Guide Contents

Project Insight: Forming Stainless Steel

Precision Meets Speed: The Critical Edge in Stainless Steel Forming

Why Speed and Precision Are Non-Negotiable in Product Development

Delays in prototyping can derail market entry timelines, costing startups millions in lost opportunities.

Precision errors in stainless steel forming lead to costly rework—especially with complex geometries requiring TIG welding or tight tolerances.

Traditional manufacturing lead times often conflict with agile product development cycles, creating bottlenecks that stall innovation.

Honyo Prototype: Your Digital Manufacturing Partner for Agile Production

Online Instant Quote: Real-time pricing in seconds. Adjust material thickness, finishes, or quantities instantly—no back-and-forth emails or delays.

AI-Powered Platform: Smart algorithms analyze designs for manufacturability (DFM), flagging issues before production begins. Reduce material waste by up to 20% and accelerate iterations through automated cost optimization.

Fast Turnaround: Prototypes delivered in 5 business days. Production scaled seamlessly to your needs—without compromising quality, precision, or your timeline.

Seamless Transition from Prototype to Production

One-Stop Solution: From CAD upload to final delivery, our integrated digital ecosystem handles everything—no coordination headaches, no hidden handoffs.

Expertise in Stainless Steel: Precision TIG welding, laser cutting, and bending for intricate structures. Consistent quality across all stages, from initial prototypes to high-volume production runs.

Data-Driven Efficiency: Our digital manufacturing ecosystem leverages real-time analytics to optimize processes, ensuring your stainless steel components meet exact specifications while minimizing costs.

At Honyo Prototype, we don’t just manufacture—we engineer solutions. With Susan Leo’s vision driving our innovation, we turn your stainless steel designs into reality faster, smarter, and with unmatched precision.

Honyo Capabilities & Technology

Precision Stainless Steel Forming Capabilities

AI-Powered Digital Manufacturing Platform

Real-Time Online Instant Quote: Get accurate pricing in seconds—no manual estimates, no delays. Our AI analyzes design complexity, material, and volume to deliver transparent costs instantly.

Automated Design for Manufacturability (DFM): AI-driven checks optimize your design for cost efficiency, reducing waste and rework while maintaining structural integrity.

Seamless Cloud Collaboration: Track progress, share feedback, and approve changes in real-time through a unified digital workflow.

