Contents

Manufacturing Insight: Free 3D Cnc Files

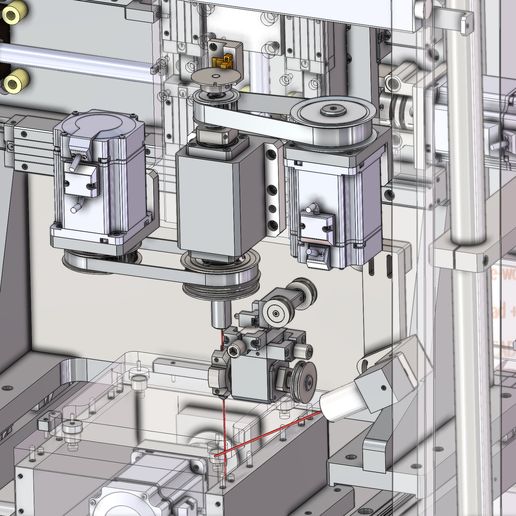

Accelerate Your Prototyping with Precision Industrial 3D Printing from Honyo Prototype

While the term “free 3D CNC files” often circulates in early design phases, true manufacturing readiness demands industrial-grade additive processes—not CNC milling—to transform concepts into functional, production-intent components. At Honyo Prototype, we specialize in high-precision industrial 3D printing for demanding sectors including aerospace, medical devices, and automotive engineering. Our end-to-end service leverages advanced metal and polymer systems—such as SLS, DMLS, and MJF—to deliver parts with certified material properties, tight tolerances (±0.05 mm), and rapid turnaround for both prototyping and low-volume production.

Forget generic file repositories; we provide actionable engineering support from initial design validation to post-processing, ensuring your geometry, material selection, and application requirements align with industrial standards. Reduce project risk and iterate faster with our no-cost design analysis. Ready to validate your part’s manufacturability? Access our Online Instant Quote platform 24/7 for transparent pricing, lead time estimates, and DFM feedback within minutes—no RFQ required. Submit your CAD file today and experience engineering-grade additive manufacturing, delivered with Honyo’s operational rigor.

Technical Capabilities

The term “free 3D CNC files” is often a misnomer. CNC (Computer Numerical Control) typically refers to subtractive manufacturing processes such as milling or turning. In contrast, the technologies listed—SLA, SLS, MJF, and DMLS—are additive manufacturing (3D printing) methods. It is likely the request refers to free 3D printable CAD or STL files compatible with these additive processes. Below are the technical specifications relevant to each technology, including supported materials such as Aluminum, Steel, ABS, and Nylon.

| Technology | Process Description | Common Materials | Layer Resolution Range | Typical Build Volume (mm) | Surface Finish | Tolerances | Key Applications |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses UV laser to cure liquid photopolymer resin layer by layer | Standard Resins, Tough/ABS-like Resins, Castable, Dental, High-Temp | 25–100 µm | 145 x 145 x 175 up to 1500 x 750 x 500 (industrial) | Smooth, glossy; post-processing improves finish | ±0.10 mm (small parts), increases with size | Prototypes, master patterns, dental models, visual models |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered material, typically nylon-based | Nylon 12 (PA12), Nylon 11 (PA11), Glass-filled Nylon, TPU | 80–150 µm | 200 x 200 x 300 up to 700 x 380 x 580 | Grainy, matte finish; bead blasting available | ±0.30 mm | Functional prototypes, end-use parts, complex geometries, ducts |

| MJF (Multi Jet Fusion) | Inkjet array deposits fusing and detailing agents on powder bed, then heated by lamps | Nylon 12 (PA12), Glass-filled Nylon, TPU (HP offers PA11 and PA12 variants) | 80 µm | 380 x 280 x 380 (HP Jet Fusion 5200) | Smooth, slightly grainy; consistent surface | ±0.20 mm | Mid-volume production, functional parts, enclosures, housings |

| DMLS (Direct Metal Laser Sintering) | High-powered laser fully melts metal powder layer by layer | Aluminum (AlSi10Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel, Tool Steel | 20–50 µm | 250 x 250 x 325 up to 500 x 400 x 400 | Rough as-printed; requires post-processing (machining, polishing, HIP) | ±0.10 mm (typical), highly dependent on geometry | Aerospace, medical implants, tooling, high-stress components |

Notes:

ABS-like properties are achieved in SLA (via tough resins) and SLS/MJF (via nylon materials), though true ABS thermoplastic is not commonly used in SLS or MJF.

Aluminum and steel materials are only applicable in metal-based processes such as DMLS.

