Introduction: Navigating the Global Market for flexible pvc sheet

In an increasingly interconnected world, sourcing high-quality flexible PVC sheets presents a unique challenge for international B2B buyers. With diverse applications spanning industries such as construction, automotive, and logistics, decision-makers must navigate a complex landscape of product specifications, supplier reliability, and pricing structures. This guide is designed to empower you with the insights necessary to make informed purchasing decisions, ensuring that your investments in flexible PVC sheets align with your business objectives and operational needs.

Throughout this comprehensive guide, you will explore various types of flexible PVC sheets, their applications across different sectors, and the critical factors to consider when vetting suppliers. We will delve into essential aspects such as cost analysis, material durability, and compliance with international standards, providing you with actionable insights tailored to your specific market needs.

Whether you are operating in Africa, South America, the Middle East, or Europe—including key markets like Saudi Arabia and Vietnam—this guide serves as a valuable resource for navigating the global market for flexible PVC sheets. By understanding the nuances of sourcing and procurement, you will be better equipped to select the right products that enhance your operational efficiency and drive your business forward.

Understanding flexible pvc sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Foam PVC Sheets | Lightweight, excellent insulation, easy to cut and shape | Signage, displays, construction | Pros: Cost-effective, versatile. Cons: Less durable than solid PVC. |

| Rigid PVC Sheets | Strong, impact-resistant, available in various thicknesses | Industrial applications, construction | Pros: High durability, excellent weather resistance. Cons: Less flexible than other types. |

| Flexible PVC Film | Highly flexible, transparent, good for visibility | Packaging, protective covers, curtains | Pros: Lightweight, customizable. Cons: May not withstand heavy impacts. |

| PVC Strip Curtains | Made from flexible strips, easy to install, provides insulation | Warehouses, cold storage, factories | Pros: Energy-efficient, easy access. Cons: Requires regular maintenance. |

| UV-Stabilized PVC Sheets | Resistant to UV degradation, maintains color and strength | Outdoor applications, signage | Pros: Long-lasting, maintains appearance. Cons: Higher initial cost. |

What are the Characteristics and Suitability of Foam PVC Sheets for B2B Buyers?

Foam PVC sheets are lightweight yet provide excellent insulation properties, making them a popular choice in signage and display applications. They are easy to cut and shape, allowing for quick customization. These sheets are suitable for various industries, including construction and advertising, where cost-effectiveness and versatility are crucial. Buyers should consider their specific application needs, as foam PVC may not offer the same durability as solid PVC options.

How Do Rigid PVC Sheets Stand Out in Durability and Applications?

Rigid PVC sheets are recognized for their strength and impact resistance, available in various thicknesses to cater to diverse industrial applications. They are commonly used in construction, manufacturing, and other sectors where durability is paramount. While they provide excellent weather resistance, buyers should weigh the benefits of rigidity against the need for flexibility in their applications, as these sheets are less adaptable than their flexible counterparts.

Why Choose Flexible PVC Film for Packaging and Protective Uses?

Flexible PVC film is characterized by its high flexibility and transparency, making it ideal for packaging, protective covers, and curtains. Its lightweight nature allows for easy handling and installation, which is beneficial in fast-paced industrial environments. However, while it offers excellent visibility, buyers should be cautious of its lower impact resistance compared to more rigid options, especially in high-traffic areas.

What Are the Benefits of PVC Strip Curtains in Industrial Settings?

PVC strip curtains are designed from flexible strips that provide easy access while maintaining insulation in warehouses and cold storage facilities. They are energy-efficient, reducing heating and cooling costs, and are easy to install. However, regular maintenance is required to ensure they remain effective, which buyers must consider when evaluating their long-term utility in their operations.

How Do UV-Stabilized PVC Sheets Enhance Outdoor Applications?

UV-stabilized PVC sheets are engineered to resist degradation from sunlight, ensuring they maintain their color and structural integrity over time. This makes them particularly suitable for outdoor applications such as signage and protective barriers. While the initial cost may be higher than standard PVC sheets, the long lifespan and reduced need for replacement can make them a worthwhile investment for B2B buyers looking for longevity in their products.

Key Industrial Applications of flexible pvc sheet

| Industry/Sector | Specific Application of flexible pvc sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Cold Chain Packaging | Maintains temperature integrity, ensuring food safety and quality | Compliance with food safety standards, durability at low temperatures |

| Manufacturing | Welding Screens | Protects workers from harmful radiation and enhances workplace safety | UV resistance, tear strength, and compliance with safety regulations |

| Construction & Design | Interior Partitions | Provides flexibility in design while enhancing sound insulation | Custom sizes, thickness options, and aesthetic finishes |

| Logistics | Flexible Doors and Curtains | Facilitates smooth traffic flow while providing insulation | Thickness, transparency, and adaptability to environmental conditions |

| Agriculture | Greenhouse Covers | Enhances plant growth by optimizing light transmission | UV stabilization, durability against weather conditions |

How is Flexible PVC Sheet Used in Cold Chain Packaging for Food & Beverage?

