Contents

Manufacturing Insight: Five-Axis Cnc

Precision Engineering Elevated Through Five-Axis CNC Machining at Honyo Prototype

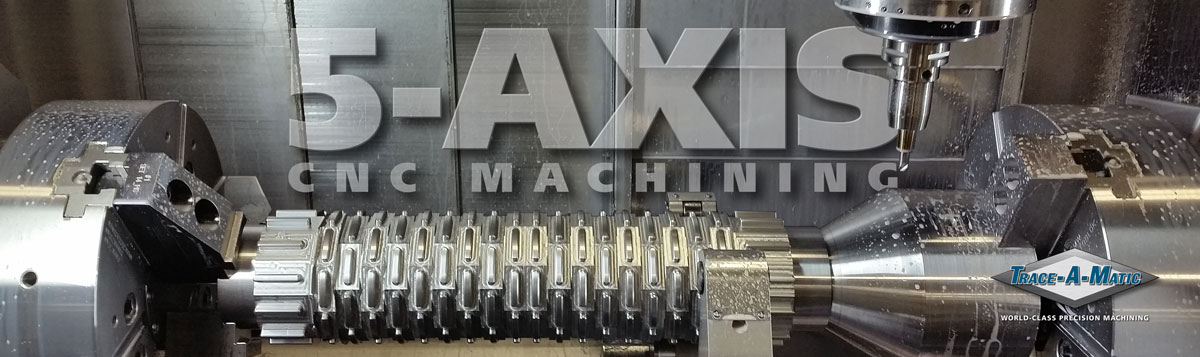

Honyo Prototype delivers unparalleled manufacturing capability for complex, high-integrity components through our advanced five-axis CNC machining services. This technology enables simultaneous movement across X, Y, Z, and two rotational axes, fundamentally transforming how intricate geometries are produced. Unlike conventional three-axis methods, five-axis machining eliminates the need for multiple fixtures and manual repositioning, ensuring exceptional part accuracy while dramatically reducing lead times and human error. For industries demanding tight tolerances and seamless surface finishes—from aerospace turbine blades to medical implants and automotive prototypes—this capability is non-negotiable for achieving first-article success.

Our investment in state-of-the-art five-axis machining centers, operated by certified engineers with deep expertise in multi-axis programming and setup, directly translates to tangible value for your project. We excel at machining monolithic structures, organic contours, and undercuts in a single setup, preserving critical datum relationships and minimizing cumulative tolerance stack-up. This approach not only enhances part quality but also optimizes material utilization and accelerates time-to-market for your most challenging designs. Honyo’s rigorous process validation and in-process metrology guarantee that every component meets stringent AS9100 and ISO 9001 standards, providing confidence in performance-critical applications.

Leverage Honyo’s engineering-driven five-axis solutions to overcome prototyping and low-volume production hurdles. To streamline your sourcing process, we provide an Online Instant Quote portal specifically engineered for complex CNC work. Upload your STEP or IGES files, specify materials and tolerances, and receive a detailed, transparent cost and timeline assessment within hours—not days. This tool eliminates procurement delays, allowing engineering and procurement teams to make faster, data-driven decisions without waiting for manual RFQ processing.

Key Advantages of Honyo’s Five-Axis Machining

| Feature | Client Impact |

|————————|———————————————–|

| Single-Setup Machining | 30-50% reduced lead time vs. multi-setup processes |

| Complex Geometry Capability | Production of integrated assemblies as single parts |

| High-Precision Toolpaths | Surface finishes ≤ 32 μin Ra and tolerances to ±0.0002″ |

| Material Versatility | Titanium, Inconel, composites, and high-temp alloys |

Accelerate your next precision component development cycle. Submit your design today through Honyo’s Online Instant Quote system and experience the convergence of advanced five-axis capability and responsive engineering partnership.

Technical Capabilities

Five-Axis CNC Machining – Technical Specifications Overview

Five-axis CNC machining enables the simultaneous movement of a workpiece across five axes (X, Y, Z, and two rotational axes), allowing for complex geometry and superior accuracy in a single setup. This capability is essential for high-precision components in aerospace, medical, and automotive industries. Honyo Prototype leverages advanced 3-axis, 4-axis, and 5-axis milling systems, as well as precision turning centers, to achieve tight tolerances across a range of engineering materials.