Free 3D model files (e.g., from platforms like GrabCAD, Thingiverse, or Printables) may be downloaded in STL or STEP format and adapted for any of these processes, but must be evaluated for manufacturability, orientation, support (except SLS/MJF), and scaling per the target technology.

Design guidelines vary significantly between technologies—e.g., minimum wall thickness, feature size, and overhang angles must be optimized for each process.

From CAD to Part: The Process

Honyo Prototype’s Free 3D CNC File Process Overview

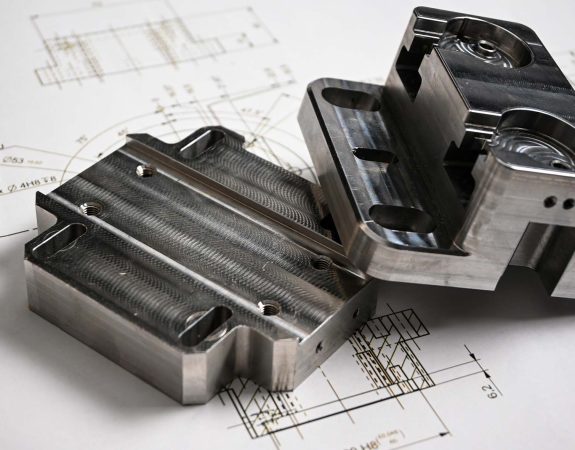

Honyo Prototype offers a streamlined workflow for generating manufacturable CNC files at no cost to the client, provided the project proceeds to production. This process eliminates quoting ambiguities and ensures design viability before machining begins. The sequence is strictly structured to maximize efficiency and reduce client risk.

Upload CAD

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure portal. Acceptable file types include 3D models with complete geometry and metadata. We reject 2D sketches, incomplete solids, or non-parametric surfaces lacking critical features. Uploaded files undergo automated validation for integrity, unit consistency, and topology errors. Invalid submissions trigger immediate client notification with specific failure reasons, requiring resubmission.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which performs concurrent cost and manufacturability analysis. The AI cross-references material databases, machine capabilities, and real-time shop floor data to generate a fixed-price quote within 2 business hours. Crucially, this stage includes preliminary CNC file generation: the system auto-creates optimized toolpaths, fixture plans, and machine-specific G-code. Clients receive this CNC file package alongside the quote, enabling technical validation prior to commitment. There is no charge for this file generation if the project moves to production.

DFM Analysis Integration

Unlike competitors, Honyo embeds comprehensive Design for Manufacturing (DFM) feedback directly into the quoting phase. Our AI evaluates 17 critical parameters, including:

| DFM Parameter Category | Specific Checks | Impact if Ignored |

|---|---|---|

| Geometric Feasibility | Minimum wall thickness, undercuts, draft angles | Part failure or scrap |

| Tolerancing | GD&T compliance, achievable tolerances | Assembly mismatches |

| Material Constraints | Grain direction sensitivity, thermal stability | Warpage or distortion |

| Machine Limitations | Tool access, work envelope clearance | Machining collisions |

Clients receive a detailed DFM report highlighting actionable revisions. The pre-generated CNC files are updated in real-time as clients adjust designs via our collaborative portal. Only after DFM sign-off do files lock for production.

Production Execution

Approved CNC files drive our Haas and DMG MORI machining centers with zero manual reprogramming. We utilize in-process probes for first-article verification against the original CAD model, ensuring dimensional accuracy per AS9100 standards. Material certifications and real-time production tracking are accessible via client dashboards. For multi-part assemblies, we maintain strict batch traceability through serialized part marking.

Delivery Commitment

Finished parts ship with certified dimensional reports, material test certificates, and the final validated CNC program files at no additional cost. Delivery timelines are contractually guaranteed (typically 5–10 business days for prototypes), with expedited options. The CNC files remain the client’s intellectual property, provided as editable .NC files alongside machine-specific post-processor documentation. This closed-loop process ensures clients receive not just parts, but fully documented, production-ready manufacturing data—eliminating re- quoting delays for future orders.

This workflow transforms CNC prototyping from a transactional service into a risk-mitigated engineering partnership, with the free CNC file generation serving as our commitment to technical transparency.

Start Your Project

Download your free 3D CNC files today and accelerate your prototyping process.

Contact Susan Leo at [email protected] to request your files.

Based in Shenzhen, our state-of-the-art manufacturing facility ensures seamless transition from design to production.

Let Honyo Prototype support your development with precision-engineered solutions made in China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.