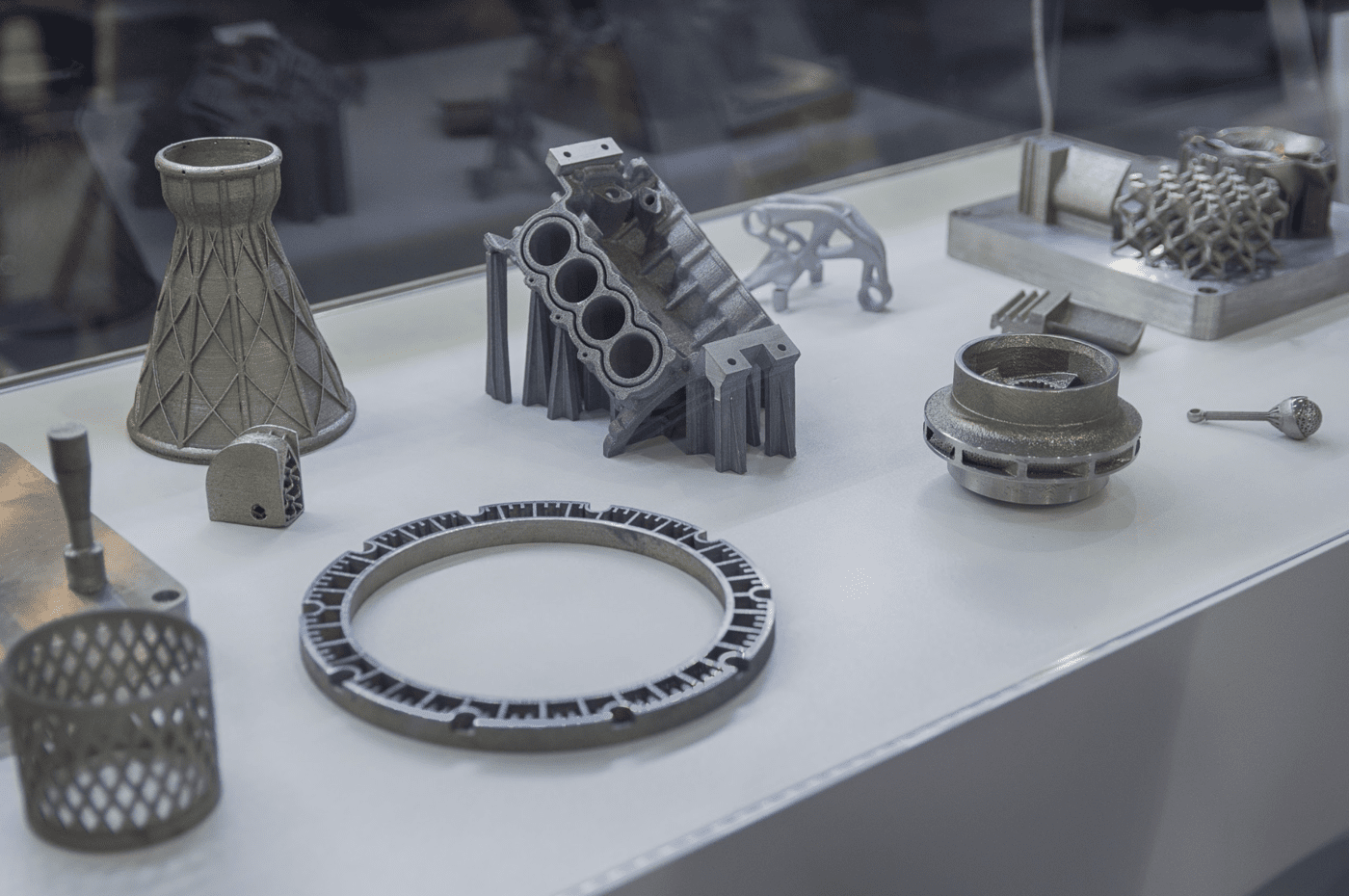

Advanced Forming Technologies

Laser Cutting & Waterjet: Precision cuts for intricate geometries (±0.1mm tolerance) with minimal heat-affected zones.

CNC Press Braking: Accurate bends up to 3000mm length with tooling flexibility for complex angles.

TIG/MIG Welding: High-strength, clean welds for stainless steel assemblies—ideal for medical, aerospace, and automotive applications.

Deep Drawing & Stamping: Complex shapes with <5% material waste, optimized for high-volume consistency.

Scalable Production from Prototype to Mass Production

Zero Minimum Order Quantities: Start with a single prototype and scale to 10,000+ parts without retooling or downtime.

End-to-End One-Stop Solution: Design, forming, finishing, and assembly—all under one roof, eliminating supply chain bottlenecks.

Agile Volume Adjustments: Seamlessly adapt to design changes or shifting demand during production cycles.

ISO-Certified Quality Assurance

Multi-Stage Inspection: In-process checks at every stage (raw material → forming → finishing) using laser scanning and CMM metrology.

Tight Tolerances: ±0.05mm precision for critical aerospace, medical, and industrial components.

Full Compliance Documentation: ISO 9001:2015 certified processes with traceable quality records for regulatory audits.

Unmatched Speed & Cost Efficiency

24–48 Hour Prototypes: Get stainless steel parts faster than industry averages—accelerate your time-to-market.

40% Faster Lead Times: AI-optimized scheduling and automated resource allocation minimize delays.

Transparent Pricing: No hidden fees—costs calculated dynamically based on material, complexity, and volume.

“From concept to production, Honyo’s digital ecosystem turns stainless steel challenges into competitive advantages.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for Stainless Steel Forming

Material Selection for Stainless Steel & Beyond

Stainless Steel Grades

304: Ideal for general-purpose applications (food processing, automotive trim). Cost-effective with excellent corrosion resistance.

316: Marine-grade durability with molybdenum enhancement. Best for chemical exposure or saltwater environments (medical devices, offshore equipment).

430: Magnetic, budget-friendly for decorative uses (appliances, automotive accents).

17-4 PH: High-strength, heat-treatable option for aerospace and precision tooling.

Other Metals

Aluminum 6061/7075: Lightweight, thermal conductivity for heat sinks and structural parts.

Titanium Grade 5: Extreme strength-to-weight ratio for medical implants and aerospace components.

Copper: Superior electrical conductivity for electronics and heat exchangers.

Plastics

ABS: Impact-resistant prototyping and enclosures.

Nylon 6/6: Wear-resistant gears and bearings.

POM (Acetal): Low-friction precision parts for automotive and robotics.

💡 Pro Tip: Honyo’s AI platform cross-analyzes material properties across metals and plastics—get instant recommendations tailored to your project’s performance, budget, and manufacturability.

