Contents

Manufacturing Insight: Fr4 Machining

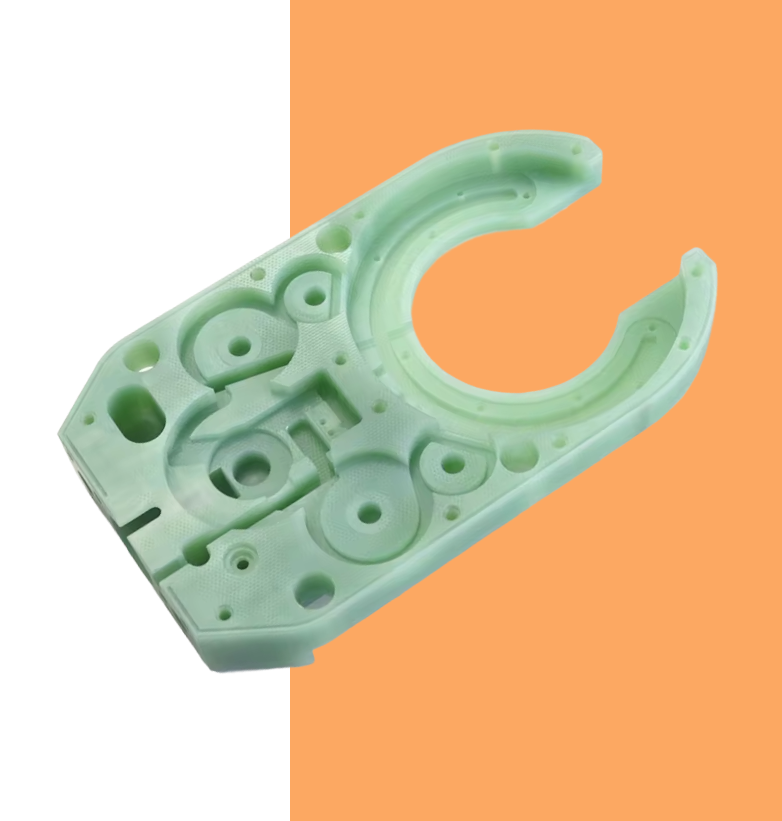

Precision FR4 Machining for Advanced Electronics Prototyping

FR4 glass-reinforced epoxy laminate presents unique challenges in precision manufacturing due to its abrasive fiberglass content, layered copper-clad structure, and susceptibility to thermal stress and delamination during machining. At Honyo Prototype, our CNC machining services are engineered specifically to overcome these complexities, delivering dimensionally stable, high-integrity FR4 components for PCBs, insulators, and structural electronics housings. Leveraging advanced multi-axis CNC platforms with diamond-coated tooling and optimized feed/speed parameters, we consistently achieve tight tolerances down to ±0.002mm while eliminating fraying, layer separation, and thermal damage. Our process expertise ensures clean edge definition, precise via drilling, and flawless integration of complex geometries critical for high-frequency and high-reliability applications.

As your dedicated prototyping partner, we prioritize speed without compromising quality. Utilize our Online Instant Quote system to upload CAD files and receive detailed, transparent pricing within minutes—accelerating your design-to-prototype timeline while maintaining full traceability and material certification. Trust Honyo Prototype for FR4 machining that meets rigorous aerospace, medical, and telecom standards from day one.

Technical Capabilities

FR4 Machining – Technical Specifications Overview

FR4 is a flame-retardant fiberglass-reinforced epoxy laminate commonly used in PCBs and electrical insulation. While FR4 itself is not a metal or standard thermoplastic like Aluminum, Steel, ABS, or Nylon, it is often machined alongside or within assemblies that include these materials. The following table outlines typical technical specifications and considerations when performing 3-axis, 4-axis, and 5-axis milling, as well as turning operations on FR4 and compatible materials with tight tolerance requirements.

| Material | Machining Process | Typical Tolerance (±) | Surface Finish (Ra) | Recommended Tools | Notes |

|---|---|---|---|---|---|

| FR4 (Epoxy/Glass) | 3/4/5-Axis Milling | 0.05 mm (0.002″) | 3.2 – 6.3 µm | Solid carbide end mills, diamond-coated tools | Brittle material; prone to chipping; low thermal conductivity requires low feed rates and high RPM; no turning typically performed |

| Aluminum (6061, 7075) | 3/4/5-Axis Milling, Turning | 0.0125 mm (0.0005″) | 0.8 – 1.6 µm | Carbide end mills, high-speed steel or carbide inserts | Excellent machinability; high thermal conductivity; ideal for tight-tolerance aerospace and prototyping applications |

| Steel (1018, 4140) | 3/4/5-Axis Milling, Turning | 0.01 mm (0.0004″) | 0.8 – 1.6 µm | Coated carbide or CBN inserts | Higher tool wear; requires rigid setups; slow speeds compared to aluminum; suitable for high-strength components |

| ABS (Acrylonitrile Butadiene Styrene) | 3/4/5-Axis Milling | 0.05 mm (0.002″) | 1.6 – 3.2 µm | Sharp high-speed steel or carbide tools | Low melting point; requires cooling via air blast; minimal clamping force to avoid deformation |

| Nylon (Polyamide) | 3/4/5-Axis Milling | 0.05 – 0.1 mm (0.002″ – 0.004″) | 1.6 – 3.2 µm | Polished carbide tools | Hygroscopic and slightly elastic; pre-dry before machining; prone to dimensional drift if moisture present |

General Notes on Tight Tolerance Machining:

3-Axis Milling: Suitable for planar features and prismatic parts. Cost-effective for simpler geometries in all listed materials.