Flexible PVC sheets are extensively used in the food and beverage industry for cold chain packaging. They ensure that perishable goods are kept at optimal temperatures during storage and transportation, which is crucial for maintaining product quality and safety. For international buyers, especially in regions like Africa and South America, it’s vital to consider the material’s compliance with food safety standards. Additionally, flexibility at low temperatures is essential, as the sheets must remain pliable in various climate conditions.

What Role Do Welding Screens Play in Enhancing Safety in Manufacturing?

In manufacturing environments, flexible PVC sheets are often utilized as welding screens to protect workers from harmful radiation and sparks generated during welding operations. These screens are designed to provide a barrier while allowing visibility, thus enhancing safety without compromising productivity. Buyers should prioritize sourcing materials with high UV resistance and tear strength to ensure longevity and compliance with occupational safety regulations, particularly in regions with stringent safety laws like Europe and the Middle East.

How Do Flexible PVC Sheets Improve Interior Partitions in Construction?

In the construction and design sectors, flexible PVC sheets serve as effective interior partitions. They offer sound insulation and can be customized to various sizes and thicknesses, allowing for flexible design solutions. For B2B buyers, especially in the Middle East and Europe, sourcing options should include aesthetic finishes and the ability to meet specific regulatory standards for building materials. This adaptability makes them ideal for modern workspaces that require reconfigurable layouts.

How Are Flexible Doors and Curtains Used in Logistics?

Flexible PVC sheets are utilized in logistics as doors and curtains that facilitate smooth traffic flow while providing insulation against temperature fluctuations, dust, and noise. These applications are particularly beneficial in warehouses and distribution centers where efficiency is paramount. Buyers should focus on sourcing sheets that offer durability and adaptability to different environmental conditions, especially in regions prone to extreme weather, such as parts of Africa and South America.

What Benefits Do Greenhouse Covers Offer in Agriculture?

In agriculture, flexible PVC sheets are commonly used as greenhouse covers, enhancing plant growth by optimizing light transmission while providing protection from harsh weather. This application is particularly relevant for international buyers in developing regions, where maximizing agricultural yield is crucial. When sourcing, it’s important to consider UV stabilization and the material’s durability against environmental stresses, ensuring long-term performance and sustainability in agricultural practices.

3 Common User Pain Points for ‘flexible pvc sheet’ & Their Solutions

Scenario 1: Sourcing Quality Materials in a Competitive Market

The Problem: B2B buyers often struggle to find high-quality flexible PVC sheets due to the overwhelming number of suppliers and the varying standards of material quality. In regions like Africa and South America, where manufacturing standards may differ significantly, buyers risk acquiring subpar products that can lead to operational inefficiencies and increased costs. This challenge is particularly pronounced when dealing with large orders, where the margin for error can be costly.

The Solution: To navigate this challenge effectively, buyers should conduct thorough market research to identify reputable suppliers. Look for manufacturers with certifications and industry endorsements that guarantee product quality, such as ISO standards. Establishing long-term relationships with reliable suppliers can also provide better pricing and assurance of quality. Additionally, consider requesting samples before placing large orders to evaluate the material’s durability, flexibility, and overall performance. Collaborating with local partners who understand regional market dynamics can further streamline sourcing efforts.

Scenario 2: Ensuring Compliance with Local Regulations

The Problem: Compliance with local regulations regarding materials can be a significant hurdle for B2B buyers, especially in regions with stringent safety and environmental standards. Flexible PVC sheets may be subject to regulations that dictate material composition, fire resistance, or recycling capabilities. Buyers can find themselves facing legal challenges or financial penalties if they unknowingly purchase non-compliant products, jeopardizing their operations and reputation.

The Solution: To mitigate compliance risks, buyers should familiarize themselves with local regulations and standards applicable to flexible PVC sheets in their market. Engaging with industry associations or regulatory bodies can provide valuable insights into compliance requirements. When sourcing products, ask suppliers for documentation proving that their materials meet local standards. Additionally, consider investing in third-party testing services to validate compliance, particularly for critical applications such as construction, packaging, or food safety. Staying informed and proactive about regulatory changes can save companies from costly mistakes.

Scenario 3: Adapting to Diverse Application Needs

The Problem: Flexible PVC sheets are used in various applications, from signage to industrial curtains, which means that buyers often face the challenge of selecting the right type of sheet for their specific needs. Misjudging the required thickness, flexibility, or UV resistance can lead to product failure, leading to increased costs and customer dissatisfaction. Buyers in diverse markets may also have unique requirements based on local conditions, such as humidity or temperature variations.

The Solution: To address application-specific challenges, buyers should invest time in understanding the technical specifications of flexible PVC sheets. It is crucial to engage with suppliers who can provide detailed information on product performance under various conditions. Creating a clear list of requirements based on intended use—such as thickness, flexibility, UV resistance, and chemical compatibility—can help narrow down options. Furthermore, consider leveraging pilot projects to test different types of flexible PVC sheets in real-world applications before committing to larger orders. This approach not only ensures compatibility but also allows for adjustments based on performance feedback, ultimately leading to better satisfaction and cost efficiency.