Precision Surface Finishes for Every Material

Stainless Steel

Mirror Polish: Ultra-reflective finish for luxury fixtures and medical instruments.

Brushed/Satin: Scratch-hiding texture for kitchen appliances and architectural panels.

Electropolishing: Removes surface impurities, boosting corrosion resistance by 50%+ for food/pharma compliance.

Passivation: Eliminates free iron contamination for ISO 13485-certified medical components.

Aluminum

Anodizing (Type II/III): Durable colored finishes with wear resistance.

Powder Coating: Custom colors and textures for consumer electronics.

Plastics

Painting: High-gloss or matte finishes for aesthetic enclosures.

Texturing: Custom surface patterns for ergonomic grips or visual appeal.

Titanium/Copper

Chemical Etching: Precision detailing for aerospace or decorative copper components.

💡 Pro Tip: Our platform shows real-time cost and lead time impacts for each finish—optimize your design for both function and budget without guesswork.

AI-Driven Efficiency for Your Project

Instant Online Quotes: Upload your CAD file and receive a detailed cost breakdown in seconds—no hidden fees, no delays.

Smart Material Recommendations: AI analyzes your design requirements to suggest the optimal material/finish combo for performance, cost, and lead time.

Fast Turnaround Guarantee: Prototype in 3 days, production in 1–2 weeks—backed by Honyo’s integrated digital manufacturing ecosystem.

One-Stop Solution: From concept validation to mass production, all under one roof with founder Susan Leo’s innovation-driven approach.

✨ Why Honyo? We eliminate guesswork with data-driven decisions—ensuring your stainless steel components meet exact specifications while cutting costs by up to 30% through smart material and process optimization.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined stainless steel fabrication through our digital manufacturing ecosystem. Our streamlined workflow—from CAD upload to delivery—delivers unprecedented speed, transparency, and precision for hardware startups and engineering teams.

1. Upload CAD File

Seamless upload of STEP, STL, IGES, or native CAD files via our secure portal

Auto-identification of stainless steel material specs (e.g., 304, 316L) and geometry constraints

Zero manual intervention—start in under 60 seconds

2. Get Instant Quote (AI Engine)

AI-driven analysis delivers real-time pricing for stainless steel fabrication in <60 seconds

Transparent cost breakdown: raw materials, labor, welding, finishing, and shipping fees—no hidden charges

Compare quotes instantly for multiple design iterations to optimize budgets

3. DFM Analysis

AI-powered validation for stainless steel-specific challenges (e.g., weld integrity, grain orientation, corrosion resistance)

Actionable recommendations to reduce rework costs by up to 30% while improving structural performance

Collaborative feedback loop—refine designs before production begins

4. Production & Delivery

End-to-end digital workflow with real-time production tracking via your dashboard

Precision forming, TIG welding, and surface finishing for stainless steel with ±0.05mm tolerances

Fast turnaround: prototypes in 3–5 days, production orders in 1–2 weeks—no supply chain delays

Why Honyo?

Our one-stop solution eliminates fragmentation between design, prototyping, and mass production. With AI-driven efficiency and Shenzhen’s manufacturing excellence, you get cost-effective, high-precision stainless steel parts—delivered faster than traditional suppliers. Focus on innovation; we’ll handle the rest.

Start Your Project with Honyo

Start Your Project with Honyo

As a leader in digital manufacturing, Honyo Prototype empowers hardware startups, engineers, and procurement teams to transform ideas into high-quality stainless steel components with unparalleled speed and precision. Under the guidance of Founder Susan Leo, our one-stop solution bridges prototyping and production through an integrated digital ecosystem—eliminating supply chain friction and accelerating your product journey.

Online Instant Quote

Upload your CAD file for real-time pricing with dynamic adjustments for materials, finishes, and tolerances

Transparent cost breakdowns with no hidden fees—see exactly what you’re paying for

Optimize your design on-the-fly to balance performance, cost, and lead time

AI-Powered Digital Manufacturing Ecosystem

Proprietary algorithms analyze geometry and material properties to recommend the most efficient forming processes

Automated Design for Manufacturability (DFM) checks prevent costly revisions before production starts

Integrated CAD/CAM workflow ensures seamless data transfer and iterative design refinement

Fast Turnaround Guaranteed

Prototype to production in as little as 3 days for standard orders

Dedicated express lanes for urgent projects with 24/7 production monitoring

Scalable capabilities from single prototypes to 10,000+ units across Shenzhen/Dongguan facilities

Ready to launch your stainless steel project? Contact Susan Leo and the Honyo team today:

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a live demo of our digital manufacturing ecosystem

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.