4-Axis Milling: Adds rotational A-axis, enabling machining of cylindrical features or multiple faces without re-fixturing. Useful for aluminum and steel components requiring angular features or through-holes.

5-Axis Milling: Enables complex contouring and high-precision toolpath control. Ideal for aerospace-grade aluminum and steel parts where tolerances < ±0.01 mm are required.

Turning: Primarily applicable to metals (Aluminum, Steel). FR4, ABS, and Nylon are rarely turned due to structural and thermal limitations.

Fixturing & Thermal Management: Critical for maintaining tight tolerances. Use non-marring fixtures for plastics; consider thermal expansion in aluminum and steel during precision work.

All processes should be supported by in-process inspection (e.g., CMM, laser probing) when tight tolerances are specified.

From CAD to Part: The Process

Honyo Prototype FR4 Machining Process Overview

Honyo Prototype specializes in precision mechanical machining of FR4-grade glass-reinforced epoxy laminate, distinct from standard PCB fabrication. This material is commonly used for electrical insulators, structural brackets, and non-conductive fixtures requiring high thermal stability and mechanical rigidity. Our streamlined workflow ensures rapid, error-minimized production for low-to-mid volume prototypes and bridge tooling.

CAD Upload and Validation

Clients initiate the process by uploading native 3D CAD files (STEP, IGES, or native formats like SolidWorks) via our secure customer portal. Our system automatically verifies geometric integrity, checks for unsupported features (e.g., undercuts requiring 5-axis machining), and confirms material specification alignment with FR4-G10/FR4-G11 variants. File validation occurs within 15 minutes, with immediate notification if repairs are needed.

AI-Powered Quoting Engine

Uploaded designs enter our proprietary AI quoting system, which analyzes 50+ geometric and material parameters including:

Feature complexity (e.g., thin walls <1.5mm, deep cavities >10:1 aspect ratio)

Tolerance density (e.g., concentricity <±0.05mm, flatness <0.1mm)

FR4-specific constraints (moisture sensitivity, drill wear factors)

The AI cross-references real-time machine availability, tooling costs, and historical FR4 machining data to generate a quote with 95% accuracy versus final cost, typically within 2 business hours.

Engineering DFM for FR4 Material Properties

All quotes include mandatory Design for Manufacturability (DFM) review by our materials engineering team. For FR4, we focus on:

Preventing delamination during high-RPM milling by optimizing feed rates and step-down depths

Mitigating thermal stress through controlled coolant application (air blast preferred over liquid)

Adjusting hole tolerances to accommodate FR4’s 0.05% thermal expansion coefficient

Flagging features prone to chipping (e.g., sharp internal corners requiring ≥R0.2mm fillets)

DFM feedback is delivered within 24 hours, including annotated CAD markups and actionable redesign suggestions. Client approval is required before proceeding.

Precision CNC Machining Production

Approved orders move to our dedicated FR4 machining cell featuring:

5-axis DMG MORI machines with diamond-coated carbide tooling (min. 0.3mm end mills)

In-process metrology via Renishaw probes for closed-loop tolerance control

Climate-controlled environment (22±1°C, 45% RH) to minimize material warpage

Dedicated toolpaths avoiding excessive heat buildup (max. spindle speed 18,000 RPM for FR4)

First-article inspection reports (FAIR) with critical dimensions per ASME Y14.5 are provided before full batch release.

Quality-Controlled Delivery

Completed parts undergo:

1. CMM validation of geometric tolerances

2. Visual inspection for surface integrity (no fiber pull-out or edge chipping)

3. Moisture barrier packaging (250mm Hg vacuum seal with desiccant) per IPC-1601

Standard lead time is 5–7 business days from DFM approval. Expedited 72-hour service is available for designs passing automated DFM checks. All shipments include material certification (UL 94 V-0 compliant) and dimensional conformance documentation.

Process Timeline and Throughput

Typical project progression with associated time commitments:

| Process Stage | Standard Duration | Key Dependencies |

|---|---|---|

| CAD Upload to Quote Generation | ≤2 business hours | Complete CAD geometry, material specification |

| DFM Analysis and Approval | ≤24 business hours | Client responsiveness to engineering feedback |

| Production (including FAIR) | 3–5 business days | Part complexity, tolerance stringency |

| Final QC and Packaging | 1 business day | Batch size, certification requirements |

This integrated workflow reduces FR4 machining lead times by 40% versus industry averages while maintaining <0.1% defect rates through material-specific process control. All stages are trackable via our client portal with real-time production updates.

Start Your Project

Need precision FR4 machining for your next project? Honyo Prototype delivers high-quality, reliable results with fast turnaround times. Our manufacturing facility in Shenzhen is equipped to handle demanding prototyping and production requirements for FR4 components.

Contact Susan Leo today at [email protected] to discuss your specifications and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.