Strategic Material Selection Guide for flexible pvc sheet

What Are the Key Properties of Flexible PVC Sheets?

Flexible PVC sheets are made from various formulations of polyvinyl chloride, tailored for specific applications. Here, we analyze four common materials used in flexible PVC sheets, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Standard Flexible PVC

Key Properties:

Standard flexible PVC exhibits excellent flexibility, good tensile strength, and moderate temperature resistance, typically ranging from -15°C to +50°C. It is also UV resistant, making it suitable for outdoor applications.

Pros & Cons:

The primary advantage of standard flexible PVC is its cost-effectiveness and ease of manufacturing. However, it may not perform well in extreme temperatures or harsh chemical environments, limiting its application in specialized industries.

Impact on Application:

This material is compatible with a range of media, including water and some chemicals, making it suitable for general-purpose applications such as signage and protective covers.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local regulations regarding material safety and environmental impact. Standards such as ASTM or DIN may apply, depending on the intended use.

2. High-Impact PVC

Key Properties:

High-impact PVC is designed for enhanced durability, offering superior impact resistance and strength. It can withstand higher pressures and is suitable for applications requiring robust performance.

Pros & Cons:

While high-impact PVC provides excellent durability, it comes at a higher cost compared to standard PVC. The manufacturing process can also be more complex, potentially leading to longer lead times.

Impact on Application:

This material is ideal for applications such as industrial doors and protective barriers, where impact resistance is critical. It can handle exposure to various media, including oils and solvents.

Considerations for International Buyers:

Buyers should verify that high-impact PVC complies with relevant safety standards in their region, particularly in industries like construction and manufacturing where safety is paramount.

3. Flexible PVC with Additives

Key Properties:

Flexible PVC can be enhanced with various additives to improve properties like flame resistance, anti-static capabilities, and UV stability. These modifications can significantly expand its application range.

Pros & Cons:

The main advantage is the versatility of the material, allowing it to meet specific application requirements. However, the addition of these compounds can increase production costs and complicate the recycling process.

Impact on Application:

These modified PVC sheets are suitable for specialized applications such as welding screens and cold chain logistics, where specific environmental conditions must be maintained.

Considerations for International Buyers:

It is crucial for buyers to understand the implications of using additives, including compliance with international safety standards and potential restrictions in certain markets.

4. Clear Flexible PVC

Key Properties:

Clear flexible PVC offers high transparency and good light transmission, making it ideal for applications requiring visibility. It maintains flexibility across a range of temperatures, typically from -15°C to +50°C.

Pros & Cons:

The transparency of this material is a significant advantage for applications like sneeze guards and display cases. However, it may be less durable than opaque alternatives and can be more susceptible to scratches.

Impact on Application:

Clear flexible PVC is particularly suited for environments where visibility is essential, such as retail and food service industries. Its compatibility with various cleaning agents makes it easy to maintain.

Considerations for International Buyers:

International buyers should ensure that clear PVC meets local health and safety regulations, especially in food-related applications. Compliance with standards such as JIS or ASTM is essential for market acceptance.

Summary Table of Flexible PVC Sheet Materials

| Material | Typical Use Case for flexible pvc sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Flexible PVC | General-purpose applications | Cost-effective and easy to manufacture | Limited performance in extreme conditions | Low |

| High-Impact PVC | Industrial doors and protective barriers | Superior impact resistance | Higher cost and complex manufacturing | High |

| Flexible PVC with Additives | Welding screens and cold chain logistics | Versatile for specific applications | Increased costs and recycling complexity | Medium |

| Clear Flexible PVC | Sneeze guards and display cases | High transparency | Susceptible to scratches | Medium |

This analysis provides B2B buyers with actionable insights into the strategic selection of flexible PVC sheet materials, ensuring informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible pvc sheet

What Are the Key Stages in the Manufacturing Process of Flexible PVC Sheets?

The manufacturing process of flexible PVC sheets involves several critical stages that ensure the final product meets industry standards and customer specifications. Here’s a breakdown of the main stages:

-

Material Preparation

The first step involves selecting high-quality PVC resin, which is often mixed with various additives to enhance specific properties such as flexibility, UV resistance, and durability. During this stage, the raw materials are measured and blended in precise ratios. Additives may include plasticizers, stabilizers, and colorants, depending on the intended application of the sheets. -

Forming

The prepared material is then processed using methods such as extrusion or calendering. In the extrusion process, the PVC mixture is heated and forced through a die to create a continuous sheet. Calendering involves passing the material through rollers to achieve the desired thickness and finish. Both methods allow for the production of sheets in various thicknesses and finishes, catering to different market needs. -

Assembly

Although flexible PVC sheets are often used as standalone products, they may sometimes require additional components, such as adhesives or protective films. This assembly phase is critical for applications where enhanced performance is needed, such as in welding screens or industrial doors. -

Finishing

The final stage of production involves cutting the sheets to size, applying surface treatments (if necessary), and packaging. This may include surface texturing, UV coating, or other modifications to improve the aesthetic and functional properties of the sheets.

