing include STL, OBJ, and 3MF. STL (Stereolithography) is the industry standard, widely supported by most 3D printers. OBJ files allow for color and texture data, while 3MF (3D Manufacturing Format) supports more complex models and metadata. When sourcing files, ensure the format is compatible with your 3D printer and software to avoid conversion issues. -

Are there any legal considerations when using free CAD files for commercial purposes?

Yes, legal considerations are crucial when using free CAD files for commercial purposes. Always check the licensing agreements associated with the files, as many are provided under specific terms that may restrict commercial use. Look for files labeled for commercial use or those with a Creative Commons license that permits such applications. Consulting with a legal expert on intellectual property can help mitigate potential risks. -

What should I consider when customizing CAD files for my business needs?

When customizing CAD files, assess the file’s complexity and your team’s design capabilities. Ensure that the original file is adaptable and consider the software compatibility for modifications. Additionally, factor in the intended use—whether for prototypes or final products—as this will influence the design adjustments. Collaborating with a skilled CAD designer can enhance the customization process, ensuring the final product meets quality and functional standards. -

What are the minimum order quantities (MOQ) for 3D printing services?

Minimum order quantities for 3D printing services can vary widely based on the provider and the complexity of the project. Some services may offer on-demand printing without a MOQ, while others may require a minimum number of units to justify production costs. It’s advisable to clarify MOQs with potential suppliers before committing, especially if you’re working on a budget or have specific project timelines. -

How do I ensure quality assurance (QA) for 3D printed parts from CAD files?

Quality assurance for 3D printed parts begins with selecting reputable suppliers who adhere to industry standards. Implement a QA process that includes reviewing samples before mass production, checking for design accuracy, and conducting material tests. Using software tools for simulation and analysis can also help identify potential issues in the design phase. Regular communication with suppliers regarding quality expectations is vital to maintain standards throughout the production process. -

What are the typical payment terms for B2B transactions involving CAD files?

Payment terms for B2B transactions can vary based on the agreement between parties. Common terms include upfront payments, net 30, or net 60 days. For larger orders, suppliers may offer discounts for early payments or flexible financing options. It’s essential to negotiate terms that align with your cash flow and project timelines. Always ensure that the payment terms are documented in the contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when sourcing CAD files internationally?

When sourcing CAD files internationally, consider the time zones, shipping logistics, and potential tariffs or import duties. Ensure that the files can be easily shared and accessed through secure platforms. Additionally, be aware of the technical support available from suppliers in different regions, as time zone differences can affect communication. Establishing clear timelines for delivery and project milestones will help streamline the process and mitigate delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Free Cad Files For 3D Printing Manufacturers & Suppliers List

1. Thingiverse – 3D Printable Designs

Domain: thingiverse.com

Registered: 2008 (17 years)

Introduction: Thingiverse is a platform for sharing digital designs for physical objects, allowing users to upload, download, and customize 3D printable files.

2. Cults – Digital Marketplace for 3D Printing Models

Domain: cults3d.com

Registered: 2013 (12 years)

Introduction: Cults is a digital marketplace for 3D printing and design, offering a wide range of downloadable 3D printer models in various formats including STL, OBJ, 3MF, CAD, STEP, SCAD, DXF, DWG, and SVG. The platform features categories such as Art, Fashion, Jewelry, Home, Architecture, Gadgets, Games, Tools, and more. Users can find popular designs, best sellers, and trending models, as well as community-…

3. Printables – Stargate SG-1 Kit

Domain: printables.com

Registered: 1996 (29 years)

Introduction: 3D models database featuring various categories such as Costumes & Accessories, Household Home Decor, Gadgets, Hobby & Makers, Automotive, and more. Key products include: 1. Stargate SG-1 Kit by Gatebuilder – Props, Costumes & Accessories, 625 downloads, 0 comments, 998 views. 2. Mushroom shelf “Oyster” by Gazzaladra – Household Home Decor, 786 downloads, 5 comments, 1,500 views. 3. Ear Plug Case …

4. 3D ContentCentral – Free 3D CAD Models

Domain: 3dcontentcentral.com

Registered: 2002 (23 years)

Introduction: 3D ContentCentral offers free 3D CAD models, 2D drawings, and supplier catalogs. It features a library of user-contributed and supplier-certified parts and assemblies, including components for injection molding, materials, and macros. Users can sign up to upload content, manage catalogs, and request models. The platform supports various CAD packages such as AutoCAD, Autodesk Inventor, SOLIDWORKS, …

5. Thangs – 3D Models & Free Downloads

Domain: thangs.com

Registered: 1995 (30 years)

Introduction: Popular models for 3D enthusiasts, Free Downloads, Categories include 3D Printers, Articulated Art, Costumes & Cosplay, Education, Fashion, Functional, Gridfinity, Health & Fitness, Hobbies, Home, Miniatures, Pop Culture, Print In Place, Seasonal, Toys & Games. Trending searches include multiboard, gridfinity, free lamp, dragon, fidget, pokemon, star wars. Marketplace options to buy and sell model…

6. Pinshape – 3D Printable Designs Marketplace

Domain: pinshape.com

Registered: 2012 (13 years)

Introduction: Pinshape offers a platform for free and premium 3D printable STL and OBJ files. Users can browse, download, and print designs from a community of over 70,000 makers and designers. The site features categories such as Toys + Games, Miniatures, Home Living, Jewelry + Fashion, Gadgets, and Art. Users can also sell their own 3D designs or share them for free. The community highlights trending and feat…

Strategic Sourcing Conclusion and Outlook for free cad files for 3d printing

In the evolving landscape of 3D printing, strategic sourcing of free CAD files is not just advantageous; it is essential for businesses aiming to enhance their operational efficiency and innovation. By leveraging platforms like GrabCAD, Cults, and 3D ContentCentral, international B2B buyers can access a wealth of designs that cater to diverse industries. This accessibility allows companies to reduce development costs, shorten time-to-market, and tap into a global community of designers and engineers.

Moreover, the ability to customize and iterate on existing models empowers businesses to better meet the specific needs of their local markets. As we look to the future, the demand for unique, high-quality 3D models will only continue to rise, particularly in regions like Africa, South America, the Middle East, and Europe.

To stay competitive, it is crucial for businesses to actively engage with these resources, build partnerships within the 3D printing community, and explore new applications for their products. By embracing strategic sourcing today, companies can position themselves for success in a rapidly changing industry. Begin your exploration of free CAD files now and unlock new possibilities for innovation and growth.