The table below outlines key technical specifications and capabilities for multi-axis CNC operations, with focus on material compatibility, tolerance, and process type.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (or C) | X, Z (with C-axis optional) | 5-axis allows full contouring on complex surfaces |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | Verified with laser interferometry |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | Critical for batch consistency |

| Typical Tolerance | ±0.010 mm | ±0.010 mm | ±0.005 mm | ±0.010 mm (±0.005 mm with finishing) | Tight tolerance achievable with controlled finish passes |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 2.5 µm | Achieved with fine toolpaths and polishing cycles |

| Spindle Speed (max) | 24,000 rpm | 20,000 rpm | 20,000 rpm | 8,000 rpm (live tooling up to 12,000 rpm) | High-speed spindles for aluminum and plastics |

| Tool Changer Capacity | 24–30 tools | 24–30 tools | 30–40 tools | 8–12 stations (Y-axis optional) | Allows unattended multi-operation runs |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS (limited), Nylon (limited) | Thermoplastics require optimized feeds/speeds |

| Max Work Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 | 700 × 500 × 400 | Ø300 × 500 length | Size varies by machine model |

| Coolant System | High-pressure through-spindle | High-pressure through-spindle | High-pressure through-spindle + mist | Flood and mist | Prevents thermal deformation |

Material-Specific Notes:

Aluminum (6061, 7075, etc.): Ideal for high-speed 5-axis milling; excellent chip evacuation and thermal conductivity. Achieves tight tolerances with minimal tool wear.

Steel (4140, 1018, Stainless 303/316): Requires rigid setups and carbide tooling; slower feed rates but maintains ±0.005 mm accuracy with proper cooling.

ABS: Low melting point; optimized cutting parameters and sharp tools prevent deformation. Suitable for prototyping and non-structural components.

Nylon (including glass-filled): Prone to deflection; requires support fixtures and reduced cutting forces. Best results in 3- and 4-axis configurations for consistent wall thickness.

Honyo Prototype maintains strict process controls, including in-process metrology and thermal compensation algorithms, to ensure dimensional stability across all materials and axis configurations. Our 5-axis systems are particularly effective for reducing setup iterations and improving geometric accuracy on complex parts.

From CAD to Part: The Process

Honyo Prototype Five-Axis CNC Manufacturing Process

Honyo Prototype executes a streamlined five-axis CNC workflow designed for precision, efficiency, and zero-defect delivery. The process begins with CAD Upload, where clients submit native 3D models (STEP, IGES, Parasolid, or native CAD formats) via our secure portal. Our system validates geometry integrity, checks for manufacturability constraints inherent to five-axis machining—such as undercuts, thin walls, or complex contours—and confirms coordinate system alignment. Invalid geometries trigger automated feedback within 15 minutes, reducing iterative delays.

The AI-Powered Quoting Engine immediately processes validated CAD data, leveraging a proprietary algorithm trained on 12,000+ historical five-axis projects. It analyzes part complexity, material density (e.g., aluminum 7075-T6 vs. Inconel 718), machine time estimates based on toolpath simulation, and secondary operations. Crucially, the AI cross-references real-time shop floor data—machine availability, tooling inventory, and labor costs—to generate a technically accurate quote within 90 minutes. This quote includes explicit notes on geometric challenges requiring engineering review, avoiding unrealistic pricing assumptions common in automated systems.

Engineering-Led DFM (Design for Manufacturability) follows, where senior CNC process engineers conduct a hands-on review. Unlike automated DFM tools, our engineers collaborate directly with the client to resolve critical issues: optimizing part orientation to minimize setups, suggesting strategic stock allowances for thin-walled features, or proposing minor geometry tweaks to eliminate collision risks during 5-axis simultaneous motion. We provide a detailed DFM report with annotated CAD markups, tolerance stack-up analysis, and material waste reduction strategies—typically resolving 85% of potential production failures upfront.

Production Execution utilizes DMG MORI and Makino five-axis vertical machining centers with 0.0001″ linear accuracy and ±2 arc-second rotary precision. Each job undergoes rigorous setup validation: laser-probed stock alignment, tool length/offset verification via Renishaw probes, and dry-run simulation in NCSIMUL software. Machining employs high-efficiency strategies like trochoidal milling for hardened steels and adaptive clearing for titanium, with in-process CMM checks at critical stages. All parts adhere to AS9100-certified quality protocols, including first-article inspection reports (FAIR) and full GD&T validation per ASME Y14.5.

Delivery and Documentation concludes the process with tracked global logistics (DHL/FedEx with real-time GPS) and comprehensive digital dossiers: final inspection certificates, material test reports (MTRs), 3D scan deviation maps, and post-machining surface roughness data. For aerospace/medical clients, we provide PPAP Level 3 documentation. Average lead time from CAD upload to delivery is 7–12 business days for complex geometries, with expedited options for time-critical projects. This end-to-end control ensures Honyo delivers five-axis components meeting ±0.005mm tolerances on the first pass, eliminating costly rework cycles.

Start Your Project

Discover precision manufacturing with Honyo Prototype’s advanced five-axis CNC machining services. Our state-of-the-art facility in Shenzhen delivers complex, high-accuracy components for aerospace, medical, automotive, and industrial applications—fast and reliable.

For expert support and project inquiries, contact Susan Leo at [email protected]. Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.