How Is Quality Assurance Implemented in Flexible PVC Sheet Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of flexible PVC sheets, ensuring that products comply with international standards and meet customer expectations. Here are the key components of a robust QA system:

-

Adherence to International Standards

Many manufacturers align their processes with international quality standards, such as ISO 9001, which provides a framework for consistent quality management. Additionally, industry-specific standards like CE marking for products sold in Europe or API standards for oil and gas applications can be critical for market acceptance. -

Quality Control Checkpoints

A comprehensive QA process includes several checkpoints throughout the manufacturing cycle:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): Regular checks during production monitor consistency in thickness, color, and other properties.

– Final Quality Control (FQC): The finished product undergoes rigorous testing for physical properties, including tensile strength, elongation, and UV resistance. This ensures that the sheets perform as required in their intended applications. -

Common Testing Methods

Various testing methods can be employed to validate the quality of flexible PVC sheets. These include:

– Tensile Testing: Measures the strength and flexibility of the material.

– UV Resistance Testing: Assesses how well the sheets withstand prolonged exposure to sunlight.

– Thermal Stability Testing: Evaluates the material’s performance under varying temperature conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps to ensure supplier reliability:

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to standards. This first-hand assessment can reveal the supplier’s commitment to quality and their operational capabilities. -

Requesting Quality Reports

Suppliers should be willing to provide documentation of their quality control processes, including test reports and certifications. Regularly updated quality management system documentation can indicate ongoing compliance with relevant standards. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes. These inspections can be particularly beneficial when dealing with new suppliers or when large orders are placed.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of quality control in international trade requires an understanding of regional regulations and standards. Here are some nuances to consider:

-

Regulatory Compliance

Different regions may have specific regulations governing the use of PVC products. For instance, products sold in the EU must comply with REACH regulations, which ensure the safety of chemical substances. Understanding these regulations can help buyers avoid compliance issues. -

Cultural Differences

Cultural perceptions of quality can vary significantly across regions. For instance, what is considered acceptable quality in one country may not meet the expectations in another. B2B buyers must communicate their quality requirements clearly and ensure that suppliers understand these expectations. -

Language Barriers

Language differences can lead to misunderstandings regarding quality specifications. It’s advisable to use clear, unambiguous language in contracts and specifications to minimize the risk of misinterpretation.

Conclusion

In summary, the manufacturing and quality assurance processes for flexible PVC sheets are intricate and vital for ensuring product reliability and performance. By understanding the key stages of production and implementing thorough quality control measures, B2B buyers can make informed decisions when selecting suppliers. Furthermore, by actively engaging in supplier audits, requesting quality documentation, and considering regional nuances, international buyers can secure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible pvc sheet’

Introduction

Sourcing flexible PVC sheets can be a strategic decision for businesses across various industries, including construction, logistics, and manufacturing. This guide offers a practical checklist for international B2B buyers to ensure that their procurement process is efficient and effective. By following these steps, you can secure high-quality materials that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify the technical requirements of the flexible PVC sheets you need. Consider factors such as thickness, flexibility, color, and any additional features like UV resistance or waterproofing.

– Why It Matters: Clear specifications help suppliers understand your needs and provide accurate quotes, reducing the chances of misunderstandings later on.

Step 2: Research Potential Suppliers

Take the time to identify and research suppliers that specialize in flexible PVC sheets. Look for companies with a solid reputation and experience in your target market regions, such as Africa, South America, the Middle East, and Europe.

– What to Look For: Supplier certifications, years in business, and customer reviews. A well-established supplier is more likely to provide reliable products and services.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers with international standards. Certifications such as ISO 9001 or ASTM can indicate that the supplier adheres to quality management systems.

– Importance: Certification ensures that the materials meet safety and quality standards, which is crucial for long-term performance and regulatory compliance.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their flexible PVC sheets. This allows you to evaluate the material’s quality, texture, and performance firsthand.

– Key Considerations: Assess the samples for durability, flexibility, and any specific characteristics that align with your project requirements. Testing in your operational conditions can provide additional insights.

Step 5: Compare Pricing and Terms

Gather pricing information from multiple suppliers and compare their offers. Pay attention to payment terms, delivery schedules, and bulk order discounts.

– Why It’s Important: A thorough comparison helps you identify the best value for your investment, ensuring that you get quality materials without exceeding your budget.

Step 6: Assess Customer Support and Communication

Evaluate the level of customer service and communication practices of your shortlisted suppliers. Effective communication is vital for resolving issues that may arise during the procurement process.

– What to Look For: Responsiveness, clarity in communication, and willingness to provide support. Good customer service can enhance your overall experience and foster a long-term partnership.

Step 7: Finalize Your Order and Review Terms

After selecting your supplier, finalize your order while carefully reviewing the terms and conditions. Ensure that all specifications, delivery timelines, and payment terms are clearly documented.

– Final Checks: Confirm the return policy and warranty information. This transparency protects your investment and sets clear expectations for both parties.

By following this step-by-step checklist, you can streamline your sourcing process for flexible PVC sheets, ensuring that you make informed decisions that align with your business goals.

Comprehensive Cost and Pricing Analysis for flexible pvc sheet Sourcing

What Are the Key Cost Components in Sourcing Flexible PVC Sheets?

When sourcing flexible PVC sheets, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The base material, PVC resin, significantly impacts pricing. Variations in quality and source can lead to price fluctuations. Premium grades that offer enhanced durability or specific characteristics (like UV resistance) tend to be more expensive.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this could be offset by potential quality control issues.

-

Manufacturing Overhead: This encompasses utilities, rent, and other operational expenses. Efficient manufacturing processes can reduce overhead, positively affecting overall pricing.

-

Tooling Costs: For customized sheets or unique specifications, tooling costs can be substantial. These costs are often spread across larger production runs, making bulk orders more economical.

-

Quality Control (QC): Implementing stringent QC measures can increase costs but is essential for ensuring product reliability, especially for applications in critical industries like food processing or medical supplies.

-

Logistics: Shipping costs can significantly influence the final price, especially for international orders. Factors such as distance, shipping method, and import duties should be considered.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market demand and competition.

What Influences the Pricing of Flexible PVC Sheets?

Several factors can affect the pricing of flexible PVC sheets:

-

Volume/MOQ: Pricing often decreases with higher order volumes. Suppliers may offer discounts for bulk purchases, making it beneficial for buyers to negotiate minimum order quantities (MOQs) that align with their needs.

-

Specifications and Customization: Custom specifications (thickness, color, finish) can lead to increased costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Material Quality and Certifications: Higher-quality materials or those meeting specific industry certifications (like ISO or FDA compliance) generally command higher prices. Buyers in regulated markets should prioritize certified suppliers.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more but can provide assurance of consistency.

-

Incoterms: Understanding the terms of trade (like FOB, CIF) is crucial, as they dictate responsibilities for shipping, insurance, and tariffs, ultimately affecting the total landed cost.

What Are the Best Tips for International B2B Buyers When Sourcing Flexible PVC Sheets?

To maximize value and minimize costs, buyers should consider the following strategies:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility based on order size, payment terms, and relationship history.

-

Cost-Efficiency: Analyze the total cost of ownership rather than just the purchase price. Consider factors such as durability, maintenance, and potential waste in decision-making.

-

Pricing Nuances for International Buyers: For regions like Africa and South America, where logistics can be complex, consider local suppliers who may offer better shipping rates. Buyers should also be aware of currency fluctuations and their impact on pricing.

-

Research and Compare: Conduct thorough market research to compare prices from different suppliers. This can help identify competitive pricing and reliable partners.

-

Long-Term Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time, as trust and reliability are built.

Disclaimer

Prices for flexible PVC sheets can vary significantly based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and request quotes from multiple suppliers to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing flexible pvc sheet With Other Solutions

In the quest for effective material solutions, businesses often evaluate various options to meet their specific needs. Flexible PVC sheets have gained popularity due to their versatility and durability, but there are alternative materials and technologies that can also be considered. This analysis compares flexible PVC sheets with two viable alternatives: Polycarbonate Sheets and Acrylic Sheets, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Flexible PVC Sheet | Polycarbonate Sheets | Acrylic Sheets |

|---|---|---|---|

| Performance | High impact resistance, good flexibility, UV resistant | Excellent impact resistance, high clarity, UV resistant | Good optical clarity, lightweight, moderate impact resistance |

| Cost | Generally low to moderate | Moderate to high | Moderate |

| Ease of Implementation | Easy to cut and install | Requires special tools for cutting | Easily cut and fabricated |

| Maintenance | Low maintenance, easy to clean | Low maintenance, resistant to staining | Moderate maintenance, prone to scratching |

| Best Use Case | Industrial applications, signage, protective barriers | Safety glazing, greenhouses, outdoor applications | Displays, light fixtures, aquariums |

What are the Key Advantages and Disadvantages of Polycarbonate Sheets as an Alternative?

Polycarbonate sheets are renowned for their exceptional impact resistance and clarity, making them ideal for applications where safety and visibility are paramount, such as in greenhouses and safety glazing. While they tend to be more expensive than flexible PVC sheets, their durability can justify the investment in high-traffic or hazardous environments. However, they can be more challenging to cut and shape, requiring specialized tools and skills, which may increase installation costs and time.

How Do Acrylic Sheets Compare to Flexible PVC Sheets in Terms of Use Cases?

Acrylic sheets offer excellent optical clarity and are lightweight, making them popular in retail displays and light fixtures. They are easier to fabricate and shape than polycarbonate, allowing for creative designs. However, acrylic is more prone to scratching and requires careful handling and maintenance compared to flexible PVC. While their cost is similar to that of flexible PVC sheets, the lower impact resistance may limit their application in high-risk environments.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right material depends on the specific requirements of your project. If your application demands high impact resistance and clarity, polycarbonate sheets may be the best choice despite their higher cost and installation complexity. For projects focused on versatility and low maintenance, flexible PVC sheets stand out as a cost-effective solution. Meanwhile, acrylic sheets serve well in aesthetic applications where clarity is essential but may require more careful handling. By weighing these factors against your project requirements, you can make an informed decision that aligns with your operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for flexible pvc sheet

Understanding the technical properties and terminology related to flexible PVC sheets is crucial for B2B buyers, particularly when making informed purchasing decisions for various applications. Here’s a concise overview of key specifications and industry jargon relevant to flexible PVC sheets.

What Are the Essential Technical Properties of Flexible PVC Sheets?

1. Material Grade

Flexible PVC sheets come in various material grades, indicating their quality and suitability for specific applications. Common grades include Type I and Type II PVC, which differ in their formulation and performance characteristics. Selecting the appropriate grade is critical for ensuring longevity and functionality in applications such as industrial doors, protective barriers, or packaging.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. For flexible PVC sheets, a typical tolerance may be ±1/8 inch (0.125 inches). Understanding tolerances is vital for B2B buyers, as improper dimensions can lead to costly errors in installation or product performance.

3. Tensile Strength

Tensile strength measures how much force a material can withstand while being stretched or pulled before breaking. For flexible PVC sheets, a tensile strength of around 16 N/mm² is common. This property is crucial for applications requiring durability and resistance to tearing, such as protective curtains or cold chain logistics.

4. Elongation at Break

Elongation at break indicates how much a material can stretch before it breaks, typically expressed as a percentage. Flexible PVC sheets can exhibit elongation values around 340%. This property is significant for applications that involve bending or flexing, ensuring that the material can withstand movement without failing.

5. UV Resistance

UV resistance measures a material’s ability to withstand degradation from ultraviolet light. PVC sheets that are UV stabilized can maintain their properties and appearance even when exposed to sunlight. This is particularly important for outdoor applications, where prolonged exposure to sunlight can lead to brittleness or discoloration.

6. Light Transmittance

Light transmittance refers to the percentage of light that passes through the material. For certain applications, such as greenhouse covers or display cases, a light transmittance of 85% is desirable. This ensures optimal light conditions for plants or visibility for products while maintaining protection from environmental factors.

What Are Common Trade Terms Related to Flexible PVC Sheets?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the context of flexible PVC sheets, buyers may work with OEMs to produce custom sheets tailored to specific applications or branding requirements.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of products a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure that they meet supplier requirements while also aligning with their inventory needs. For flexible PVC sheets, MOQs may vary based on the supplier and customization options.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. In the flexible PVC sheet market, submitting an RFQ allows buyers to compare costs, delivery timelines, and product specifications, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions involving flexible PVC sheets, as they clarify who bears the risk and costs at various stages of shipping.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In flexible PVC sheet procurement, understanding lead times is critical for planning and inventory management, particularly for projects with strict deadlines.

6. Customization

Customization involves modifying products to meet specific buyer needs. In the flexible PVC sheet sector, this could include altering dimensions, colors, or finishes. Buyers should consider customization options to ensure the product aligns perfectly with their application requirements.

By grasping these essential technical properties and trade terminology, B2B buyers can navigate the flexible PVC sheet market more effectively, ensuring they select the right products for their needs while maximizing operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the flexible pvc sheet Sector

What Are the Current Trends Shaping the Flexible PVC Sheet Market?

The flexible PVC sheet market is witnessing robust growth, driven by various global dynamics. Key factors include the increasing demand for lightweight and durable materials in diverse industries such as construction, automotive, and packaging. The versatility of PVC sheets allows them to be used in applications ranging from signage and furniture to marine and industrial solutions. Emerging trends highlight a shift towards customization, with B2B buyers seeking tailored solutions that meet specific project requirements. Moreover, advancements in manufacturing technologies are facilitating the production of thinner, stronger, and more sustainable PVC sheets, enhancing their appeal.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that utilize digital platforms for streamlined sourcing and communication. The adoption of e-commerce and digital marketplaces is transforming procurement processes, making it easier for buyers to compare options, evaluate quality, and negotiate prices. Additionally, the rise of smart manufacturing is enabling suppliers to offer just-in-time delivery and inventory management solutions, further appealing to cost-sensitive markets.

How Important is Sustainability and Ethical Sourcing in the Flexible PVC Sheet Industry?

Sustainability is becoming a critical consideration in the flexible PVC sheet sector. The environmental impact of PVC production, particularly regarding plastic waste and resource consumption, is prompting buyers to seek suppliers committed to sustainable practices. This includes using recycled materials, minimizing energy usage during production, and implementing waste reduction strategies.

Ethical sourcing is equally important, as buyers are increasingly aware of the need for transparency in supply chains. Suppliers that adhere to ethical labor practices and possess certifications like ISO 14001 for environmental management are gaining a competitive edge. Additionally, the market is seeing a rise in the availability of “green” PVC materials, which are manufactured using environmentally friendly processes and are recyclable at the end of their life cycle. Buyers are encouraged to engage with suppliers who can provide documentation on their sustainability practices and certifications, ensuring that their purchases align with corporate social responsibility goals.

What Is the Historical Context of Flexible PVC Sheets in B2B Markets?

The evolution of flexible PVC sheets dates back to the mid-20th century when PVC became widely recognized for its versatility and durability. Initially used in industrial applications, its lightweight nature and resistance to moisture and chemicals opened doors to various sectors, including construction and automotive. Over the decades, innovations in PVC formulations and production techniques have enhanced its performance characteristics, making it suitable for a broader range of applications, including consumer products and specialized industrial uses.

Today, flexible PVC sheets are an integral part of the global supply chain, with manufacturers continuously adapting to meet changing market demands. The historical trajectory of PVC reflects a broader trend towards the integration of technology and sustainability, shaping the future of material sourcing and product development in the B2B landscape. As global markets evolve, the importance of flexible PVC sheets remains steadfast, driven by their adaptability and enduring performance across diverse applications.

Frequently Asked Questions (FAQs) for B2B Buyers of flexible pvc sheet

-

1. How do I ensure I am sourcing high-quality flexible PVC sheets?

To source high-quality flexible PVC sheets, start by evaluating potential suppliers based on their certifications and industry standards. Request product samples to assess the material’s flexibility, durability, and any specific features such as UV resistance or fire retardancy. Additionally, verify the supplier’s quality assurance processes, including testing methodologies and production facilities. Engaging in direct communication with the supplier can also help clarify any doubts regarding their manufacturing practices and product specifications. -

2. What is the best thickness for flexible PVC sheets for industrial applications?

The best thickness for flexible PVC sheets in industrial applications typically ranges from 0.060 inches to 0.236 inches. Thicker sheets provide enhanced durability and resistance to wear and tear, making them ideal for applications like industrial doors, cold chain logistics, and welding screens. However, the specific thickness required will depend on the intended use, environmental conditions, and any applicable regulations. It’s advisable to consult with your supplier to determine the optimal thickness based on your specific application needs. -

3. What customization options are available for flexible PVC sheets?

Many suppliers offer customization options for flexible PVC sheets, including cut-to-size dimensions, colors, and finishes. Some can provide specific formulations to meet unique requirements, such as increased UV stability or enhanced chemical resistance. When discussing customization, be clear about your specifications and intended applications. Additionally, inquire about the minimum order quantities (MOQs) for custom products, as this may vary between suppliers. -

4. What are the common payment terms for international purchases of flexible PVC sheets?

Common payment terms for international purchases often include options such as Letter of Credit (LC), Telegraphic Transfer (T/T), or PayPal. Payment terms can vary based on the supplier’s policy and the buyer’s creditworthiness. It is crucial to establish clear terms upfront, including payment schedules, deposits, and any contingencies for delays or issues. Always ensure that payment methods align with your risk tolerance and provide adequate protection for your investment. -

5. How can I vet suppliers for flexible PVC sheets in international trade?

Vetting suppliers in international trade involves several steps. Start by researching the supplier’s reputation through reviews, ratings, and testimonials from other buyers. Verify their business credentials, such as registration and compliance with local regulations. Request references and check their production capabilities, quality control processes, and certifications. Engaging in preliminary discussions can also help gauge their responsiveness and willingness to accommodate your needs. -

6. What are the logistics considerations when importing flexible PVC sheets?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Determine the most cost-effective shipping option (air or sea) based on your urgency and budget. Work with a freight forwarder to navigate customs regulations and ensure all necessary documentation is in order. Additionally, factor in potential delays due to customs inspections or unforeseen circumstances, and communicate these timelines to your stakeholders to manage expectations. -

7. How do I handle quality assurance for flexible PVC sheets after purchase?

Implement a quality assurance process by establishing criteria for inspecting the received PVC sheets upon arrival. Check for conformity to specifications such as thickness, color, and flexibility. Consider conducting tests for durability, UV resistance, and other relevant properties depending on the intended application. If discrepancies arise, maintain open communication with the supplier to resolve issues promptly, potentially through returns or replacements as per your agreement. -

8. Are there specific regulations for importing flexible PVC sheets into different countries?

Yes, regulations for importing flexible PVC sheets vary by country and may include safety standards, material composition requirements, and environmental regulations. It’s essential to research the specific regulations in your target market, which may involve compliance with industry standards or obtaining necessary certifications. Collaborating with a knowledgeable customs broker can provide valuable insights and assist in navigating the regulatory landscape to ensure smooth importation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Flexible Pvc Sheet Manufacturers & Suppliers List

1. Interstate Plastics – PVC Extruflex Flexible Clear Film Sheet Rolls

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “PVC Extruflex Flexible Clear Film Sheet Rolls”, “sizes”: [{“thickness”: “.060”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.080”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.120”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.160”, “width”: “48”, “length”: “60ft”}], “price”: “$492.04”, “warnings”: [“This product can expose you to chemicals including Polyvinyl Chlo…

2. Grafix Plastics – Flexible Vinyl Sheets and Film

Domain: grafixplastics.com

Registered: 1997 (28 years)

Introduction: Flexible Vinyl (PVC) sheets and film offered by Grafix Plastics come in various finishes, colors, and flexibilities. They are used in applications such as stationary products, office products, pool liners, graphic films, furniture coverings, decorative films, wallcovering materials, cable & wire insulation, and automotive interiors. Key specifications include:

– Types: Super Clear, Economy Clear, …

3. Gteek – Flexible Crystal Clear PVC Roll

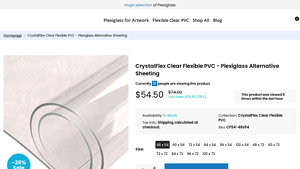

4. CrystalFlex – Clear Flexible PVC Sheeting

Domain: cutplex.com

Registered: 2020 (5 years)

Introduction: Product Name: CrystalFlex Clear Flexible PVC – Plexiglass Alternative Sheeting

Price: $54.50 (originally $74.00, 26% off)

Availability: In stock

SKU: CF54-48×54

Thickness: 0.5mm

Sizes Available: 48 x 54, 60 x 54, 72 x 54, 84 x 54, 96 x 54, 120 x 54, 48 x 72, 60 x 72, 72 x 72, 84 x 72, 96 x 72, 120 x 72

Features:

– Soft Acrylic that bends and folds easily

– Compact storage and easy shipping

– Easy…

5. Interstate Am – PVC Extruflex Flexible Clear Film Sheet Rolls

Domain: interstateam.com

Registered: 2022 (3 years)

Introduction: Product Name: PVC Extruflex Flexible Clear Film Sheet Rolls

SKU: PVCCU

Available Sizes:

– .060″ x 48″ – 60ft.

– .080″ x 48″ – 60ft.

– .120″ x 48″ – 60ft.

– .160″ x 48″ – 60ft.

Price for .060″ x 48″ – 60ft.: $492.04

Estimated Shipping: $22.22

Material: PVC TYPE I

Density: 1.22 g/cm³

Tensile Strength: 16 N/mm² @ Break

Elongation: 68% @ Break

Hardness: 80 (Shore A)

Vicat Softening Temp: 50°C

Light T…

6. Walton Plastics – Flexible PVC

Domain: waltonplastics.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Flexible PVC”, “manufacturer”: “Walton Plastics”, “features”: {“hardness_range”: “75 Shore A to 95 Shore A”, “thickness_range”: “.040 inch to over .400 inch”, “widths”: “up to 66 inches”, “formulations”: “NFPA-701 available”, “smoke_and_flammability_options”: “low smoke and flammability options”, “color_options”: “stock and custom colors available”}, “advantages”: [“flexibility”,…

7. eBay – Flexible PVC Plastic Sheet

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Flexible PVC Plastic Sheet with Film, Size: 300x200mm, Thickness Options: 0.3mm or 0.5mm, Available Colors: Clear, Matte, Red, Green, Blue, Condition: New, Price: $4.98 each, Shipping: $3.99, Estimated Delivery: Fri, Jul 25 – Fri, Aug 8, Bulk Savings: Discounts available for purchasing multiple units.

8. AliExpress – A4 Flexible PVC Plastic Sheet

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, AliExpress – A4 Flexible PVC Plastic Sheet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for flexible pvc sheet

What Are the Key Takeaways for B2B Buyers of Flexible PVC Sheets?

In the competitive landscape of flexible PVC sheets, strategic sourcing emerges as a pivotal factor for success. Buyers should prioritize understanding the diverse applications and benefits of flexible PVC, from industrial doors to cold chain logistics. By leveraging the material’s versatility and durability, businesses can optimize their operations and meet specific needs across various sectors. Establishing strong relationships with reliable suppliers can enhance procurement efficiency, ensuring access to high-quality materials that align with project requirements.

How Can Buyers Position Themselves for Future Growth?

As markets continue to evolve, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should remain proactive in their sourcing strategies. Emphasizing sustainability and recyclability in purchasing decisions will not only align with global trends but also enhance brand reputation. By keeping abreast of innovations in flexible PVC technologies and market dynamics, buyers can position themselves favorably for long-term growth.

In conclusion, the future of flexible PVC sheets is bright, with expanding applications and opportunities. Now is the time for buyers to engage with suppliers, explore innovative solutions, and harness the full potential of flexible PVC to drive their business forward. Your strategic sourcing decisions today will shape the success of your projects tomorrow.